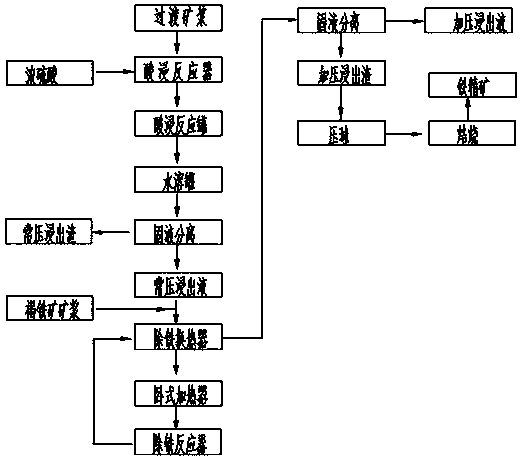

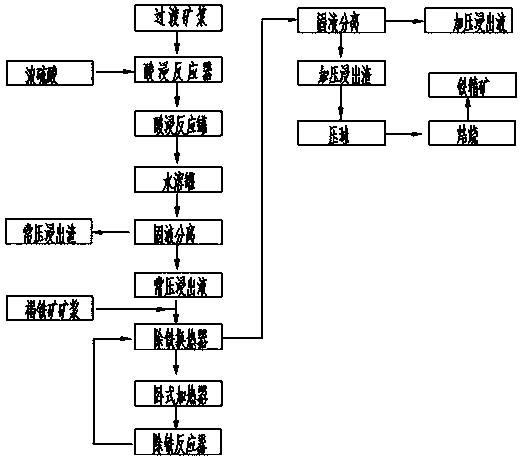

Hydrometallurgy method for treating low-grade laterite-nickel ore through normal pressure and pressurization combined acid leaching

A technology for acid leaching treatment and laterite nickel ore, which is applied in the direction of improving process efficiency and can solve the problems of increased consumption of sulfuric acid, inability to develop and utilize economically and effectively, and low operating rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Table 1-1 Main Components of Ore

[0032] ore type Ni(%) Co(%) Fe(%) MgO(%) SiO 2 (%))

Limonite 1.13 0.20 48.76 0.23 3.58 Transition mine 1.80 0.35 32.24 2.07 24.45

[0033] Take 500Kg of transition ore (dry) and add 500Kg of water to make transition slurry, prepare 500Kg of concentrated sulfuric acid with a mass fraction of 98%, heat the transition slurry to 60°C, and the concentrated sulfuric acid to 200°C, then use a mortar pump and a concentrated sulfuric acid pump to heat the The final transitional pulp and concentrated sulfuric acid are added to the feed port of the acid leaching reactor synchronously. After rapid mixing, the transitional pulp and concentrated sulfuric acid are forced to flow into the acid leaching reactor for rapid reaction to dissolve soluble non-ferrous metals and soluble iron. React for 1 minute Finally, the reaction materials are pushed out of the acid leaching reactor. Cool down to below 60°C,...

Embodiment 2

[0050] Organize embodiment 2 operation according to embodiment 1 step, the limonite implementation example result of table 2-1:

[0051] Table 2-1 Main Components of Ore

[0052] ore type Ni(%) Co(%) Fe(%) Mg(%) Si(%)) Limonite 1.07 0.22 43.79 0.14 2.67

[0053] Table 2-2 Statistical table of atmospheric pressure leaching slag composition

[0054] Element Ni co Fe Mg Si content(%) 0.22 0.043 17.96 1.37 11.75

[0055] Table 2-3 Statistical table of atmospheric pressure leachate components

[0056] Element Ni co Fe Mg Content (g / L) 3.23 0.036 102.01 0.21

[0057] Table 2-4 Statistical table of components of pressure leaching slag

[0058] Element Ni co Fe Mg Si content(%) 0.026 0.0017 59 0.17 0.06

[0059] Table 2-5 Statistical Table of Components of Pressurized Leach Solution

[0060] Element Ni co Fe Mg Content (g / L) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com