Method for improving metallization ratio and concentrate iron grade of beach placer reduction product

A technology of metallization rate and iron grade, applied in the direction of fluidized bed furnace, etc., can solve the problems of low metallization rate and iron grade of biomass direct reduction seashore placer products, and difficulty of solid state reduction, so as to reduce the difficulty of solid state reduction , Save process cost, reduce temperature and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

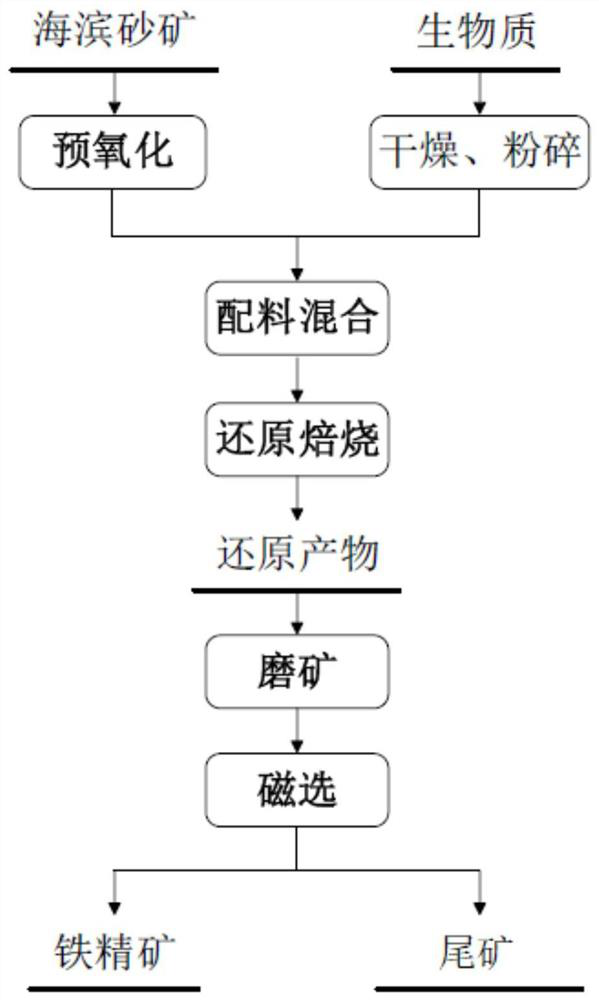

[0039] The technological process of this embodiment is as figure 1 As shown, the specific steps are as follows:

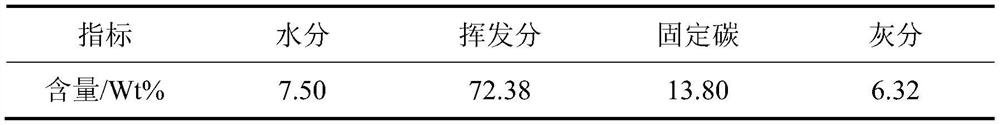

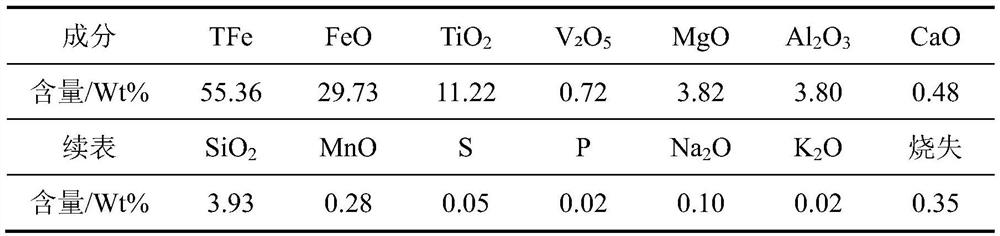

[0040] (1) Put 1 kg of seashore placer into a rotary tube furnace at 1000°C, the rotating speed of the tube furnace is 100r / min, air is blown into the furnace by an air compressor for oxidation, the flow rate of air is 1.0L / min, pre-oxidation After 30 min, the sample was cooled to room temperature and taken out. The biomass was taken, dried and pulverized, dried at 100° C. for 6 hours, and pulverized to a particle size of less than 1 mm.

[0041] (2) The biomass whose mol (C / Fe) is 1.0 (the molar ratio of the fixed carbon content in the reducing agent to the total iron content in the seaside placer) is added, and the seaside placer after the pre-oxidation of the calculated quality is added, fully mixed uniform.

[0042] (3) Place 80 g of the mixture obtained in step (2) in a graphite crucible (the specification of the graphite crucible is 50 mm in inner diameter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| magnetic flux density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com