Local slope type reduction ironmaking furnace and process

A slope-type, iron-making furnace technology, applied in the reduction iron-making furnace and the iron-making process, the reduction-iron-making process, the integrated reduction iron-making furnace field, can solve the problem of wall hanging, uneven reaction of furnace materials and low production efficiency And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

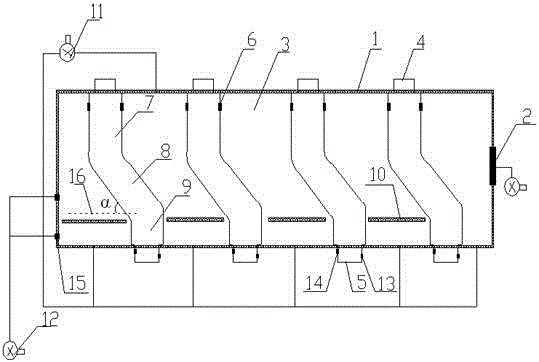

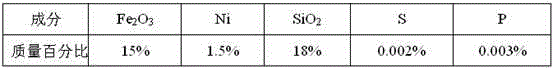

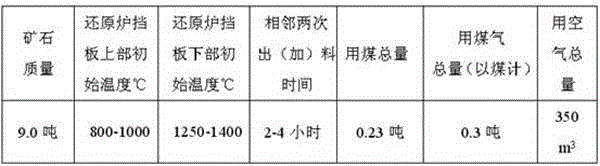

[0058] Such as figure 1 The partial slope reduction ironmaking furnace shown (referred to as the reduction ironmaking furnace, the same below) includes a closed furnace body 1, and an exhaust port 2 for exhausting gas is provided on the furnace body. The exhaust port is located in the middle of the furnace body, close to The position of the last reduction chamber is equipped with an induced draft fan and other devices on the exhaust port to discharge the carbon dioxide in the furnace body. Four reduction chambers are arranged in sequence in the furnace body. Of course, the number of reduction chambers can be freely allocated in practical applications. Here only Taking a reduction furnace with four reduction chambers as an example to illustrate its structure, the four reduction chambers are independent. The top of the reduction chamber is provided with a feed port 4, and the bottom is provided with a discharge port 5. Both the feed port and the discharge port are located outsi...

Embodiment 2

[0062] The structure of the local slope reduction ironmaking furnace of the present invention can be adjusted appropriately on the basis of Embodiment 1, for example, the number of air extraction device and air supply device can be one, and one can also be arranged at each cavity, When only one is used, the air extraction device and the air delivery device are preferably installed at a position away from the exhaust port.

Embodiment 3

[0064] The structure of the local slope-type reduction ironmaking furnace of the present invention can be appropriately adjusted on the basis of Embodiment 1, for example, an air inlet can be arranged at the position above the baffle and below the baffle at each cavity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com