Preparation method of polythiol compound for optical resin

A technology of polythiol compounds and polyol compounds, which is applied in the field of optical resins, can solve the problems of high chroma of polythiol compounds, which cannot meet the raw material requirements of optical resin lenses, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

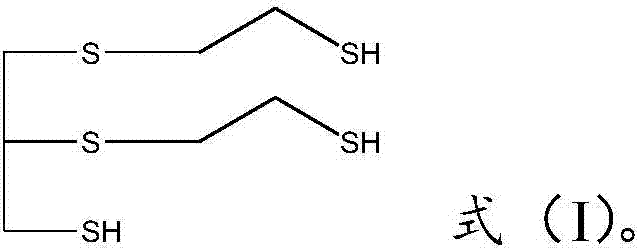

[0023] The invention provides a kind of preparation method of polythiol compound for optical resin, comprising the following steps:

[0024] a) carrying out a polyalcoholation reaction with mercaptoethanol and epichlorohydrin in an alkaline solution to obtain a reaction mixture with a polyol compound;

[0025] b) performing a thiolation reaction with the reaction mixture having a polyol compound obtained in step a) and thiourea in an acidic solution to obtain a reaction mixture having a polythiol compound;

[0026] c) performing a hydrolysis reaction on the reaction mixture having polythiol compounds obtained in step b), followed by washing with water and drying to obtain polythiol compounds for optical resins;

[0027] The iron content of the mercaptoethanol is greater than 0 and less than 10ppm; the iron content of the epichlorohydrin is greater than 0 and less than 10ppm.

[0028] In the present invention, the polyalcoholization reaction of mercaptoethanol and epichlorohyd...

Embodiment 1

[0045] (1) the 2-mercaptoethanol (2mol) that 156g iron content is 3ppm and the epichlorohydrin (0.8mol) that 74g iron content are 4ppm are added to 200g mass concentration successively and be 20% sodium hydroxide (1mol) In the solution, react at 10° C. for 1 h to obtain a reaction mixture with polyol compound;

[0046] (2) adding 228g thiourea (3mol) and 536.8g mass concentration to the reaction mixture with polyol compound obtained in step (1) is 34% hydrochloric acid (HCl is 5mol), and carries out thiolation reaction at 100°C for 3h , to obtain a reaction mixture with a polythiol compound;

[0047] (3) After cooling down to room temperature, 450 g of a mass concentration of 40% sodium hydroxide (4.5 mol) solution was added to the reaction mixture with polythiol compound obtained in step (2), and the hydrolysis reaction was carried out at 50° C. for 3 h, Obtain a reaction mixture with a crude product; finally, wash the reaction mixture with a crude product twice with water, ...

Embodiment 2

[0051] (1) the 2-mercaptoethanol (2mol) that 156g iron content is 5ppm and the epichlorohydrin (0.8mol) that 74g iron content are 2ppm are added to 200g mass concentration successively and be 20% sodium hydroxide (1mol) In the solution, react at 10° C. for 1 h to obtain a reaction mixture with polyol compound;

[0052] (2) adding 228g thiourea (3mol) and 536.8g mass concentration to the reaction mixture with polyol compound obtained in step (1) is 34% hydrochloric acid (HCl is 5mol), and carries out thiolation reaction at 100°C for 3h , to obtain a reaction mixture with a polythiol compound;

[0053] (3) After cooling down to room temperature, 450 g of a mass concentration of 40% sodium hydroxide (4.5 mol) solution was added to the reaction mixture with polythiol compound obtained in step (2), and the hydrolysis reaction was carried out at 50° C. for 3 h, A reaction mixture with a crude product was obtained; finally, the reaction mixture with the crude product was washed with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com