Patents

Literature

49results about How to "Reduce recycling steps" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for recovering rare-earth waste material

ActiveCN102643992AHigh recovery rateReduce recycling stepsProcess efficiency improvementRare-earth elementDecomposition

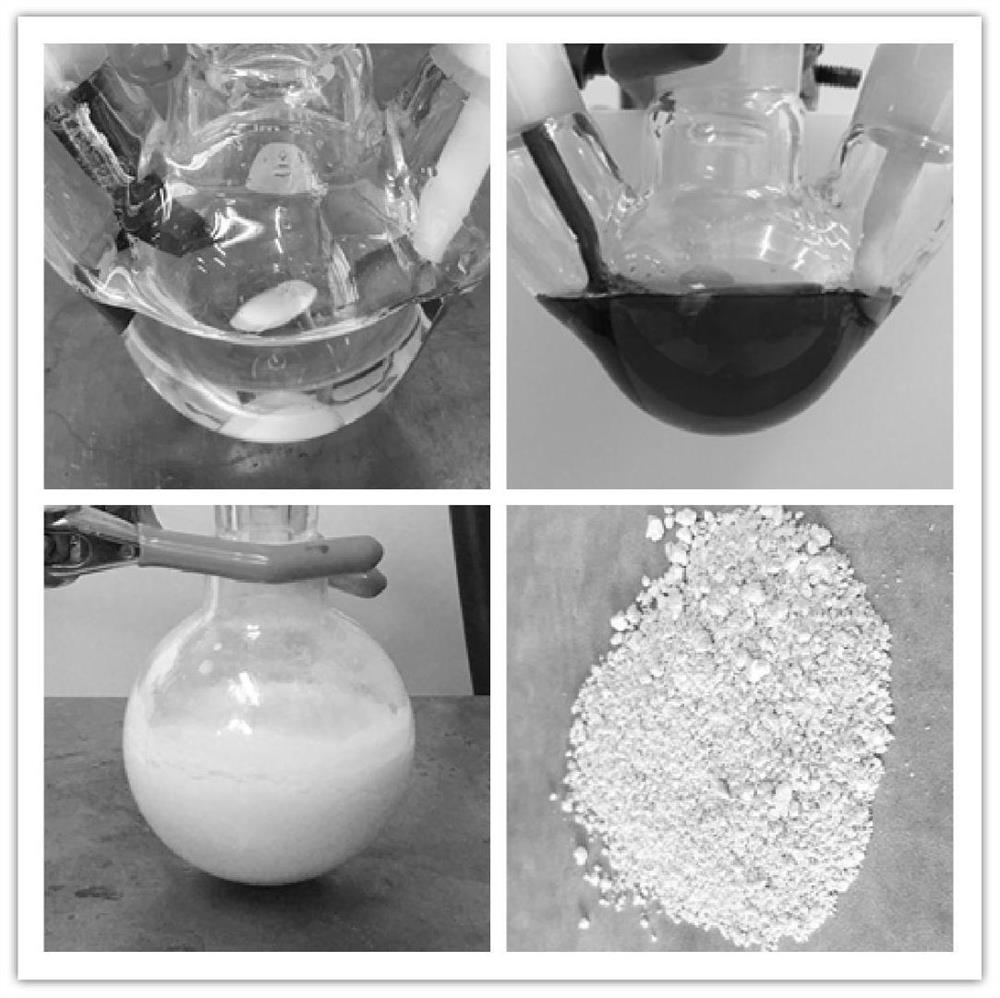

The invention relates to a method for recovering a rare-earth waste material. The method comprises the following steps of: (1) adding a decomposition auxiliary agent and fluxing agent powder into the rare-earth waste material, and evenly mixing to obtain mixed material, wherein the dosage of the decomposition auxiliary agent is 20-200wt% of the total weight of the rare-earth waste material, and the dosage of the fluxing agent powder is 1-20 wt% of the total weight of the rare-earth waste material; (2) roasting the mixed material obtained in the step (1) for 1-6 hours at the temperature of 600-1400 DEG C; (3) adding an acid solution into the roasted product obtained in the step (2) for acid dissolution, filtering and separating to obtain acid leaching liquor which mainly contains rare-earth elements and acid leaching residue; and (4) separating the rare-earth elements from other metal elements in the acid leaching liquor. The method provided by the invention realizes the cyclic utilization of the rare-earth waste material, is simple to operate, high in recovery rate of valuable elements in the waste material and low in reagent cost, saves energy, reduces emission and is low in environment harmfulness, and has important significance in the aspects of ecological protection and economic development promotion.

Owner:CHINA MINMETALS BEIJING RES INST OF RE

Method for improving dispersibility of insoluble sulfur

ActiveCN104961106AReduce usageReduce recycling stepsSulfur preparation/purificationOrganic solventOrganic matter

The invention discloses a method for improving the dispersibility of insoluble sulfur. The method comprises the following steps: selecting an organic matter having the melt point or the softening point being 40-100 DEG C as a dispersible material; heating to enable the dispersible material to be kept a molten state before filling oil to the dispersible material; then, uniformly spraying the molten dispersible material onto the surface of the insoluble sulfur in a mist form; carrying out filled sealing on micropores on the surface of the insoluble sulfur; carrying out oil filling after the dispersible material and the insoluble sulfur are sufficiently mixed. According to the method disclosed by the invention, the use of an organic solvent can be avoided by defining and improving the melt point or the softening point of the dispersible material and adding the dispersible material at a molten state in a spraying manner before oil filling rather than an organic solvent dissolving manner, and recovery steps of the organic solvent are also reduced, so that the consumption of resources and energy sources is reduced; meanwhile, the method is simple and feasible, and is beneficial for improving the production efficiency.

Owner:SHANDONG YANGGU HUATAI CHEM

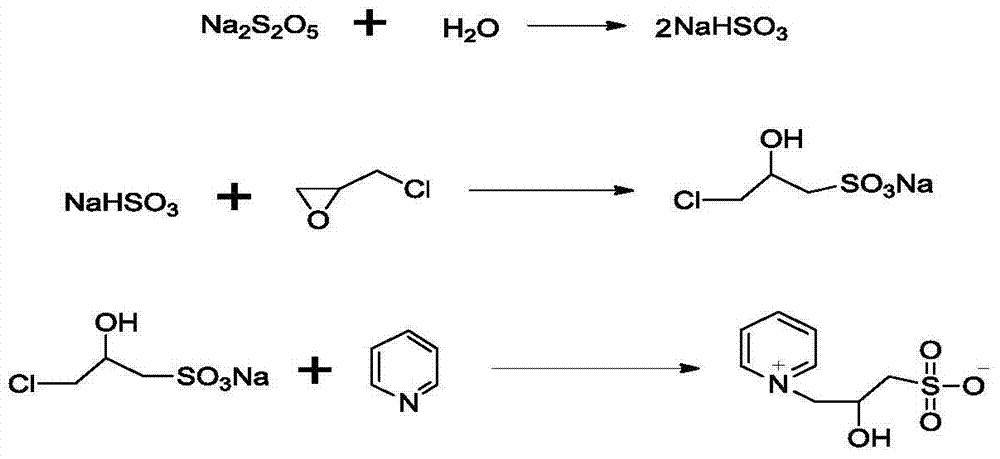

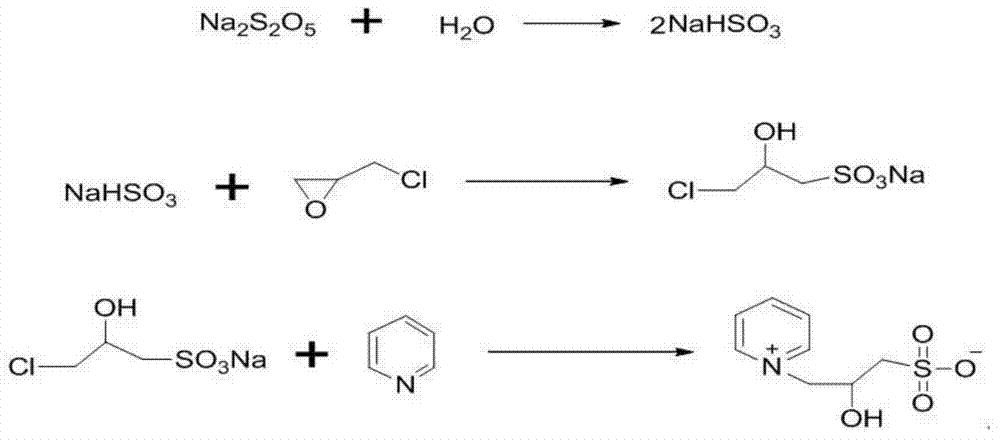

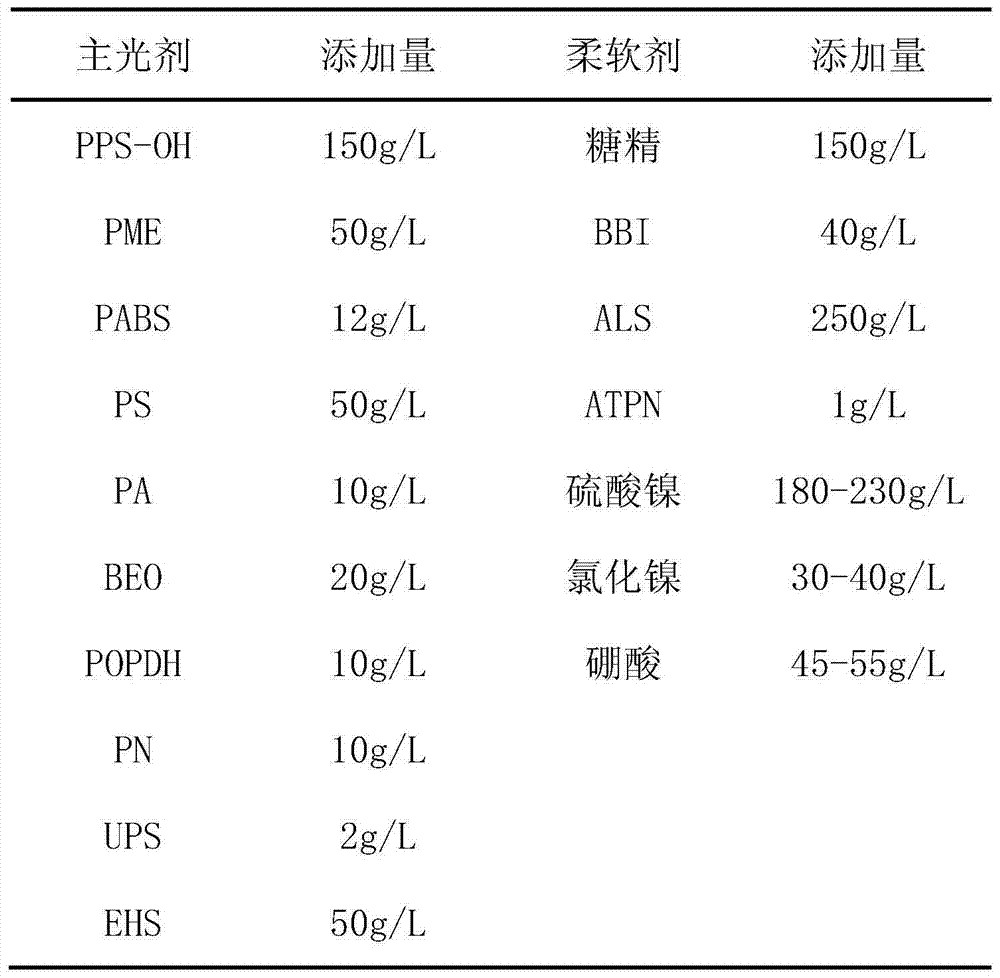

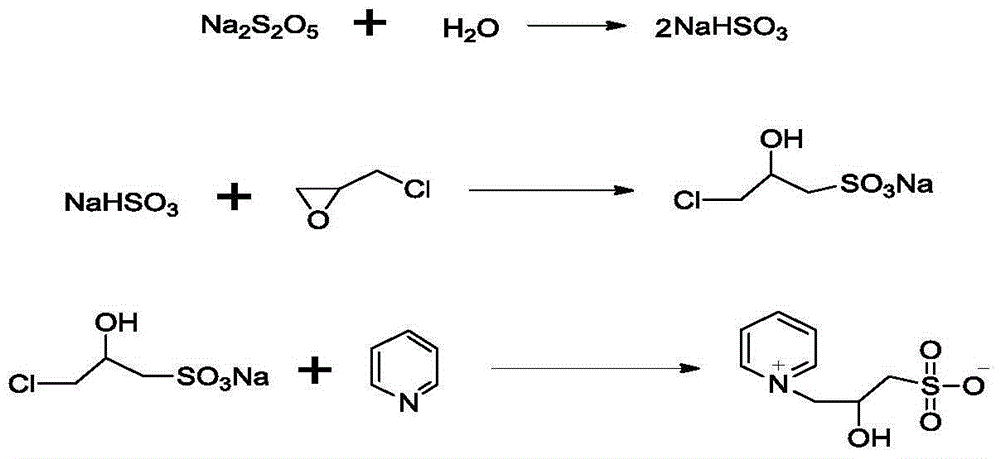

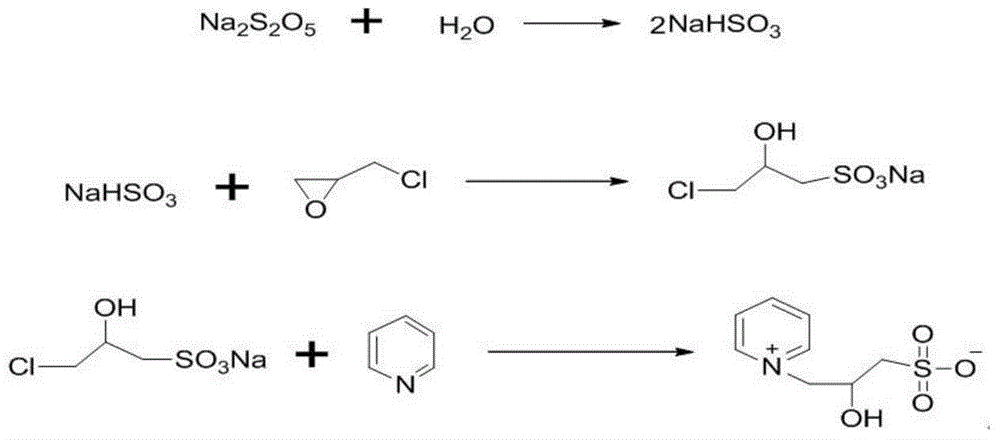

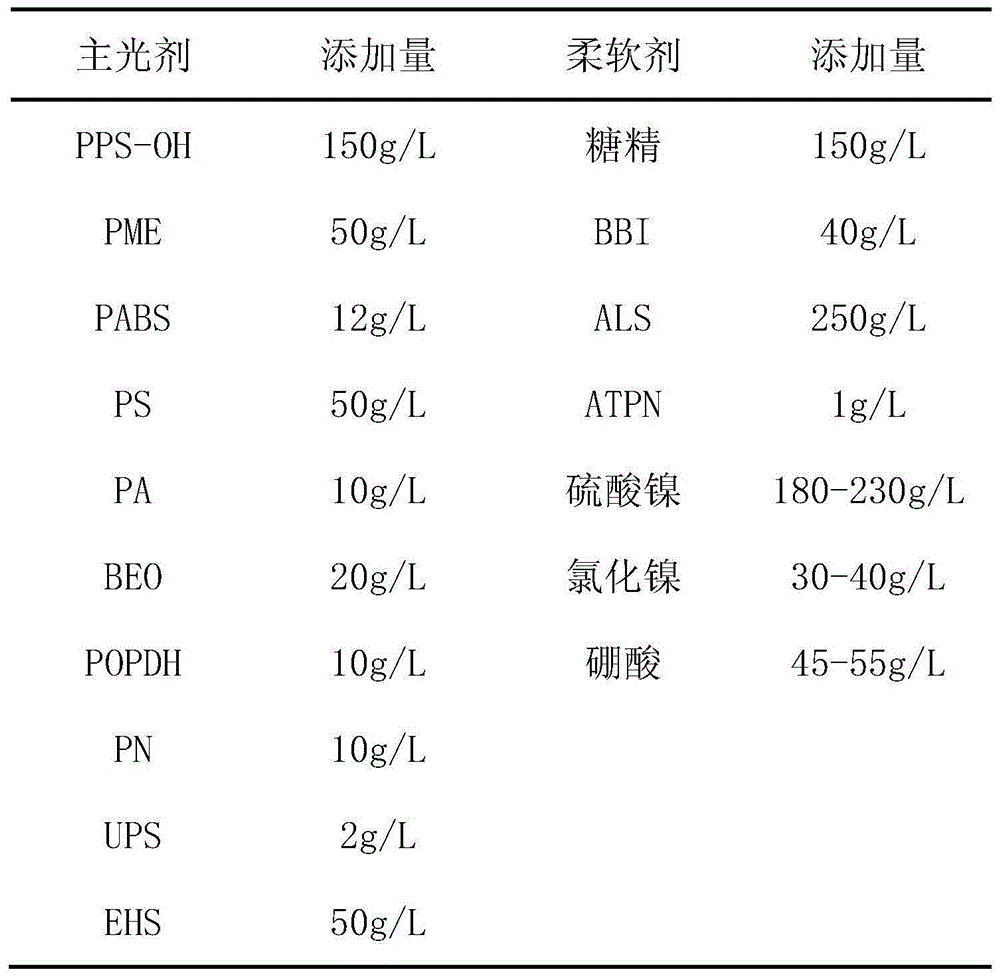

Synthetic method of pyridinium hydroxy propyl sulfobetaine

The invention relates to a synthetic method of pyridinium hydroxy propyl sulfobetaine. The synthetic method comprises the following steps: sufficiently dissolving hydrosulphite or pyrosulfite in water at normal temperature, adding sodium sulfite as an auxiliary sulfonating agent to adjust the pH value of the system to be 5.2-5.5, and then adding polyether F-6 as a catalyst; then adding a complexing agent, controlling the environment conditions, adding epichlorohydrin, and carrying out loop-opening reaction to obtain 3-chloro-2-hydroxy propanesulfonate; adding pyridine to the system, controlling the temperature to carry out reflux reaction, adding triethylamine as an impurity removing agent, reacting for 1 hour, then dehydrating and decoloring, adjusting the pH to 2-5, and adding 4-hydroxyl-2, 2, 6, 6-tetramentylniperidine-1-oxygen radical as a stabilizer and a vitamin C derivative to obtain an aqueous solution of the pyridinium hydroxy propyl sulfobetaine. The pyridinium hydroxy propyl sulfobetaine synthesized by the synthetic method is produced by adopting a one-pot method, which accords with the electroplating industry development demands at present; the pyridinium hydroxy propyl sulfobetaine is low in impurity content, good in appearance and low in production cost.

Owner:湖北吉和昌化工科技有限公司

Method for extracting haematochrome from mulberry red

The invention belongs to the technical field of pigment extraction, and particularly relates to a method for extracting haematochrome from mulberry red. The method comprises the following steps of (1) preprocessing; (2) preparing a separating medium through a freezing wall-breaking method; (3) extracting an extracting solution through distilled water; (4) degumming through an enzymic method; and (5) recycling haematochrome through distilling. The method has the beneficial effects that natural biological activity pigment component in the mulberry pulp is furthest reserved due to the freezing wall-breaking method, and the natural edible haematochrome prepared by the method has strong water solubility, is amaranth, reserves maximum nutritional ingredients of the mulberry, and can be used in food, beverage, cosmetics and the like.

Owner:CHONGQING DANQING BIOLOGY TECH

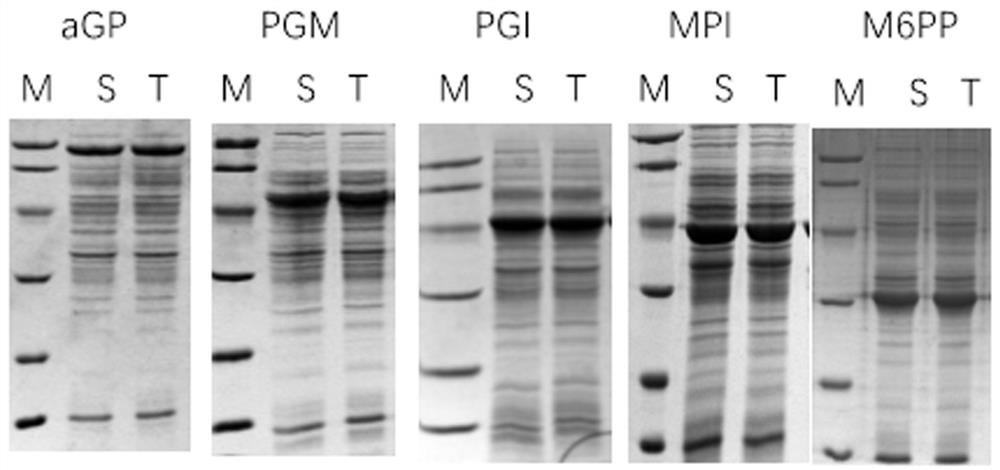

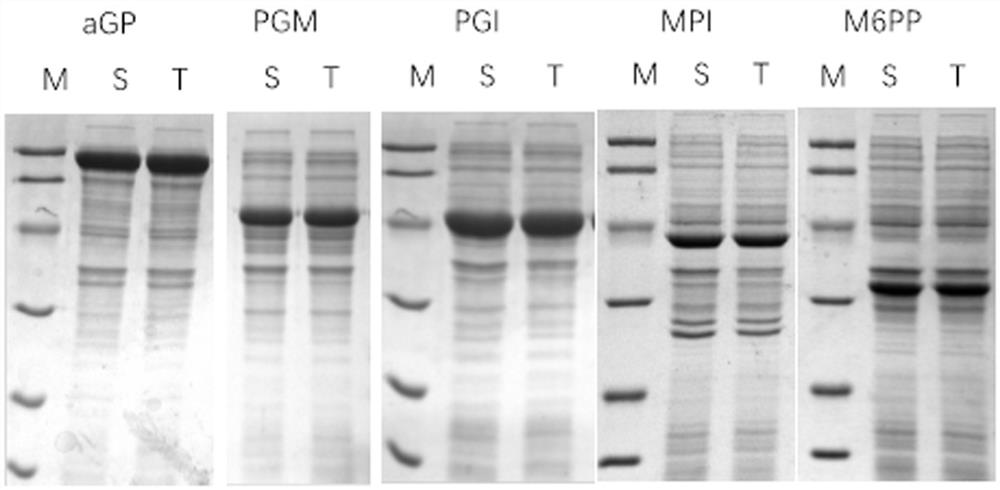

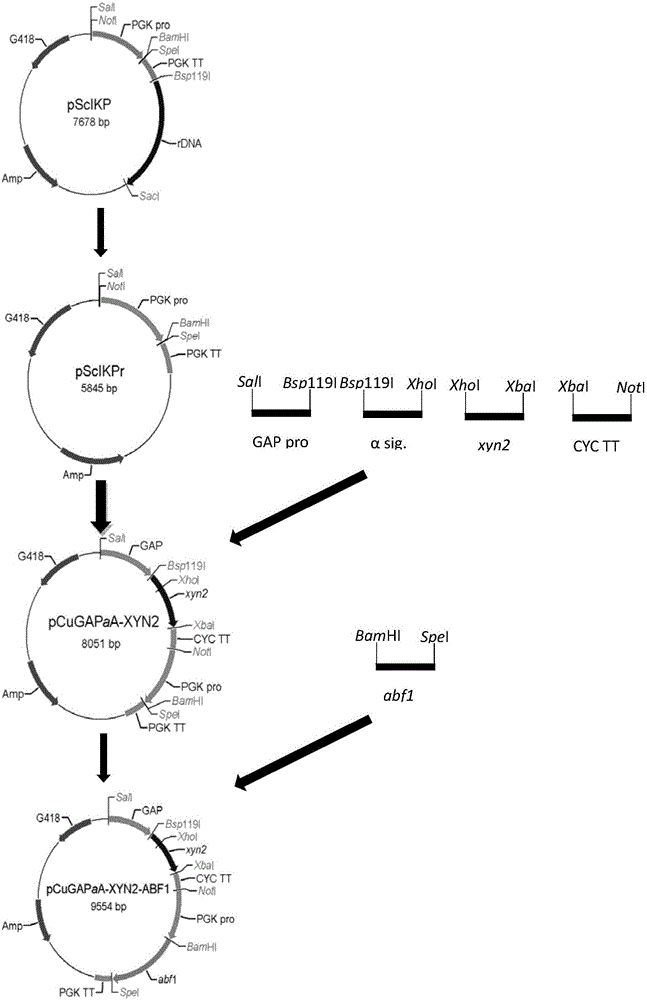

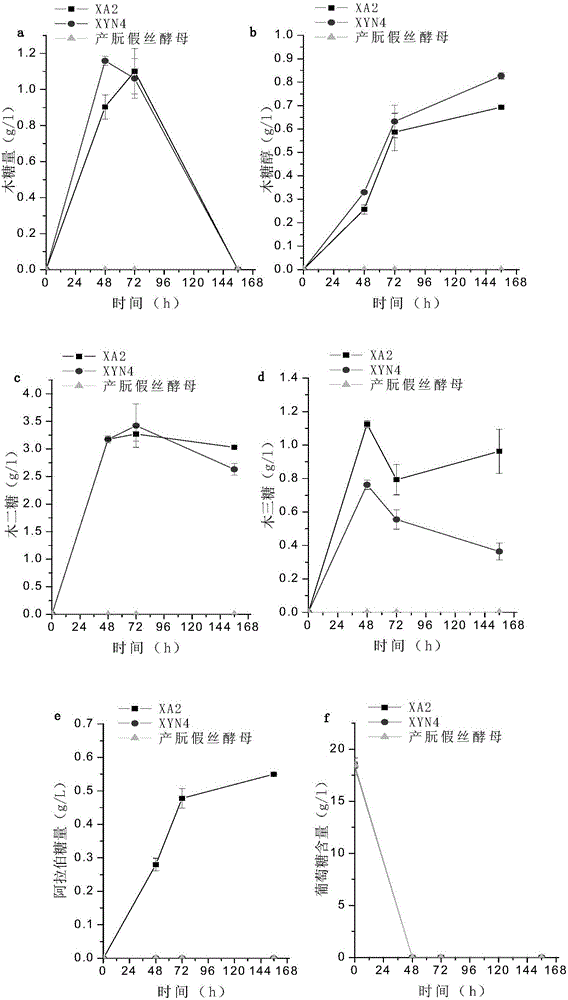

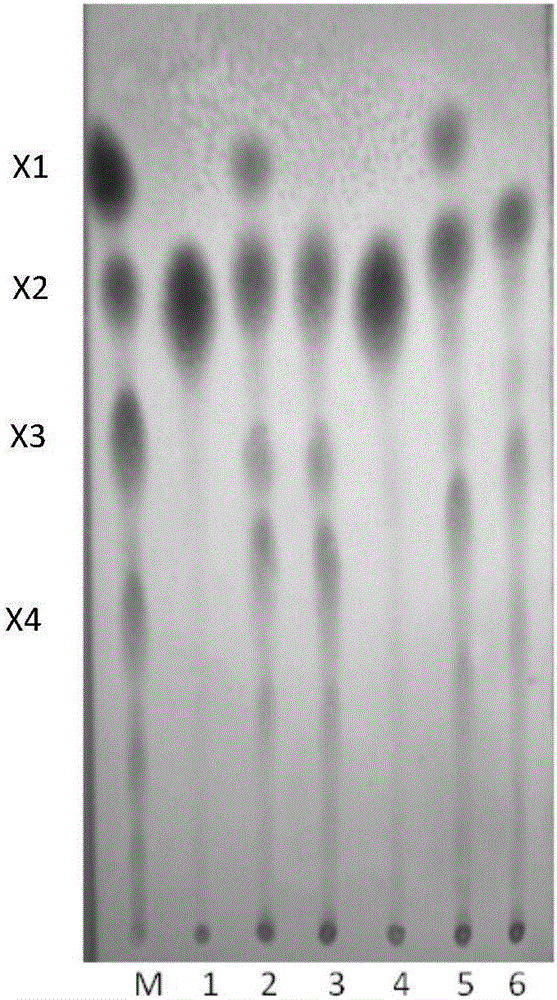

Gene recombined candida utilis capable of degrading and utilizing hemicellulose and applications of gene recombined candida utilis

The invention discloses gene recombined candida utilis capable of decomposing hemicellulose and applications of the gene recombined candida utilis. The gene recombined candida utilis can stably express xylanase coming from trichoderma reesei and Arabinfuranosidease. With the gene recombined yeast, an integrated biotechnology capable of degrading hemicellulose for co-producing xylooligosaccharide, arabinose and newtol is established. According to the process, 20g / l bagasse hemicellulose is taken as a substrate, after culture for 156h, xylose produced in the middle process is consumed up by the yeast, the yield of xylooligosaccharide is 20%, at the time, the highest yields of newtol and arabinose, namely, 3.5% and 2.7% are achieved, and the hydrolysis rate of hemicellulose is 40.4%. The integrated biotechnology belongs to a co-production technology which is environmentally friendly, convenient and rapid, and effective.

Owner:GUANGDONG QIZHI BIOTECHNOLOGY CO LTD

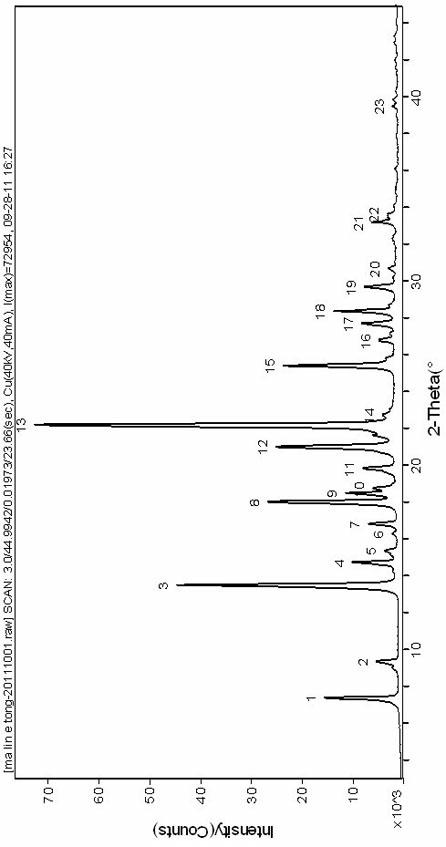

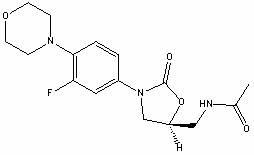

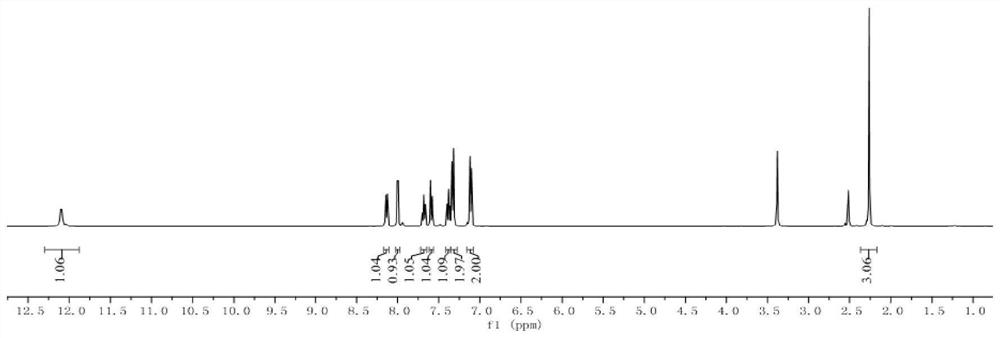

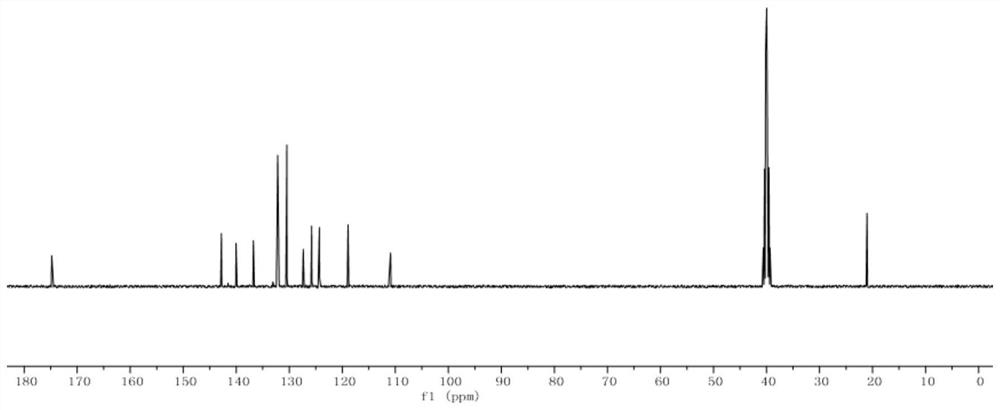

Suspension crystallization method for preparing crystal form I of linezolid

The invention discloses a suspension crystallization method for preparing a crystal form I of linezolid. The method comprises the following steps of: mixing 1 to 10 weight part of water and 1 weight part of linezolid, heating to the temperature of between 95 and 105DEG C to obtain suspension, crystallizing at the temperature of between 70 and 100DEG C, filtering at the temperature of between 0 and 90DEG C, and performing vacuum drying on a filter cake at the temperature of between 30 and 90DEG C to obtain the crystal form I of the linezolid. The method has the advantages that: water is taken as a suspension solvent, organic solvents are not used at all, the method is green, safe, environment-friendly and pollution-free, the product yield is high, the filter cake is not required to be washed, the filtered mother solution can be repeatedly used, the volume of the mother solution cannot be increased due to reuse, the energy consumption in the production process is obviously reduced, and clean production can be realized.

Owner:ZHEJIANG LEPU PHARMA CO LTD

Process for synthesizing p-tert-butylbenzoic acid

ActiveCN102617335AReduce usageReduce recycling stepsOrganic compound preparationCarboxylic compound separation/purificationOxygenMoisture

The invention relates to a process for synthesizing p-tert-butylbenzoic acid. The process comprises the following steps of: adding p-tert-butyltoluene and cobalt acetate into a reaction kettle, introducing oxygen-containing gas, triggering at the temperature of between 150 and 155 DEG C, performing oxidation reaction for 0.5 to 1 hour, and continuously reacting at the temperature of between 135 and 145 DEG C for more than 5 hours to obtain a p-tert-butylbenzoic acid crude product; cooling the p-tert-butylbenzoic acid crude product to crystallize, performing centrifuge dripping, and striking and washing by using p-tert-butyltoluene to obtain a centrifugation crude product; and adding the centrifugation crude product into a dissolution kettle, adding methylbenzene, raising temperature and dissolving, filtering when a mixture is hot to remove impurities, adding water to wash, transferring materials to a recrystallization kettle, cooling to crystallize, centrifuging, striking and washing by using methylbenzene, and drying to obtain a p-tert-butylbenzoic acid finished product. The prepared p-tert-butylbenzoic acid is white crystals and does not contain mechanical impurities; and the melting point is 164.0 to 167.0 DEG C, the acid value is 312 to 316mgKOH / g, high performance liquid chromatography (HPLC) purity is more than or equal to 99.2 percent, moisture is less than or equal to 0.08 percent, and methylbenzene is less than or equal to 0.05 percent.

Owner:SUQIAN COSMOS CHEM +1

Electrochemical synthesis method of 3-arylseleno quinolinone compound

ActiveCN111910209ASelectiveImprove compatibilityElectrolysis componentsElectrolytic organic productionElectrolytic agentElectrochemical response

The invention discloses an electrochemical synthesis method of a 3-aryl seleno quinolinone compound. According to the method, a solution containing a quinolinone compound, diaryldiselenide and potassium iodide is used as an electrolytic solution, a glassy carbon anode and a glassy carbon cathode are placed in the electrolytic solution, direct current is introduced, and an electrochemical reactionis carried out to obtain the 3-aryl seleno quinolinone compound. The method has the advantages of mild reaction conditions, simple operation, environmental protection, easily available raw materials,excellent compatibility of substrate functional groups, high reaction yield and the like.

Owner:HUNAN UNIV OF SCI & ENG

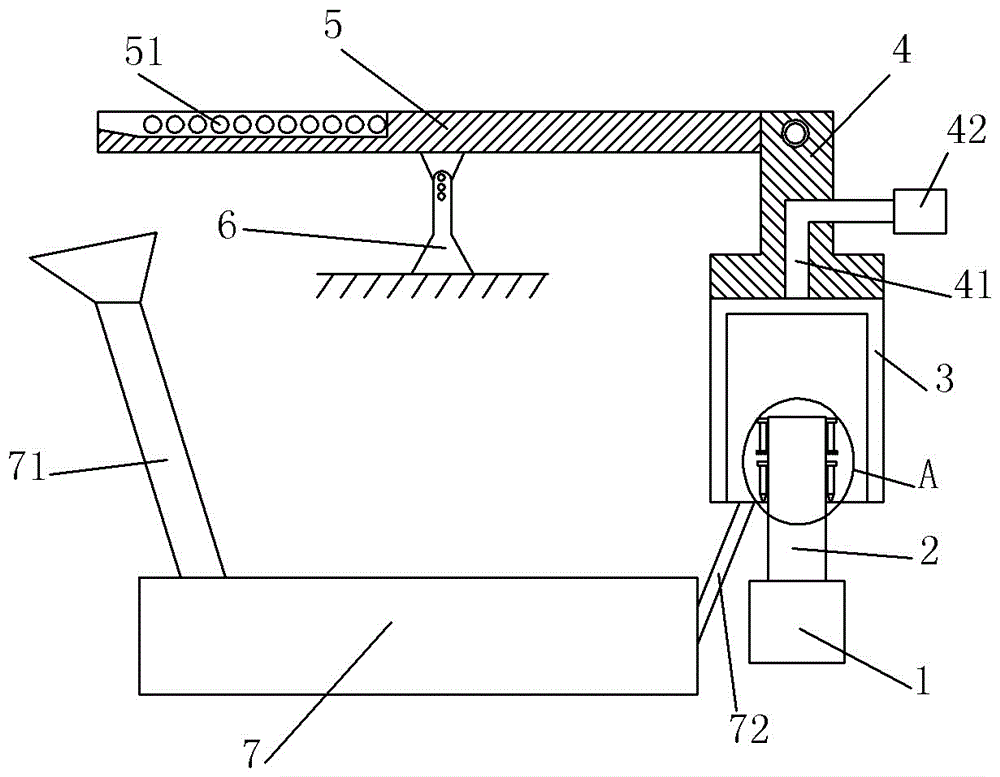

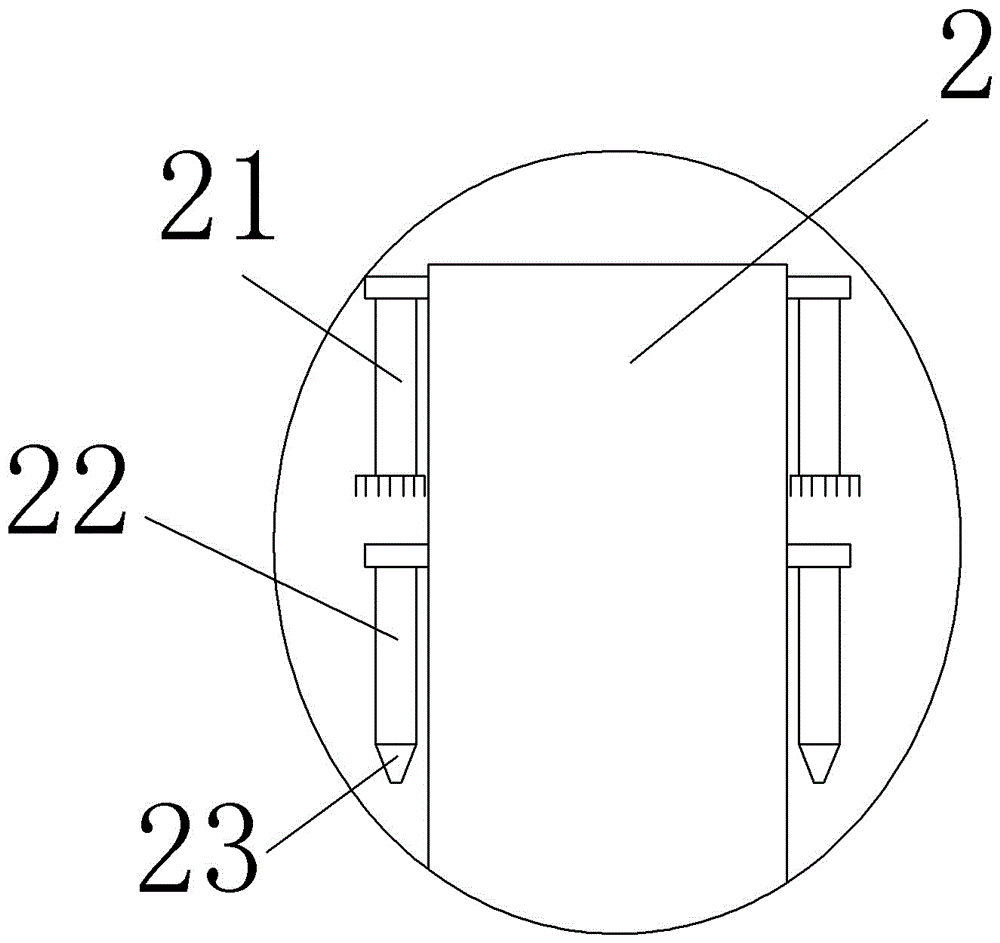

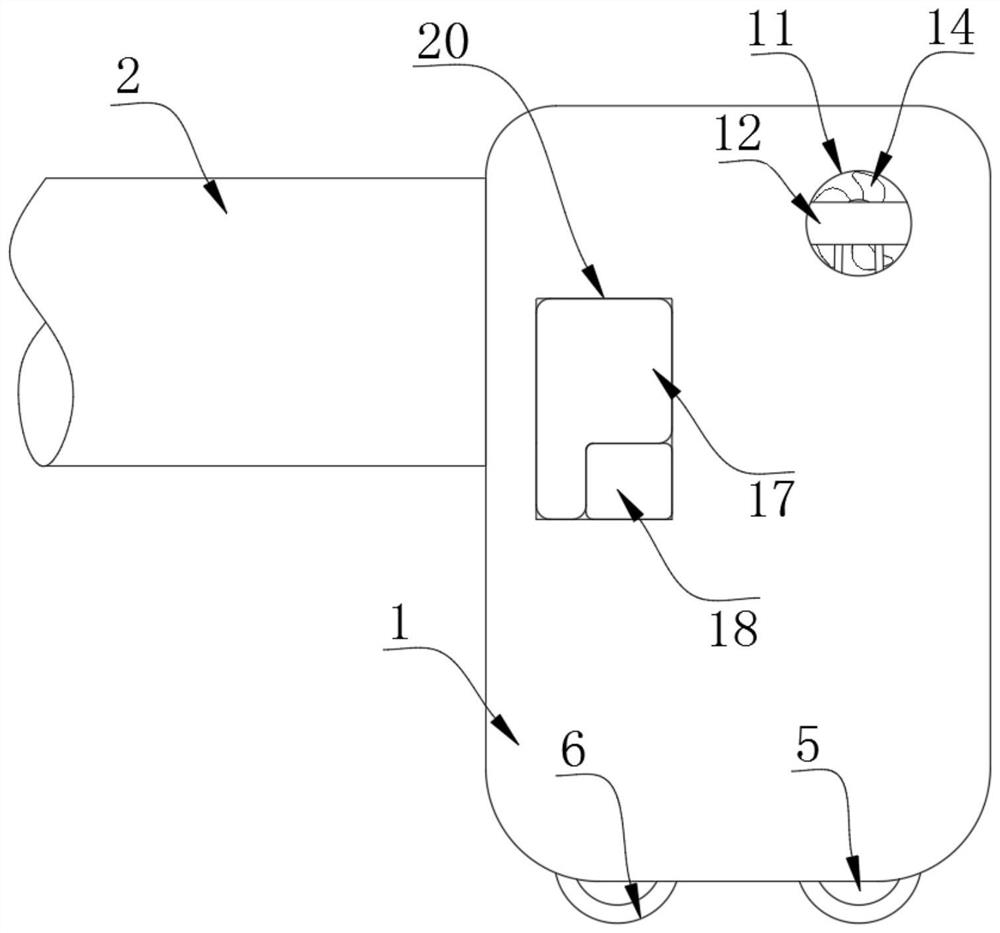

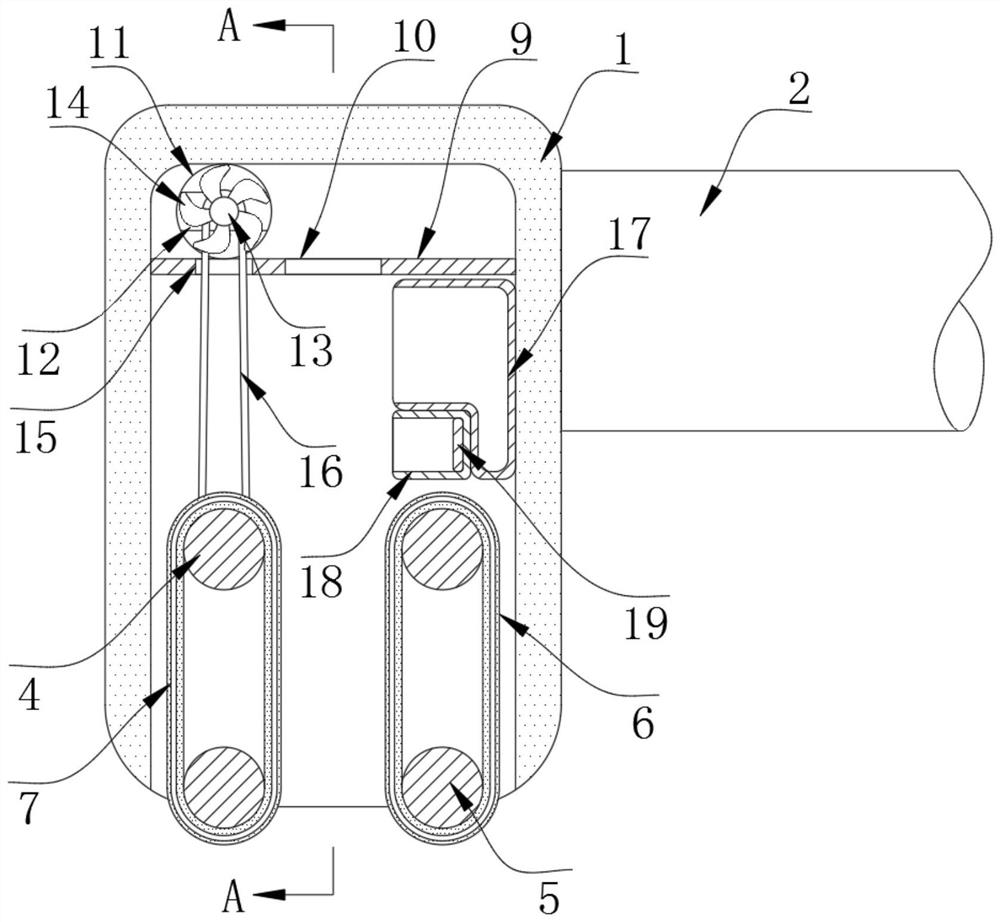

Machining method of recycling sanding machine for iron plate

InactiveCN111791130AEliminate the disadvantages of unevennessImprove grinding effectGrinding drivesAbrasion apparatusSanderElectric machinery

The invention discloses a machining method of a recycling sanding machine for an iron plate. The method mainly comprises the following steps of abrasive paper mounting, plate sanding machining, dust clearing and waste recycling, machining equipment used in an iron plate recycling type sanding machine machining process comprises a shell and a holding handle mounted on the outer wall of the shell, two grinding mechanisms are symmetrically mounted on the inner wall of the shell, each grinding mechanism comprises a motor fixed to the inner wall of the shell, an output shaft of the motor is fixedlyprovided with a rotating shaft rotatably connected with the inner wall of the shell, and the method has the advantages that through arranging of two motors with the different rotating directions, grinding directions of two grinding belts are different, the grinding effect is better, the defect of unevenness brought by a small contact can be removed, whole sanding treatment is greatly improved, through one-time moving, two-time machining is finished, the machining efficiency of the same position can be greatly improved, and the whole machining speed is improved.

Owner:郑学成

Method for preparing high-purity and high-dispersibility insoluble sulfur

InactiveCN105752941AReduce usageReduce recycling stepsChemical industrySulfur preparation/purificationMolten stateOrganic solvent

The invention discloses a method for preparing high-purity and high-dispersibility insoluble sulfur, and relates to the field of fine chemical engineering.The method includes steps of (1), melting and heating raw materials; (2), atomizing and quenching the raw materials; (3), solidifying the raw materials; (4), extracting and filtering the raw materials; (5), dispersing the raw materials; (6), coating the raw materials; (7), drying the raw materials and filling the raw materials with oil.The method has the advantages that disperse materials in molten states are added into the raw materials in a mist spray mode instead of an organic solvent melting mode before the raw materials are filled with the oil, accordingly, organic solvents can be omitted, steps for recycling the organic solvents can be omitted, resource and energy consumption can be reduced, and the purity, the high heat stability and the dispersibility of the high-purity and high-dispersibility insoluble sulfur prepared by the aid of the method can be greatly improved.

Owner:SHANGHAI JINGHAI ANHUI CHEM

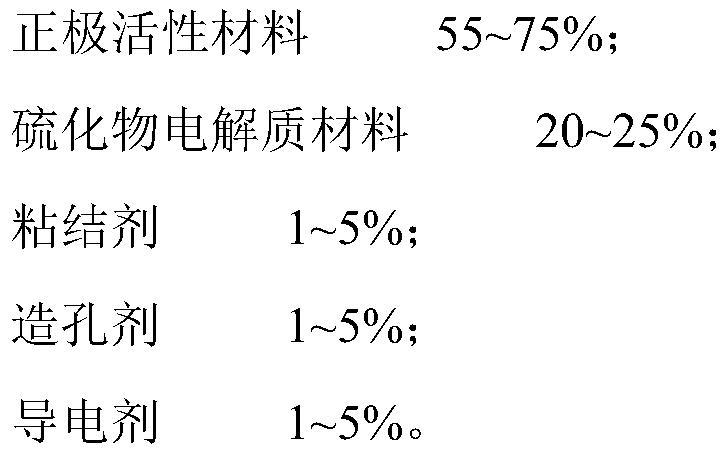

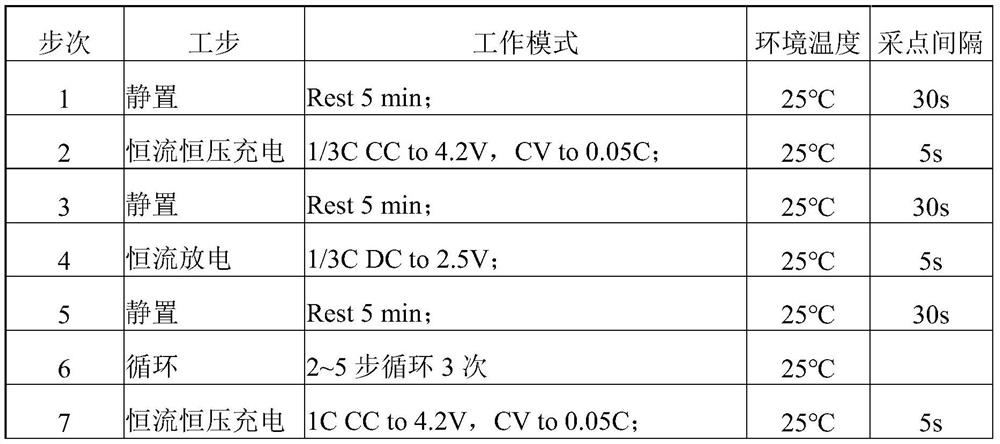

Positive plate, preparation method of positive plate, solid-state lithium ion battery, semi-solid-state lithium ion battery and preparation method of semi-solid-state lithium ion battery

ActiveCN113540394AIncrease loadIncrease surface areaFinal product manufactureSecondary cellsSolid state electrolytePhysical chemistry

The invention discloses a positive plate, a preparation method of the positive plate, a solid-state lithium ion battery, a semi-solid-state lithium ion battery and a preparation method of the semi-solid-state lithium ion battery. The positive plate comprises a current collector and a positive electrode slurry layer covering the current collector, and a plurality of holes are formed in the positive electrode slurry layer. The positive electrode slurry layer comprises a positive electrode active material, a sulfide electrolyte material and a binder. According to the positive plate, a thick electrode is adopted, the loading capacity of the positive electrode is increased, meanwhile, a porous structure is adopted, the surface area of the positive plate is increased, transmission channels of lithium ions are increased, and the transmission performance of the lithium ions is improved. The preparation method of the positive plate reduces the cost of a battery. According to the semi-solid lithium ion battery, a lithium ion transmission channel is added, and a liquid electrolyte is injected, so that good contact between the solid electrolyte and the active substance can be ensured, the lithium ion transmission distance is shortened the dynamic performance of the battery is improved, and the low-temperature capacity, the normal rate capability, the normal-temperature cycle life and the 45 DEG C high-temperature cycle performance of the battery are improved.

Owner:远景动力技术(湖北)有限公司 +2

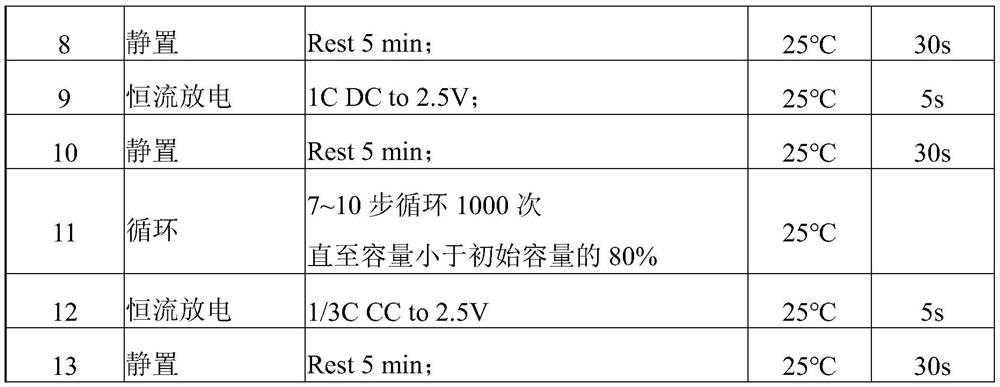

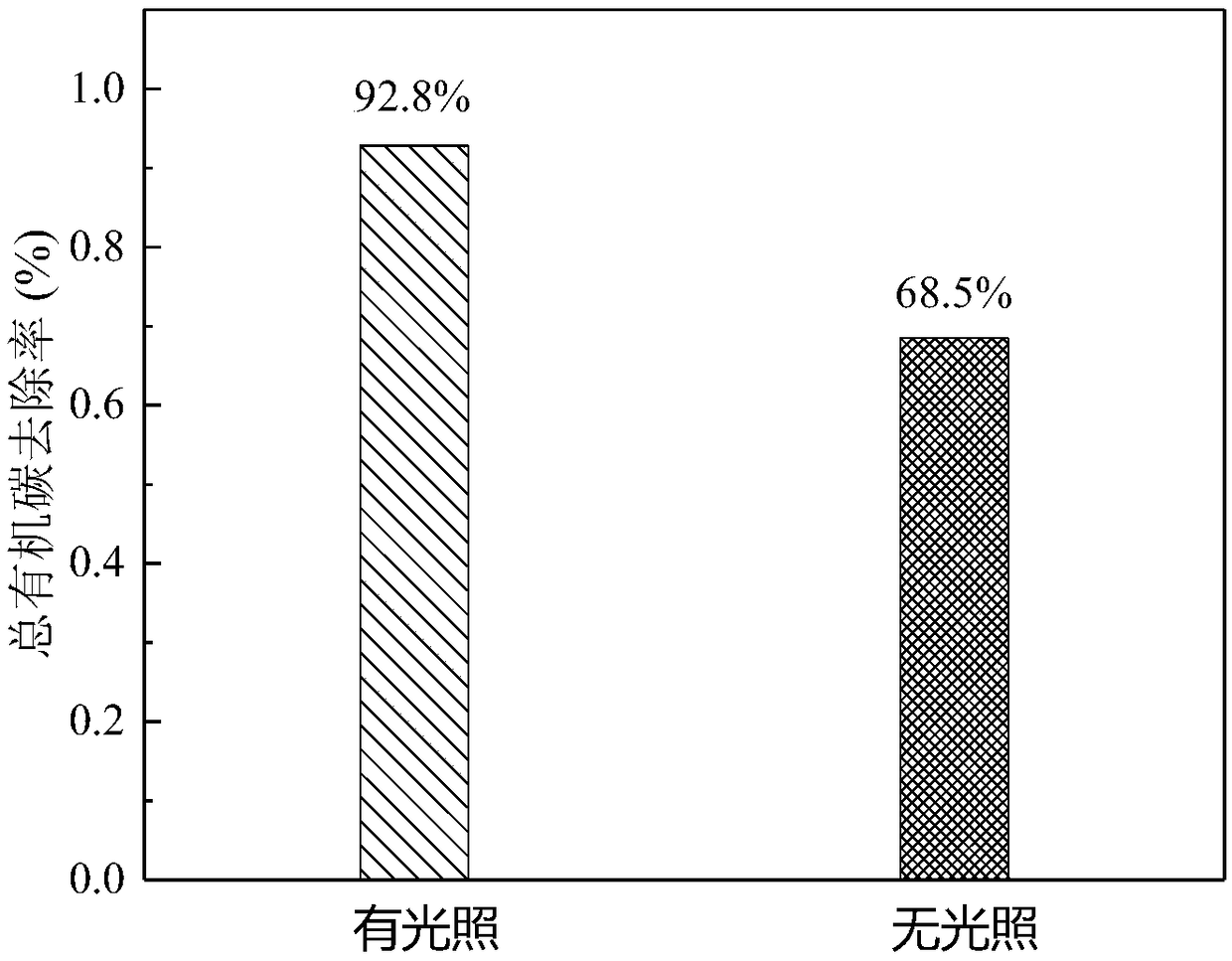

Microbial fuel cell with photocatalytic material loaded on positive electrode and preparation method and application of microbial fuel cell

PendingCN109160594AImproved degradation efficiency and mineralizationReduce recombination rateTreatment by combined electrochemical biological processesCell electrodesChlorophenolEngineering

The invention discloses a microbial fuel cell with a photocatalytic material loaded on a positive electrode and a preparation method and application of the microbial fuel cell, and belongs to the technical field of environment water pollution treatment and energy recovery. The photocatalytic material is loaded on the positive electrode of the microbial fuel cell, a negative electrode is an air electrode; and a resistor is connected between the positive electrode and the negative electrode. The preparation method comprises the following steps: dissolving the photocatalytic material, coating onthe surface of a carbon electrode, heating to obtain the carbon electrode loaded with the photocatalytic material, taking the carbon electrode as the positive electrode and the air electrode as the negative electrode, connecting the resistor between the positive electrode and the negative electrode; connecting the positive electrode, the negative electrode and the resistor in series, putting in areactor, and forming the microbial fuel cell with the photocatalytic material loaded on the positive electrode. The microbial fuel cell with the photocatalytic material loaded on the positive electrode can rapidly thoroughly degrade the organic matters like chlorophenols, and the electricity generation performance of the fuel cell is improved.

Owner:HUAZHONG UNIV OF SCI & TECH

A kind of synthetic method of hydroxypropanesulfonic acid pyridinium salt

The invention relates to a synthetic method of pyridinium hydroxy propyl sulfobetaine. The synthetic method comprises the following steps: sufficiently dissolving hydrosulphite or pyrosulfite in water at normal temperature, adding sodium sulfite as an auxiliary sulfonating agent to adjust the pH value of the system to be 5.2-5.5, and then adding polyether F-6 as a catalyst; then adding a complexing agent, controlling the environment conditions, adding epichlorohydrin, and carrying out loop-opening reaction to obtain 3-chloro-2-hydroxy propanesulfonate; adding pyridine to the system, controlling the temperature to carry out reflux reaction, adding triethylamine as an impurity removing agent, reacting for 1 hour, then dehydrating and decoloring, adjusting the pH to 2-5, and adding 4-hydroxyl-2, 2, 6, 6-tetramentylniperidine-1-oxygen radical as a stabilizer and a vitamin C derivative to obtain an aqueous solution of the pyridinium hydroxy propyl sulfobetaine. The pyridinium hydroxy propyl sulfobetaine synthesized by the synthetic method is produced by adopting a one-pot method, which accords with the electroplating industry development demands at present; the pyridinium hydroxy propyl sulfobetaine is low in impurity content, good in appearance and low in production cost.

Owner:湖北吉和昌化工科技有限公司

Dong medicine for promoting wound healing

InactiveCN111297961APromote healingReduce formationPowder deliveryAntipyreticBiotechnologyMedicinal herbs

The invention belongs to the technical field of traditional Chinese medicine preparations, and particularly relates to a Dong medicine for promoting wound healing. The Dong medicine is composed of camellia oil as base oil, plant soot, lithospermum, bletilla striata, ninebark, agrimonia pilosa and other medicinal materials by combining folk medicine experience of the Dong nationality with traditional medicine knowledge, has effects of resisting bacteria, diminishing inflammation, decaying carrion and generating new muscles, and can promote wound healing, shorten treatment cycle and reduce formation of scars.

Owner:黎平通武中草药种植专业合作社

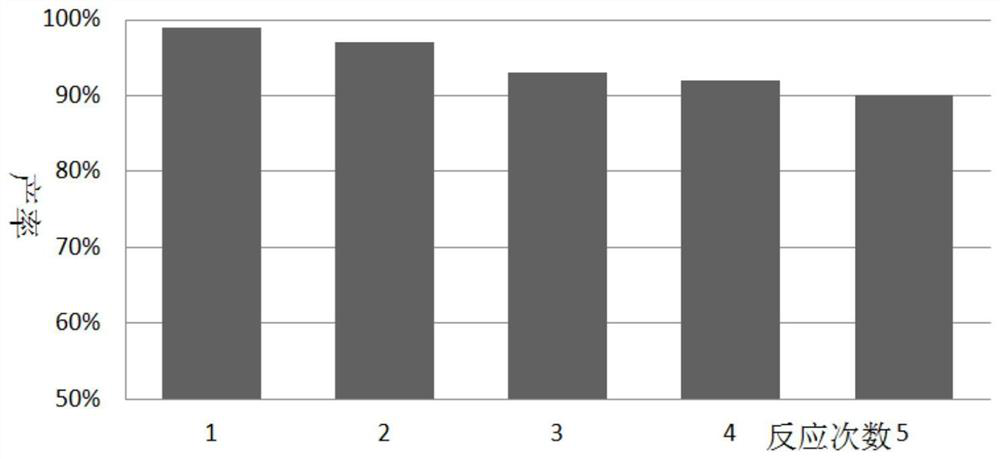

Synthetic method of 3-[2-(ethylhexyl)oxyl]-1,2-propandiol

ActiveCN107216240AImprove timelinessImprove responseEther separation/purificationOrganic compound preparationOctoxyglycerinAcetic anhydride

The invention discloses a synthetic method of 3-[2-(ethylhexyl)oxyl]-1,2-propandiol, which relates to the field of synthesis of daily chemical additives. The invention aims at providing a synthetic method with high yield. According to the technical scheme, the synthetic method comprises the following steps: step 1: adding 1,2-epoxy-3-[(2-ethylhexyl)oxy]-propane and a catalyst into acetic anhydride, and reacting for 1 to 2h to obtain a midbody; step 2: adjusting the pH of the system to be 12 to 14, stirring for 1h, standing, and layering; and step 3: washing an oil phase by successively utilizing ammonium chloride solution and water, rectifying the oil phase, and obtaining the 3-[2-(ethylhexyl)oxyl]-1,2-propandiol. The synthetic method is used for preparing high-purity 3-[2-(ethylhexyl)oxyl]-1,2-propandiol.

Owner:HUBEI ARTEC CARBOHYDRATE CHEM

Method combining waste ternary positive electrode material recovery and electrochemical hydrogen production

InactiveCN112680596AAchieve three-phase separationAchieve preparationElectrolysis componentsWaste accumulators reclaimingLithiumAdhesive

The invention relates to a method for combining waste ternary positive electrode material recovery and electrochemical hydrogen production. The method comprises the following steps of (1) recovering a waste ternary positive electrode material and carrying out mechanical activation, sieving and drying on the same to obtain waste ternary positive electrode material recovered powder; (2) mixing the waste ternary positive electrode material recovered powder with a conductive agent and an adhesive, dispersing the same in an N-methyl pyrrolidone solution, and carrying out coating, and drying to obtain a pole piece; (3) taking the pole piece as a positive electrode, taking an inert electrode as a negative electrode, charging the same in an electrolyte solution, generating hydroxide precipitates of nickel and manganese at the positive electrode, and generating hydrogen at the negative electrode; and (4) after the reaction is finished, carrying out solid-liquid separation on a reaction system to obtain a lithium-rich solution, the hydroxide precipitates of the nickel and the manganese and the positive pole piece, and carrying out high-temperature calcination on the positive pole piece to obtain an oxide of cobalt. According to the method, the resource recycling of the waste ternary positive electrode material is realized in a simple, quick, low-energy-consumption and environment-friendly mode.

Owner:CENT SOUTH UNIV

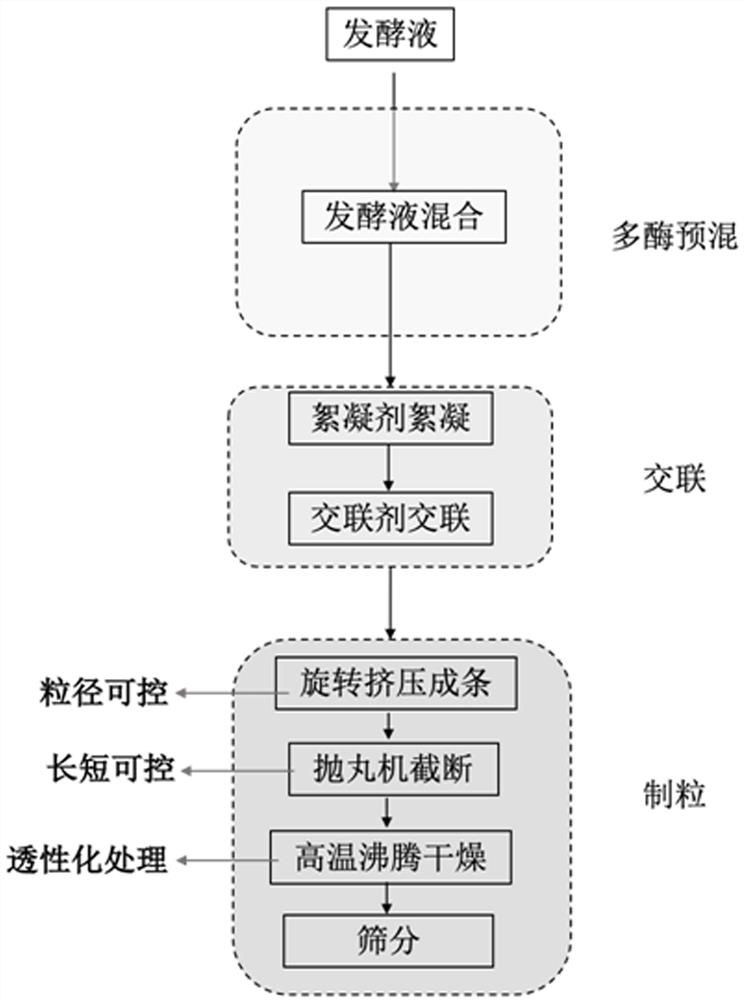

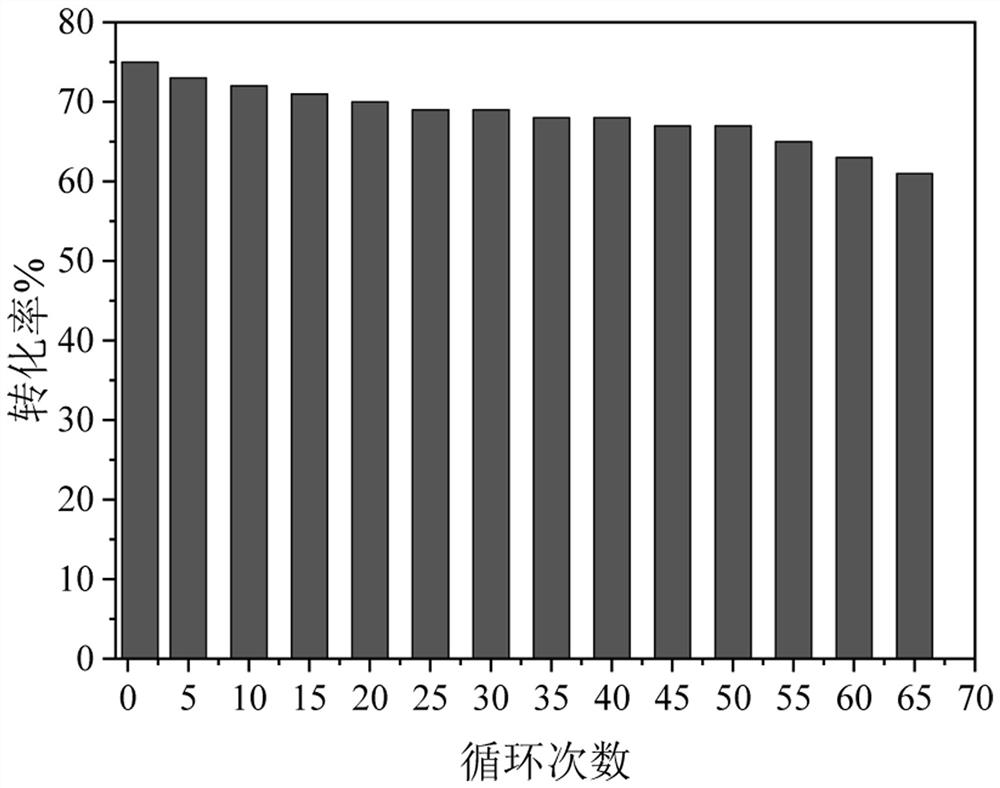

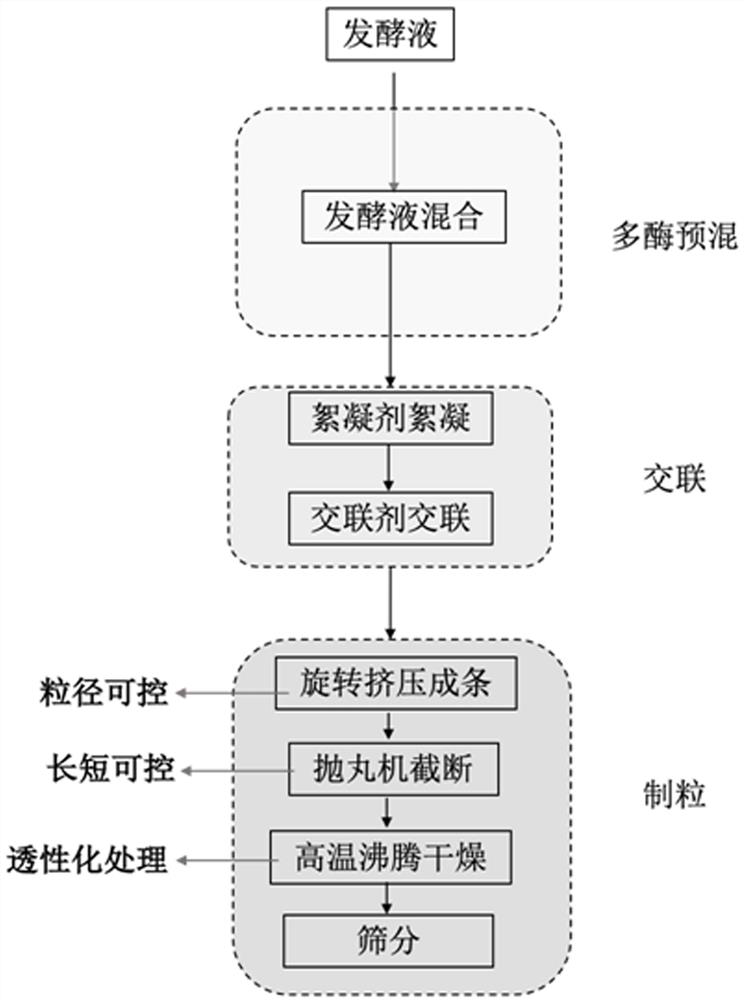

Preparation method and application of immobilized cells for tagatose production

ActiveCN113249371AEasy to produceIncrease profitMicroorganism based processesOn/in organic carrierBiotechnologyEscherichia coli

The invention discloses a preparation method of immobilized cells for tagatose production and a method for producing tagatose by using the immobilized cells. When immobilized bacillus subtilis is subjected to continuous catalytic reaction, the yield of an initial product can reach 75% at most, and after continuous catalysis is carried out for 65 batches, the yield of the product can still be maintained to be 61%. When immobilized Escherichia coli is subjected to continuous catalytic reaction, the yield of an initial product can be up to 74% at most, and after continuous catalysis is carried out for 65 batches, the yield of the product can still be maintained to be 60%. The separation and purification steps of the enzyme required in tagatose production are simplified, the recycling rate of the enzyme is improved, and the recycling of the enzyme is realized. The method has the advantages of easiness in product separation, simple production process, low cost and the like.

Owner:天津怡和生物科技有限责任公司

Bone-setting application pulvis

InactiveCN111671872AStable sustained releasePromote healingAntipyreticAnalgesicsMedicinal herbsEngineering

The invention belongs to the technical field of traditional Chinese medicine preparations, and specifically relates to bone-setting application pulvis. Civil medication experiences are combined with traditional medicine knowledge, more than ten traditional Chinese medicinal materials are selected and processed in different manners, and sticky rice is combined with the medicinal materials to form aglutinous rice cake type dressing, so that the dressing is convenient to change; and effective components in the dressing can be stably and continuously released so as to promote healing of bone fracture, so that a treatment period is shortened, and fracture patients can basically be healed within 15-30 days.

Owner:姜金林

Non-chemically modified food starches

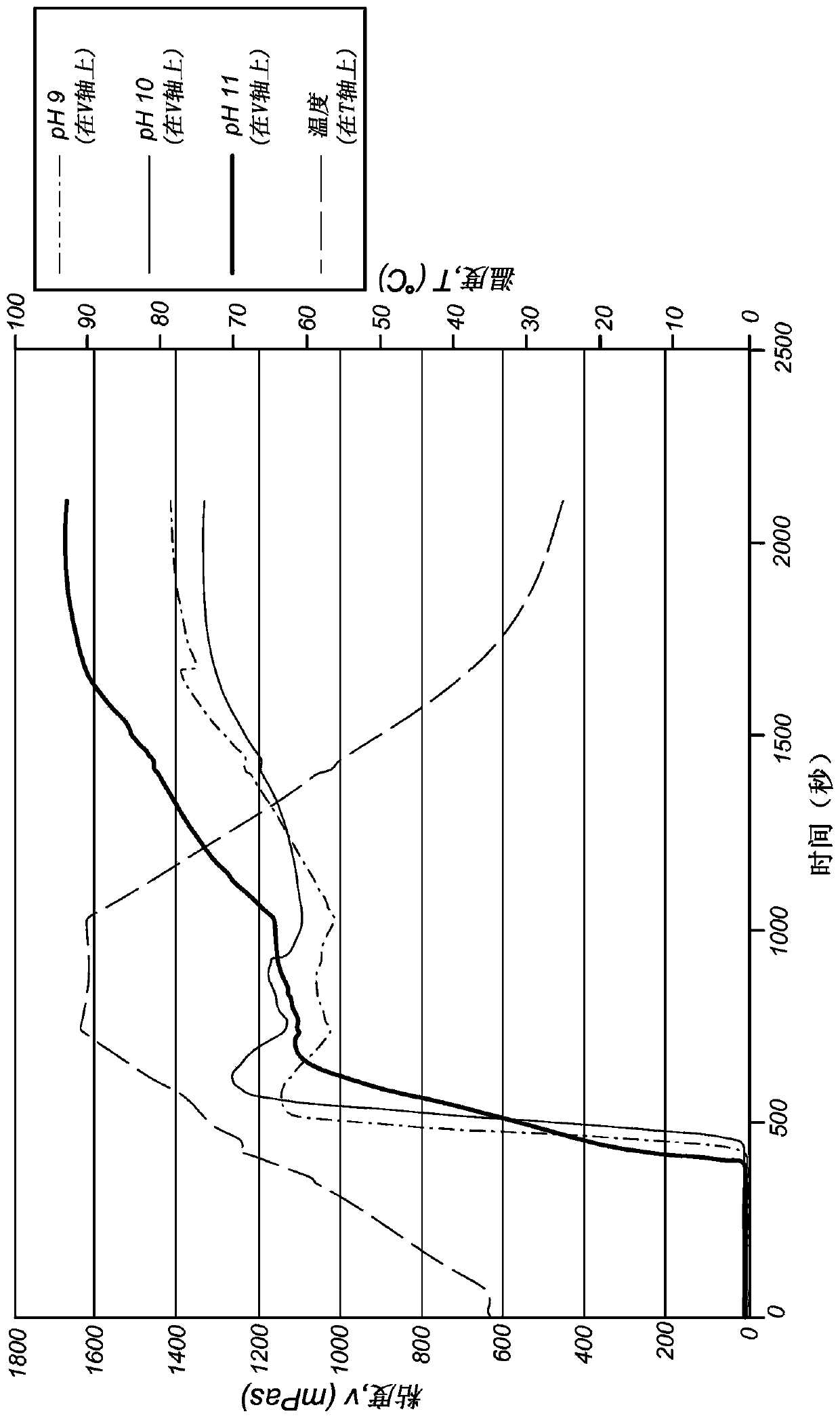

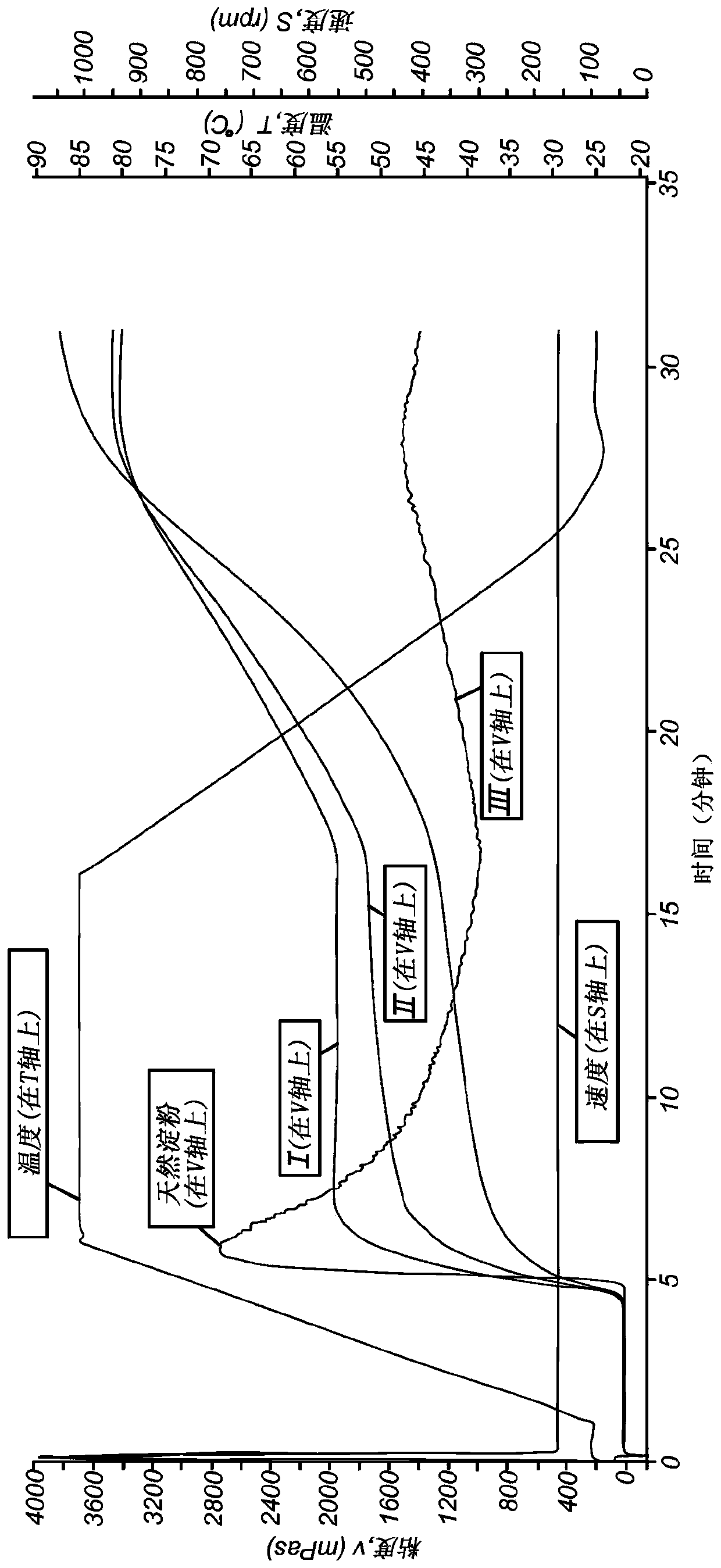

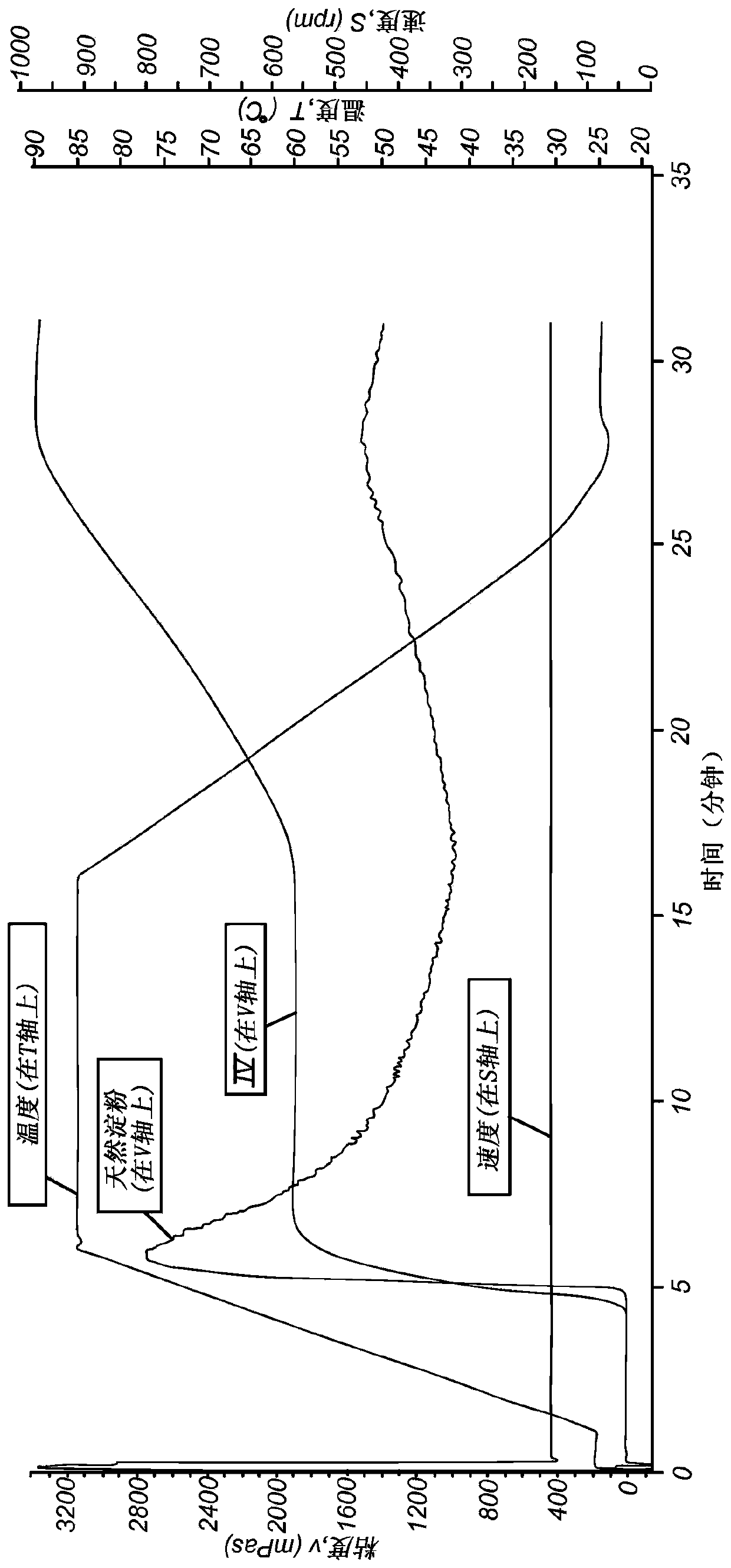

A process for producing thermally inhibited starch, specifically thermally inhibited non- pregelatinized granular starch, is described, resulting in a viscostable starch product. The process comprising providing an alkaline starch, specifically an alkaline non-pregelatinized granular starch,having a pH of at least 8; subjecting the starch to a hydrothermal treatment, specifically to obtain a hydrothermally treated non-pregelatinized granular starch, said hydrothermal treatment being at a temperature of 45-200DC with steam at a steam pressure of 0.1-15 bar or a gas mixture comprising water vapor at a partial water vapor pressure of 0.1-1 bar; dehydrating the starch, specifically the hydrothermally treated non-pregelatinized granular starch,to a moisture content of 2 wt% or lower and subjecting the starch to a thermal treatment by heating the starch to a temperature of 120-190DC to obtain viscostability,cooling and optionally further processing the starch.

Owner:STICHTING WAGENINGEN RES

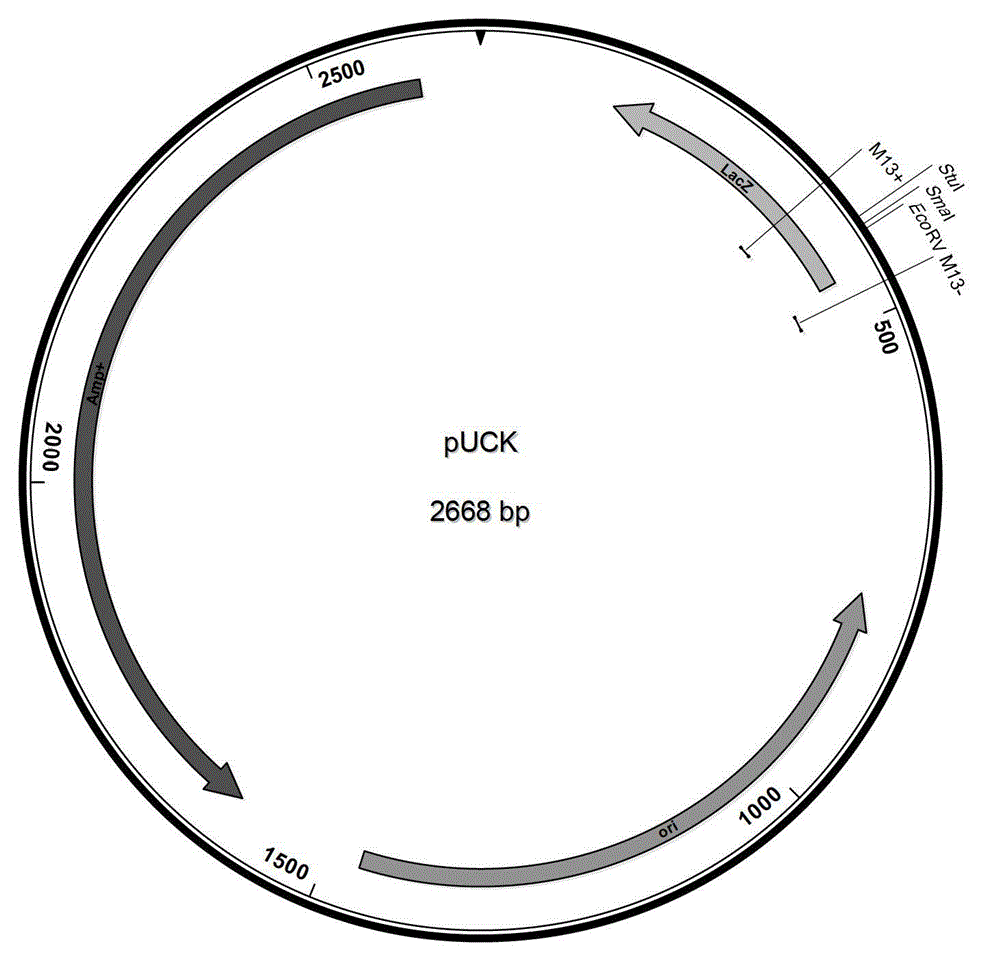

Modified cloning vector and application thereof

ActiveCN103088048BEasy to useWide range of usesVector-based foreign material introductionEnzyme digestionGenetics

The invention relates to a modified cloning vector and an application thereof. The modified cloning vector is an annular cloning vector, and is obtained by replacing multiple cloning sites of a pUC57 vector by employing three flush end cloning sites of EcoRV, SmaI and StuI and removing an NdeI enzyme digestion site at the LacZ downstream in the pUC57 vector, and the modified cloning vector only comprises three cloning sites of EcoRV, SmaI and StuI. The vector can completely replace any one cloning vector and is convenient to use and is wide in application.

Owner:生工生物工程(上海)股份有限公司

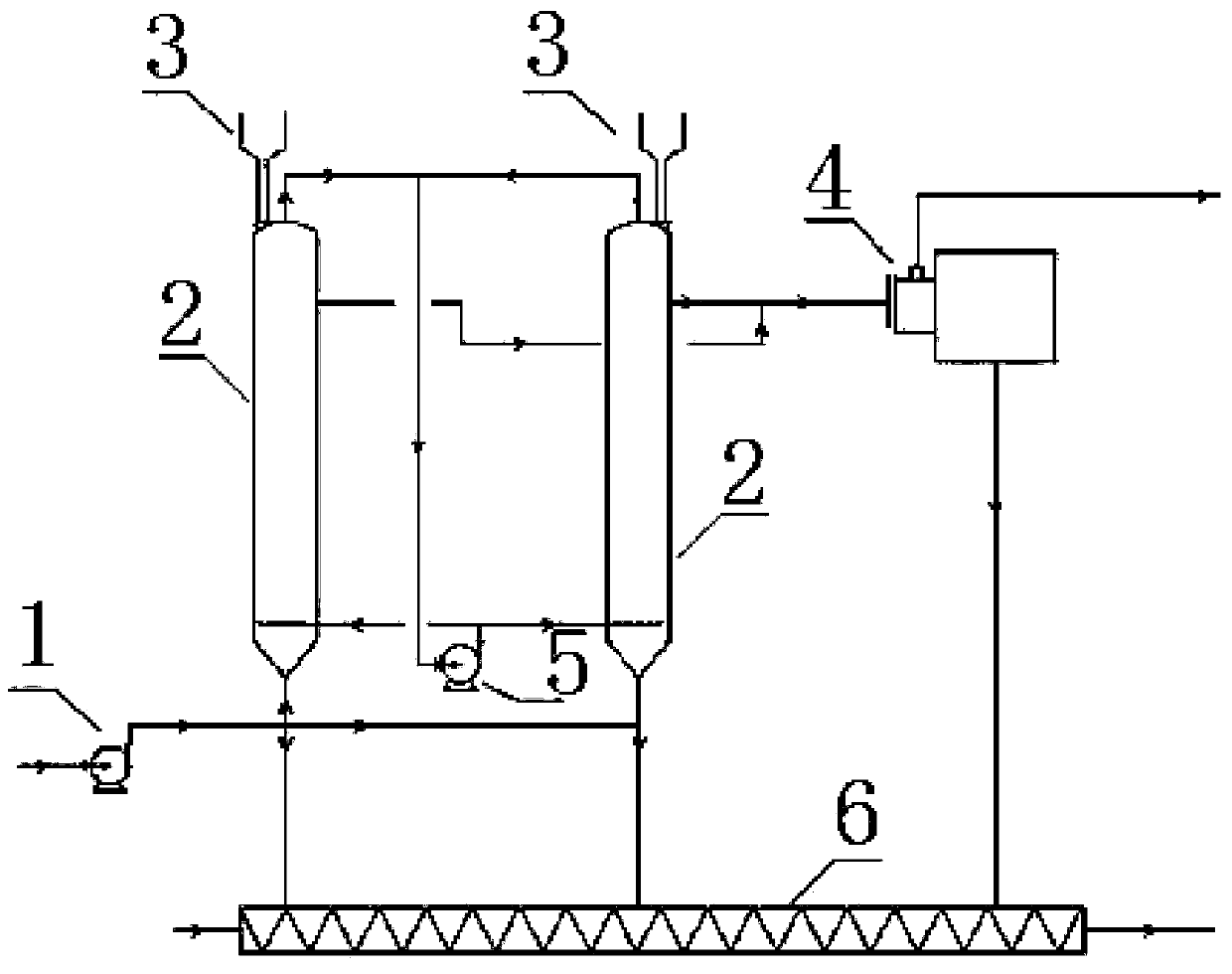

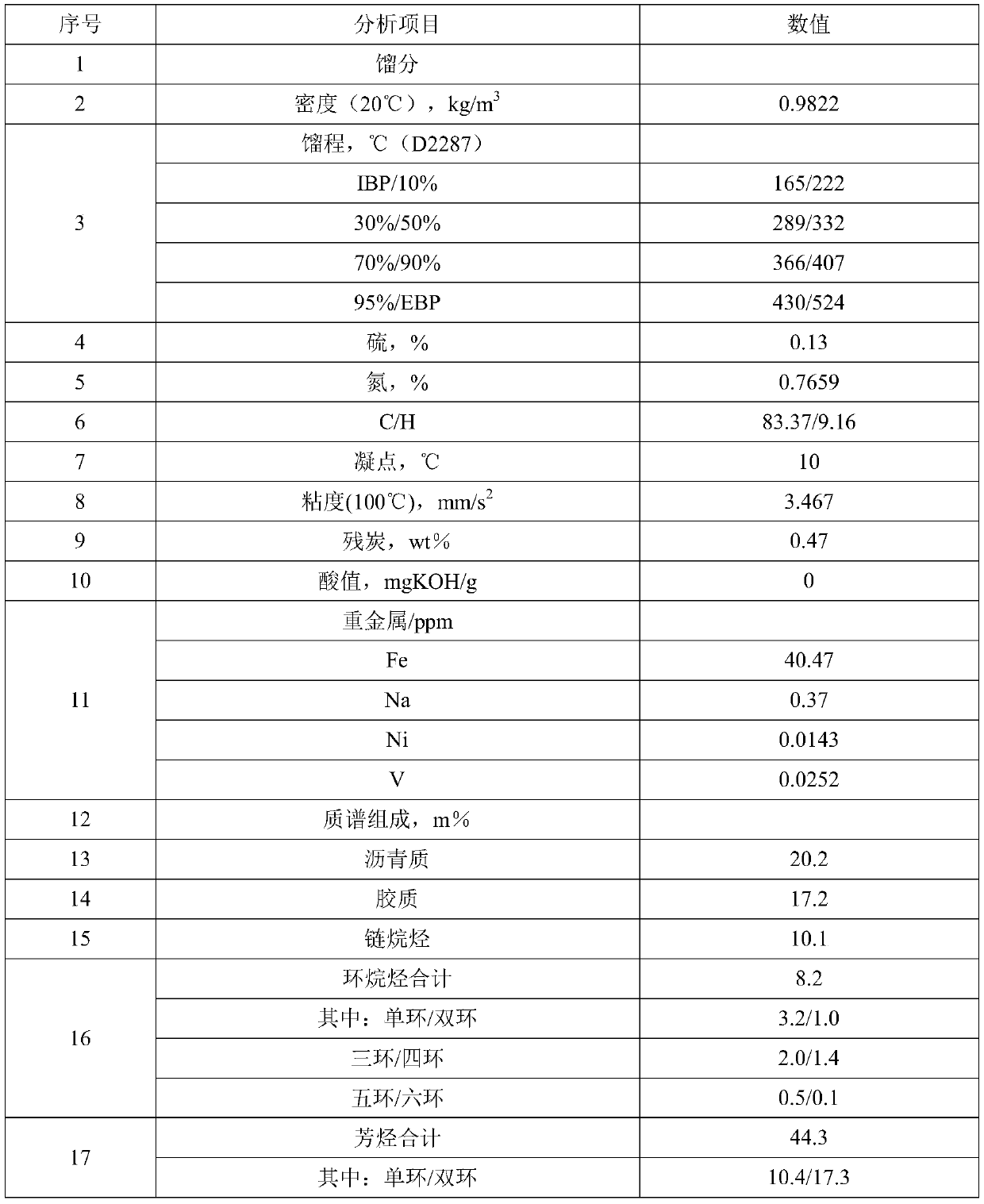

A kind of coal tar pretreatment method and its device

The invention discloses a method or device for pretreating coal tar. The method for pretreating the coal tar includes the following steps of: (1) performing contact between the coal tar and adsorbentin a fluidized state so as to generate an effect of adsorption, wherein the adsorbent is semi-coke and / or kaolin; (2) after the adsorption in the step (1) is completed, performing sedimentation and layering, and collecting an upper-layer liquid phase; (3) and performing solid-liquid separation on the upper-layer liquid phase, and collecting a liquid phase to obtain purified coal tar. The method for pretreating the coal tar has a simple procedure, mild adsorption conditions and low-cost pretreatment, and colloid and asphaltene in the coal tar can be removed effectively. The device has simple connection and easy assembly, and the purpose of removal of the colloid, asphaltene and other solid impurities in the coal tar can be achieved effectively.

Owner:BEIJING HUASHI UNITED ENERGY TECH & DEV

A method for improving the dispersibility of insoluble sulfur

ActiveCN104961106BReduce usageReduce recycling stepsSulfur preparation/purificationMolten stateOrganic solvent

The invention discloses a method for improving the dispersibility of insoluble sulfur. The method comprises the following steps: selecting an organic matter having the melt point or the softening point being 40-100 DEG C as a dispersible material; heating to enable the dispersible material to be kept a molten state before filling oil to the dispersible material; then, uniformly spraying the molten dispersible material onto the surface of the insoluble sulfur in a mist form; carrying out filled sealing on micropores on the surface of the insoluble sulfur; carrying out oil filling after the dispersible material and the insoluble sulfur are sufficiently mixed. According to the method disclosed by the invention, the use of an organic solvent can be avoided by defining and improving the melt point or the softening point of the dispersible material and adding the dispersible material at a molten state in a spraying manner before oil filling rather than an organic solvent dissolving manner, and recovery steps of the organic solvent are also reduced, so that the consumption of resources and energy sources is reduced; meanwhile, the method is simple and feasible, and is beneficial for improving the production efficiency.

Owner:SHANDONG YANGGU HUATAI CHEM

A method for electrochemically synthesizing 3-alkylselenyl-4-aminocoumarin compounds

ActiveCN112359375BEasy to separate and purifyHigh selectivityElectrolysis componentsElectrolytic organic productionAminocoumarinsElectrolytic agent

The invention discloses a method for electrochemically synthesizing 3-alkylselenyl-4-aminocoumarin compounds. The method is to use the solution containing 4-anilinocoumarin compound, dialkyl diselenide and bromine salt as the electrolyte, place a nickel anode and a graphite rod cathode in the electrolyte, feed in a direct current, and carry out electrolysis. 3-Alkylselenyl-4-anilinocoumarin compound can be obtained through chemical reaction; the method has the advantages of mild reaction conditions, simple operation, environmental protection, easy availability of raw materials, excellent compatibility of substrate functional groups, and high reaction yield.

Owner:HUNAN UNIV OF SCI & ENG

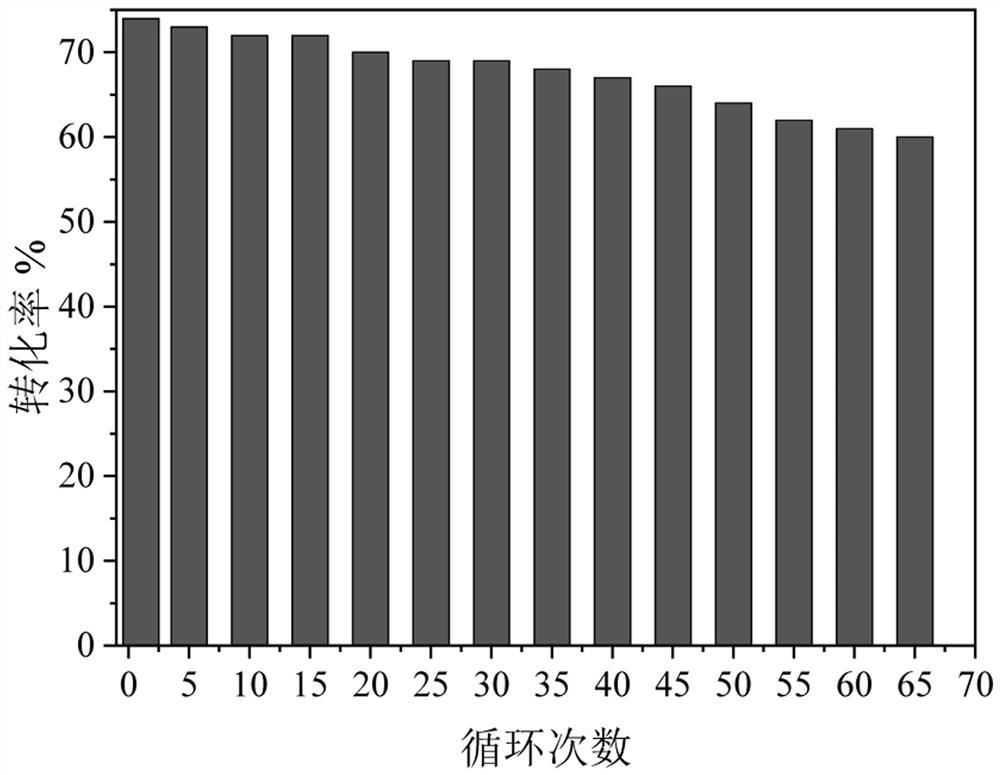

A preparation method and application of immobilized cells for mannose production

ActiveCN113249372BEasy to produceIncrease profitMicroorganism based processesOn/in organic carrierBiotechnologySporolactobacillus

The invention discloses a method for preparing immobilized cells for producing mannose and a method for producing mannose. Wherein, when the immobilized Bacillus subtilis of the present invention continuously catalyzes the reaction, the initial product yield can reach up to 65%, and after 25 batches of continuous catalysis, the product yield can still maintain 45%. When the immobilized Escherichia coli of the present invention continuously catalyzes the reaction, the initial product yield can reach up to 65%, and after 25 batches of continuous catalysis, the product yield can still maintain 44%. The invention simplifies the separation and purification steps of the enzyme, improves the recycling rate of the enzyme, and realizes the recycling of the enzyme. The method of the invention has the advantages of easy product separation, simple production process, low cost, etc., and provides reference for industrial application.

Owner:天津怡和生物科技有限责任公司

Process for synthesizing p-tert-butylbenzoic acid

ActiveCN102617335BReduce usageReduce recycling stepsOrganic compound preparationCarboxylic compound separation/purificationMoistureImpurity

The invention relates to a process for synthesizing p-tert-butylbenzoic acid. The process comprises the following steps of: adding p-tert-butyltoluene and cobalt acetate into a reaction kettle, introducing oxygen-containing gas, triggering at the temperature of between 150 and 155 DEG C, performing oxidation reaction for 0.5 to 1 hour, and continuously reacting at the temperature of between 135 and 145 DEG C for more than 5 hours to obtain a p-tert-butylbenzoic acid crude product; cooling the p-tert-butylbenzoic acid crude product to crystallize, performing centrifuge dripping, and striking and washing by using p-tert-butyltoluene to obtain a centrifugation crude product; and adding the centrifugation crude product into a dissolution kettle, adding methylbenzene, raising temperature and dissolving, filtering when a mixture is hot to remove impurities, adding water to wash, transferring materials to a recrystallization kettle, cooling to crystallize, centrifuging, striking and washing by using methylbenzene, and drying to obtain a p-tert-butylbenzoic acid finished product. The prepared p-tert-butylbenzoic acid is white crystals and does not contain mechanical impurities; and the melting point is 164.0 to 167.0 DEG C, the acid value is 312 to 316mgKOH / g, high performance liquid chromatography (HPLC) purity is more than or equal to 99.2 percent, moisture is less than or equal to 0.08 percent, and methylbenzene is less than or equal to 0.05 percent.

Owner:SUQIAN COSMOS CHEM +1

Crude product aftertreatment new technique for preparing 2-amino-4, 6-dimethoxy pyrimidine

ActiveCN106966993AReduce recycling stepsReduce manufacturing costOrganic chemistryEnvironmental resistanceOrganic solvent

The invention discloses a crude product aftertreatment new technique for preparing 2-amino-4, 6-dimethoxy pyrimidine, wherein the technique includes steps of transferring a liquid crude product of 2-amino-4, 6-dimethoxy pyrimidine in a distilling kettle by vacuum, and performing depressurization and distilling; adding pure water and stabilizer to the product acquired by distilling and cooling; heating to 75-95 DEG C and melting; then stirring while slowly cooling to 30-50 DEG C; filtering the product; drying a filter cake and acquiring a white crystal particle shaped pure product of 2-amino-4, 6-dimethoxy pyrimidine. The new technique applies easy-acquired water at lower price as the dispersing agent to replace methylbenzene, xylene and other organic solvents, reduces the solvent recycling step, and further reduces the production cost. The new technique eliminates the safety hidden trouble of low-boiling and flammable organic solvent and the environment protection pressure of volatile component which can pollute the production environment; the weak alkali type stabilizer is introduced, thus the process of generating polarity impurities from dropped methyl of 2-amino-4, 6-dimethoxy pyrimidine is effectively inhibited, thus the product quality is further promoted.

Owner:HUBEI HUIDA HIGH TECH CO LTD +1

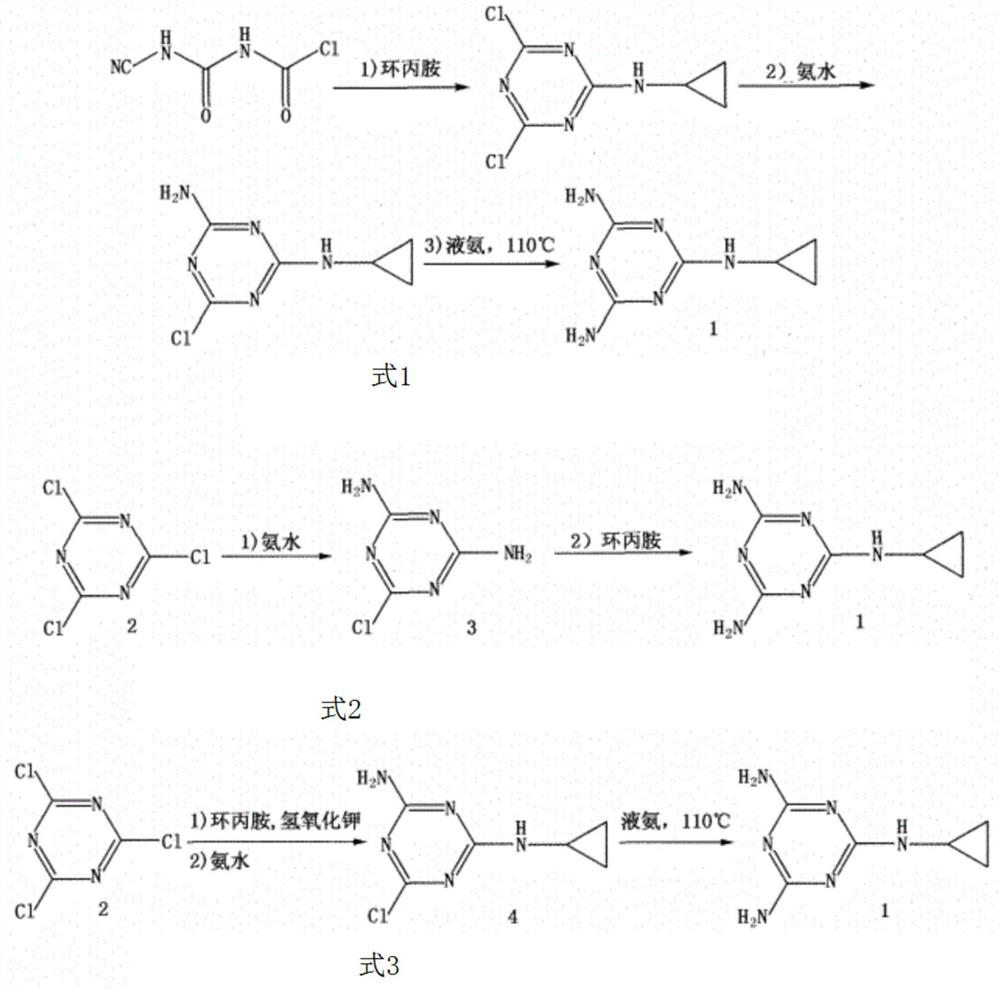

Synthesis method of cyromazine active compound with high yield

The invention relates to a synthesis method of a cyromazine active compound with high yield, cyanuric chloride, cyclopropylamine and ammonia gas are used as raw materials, single toluene is used as a solvent to synthesize the cyromazine active compound, the purity is more than 98%, and the yield is as high as 93%. The method has the characteristics of simplicity in operation, high solvent utilization rate, high product yield, less environmental pollution and the like. The labor load of workers is reduced, the production cost is reduced, and the environmental pollution is reduced.

Owner:SHANDONG DOCRIS CHEM

A kind of solid acetal and preparation method thereof

ActiveCN110642686BReduce recycling stepsLow costOrganic chemistryOrganic compound preparationEpoxyOrganosolv

The invention discloses a solid acetal and a preparation method thereof. The preparation method includes: step 1, crushing and sorting thermosetting epoxy resin waste to obtain non-metal powder; step 2, adding non-metal powder to inorganic acid, and reacting at 70-110°C for 12-120 hours; step 3, filtering , collect the filtrate, and adjust the pH value; Step 4, add organic aldehyde to the filtrate, heat and stir to prepare solid acetal; Step 5, wash the solid acetal with lye and deionized water to obtain pure solid acetal. The method of the present invention directly synthesizes the epoxy resin in the filtrate into solid acetal, the epoxy resin can be separated from the solution by simple filtration, and the solid acetal with higher added value is obtained, and the recovery of the epoxy resin by the extraction method is avoided The organic solvent used saves cost and is friendly to the environment.

Owner:SHANGHAI SECOND POLYTECHNIC UNIVERSITY

Method for recovering rare-earth waste material

ActiveCN102643992BHigh recovery rateReduce recycling stepsProcess efficiency improvementRecovery methodRare-earth element

The invention relates to a method for recovering a rare-earth waste material. The method comprises the following steps of: (1) adding a decomposition auxiliary agent and fluxing agent powder into the rare-earth waste material, and evenly mixing to obtain mixed material, wherein the dosage of the decomposition auxiliary agent is 20-200wt% of the total weight of the rare-earth waste material, and the dosage of the fluxing agent powder is 1-20 wt% of the total weight of the rare-earth waste material; (2) roasting the mixed material obtained in the step (1) for 1-6 hours at the temperature of 600-1400 DEG C; (3) adding an acid solution into the roasted product obtained in the step (2) for acid dissolution, filtering and separating to obtain acid leaching liquor which mainly contains rare-earth elements and acid leaching residue; and (4) separating the rare-earth elements from other metal elements in the acid leaching liquor. The method provided by the invention realizes the cyclic utilization of the rare-earth waste material, is simple to operate, high in recovery rate of valuable elements in the waste material and low in reagent cost, saves energy, reduces emission and is low in environment harmfulness, and has important significance in the aspects of ecological protection and economic development promotion.

Owner:CHINA MINMETALS BEIJING RES INST OF RE

Automatic recycling method for plastic bottles

The invention discloses an automatic recycling method for plastic bottles. An automatic cleaning and shredding machine is used in the method; when a plastic bottle body is recycled by the method, a rotating shaft is arranged at one end of an opening of the plastic bottle body; a part, which extends into the plastic bottle body, of the rotating shaft is respectively hinged to a first connecting rod and a second connecting rod; a brush is arranged on the first connecting rod; a blade is arranged on the second connecting rod; an adsorption block is arranged at the other end of the opening of the plastic bottle body; an air channel is formed in the adsorption block and is connected with an air extractor; the automatic cleaning and shredding machine further comprises a connecting rod; a mounting seat is hinged to the middle of the connecting rod and is fixed on an external rack; one end of the connecting rod is hinged to the adsorption block; a slot is formed in the other end of the connecting rod; and a plurality of steel balls which can move along the slot and are discharged out of the slot are arranged in the slot. After being shredded in the scheme, the plastic bottle body can also be cleaned, the step of recycling the plastic bottle body is omitted, and the recycling efficiency of the plastic bottle body is improved effectively.

Owner:CHONGQING YONGCHUAN HUIMIAN PLASTICS FACTORY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Synthetic method of 3-[2-(ethylhexyl)oxyl]-1,2-propandiol Synthetic method of 3-[2-(ethylhexyl)oxyl]-1,2-propandiol](https://images-eureka.patsnap.com/patent_img/53e04bb7-ae8b-422f-8218-740b7dcd78b8/BDA0001358236340000031.png)