Preparation method and application of immobilized cells for tagatose production

A technology for immobilizing cells and tagatose, applied in the production and preparation of tagatose, and in the field of bioengineering, can solve the problems of uneven particle size of immobilized enzymes, loss of immobilization efficiency of enzymes, cumbersome production steps, etc., and achieve simple immobilization Chemical process, which is beneficial to separation and purification, and simplifies the effect of production and preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Example 1: Preparation of Bacillus Bacillus Bacillus

[0036] Picking with heat-resistant α-glucan phosphorylase gene, expressing heat-resistant glucose phosphate amzyase gene, expressing heterosphosphoric acid resistance of heat-resistant glucose phosphate, expression of heat-resistant 6-phosphate straw glycetin Gene, expressed by Bacillus recombinant, Bacillus, Bacillus, Bacillus, Bacillus, Bacillus, Bacillus, Selected SCK6, see CN112342179B), and inoculated in LB medium, 37 ° C oscillated overnight culture. The culture was transferred to the lb medium at 1% inoculation, and the bunch of Bacillus fermentation liquid expressed by heat-resistant alpha-glucan phosphatase was obtained at 37 ° C to expressed heat-resistant glucose phosphate. Bacillus fermentation broth, Bacillus fermentation broth, expression of hemorrhosphate, Bacillus, Bacillus, Bacillus, Bacillus, Bacillus, Bacillus, Bacillus, Bacillus, Bacillus, Bacillus, Bacillus, Bacillus, Expression, Bacillus, Expressin...

Embodiment 2

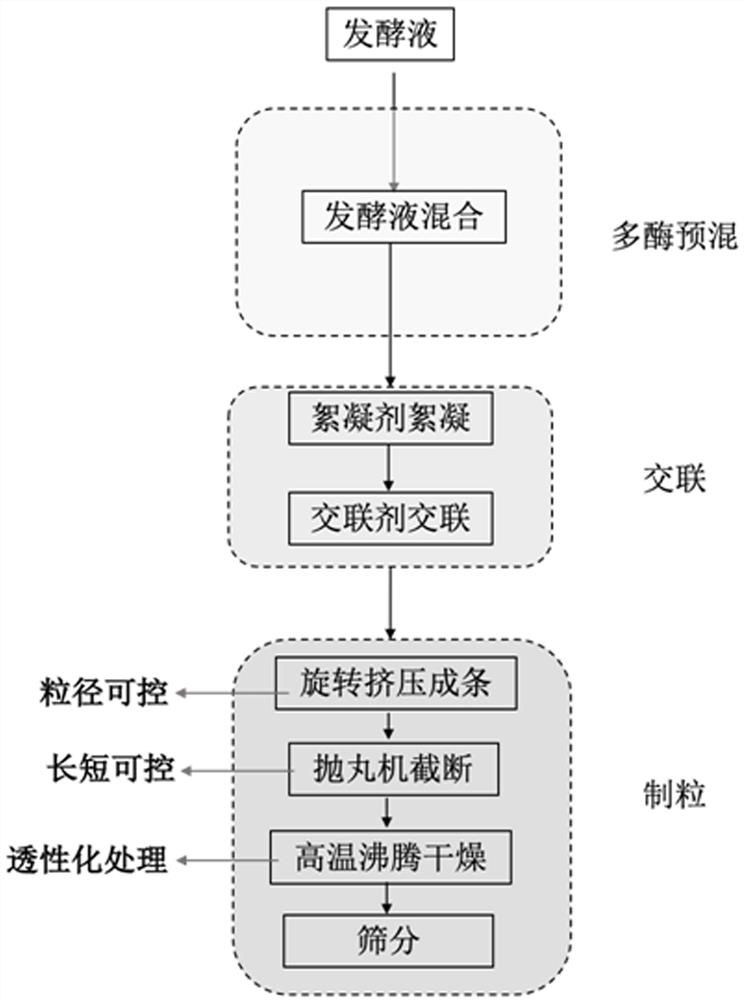

[0037] Example 2: Fixed brown sporosine production Taggosa

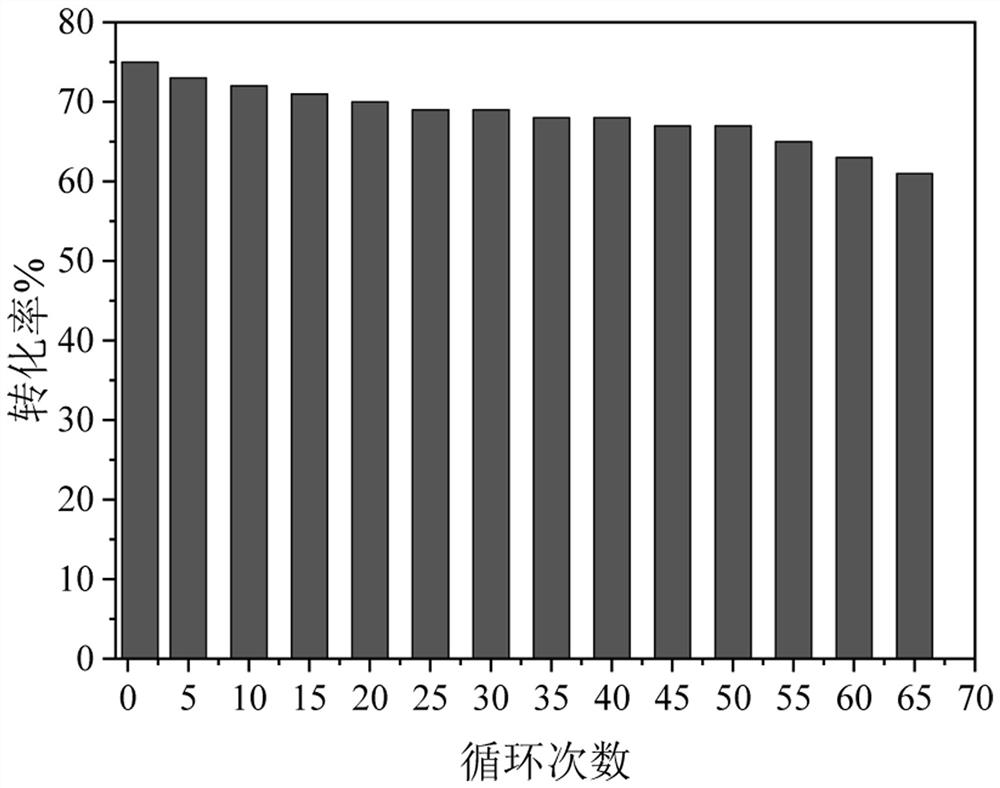

[0038] The Bacillus fermentation of Bacillus acid-resistant alpha-glucan phosphatase prepared according to OD600 ratios 1: 1: 1: 1: 1, Bacillus Bacillus expressing heat-resistant glucose phosphatase Bacillus fermentation of Bacillus, Bacillus, Bacillus, Bacillus, Bacillus, Bacillus, Bacillus, Bacillus, Bacillus, Bacillus, Bacillus, Bacillus fermentation, expressing heat-resistant 6-phosphate tartlastinase Bacillus fermentation broth was mixed such that OD 600 = 100, 1% w / v montmorillonite was added to the bacterial suspension, and stir evenly. Subsequently, a 0.5% W / V molecular weight of 10,000 polyethyleneimine solution was flocculated under room temperature conditions. Then, 2% V / V glutaraldehyde aqueous solution was added to each other under room temperature. After the vacuum was filtered, the filter cake was obtained, and the filter cake was crimped into a long strip shape of 1.0 mm particle diameter, and then ...

Embodiment 3

[0040] Example 3: Comparative Tagguria

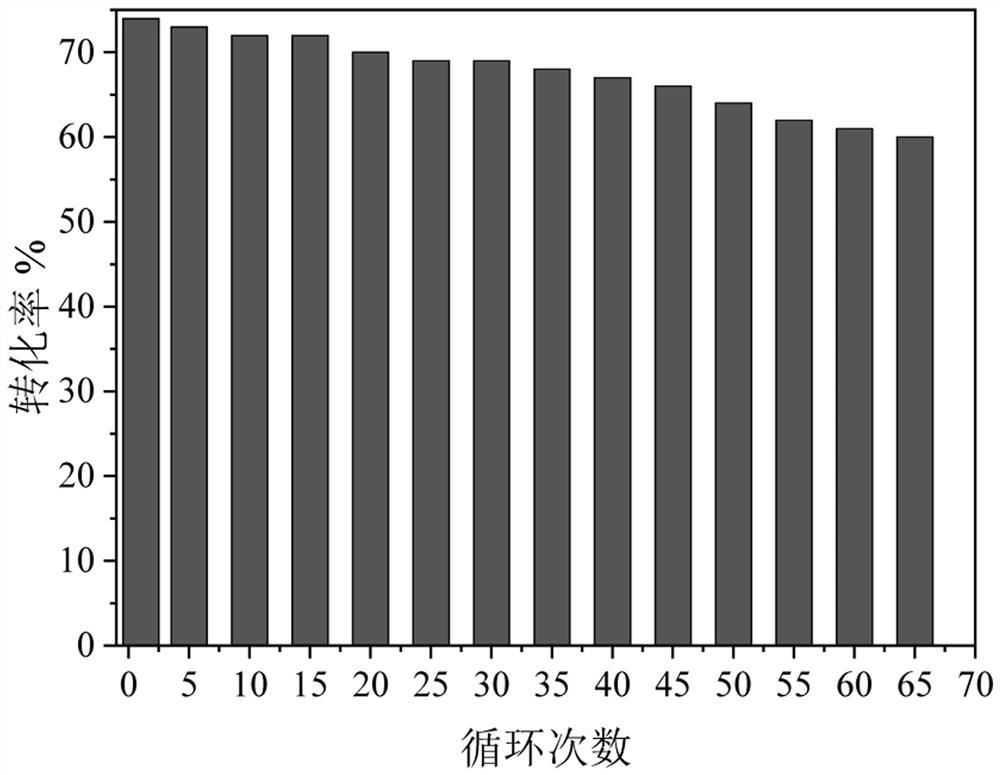

[0041] The Bacillus fermentation of Bacillus acid-resistant alpha-glucan phosphatase prepared according to OD600 ratios 1: 1: 1: 1: 1, Bacillus Bacillus expressing heat-resistant glucose phosphatase Bacillus fermentation of Bacillus, Bacillus, Bacillus, Bacillus, Bacillus, Bacillus, Bacillus, Bacillus, Bacillus, Bacillus, Bacillus, Bacillus fermentation, expressing heat-resistant 6-phosphate tartlastinase Bacillus fermentation broth was mixed, allowing OD 600 = 100, and 5% w / v celite was added to the bacterial suspension, and stir evenly. Subsequently, a 0.1% W / V molecular weight of 70000 was added to flocculate under room temperature conditions. Then, a 1% V / V glutaraldehyde solution was added to crosslink 2 h under room temperature conditions. After the vacuum was filtered, the filter cake was obtained, and the filter cake was extracted with a rotary granulator, and then the length of the particle diameter was concentrated, and then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com