Suspension crystallization method for preparing crystal form I of linezolid

A technology of linezolid and suspension crystallization, which is applied in the field of compound preparation, can solve the problems that the yield of linezolid crystal form I is not higher than 90%, the difficulty of solvent recovery, and the inability to directly reuse, etc., to achieve high product yield , the effect of energy consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

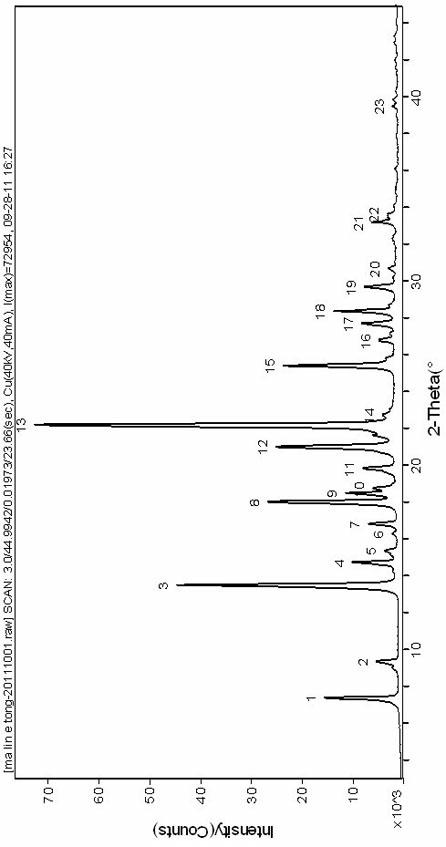

[0019] Add 100g of linezolid crystal form II to a 1000ml flask, add 100g of water, stir and heat to 105°C to make a suspension, cool down to 100°C for crystallization, filter while hot at 90°C, and vacuum dry the filter cake at 30°C to obtain linezolid Azolamide crystal form I is 95.2g, and the yield is 95.2%. The X-ray powder diffraction (XRPD) pattern of Linezolid Form I is shown in figure 1 .

Embodiment 2

[0021] Add 100g of linezolid mixed crystals (Form I and Form II) into a 1000ml flask, add 300g of water, stir and heat to 100°C to make a suspension, cool to 85°C for crystallization, then cool to 0°C and filter, filter The cake was vacuum-dried at 50°C to obtain 99.1 g of Linezolid Form I, with a yield of 99.1%.

Embodiment 3

[0023] 100 g of linezolid crystalline form II was added to a 1000 ml flask, 290 g of the mother liquor was filtered by adding Example 2, and the rest was the same as in Example 2 to obtain 99.3 g of linezolid crystalline form I with a yield of 99.3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com