Automatic recycling method for plastic bottles

A technology for automatic recycling of plastic bottles, applied in the field of plastic bottle recycling, can solve the problems of increasing the efficiency of plastic bottles, achieve the effect of reducing the steps of recycling and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below by means of specific embodiments:

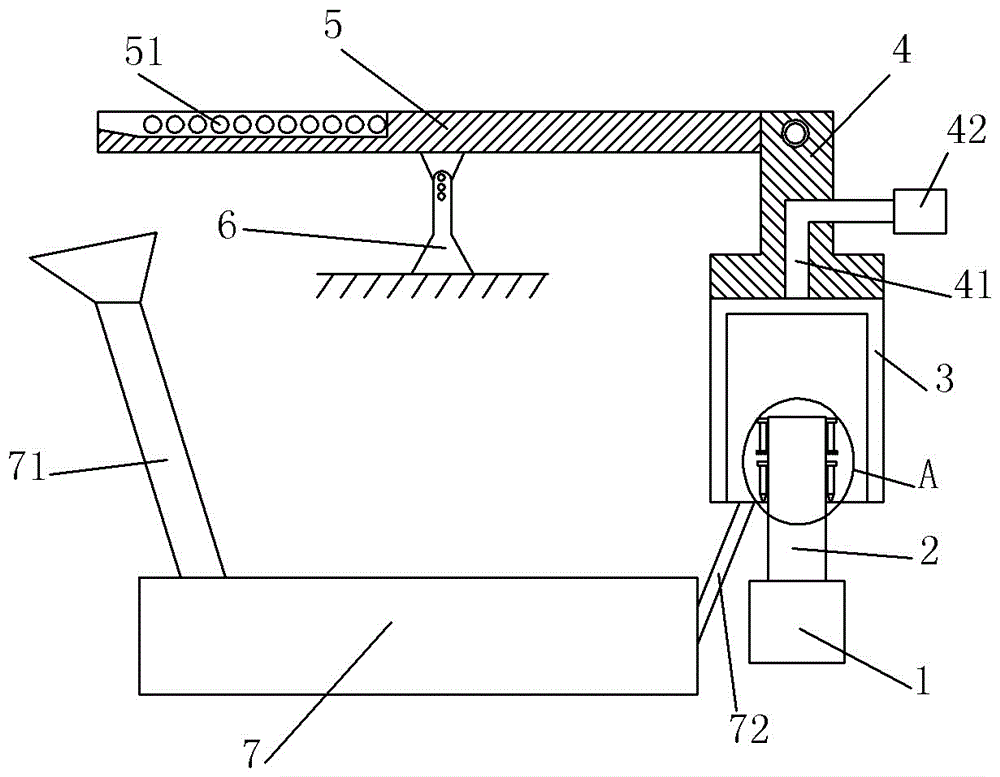

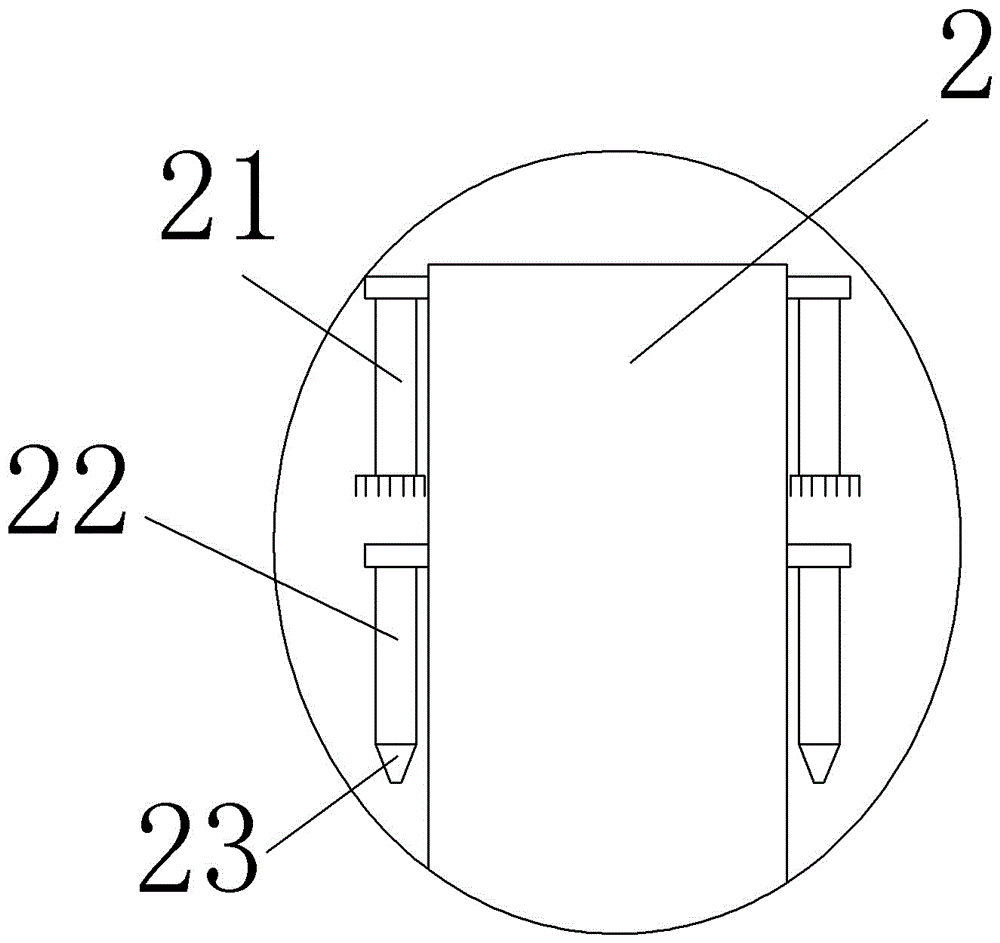

[0024] The reference signs in the drawings of the description include: frequency conversion motor 1, rotating shaft 2, first connecting rod 21, second connecting rod 22, blade 23, plastic bottle body 3, adsorption block 4, air channel 41, air extraction device 42, Connecting rod 5, steel ball 51, mounting seat 6, water tank 7, first water pipe 71, second water pipe 72.

[0025] An automatic recycling method for plastic bottles, the method uses an automatic cleaning shredder, specifically comprising the following steps:

[0026] (1) Turn the opening of the plastic bottle body 3 to be processed downward, and the rotating shaft 2 extends into the plastic bottle body 3 from one end of the opening of the plastic bottle body 3 , and the other end of the opening of the plastic bottle body 3 fits the adsorption block 4 ;

[0027] (2) Start the air extraction device 42, so that a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com