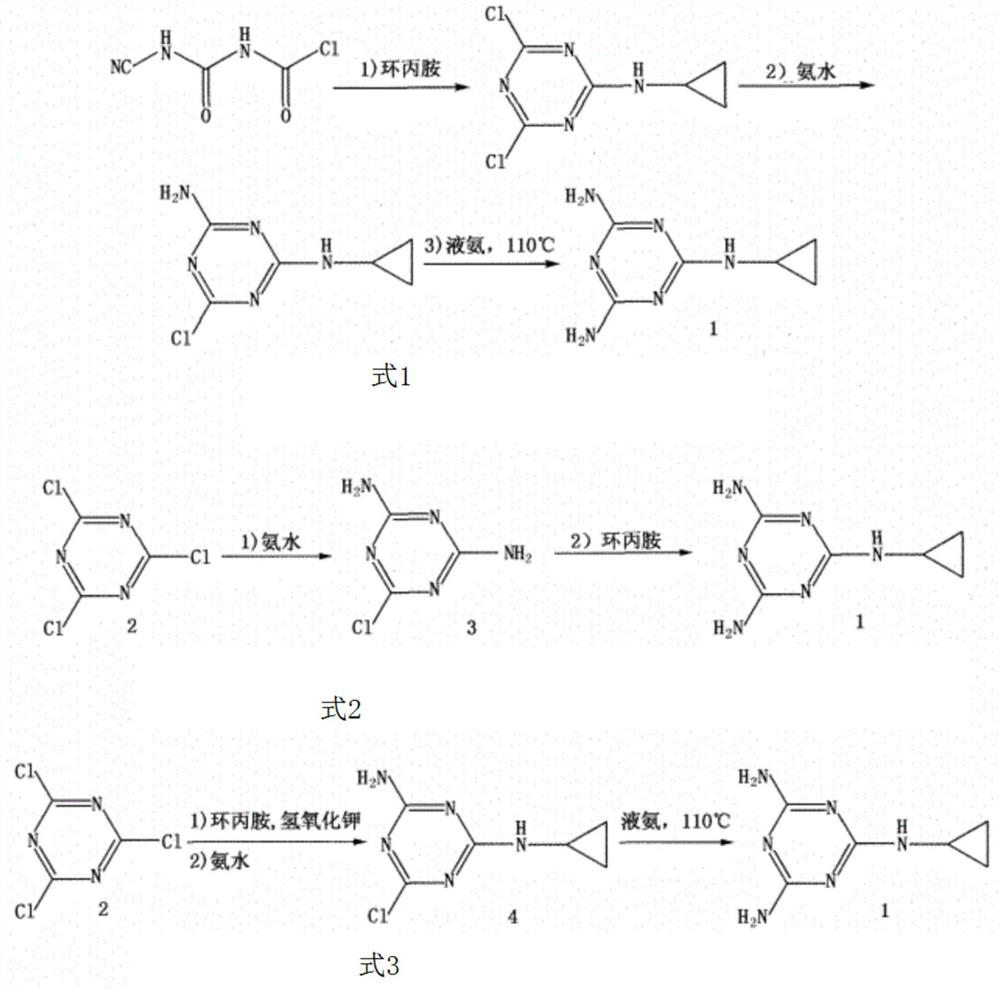

Synthesis method of cyromazine active compound with high yield

A technology of cyromazine technical and synthetic method, which is applied in the field of synthesis of high-yield cyromazine technical, can solve the problems of cost increase, complex process, easy volatility, etc., and reduce product loss, optimize reaction process, optimize The effect of the action steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A kind of synthetic method of high-yield cyromazine former drug, comprises the steps:

[0043] 1) prepare cyanuric chloride toluene solution, the concentration of cyanuric chloride is 23%, cool down to -10°C for later use,

[0044] 2) prepare cyclopropylamine toluene solution, the concentration of cyclopropylamine is 45%, cool down to 0°C for later use,

[0045]3) in 1300kg cyanuric chloride buffer solution, dropwise add 130kg cyclopropylamine solution, temperature is controlled at 0 ℃, after dropwise is completed, drips the sodium hydroxide solution of 260kg mass concentration 30% in system again, temperature is controlled at- 5°C;

[0046] 4) The reaction solution in step 3) is heated and stratified, the oil phase is transferred to the ammoniation kettle, and the water phase is transferred to the storage tank;

[0047] 5) Add 400kg of water into the ammoniation kettle, and feed ammonia gas while stirring. When the pressure in the ammoniation kettle reaches 0.6Mpa, s...

Embodiment 2

[0050] A kind of synthetic method of high-yield cyromazine former drug, comprises the steps:

[0051] 1) prepare cyanuric chloride toluene solution, the concentration of cyanuric chloride is 25%, cool down to -10°C for later use,

[0052] 2) prepare cyclopropylamine toluene solution, the concentration of cyclopropylamine is 45%, cool down to 0°C for later use,

[0053] 3) Add cyclopropylamine solution dropwise to the cyanuric chloride buffer solution, the molar ratio of cyanuric chloride to cyclopropylamine is 1:1.1, and the temperature is controlled at -6°C. After the dropping is completed, add 260kg dropwise to the system Sodium hydroxide solution with a mass concentration of 30%; the temperature is controlled at -5°C;

[0054] 4) The reaction solution in step 3) is heated and stratified, the oil phase is transferred to the ammoniation kettle, and the water phase is transferred to the storage tank;

[0055] 5) Add 400kg of water into the ammoniation kettle, and feed ammoni...

Embodiment 3

[0058] A kind of synthetic method of high-yield cyromazine former drug, comprises the steps:

[0059] 1) prepare cyanuric chloride toluene solution, the concentration of cyanuric chloride is 35%, cool down to -10 ℃ for later use,

[0060] 2) prepare cyclopropylamine toluene solution, the concentration of cyclopropylamine is 45%, cool down to 0°C for later use,

[0061] 3) Add cyclopropylamine solution dropwise to the cyanuric chloride buffer solution, the molar ratio of cyanuric chloride to cyclopropylamine is 1:1, and the temperature is controlled at -10°C. After the dropping is completed, add 260kg dropwise to the system Sodium hydroxide solution with a mass concentration of 30%, the temperature is controlled at -5°C;

[0062] 4) The reaction solution in step 3) is heated and stratified, the oil phase is transferred to the ammoniation kettle, and the water phase is transferred to the storage tank;

[0063] 5) Add 400kg of water into the ammoniation kettle, and feed ammonia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com