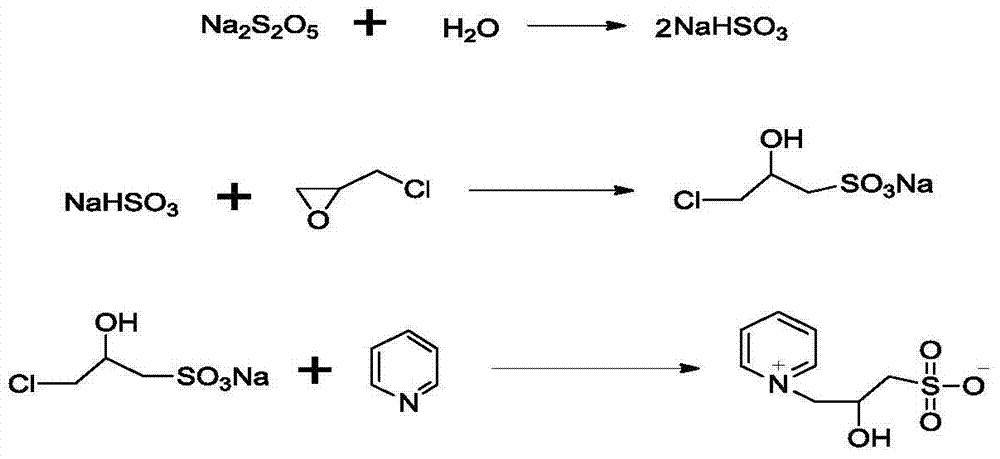

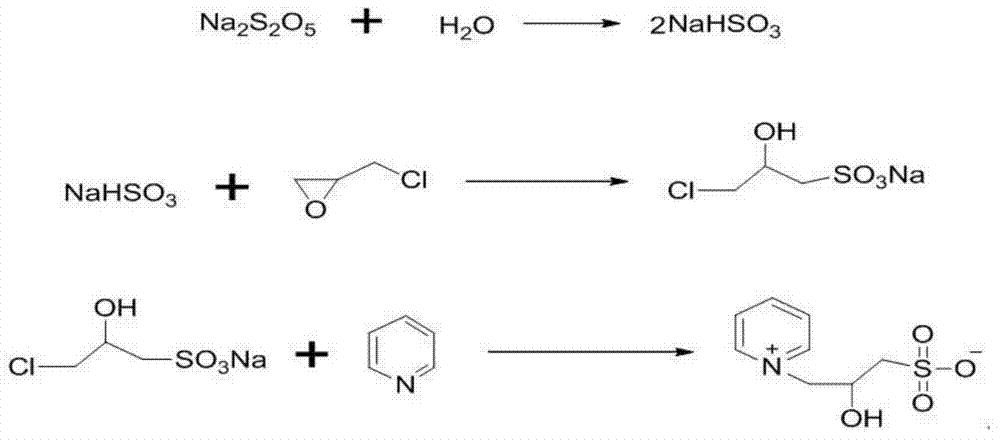

Synthetic method of pyridinium hydroxy propyl sulfobetaine

A technology of hydroxypropane sulfonate pyridinium salt and hydroxypropane sulfonate, which is applied in the field of preparation of nickel-plating intermediate hydroxypropane sulfonate pyridinium salt, can solve problems such as difficulty in producing high-end refined products, and avoid product Effects of discoloration, accelerated reaction rate, and improved conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

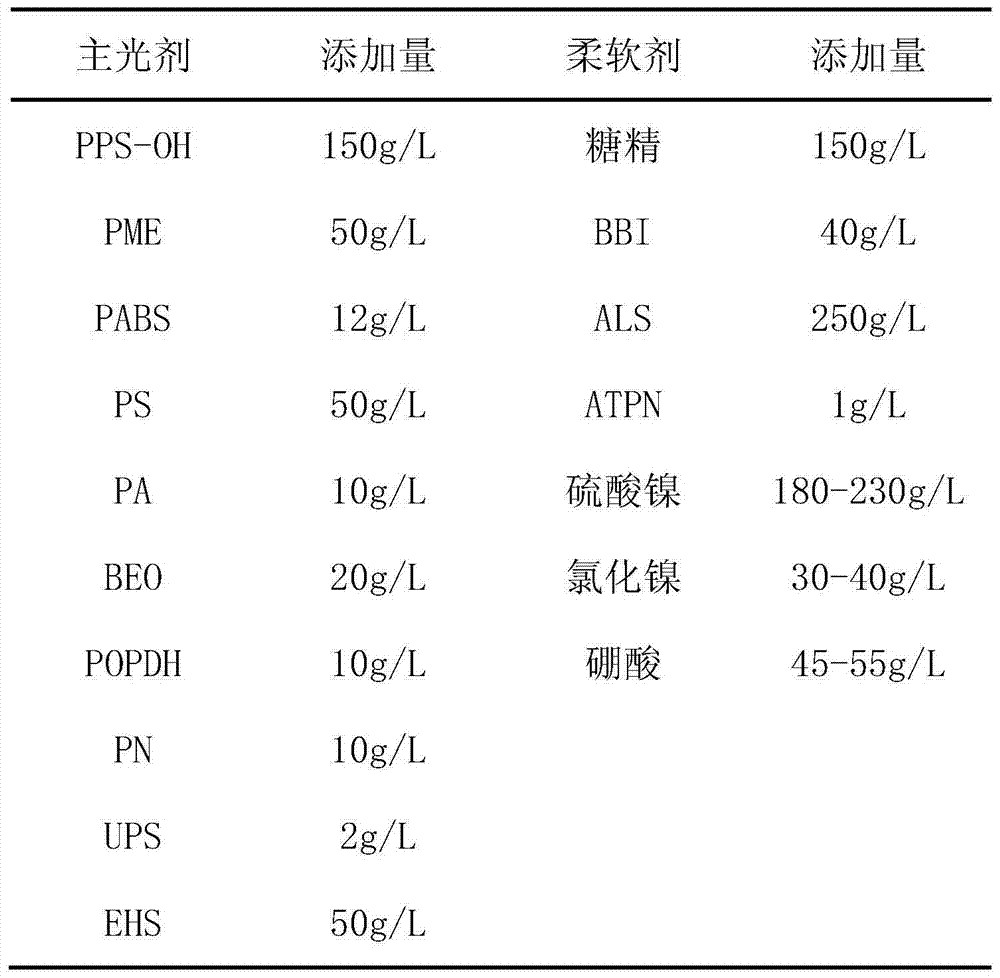

Method used

Image

Examples

example 1

[0036] Add deionized water (335g, 18.59mol) and sodium metabisulfite (97g, 0.51mol) to a 500ml four-necked flask with a mechanical stirrer, a thermometer, a reflux condenser, and a constant pressure dropping funnel, and stir thoroughly to dissolve it. , add auxiliary sulfonating agent sodium sulfite (11.57g, 0.091mol) to adjust the pH of the system to 5.5, add 0.2552g catalyst polyether F-6 (polymer of allyl alcohol and ethylene oxide, propylene oxide), citric acid 0.0028g . After the system is heated up to 60-65°C, nitrogen protection is introduced, and epichlorohydrin (92.31g, 1.0mol) is slowly added dropwise, and the dropping temperature is controlled to be between 60-65°C. The heat preservation reaction was carried out for 4 hours, and then the temperature was raised to 70-75° C. for 1 hour heat preservation reaction. At the end of the heat preservation reaction, pyridine (73.77 g, 0.93 mol) was added, and the temperature was raised to 90-105° C. for reflux reaction for 1...

example 2

[0039]Add deionized water (775g, 43mol) and sodium pyrosulfite (194.20g, 1.02mol) to a 2000ml four-necked flask with mechanical stirring, a thermometer, a reflux condenser, and a constant pressure dropping funnel. , add auxiliary sulfonating agent sodium sulfite (20.42g, 0.162mol) to adjust the pH value of the system to 5.35, add 0.933g catalyst polyether F-6 (namely: allyl alcohol and ethylene oxide, propylene oxide polymer), complex Mixture citric acid 0.058g. After the temperature of the system was raised to 65-70°C, nitrogen protection was introduced, and epichlorohydrin (185.07 g, 2.0 mol) was slowly added dropwise. After the dropwise addition is completed, the temperature is kept at 65-70°C for 3 hours, and then the temperature is raised to 75-80°C for 1 hour. Add pyridine (147.66g, 1.86mol) at the end of the heat preservation reaction, and raise the temperature to 95-105°C for reflux reaction, and add 11.07g of impurity remover triethylamine at the end of reflux. Afte...

example 3

[0042] Add 1600kg of deionized water into the 3000L standard reaction kettle, put in sodium metabisulfite (500Kg, 2.63kmol) under stirring to dissolve, add sodium sulfite (38kg, 0.3kmol) to adjust the pH value to 5.35, add catalyst 2.06kg polyether F-6 (ie : allyl alcohol and ethylene oxide, propylene oxide polymer), complexing agent citric acid 0.15kg. Raise the temperature to 60-70°C and pass through nitrogen protection, slowly add epichlorohydrin (470kg, 5.07kmol) dropwise, at this time the heat release is obvious. After the dropwise addition, the temperature was controlled at 65-70°C for 4 hours, and then the temperature was raised to 80-90°C for 1 hour. After the reaction, pyridine (375kg, 4.74kmol) was added. After heating up to 100-110 DEG C of reflux reaction for 14 hours, add 18.75kg of impurity remover triethylamine. After dehydration and decolorization, adjust the pH value to 3.5 with hydrochloric acid, add 5.88kg of stabilizer 4-hydroxy-2,2,6,6-tetramethylpiperidi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com