Machining method of recycling sanding machine for iron plate

A technology of iron plate and processing method, which is applied in the field of plate processing, and can solve the problems of poor recycling effect of waste materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

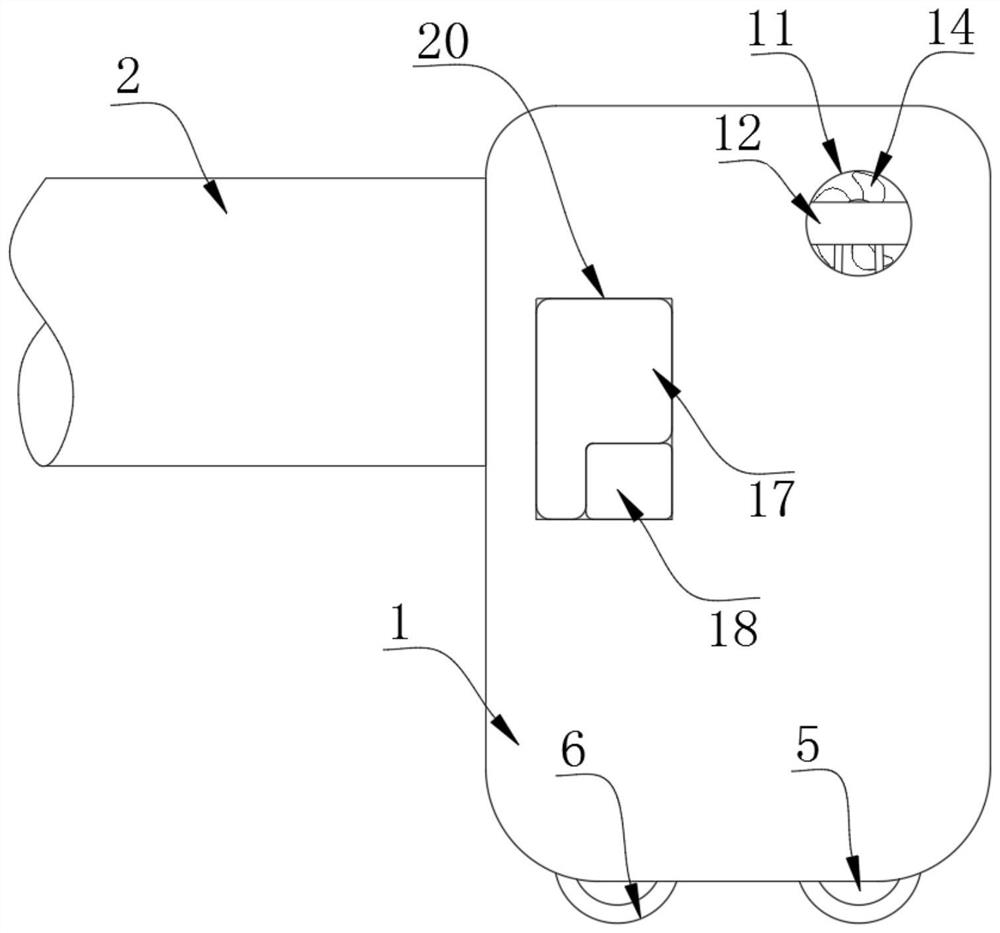

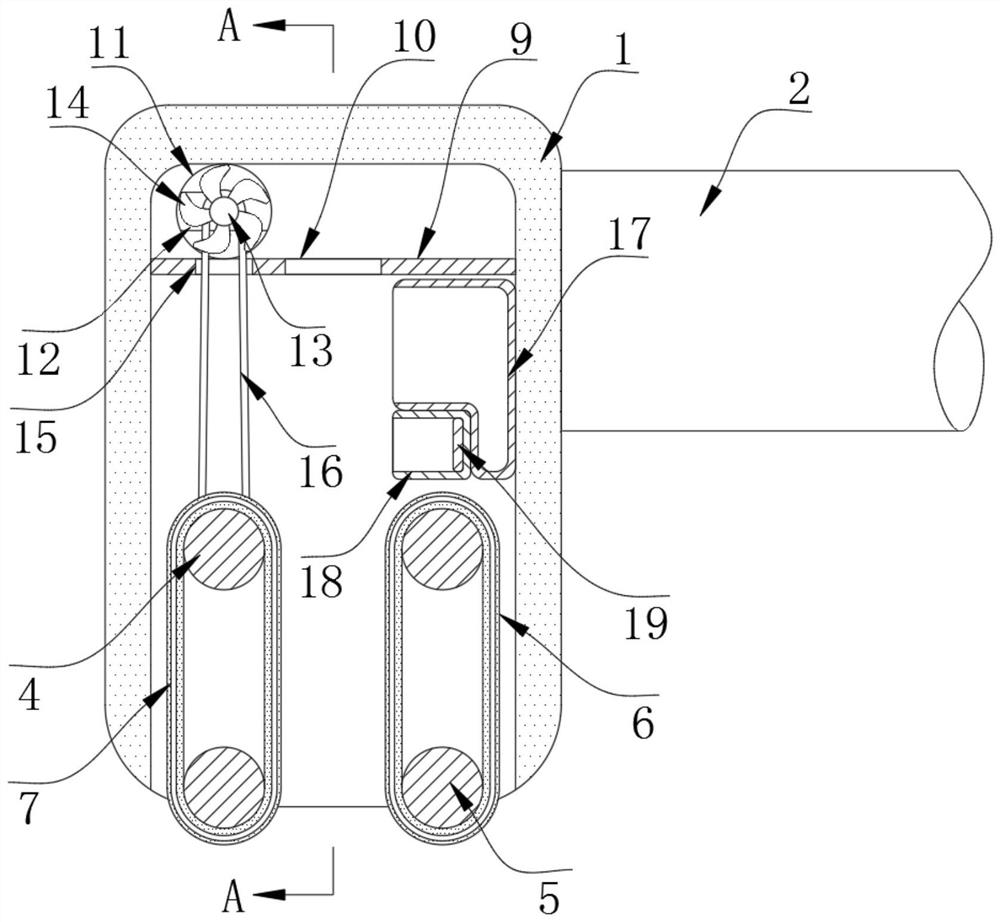

[0025] refer to Figure 1-4 , a method for processing iron plates with a recycling sander mainly includes the following processing steps:

[0026] S1. Sandpaper installation: Take out the self-adhesive sandpaper and cut it to a suitable length for later use, then stick one end of the sandpaper on the surface of the sanding belt 6, and slowly manually rotate the driven shaft 5 to make the sanding belt 6 rotate accordingly, so that the sandpaper can be attached slowly on the entire grinding belt 6 surface, and then complete the installation of sandpaper;

[0027] S2. Plate sanding process: place the plate to be processed stably on the processing table, then start the motor 3 to drive the rotating shaft 4 to rotate, so that the grinding belt 6 rotates, and then the sand rotates to prepare for sanding process, and then start the electrostatic generator 8. Finally, the rotating sandpaper is slowly approached to the plate processing position to complete the processing and dust sepa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com