A kind of coal tar pretreatment method and its device

A technology for pretreatment and coal tar, applied in the field of coal chemical industry, can solve the problems of ineffective removal of colloids and asphaltenes in coal tar, high pretreatment cost, and achieves reduced treatment difficulty, less usage, and mild adsorption conditions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

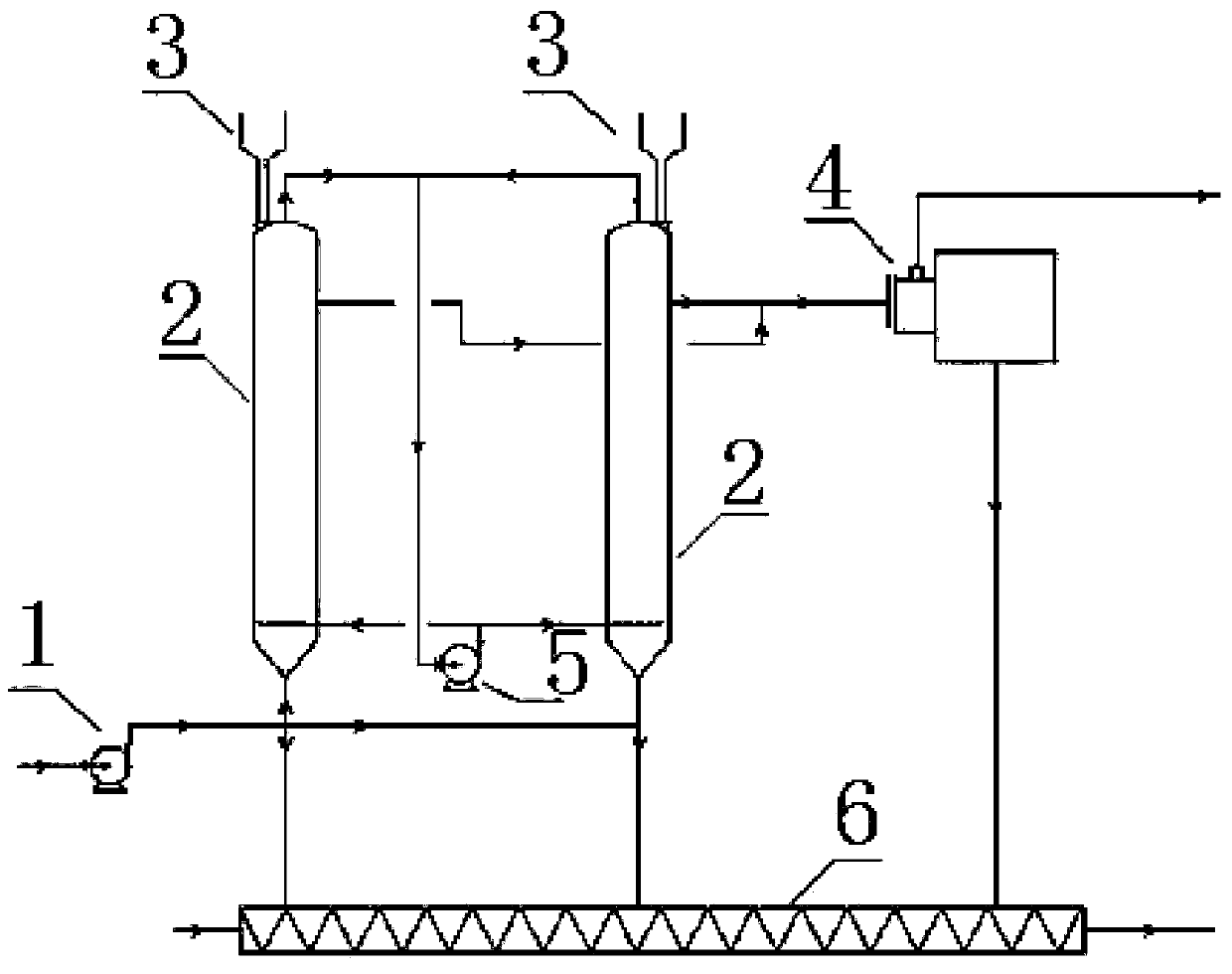

Method used

Image

Examples

Embodiment 1

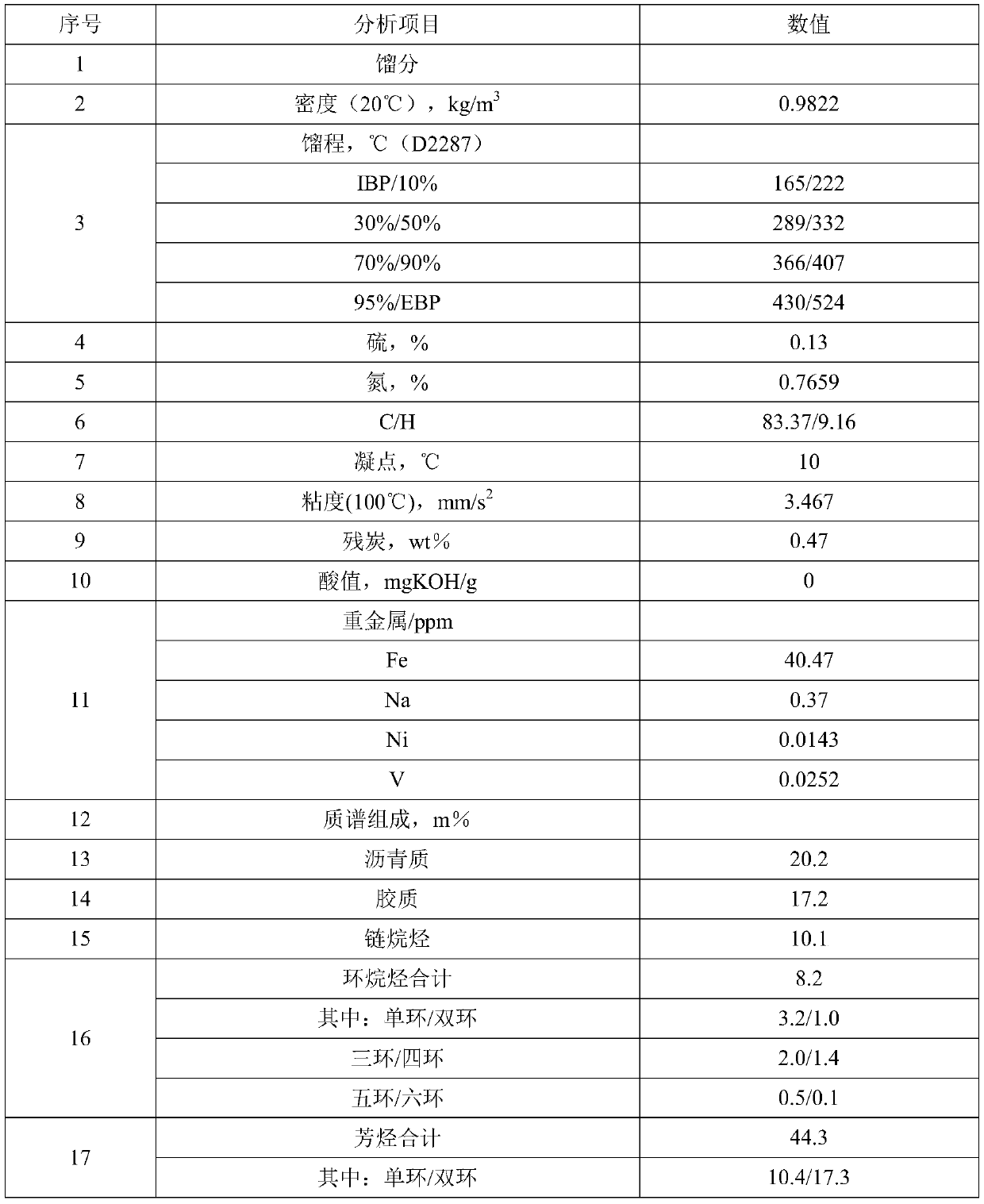

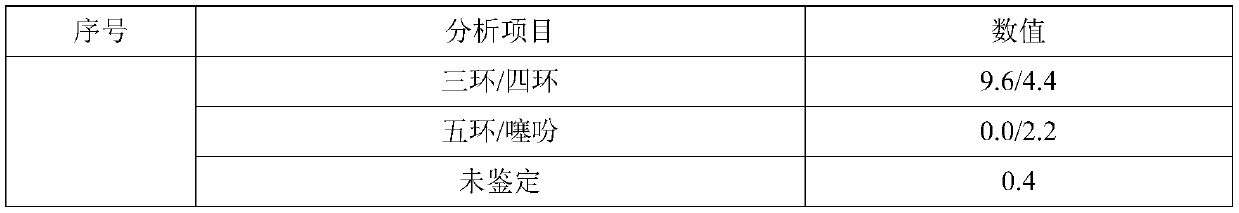

[0047] The present embodiment provides a kind of pretreatment method of coal tar, comprises the steps:

[0048] (1) Pass into air in described coal tar, make particle diameter be 0.2mm, specific surface area be 150m 2 / g of semi-coke powder and coal tar are back-mixed and contacted at a mass ratio of 0.1:1, adsorbed at 50°C and 0MPa, and the air flow required for every 1kg of the semi-coke powder is 0.5m 3 / s;

[0049] (2) After the adsorption is completed, sedimentation and stratification are carried out, and the upper liquid phase and the lower layer slurry are collected respectively;

[0050] (3) Carry out solid-liquid separation to the upper liquid phase, collect liquid phase and solid phase, obtain the coal tar after purification;

[0051] (4) Combine the lower layer slurry and the solid phase, and knead the combined mixture and coal powder at a mass ratio of 1:1 to obtain caking asphalt.

[0052] Compared with the coal tar before pretreatment, the residual carbon value...

Embodiment 2

[0054] The present embodiment provides a kind of pretreatment method of coal tar, comprises the steps:

[0055] (1) Pass into air in described coal tar, make particle diameter be 0.5mm, specific surface area be 300m 2 / g of semi-coke powder and coal tar are back-mixed and contacted at a mass ratio of 0.2:1, adsorbed at 80°C and 1.0MPa, and the air flow required for every 1kg of the semi-coke powder is 0.8m 3 / s;

[0056] (2) After the adsorption is completed, sedimentation and stratification are carried out, and the upper liquid phase and the lower layer slurry are collected respectively;

[0057] (3) Carry out solid-liquid separation to the upper liquid phase, collect liquid phase and solid phase, obtain the coal tar after purification;

[0058] (4) Combine the lower layer slurry and the solid phase, and knead the combined mixture and coke powder at a mass ratio of 1.5:1 to obtain a bonded asphalt.

[0059] Compared with the coal tar before pretreatment, the residual carbo...

Embodiment 3

[0061] The present embodiment provides a kind of pretreatment method of coal tar, comprises the steps:

[0062] (1) Pass into air in described coal tar, make particle diameter be 1mm, specific surface area be 500m 2 / g of semi-coke powder and coal tar are back-mixed and contacted at a mass ratio of 0.05:1, adsorbed at 100°C and 0.5MPa, and the air flow required for every 1kg of the semi-coke powder is 1m 3 / s;

[0063] (2) After the adsorption is completed, sedimentation and stratification are carried out, and the upper liquid phase and the lower layer slurry are collected respectively;

[0064] (3) Carry out solid-liquid separation to the upper liquid phase, collect liquid phase and solid phase, obtain the coal tar after purification;

[0065] (4) Combine the lower layer slurry and the solid phase, and knead the combined mixture and coal powder at a mass ratio of 0.5:1 to obtain caking asphalt.

[0066] Compared with the coal tar before pretreatment, the residual carbon va...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com