Microbial fuel cell with photocatalytic material loaded on positive electrode and preparation method and application of microbial fuel cell

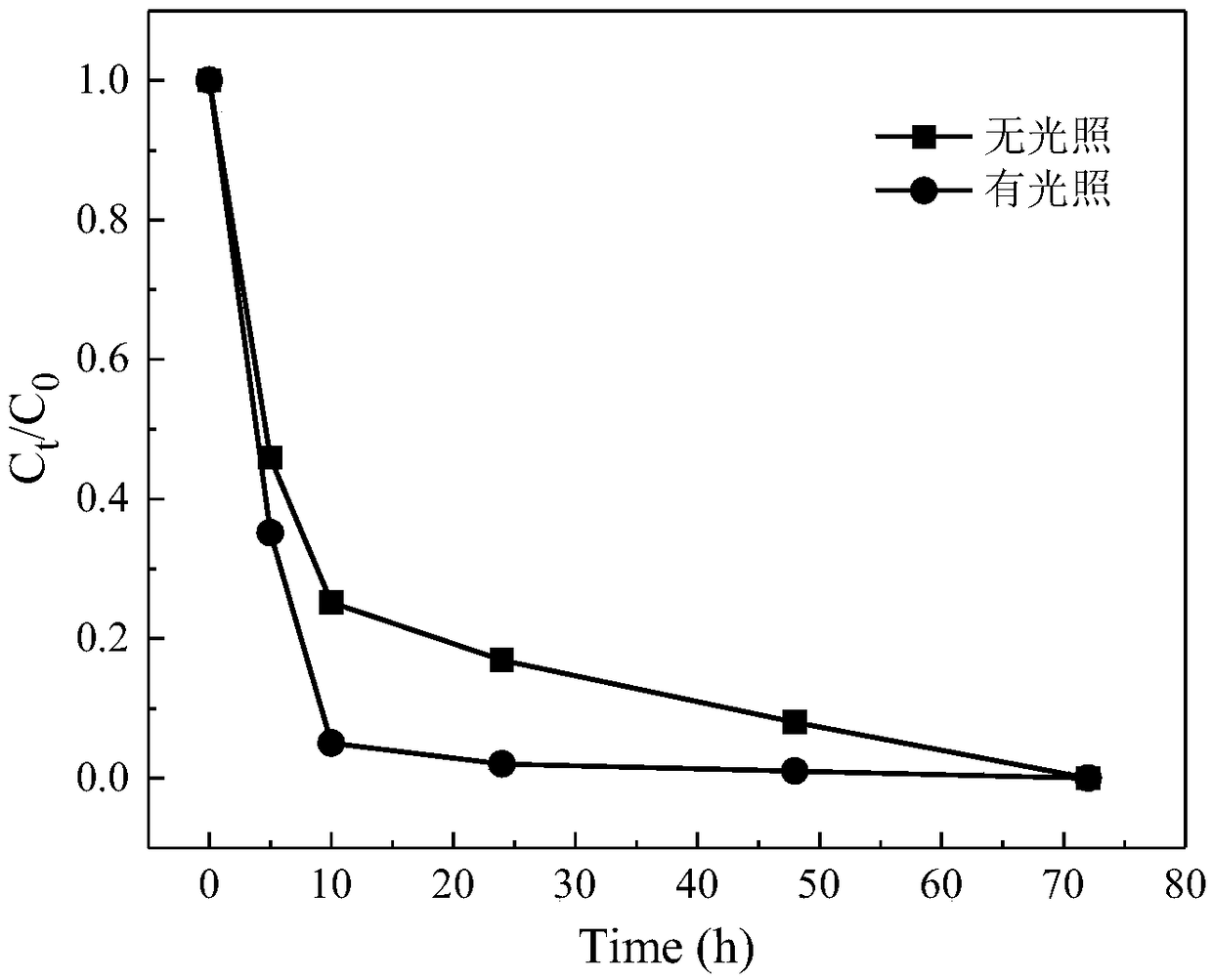

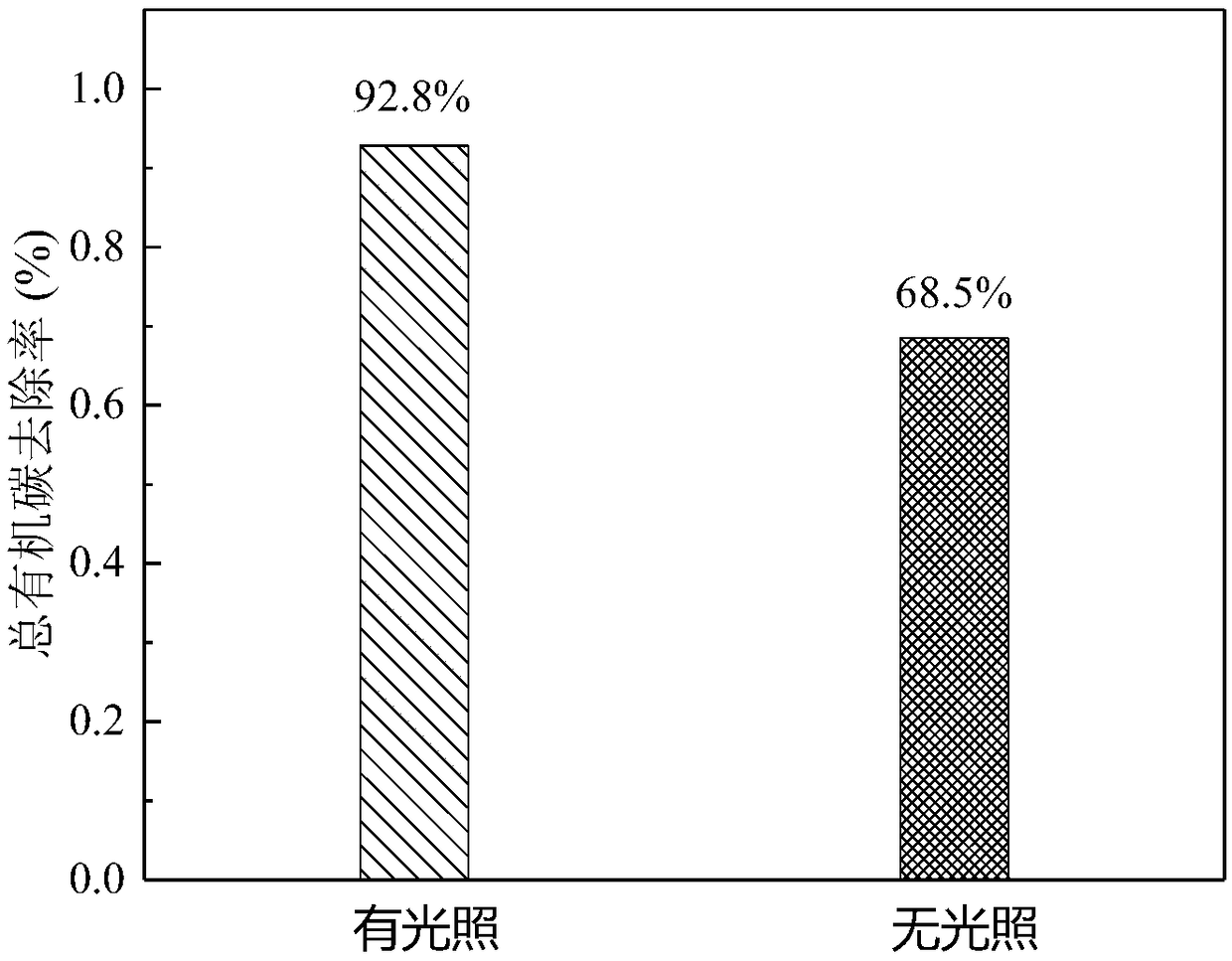

A photocatalytic material, anode-loaded technology, applied in biochemical fuel cells, chemical instruments and methods, electrochemical biocombination treatment, etc., can solve the problem of incomplete mineralization of photocatalytic technology Low electricity and other problems, to achieve the effects of improved photocatalytic efficiency, improved degradation efficiency and mineralization degree, and increased power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The preparation method of the microbial fuel cell of the anode load photocatalytic material of the present invention comprises the following steps:

[0029] (1) Mesoporous graphitic carbon nitride (mpg-C 3 N 4 ) photocatalytic material preparation: 10g NH 4 SCN was dissolved in 10 mL of deionized water, and then 10 g of 40% silica sol (SiO 2 nanoparticles) by adding NH 4 In SCN solution, the SiO 2 Nanoparticles and NH 4 The mass ratio of SCN is (0.1~2); it is stirred and heated at 100°C until the water is evaporated to dryness and becomes a white solid. The white solid was taken out and put into a crucible, and fired at a high temperature of 550°C in a muffle furnace for 2h at a heating rate of 5°C / min. After it was cooled, it was taken out to obtain a yellow solid powder. Then add the yellow solid powder into 100mL ammonium bifluoride solution (4mol / L), mix and stir in the fume hood for 24h to remove SiO 2 Nano-particles, finally filtered and washed with deioni...

Embodiment 2

[0034] The preparation method of the microbial fuel cell of the anode load photocatalytic material of the present invention comprises the following steps:

[0035] (1) TiO 2 Photocatalytic anode preparation: weigh 300mg TiO 2 Photocatalytic material, mix it with polyvinylidene fluoride in a beaker, stir and ultrasonically disperse it evenly, then evenly load it on the surface of a 4×2×1cm carbon cloth electrode, heat it at 70°C for 20h, and dry it TiO can be obtained 2 Photocatalytic composite photocatalytic anode.

[0036] (2) Preparation of air cathode: After shaking and mixing 300 mg of activated carbon powder, 30 mg of carbon black powder and 1 mL of 10% polyvinylidene fluoride solution, evenly load it on the surface of a 50-mesh stainless steel mesh with a diameter of 4.8 cm, and immerse it in deionized water for 15 min Finally, take it out and dry it naturally in the air for 8 hours to make an air cathode.

[0037] (3) Photocatalytic microbial fuel cell (MFC) reactor...

Embodiment 3

[0039] The preparation method of the microbial fuel cell of the anode load photocatalytic material of the present invention comprises the following steps:

[0040] (1) Preparation of ZnO photocatalytic anode: Weigh 300mg of ZnO photocatalytic material, mix it with polytetrafluoroethylene in a beaker, stir and ultrasonically disperse it evenly, and then evenly load it on a 4×2×1cm graphite plate electrode surface, heated at 80°C for 18 hours, and dried to prepare a ZnO composite photocatalytic anode.

[0041] (2) Preparation of air cathode: After shaking and mixing 300 mg of activated carbon powder, 30 mg of carbon black powder and 1 mL of 10% polyvinylidene fluoride solution, evenly load it on the surface of a 50-mesh stainless steel mesh with a diameter of 4.8 cm, and immerse it in deionized water for 15 min Finally, take it out and dry it naturally in the air for 8 hours to make an air cathode.

[0042] (3) Photocatalytic microbial fuel cell (MFC) reactor: the ZnO composite...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com