Solar cell

a solar cell and current conversion technology, applied in the field of solar cells, can solve the problem of low current conversion efficiency of solar cells, and achieve the effect of solar cell efficiency according to the situation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

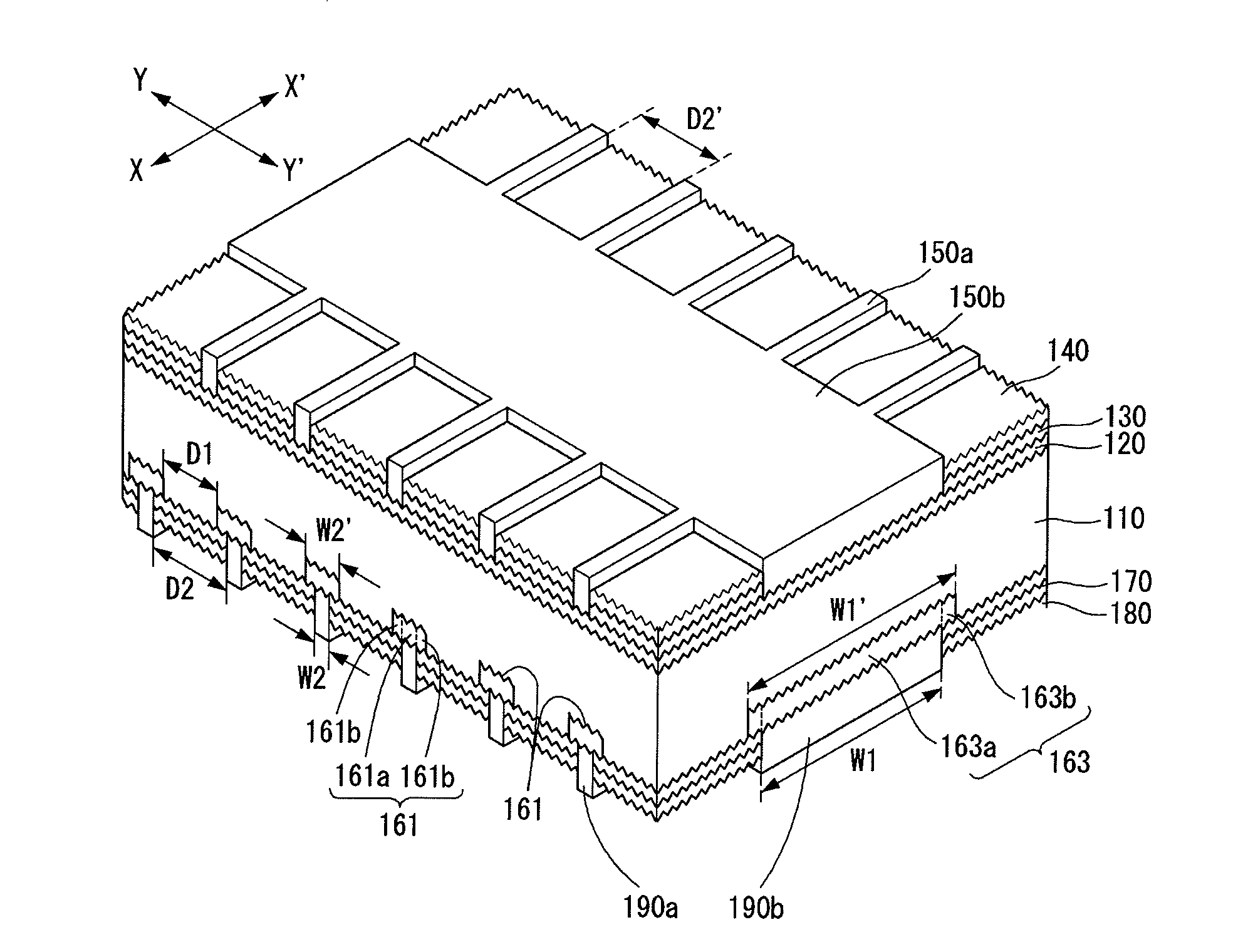

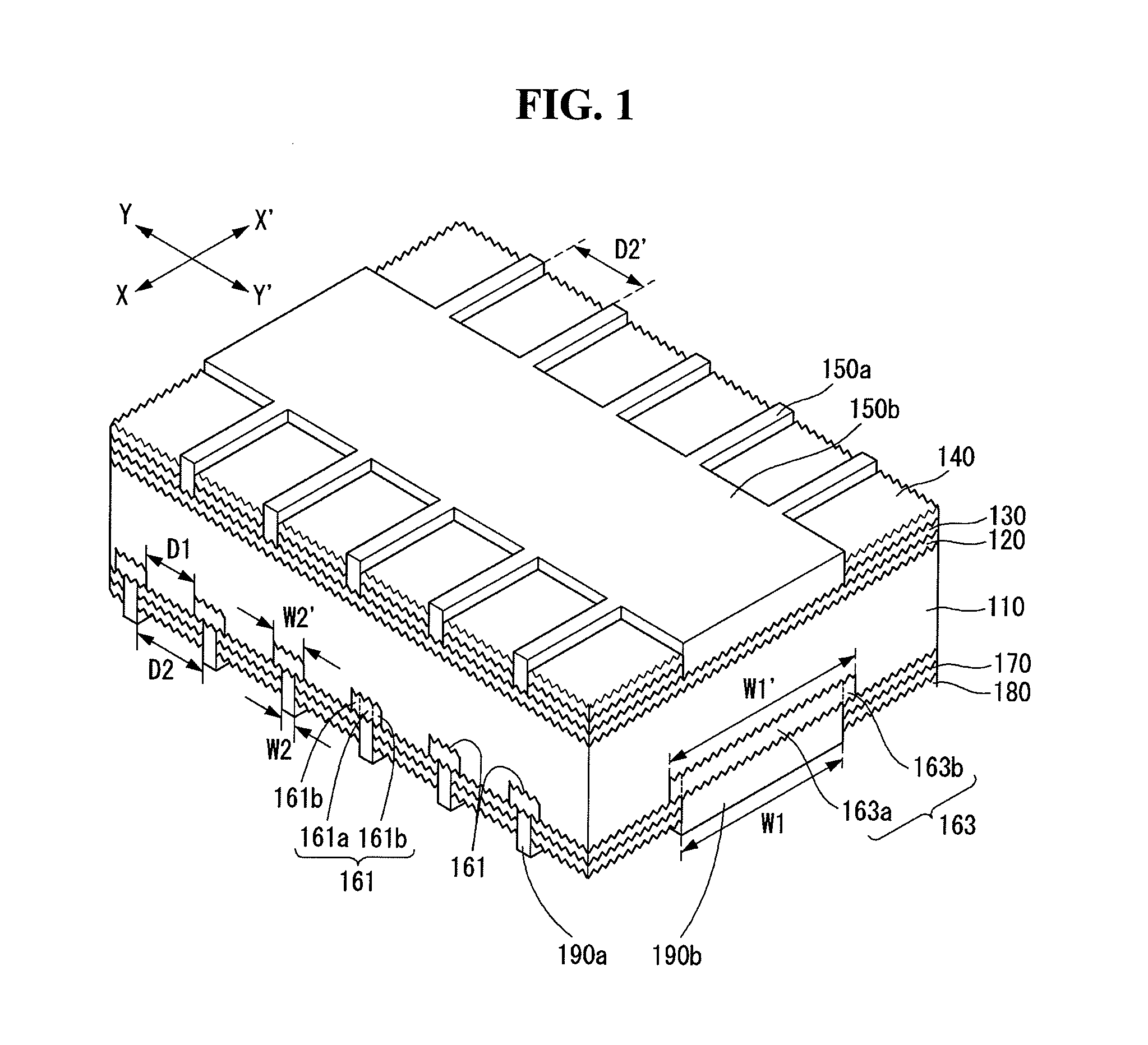

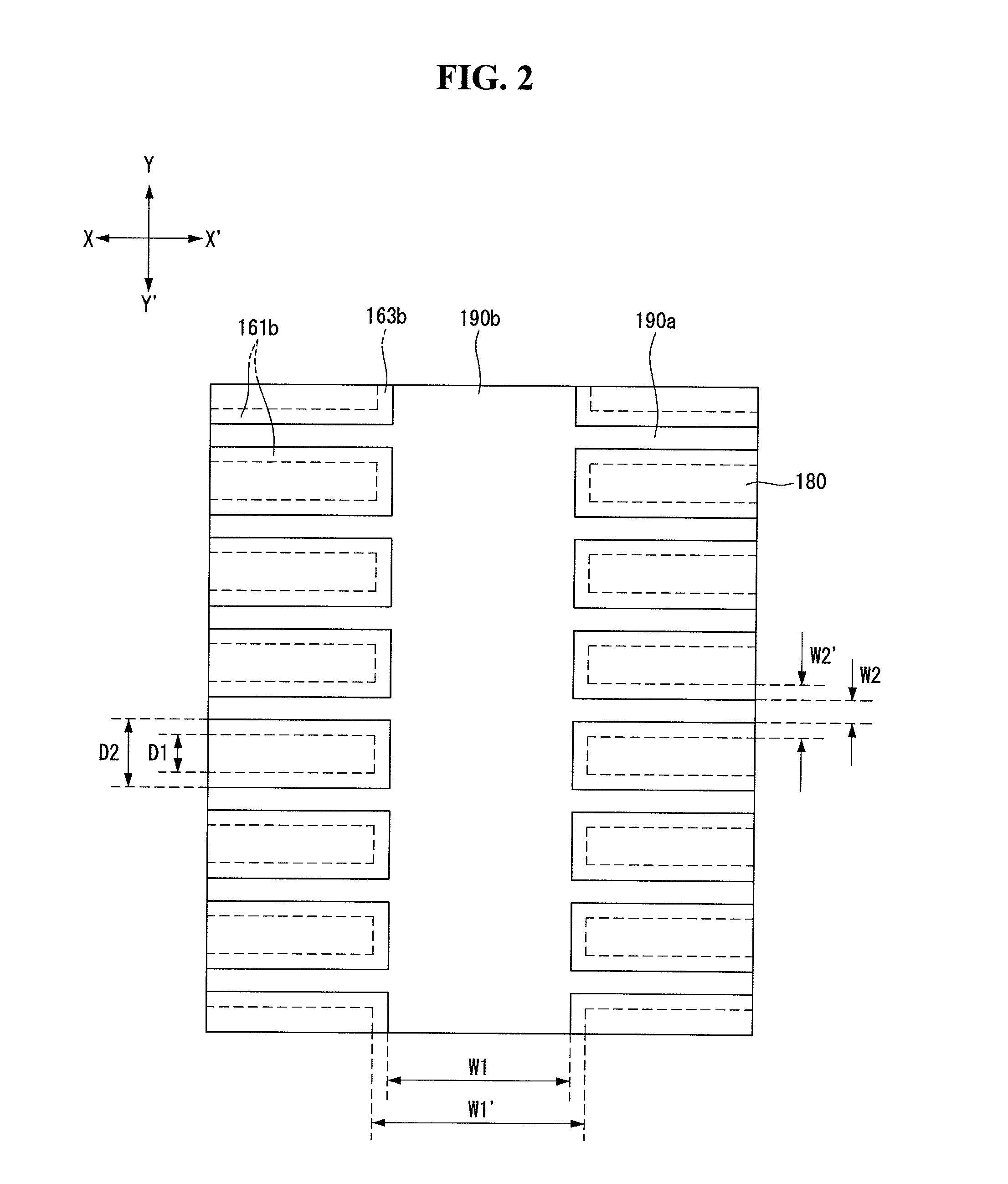

[0045]FIG. 1 is a schematic perspective view of a solar cell according to the invention. FIG. 2 is a plane view showing a back surface of the solar cell shown in FIG. 1.

[0046]As shown in FIG. 1, the solar cell according to the first embodiment of the invention includes a substrate 110, an emitter region 120 positioned at one surface of the substrate 110, for example, a front surface of the substrate 110, a first passivation layer 130 positioned on the emitter region 120, a first anti-reflection layer 140 positioned on the first passivation layer 130, a plurality of first electrodes 150a and a first current collector 150b positioned on the emitter region 120 on which the first passivation layer 130 and the first anti-reflection layer 140 are not positioned, a back surface field (BSF) region (shown as elements 161 and 162) positioned at a back surface of the substrate 110, a second passivation layer 170 positioned on the back surface of the substrate 110, a second anti-reflection laye...

second embodiment

[0104]A solar cell according to the invention is described below with reference to FIGS. 3 and 4.

[0105]Since configuration of the solar cell according to the second embodiment of the invention is substantially the same as the solar cell according to the first embodiment of the invention except an emitter region and a back surface field region, a further description may be briefly made or may be entirely omitted.

[0106]The emitter region 120 of the solar cell according to the first embodiment of the invention substantially has a uniform doping concentration throughout the entire front surface of the substrate 110. Thus, the emitter region 120 according to the first embodiment of the invention may be easily manufactured through a simple process, but a recombination rate of carriers may increase because of the high doping concentration of the emitter region 120. As a result, an improvement in the efficiency of the solar cell may be limited.

[0107]Accordingly, the solar cell according to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com