Preparation method of Bi/Bi4O5X2(X is equal to Br, I) photocatalyst of organic boron oxide under visible light

A visible light and catalyst technology, which is applied in the direction of physical/chemical process catalysts, chemical instruments and methods, oxidized water/sewage treatment, etc., can solve problems such as unsatisfactory utilization of solar energy, achieve improved photocatalytic performance, improved photocatalytic activity, The effect of improving photocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0044] Example 1

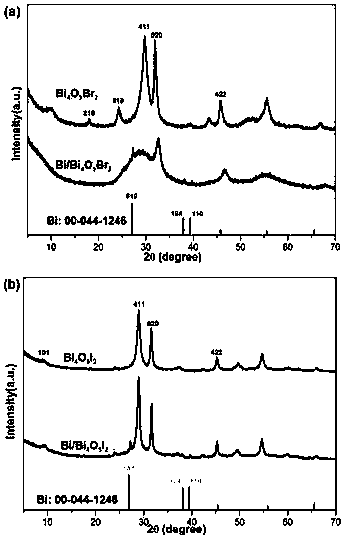

[0045] Use an analytical balance to weigh 3.7835g and 5.0477g bismuth nitrate pentahydrate respectively and dissolve in 40mL glycerol, weigh 0.476g potassium bromide and 0.664g potassium iodide and dissolve in 40mL glycerol, use a rubber tip dropper to dissolve the potassium iodide The solution of potassium bromide and potassium bromide were added dropwise to the glycerol solution of bismuth nitrate pentahydrate. After magnetic stirring at room temperature for 60 minutes, the mixed solution was transferred to the reactor and reacted in an oven at 160°C for 16 hours. And collect the precipitate. The precipitate was dried in an oven at 70°C for 12 hours. Weigh 0.3g of the reaction precursor obtained and add 50mL of distilled water, Bi / Bi at a water bath temperature of 50℃ 4 O 5 Br 2 Hydrolysis for 24h, Bi / Bi 4 O 5 I 2 Hydrolyze for 2h, dry the precipitate obtained from the reaction at 70℃ for 12h, the solid powder obtained is Bi / Bi 4 O 5 X 2 (X=Br,I) Bi-rich com...

Example Embodiment

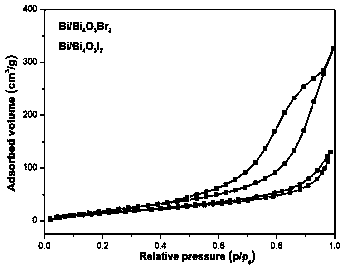

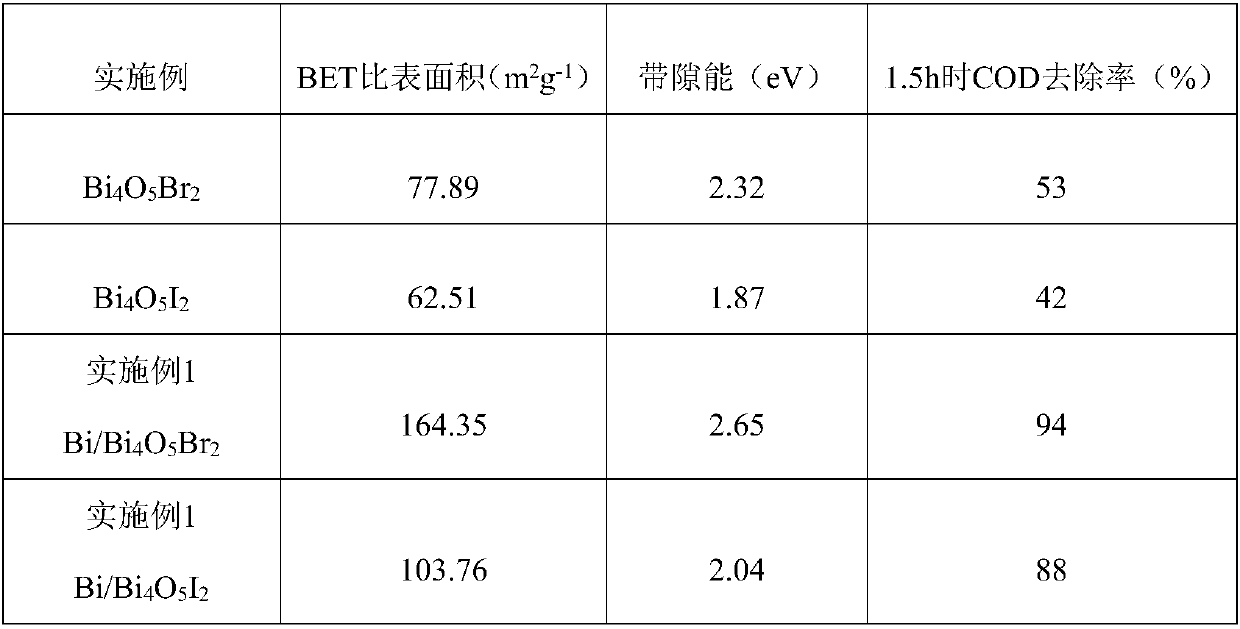

[0046] Example 1 Obtained Bi / Bi 4 O 5 X 2 (X=Br,I) Bi-rich composite photocatalyst and single bismuth-rich photocatalyst Bi 4 O 5 X 2 (X = Br, I) various performance values are listed in Table 1. It can be seen from the table that the Bi / Bi prepared in Example 1 4 O 5 Br 2 The specific surface area of the catalyst is 164.35m 2 g -1 , Bi / Bi 4 O 5 I 2 The specific surface area of the catalyst is 103.76m 2 g -1 , The removal efficiency of organoboron under visible light is Bi 4 O 5 X 2 (X=Br,I) 2 times the monomer.

[0047] The photocatalytic activity test in Table 1 was characterized by oxidizing under visible light to remove organoboron in the pressure return liquid. A 500W xenon lamp was used as the light source, and the visible light in the range of 420 to 780 nm was obtained after the filter. The catalyst dosage was 0.05g each , The original COD concentration of the organic boron solution is 210mg / L. After catalytic oxidation, the COD is measured with a water quality analy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com