Hydrothermal preparation method of flaky nano copper oxide/graphene composite materials

A technology of nano-copper oxide and composite materials, applied in chemical instruments and methods, nanotechnology, metal/metal oxide/metal hydroxide catalysts, etc., can solve problems such as easy agglomeration of samples, difficult control of sample quality, and expensive raw materials , to achieve high sample uniformity, reduce recombination rate, and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

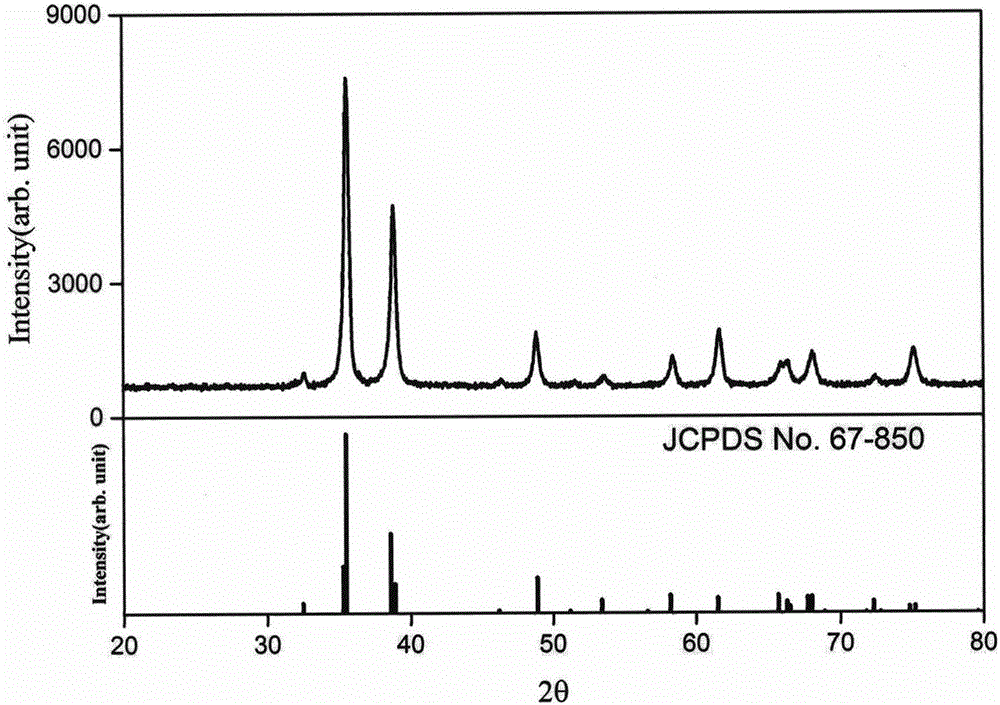

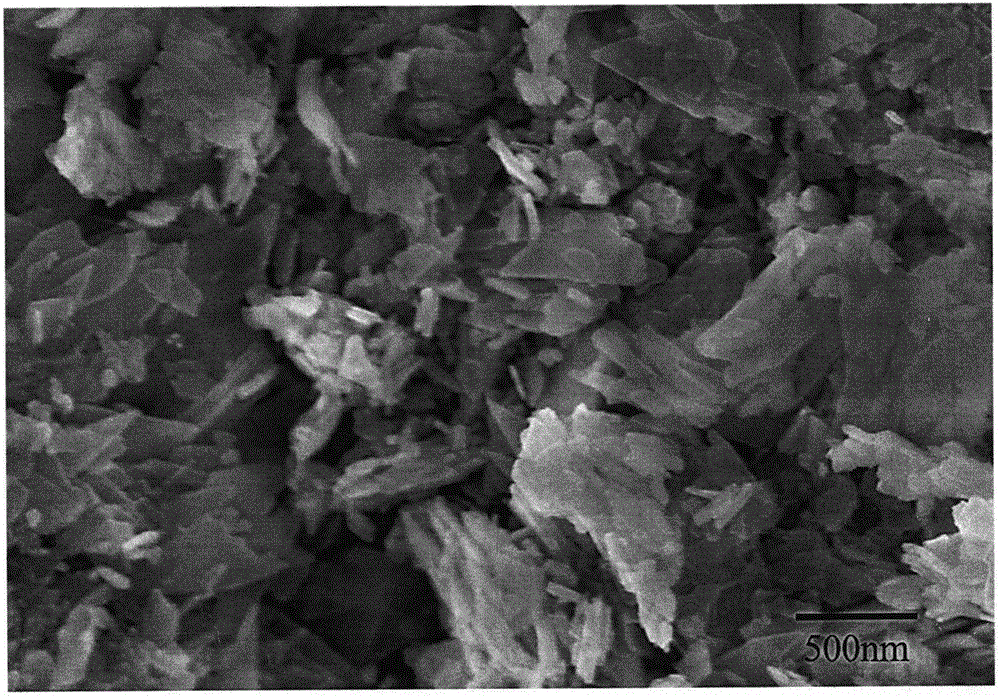

[0028] Dissolve 833 mg of copper acetate monohydrate in 25 ml of deionized water, stir magnetically for 10 minutes, then add a solution containing 50 mg of graphene oxide to the copper acetate solution, and continue magnetically stirring for 10 hours; dissolve 3.331 g of sodium hydroxide in 15 ml of deionized water, stirred for 10 minutes, then added to the mixed solution of copper acetate and graphene oxide, magnetically stirred for 1 hour, then the mixed solution was transferred to the Teflon liner of a 100 ml stainless steel autoclave, Use a blast drying oven to keep warm at 100 degrees Celsius for 10 hours, then let it cool to room temperature naturally, take out the sample, wash the sample with deionized water for several times, until the pH of the waste liquid after washing is neutral, send the solid to Put into a vacuum drying oven and dry at 60 degrees centigrade for 12 hours under vacuum conditions, after which a copper oxide / graphene composite material was obtained. ...

Embodiment 2

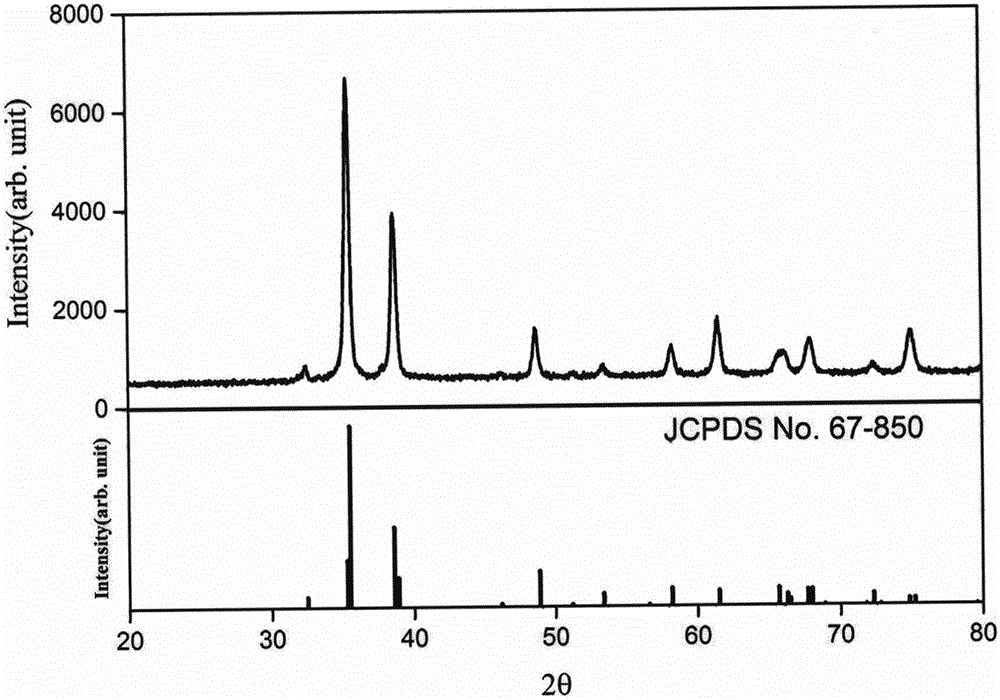

[0030] Dissolve 1249 mg of copper acetate monohydrate in 25 ml of deionized water, stir magnetically for 10 minutes, then add a solution containing 50 mg of graphene oxide to the copper acetate solution, and continue magnetic stirring for 10 hours; dissolve 4.997 g of sodium hydroxide in 15 ml of deionized water, stirred for 10 minutes, then added to the mixed solution of copper acetate and graphene oxide, magnetically stirred for 1 hour, then the mixed solution was transferred to the Teflon liner of a 100 ml stainless steel autoclave, Use a blast drying oven to keep warm at 100 degrees Celsius for 10 hours, then allow it to cool naturally to room temperature, take out the sample, and wash the sample with deionized water for several times until the pH of the waste liquid after washing is neutral. Put into a vacuum drying oven and dry at 60 degrees centigrade for 12 hours under vacuum conditions, after which a copper oxide / graphene composite material was obtained. image 3It is...

Embodiment 3

[0032] Dissolve 1666 mg of copper acetate monohydrate in 25 ml of deionized water, stir magnetically for 10 minutes, then add a solution containing 50 mg of graphene oxide to the copper acetate solution, and continue magnetically stirring for 10 hours; dissolve 6.662 g of sodium hydroxide in 15 ml of deionized water, stirred for 10 minutes, then added to the mixed solution of copper acetate and graphene oxide, magnetically stirred for 1 hour, then the mixed solution was transferred to the Teflon liner of a 100 ml stainless steel autoclave, Use a blast drying oven to keep warm at 100 degrees Celsius for 10 hours, then let it cool to room temperature naturally, take out the sample, wash the sample with deionized water for several times, until the pH of the waste liquid after washing is neutral, send the solid to Put into a vacuum drying oven and dry at 60 degrees centigrade for 12 hours under vacuum conditions, after which a copper oxide / graphene composite material was obtained. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com