Positive plate, preparation method of positive plate, solid-state lithium ion battery, semi-solid-state lithium ion battery and preparation method of semi-solid-state lithium ion battery

A lithium-ion battery and positive electrode technology, which is applied to battery electrodes, non-aqueous electrolyte battery electrodes, positive electrodes, etc., can solve the problems of decreased battery particle cohesion, decreased battery coulombic efficiency, low ionic conductivity, etc. Improve dynamics, increase the effect of transmission channels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

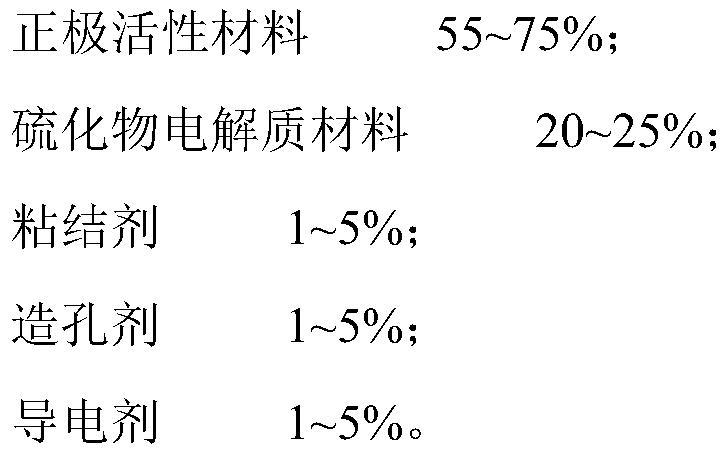

[0098] Embodiment 1, the preparation of positive electrode sheet

[0099] The preparation process of the positive electrode sheet is completely completed under the dew point condition of -70°C. Before the experimental operation, it is necessary to dewater the selenium disulfide, lithium nitrate, and materials to ensure that the water content of the materials is ≤10ppm.

[0100] The NCM622 material, Li 6 P.S. 5 Cl, PTFE powder, Super-P and selenium disulfide are mixed, and the mass fraction of NCM622 material is 70%, Li 6 P.S. 5 The mass fraction of Cl is 23%, the mass fraction of PTFE powder is 3%, the mass fraction of Super-P is 2%, and the mass fraction of selenium disulfide is 2%. Use a Waring 800s high-speed pulverizer to stir for 2 minutes, rest for 1 minute, and repeat this operation 15-20 times to obtain positive electrode slurry.

[0101] The obtained positive electrode slurry was repeatedly rolled using a vertical roller press, the rolling gap was gradually reduce...

Embodiment 2

[0102] Embodiment 2, the preparation of electrolyte layer

[0103] The preparation process is completely carried out in an argon environment glove box with water ≤ 0.1ppm, oxygen ≤ 0.1ppm, and carbon dioxide ≤ 0.1ppm. Before the experimental operation, it is necessary to remove 2,2'-dithiobipyridine and LiTFSI materials first. Water work, to ensure that the water content of the material is ≤10ppm;

[0104] (1) Preparation of sulfide skeleton layer

[0105] Lithium phosphorus sulfur chloride (Li 6 P.S. 5 Cl) Electrolyte materials, selenium disulfide with a mass fraction of 10% are mixed, and dimethyl carbonate is used as a solvent with a solid content of about 50-60%. Use a Thinky defoaming mixer to stir at 2000rmp for 10 minutes, and then 500rmp for defoaming and stirring for 5 minutes ;

[0106] The mixed sulfide electrolyte slurry is uniformly coated on the aluminum foil with a coating gap of 100 microns, and the coated material is vacuum-dried at room temperature to obt...

Embodiment 3

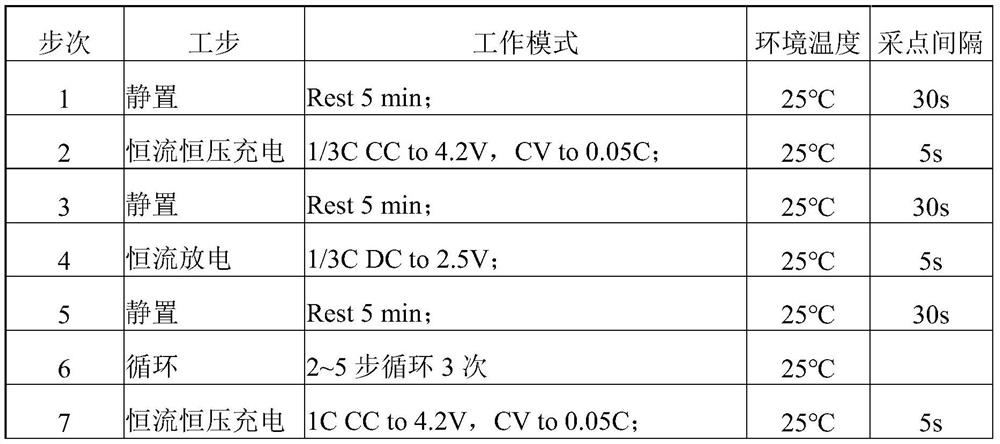

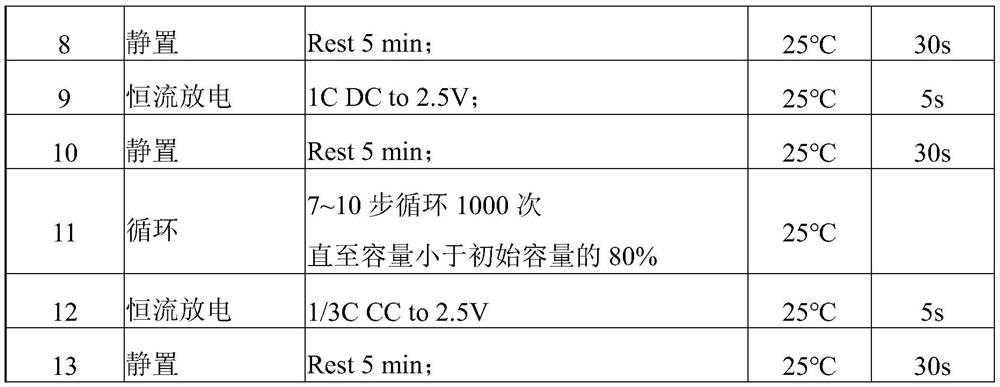

[0111] Embodiment 3, the preparation of semi-solid lithium ion battery

[0112] Liquid electrolyte configuration:

[0113] Lithium nitrate was dissolved in PyR14TFSI ionic liquid to configure a 2mol / L lithium nitrate solution.

[0114] Lithium-ion battery assembly:

[0115] The positive electrode sheet prepared in Example 1, the electrolyte layer prepared in Example 2, and the lithium metal negative electrode sheet (lithium-copper composite strip, lithium foil thickness 50 μm, copper foil thickness 10 μm) were welded on the positive electrode sheet and the negative electrode sheet, The negative plate is welded with nickel-copper lugs, and the positive plate is welded with aluminum lugs, and then the upper part is sealed with a side sealing machine, and the prepared liquid electrolyte is injected into one side, and the liquid electrolyte is added to the battery at a ratio of 1g / Ah. After the injection is completed Stand at room temperature for 48 hours, and finally use a pack...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com