Non-chemically modified food starches

A technology of starch and granular starch, which is applied in the field of non-pregelatinized granular starch and non-pregelatinized granular starch, which can solve problems such as viscosity reduction and crushing, and achieve good product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0156] Example 1: with the method according to the invention (hydrothermal treatment) (ie, non-pregelatinized granular starch hydrothermally treated) Compared to thermal inhibition by conventional methods (anhydrous heat treatment) (i.e., non-hydrothermally treated non-pregelatinized granular starch)

[0157] Since the viscosity diagrams measured under acidic conditions show that non-pregelatinized granules inhibited by traditional methods lose stability in acidic environments compared to those of the present invention (see Example 2), the choice of Measured viscosity graphs to allow fair comparison of disintegration viscosities.

[0158] Table 1: Thermal inhibition results by conventional method (anhydrous heat treatment) (ie, non-hydrothermally treated non-pregelatinized granular starch)

[0159]

[0160] Table 2: Thermal inhibition results by the method (hydrothermal treatment) according to the invention (ie hydrothermally treated non-pregelatinized granular starch) ...

Embodiment 2

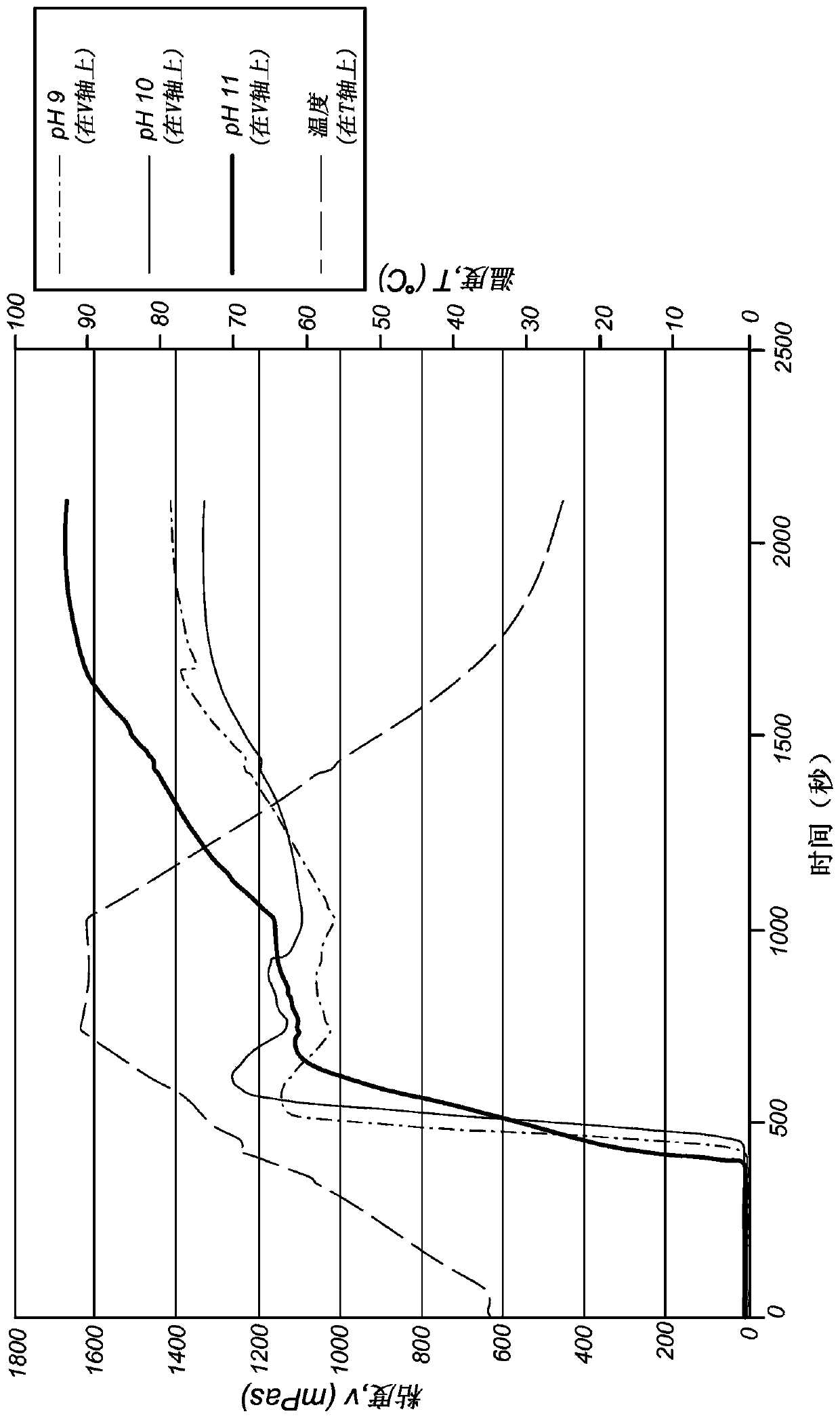

[0163] Example 2: According to the traditional method and according to the method of the invention, under neutral and acidic conditions for thermal inhibition Viscosity diagram of pregelatinized granular starch

[0164] Figure 1A-Figure 1D Viscographs are shown for heat inhibited non-pregelatinized granular starch samples with initial pH of 9, 10 and 11 and initial moisture content of 10 wt%. Figure 1A shows the neutral Brabender viscosity diagram for heat-inhibited non-pregelatinized granular starch (obtained according to section 1.2) according to the conventional method after heat treatment at 165°C for 3 hours, and Figure 1B-Figure 1D Non-pregelatinized granular native waxy potato starch [native starch (on the v-axis)] and heat-inhibited non-pregelatinized granular starch according to the process of the invention are shown under various hydrothermal and / or thermal treatment conditions as follows Neutral RVA viscosity diagram (described in Section 1.3): Figure 1B (...

Embodiment 3

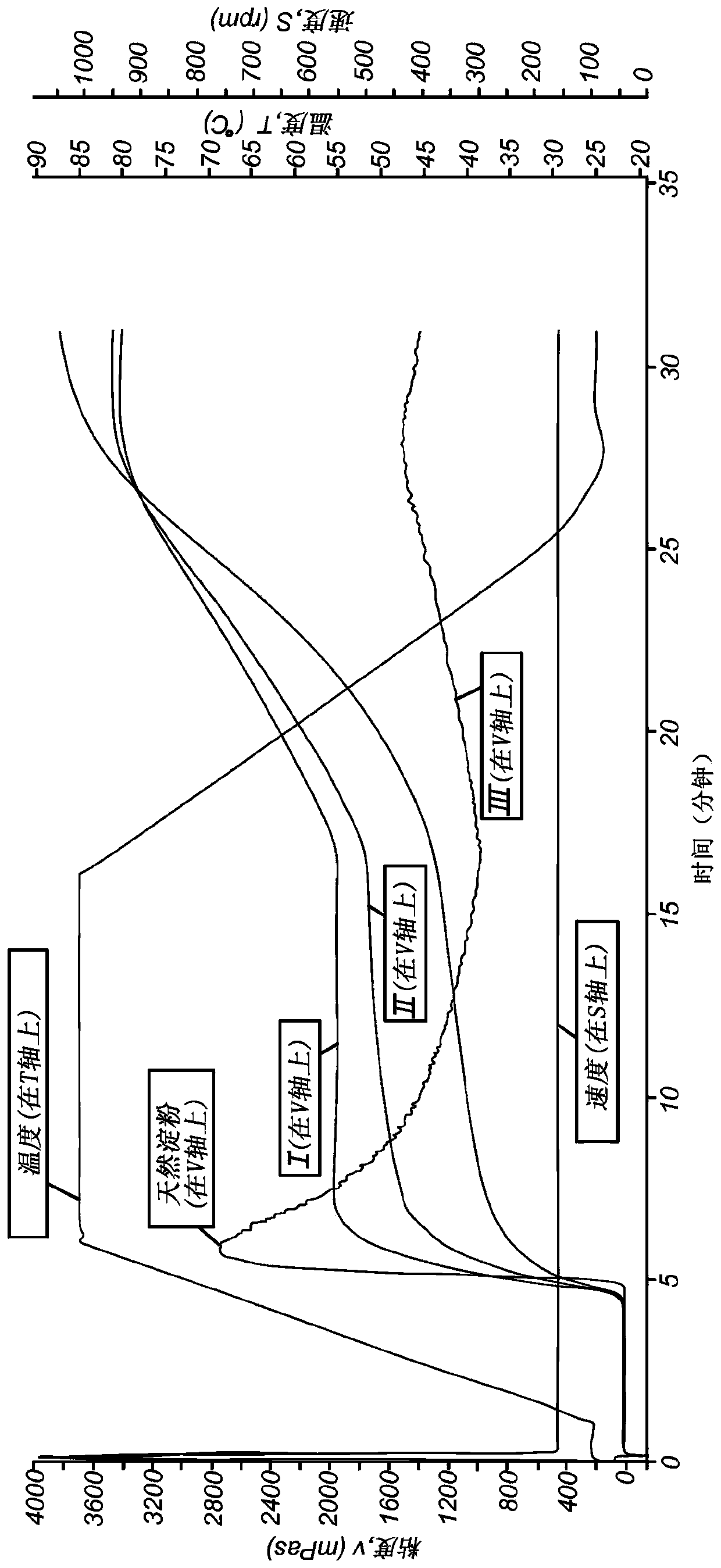

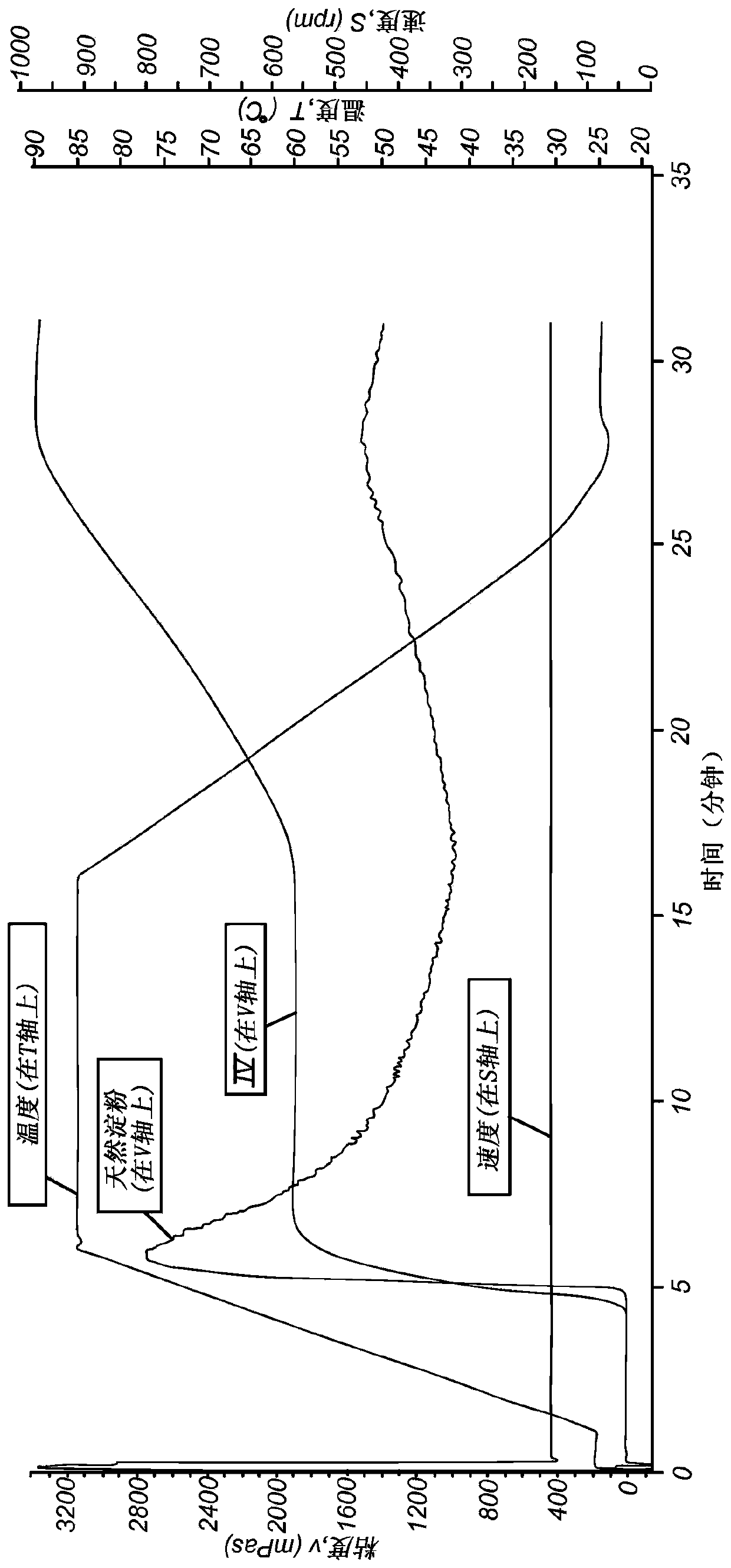

[0169] Example 3: Thermally inhibited viscosity stability of non-pregelatinized granular starch under acidic and neutral conditions according to the invention maintain viscosity

[0170] The peak viscosity of the non-pregelatinized granular natural waxy potato starch was about 1600 mPa·s under acidic conditions and 2800 mPa·s under neutral conditions as determined from the RVA viscosity diagram.

[0171] The viscosity during the holding phase (holding phase) of the non-pregelatinized granular waxy potato starch according to the present invention is 850 mPa.s for acidic RVA and 1700 mPa.s for neutral RVA (as according to under the following conditions, As determined by the RVA viscosity diagram of the sample treated as described in Section 1.3: initial pH value 9, initial moisture content 10 wt% for obtaining hydrothermally treated non-pregelatinized granular starch at 120 °C in equilibrium Steam pressure for 60 minutes; heat treatment at 165°C for 120 minutes). These reta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com