Novel edible antibacterial food packaging film and preparation method thereof

A food packaging film, edible technology, applied in the field of new edible antibacterial food packaging film and its preparation, can solve the problems of poor mechanical strength, poor antibacterial performance, etc., and achieves enhanced antibacterial preservation effect, poor water resistance, and wide source of raw materials. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

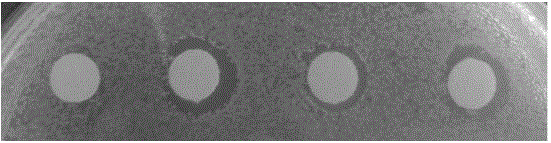

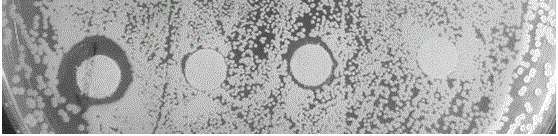

Image

Examples

Embodiment 1

[0025] A new type of edible antibacterial food packaging film, the composition of which is: 2g chitosan, 2g gelatin, 0.30%wt glycerin, 0.04g Tween 80, 0.2%wt cinnamon essential oil. Its preparation method is:

[0026] (1) Weigh 2g of chitosan and add it to a 250ml conical flask, then add 200ml of deionized water, stir for 3 minutes, after the chitosan is evenly dispersed, add 2ml of acetic acid solution dropwise while stirring, and stir fully to obtain chitosan solution.

[0027] (2) Weigh 2 g of gelatin, expand it in cold water for 15 min, and then dissolve it under magnetic stirring for 2 h at 35°C to prepare a 1% w / v gelatin solution.

[0028] (3) Then add 0.30%wt glycerin to the chitosan and gelatin solutions respectively, and stir and mix for 30min.

[0029] (4) After mixing the chitosan / glycerin and gelatin / glycerin solutions at a mass ratio of 4:6, add 0.04 g of Tween 80 emulsifier, and continue to stir and mix for 30 minutes until uniform, so as to assist the dispers...

Embodiment 2

[0034] A new type of edible antibacterial food packaging film, the composition of which is: 1g chitosan, 1g gelatin, 0.25%wt glycerin, 0.08g Tween 80, 0.4%wt cinnamon essential oil. Its preparation method is:

[0035] (1) Weigh 1g of chitosan and add it to a 250ml Erlenmeyer flask, then add 100ml of deionized water and stir for 3 minutes to disperse the chitosan evenly, then add 1ml of acetic acid solution dropwise while stirring, and stir thoroughly to obtain chitosan solution.

[0036] (2) Weigh 1g of gelatin, expand it in cold water for 15min, and then dissolve it under magnetic stirring for 2h at 35°C to prepare a 1% gelatin solution.

[0037] (3) Then add 0.25%wt glycerin to the chitosan and gelatin solutions respectively, and stir and mix for 30min.

[0038] (4) After mixing the chitosan / glycerin and gelatin / glycerin solutions at a mass ratio of 5:5, add 0.08g of Tween 80 emulsifier, and continue to stir and mix for 30 minutes until uniform, so as to assist the dispers...

Embodiment 3

[0043] A new type of edible antibacterial food packaging film, the composition of which is: 2g chitosan, 2g gelatin, 0.40%wt glycerin, 0.08g Tween 80, 0.4%wt cinnamon essential oil. Its preparation method is:

[0044] (1) Weigh 2g of chitosan and add it to a 250ml conical flask, then add 200ml of deionized water, stir for 3 minutes, after the chitosan is evenly dispersed, add 2ml of acetic acid solution dropwise while stirring, and stir fully to obtain chitosan solution.

[0045] (2) Weigh 2g of gelatin, expand it in cold water for 15min, and then dissolve it under magnetic stirring for 2h at 35°C to prepare a 1% gelatin solution.

[0046] (3) Then add 0.40%wt glycerin to the chitosan and gelatin solutions respectively, and stir and mix for 30min.

[0047] (4) After mixing the chitosan / glycerin and gelatin / glycerin solutions at a mass ratio of 6:4, add 0.08g of Tween 80 emulsifier, and continue to stir and mix for 30 minutes until uniform, so as to assist the dispersion and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com