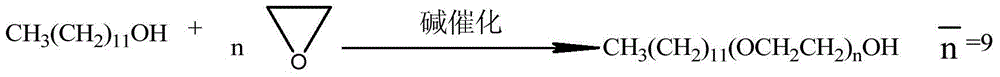

Laurinol purification method and lauromacrogol preparation method

A purification method and technology of lauryl alcohol, applied in the field of medicine and chemical industry, can solve the problems of not fully complying with the quality standards of the European Pharmacopoeia and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

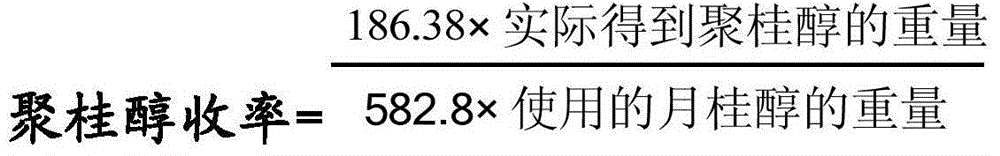

Method used

Image

Examples

preparation example 1

[0119] Preparation Example 1: Preparation of Lauryl Alcohol Purification Sample 1

[0120] Add 250g of lauryl alcohol and 250g of toluene into the reaction kettle, stir and mix well, then slowly raise the temperature to reflux state, control the temperature to keep the mixture in azeotropic state, and collect the distillation product under reduced pressure. The distillation product is first distilled at 100°C and controlled pressure ≤ -0.1Mpa until no liquid flows out, and then gradually heated up to 150°C-160°C and -0.1Mpa to continue vacuum distillation for 4-5 hours. Toluene is recovered and reused until the lauryl alcohol is completely distilled off.

[0121] According to the requirements of related substances in the imported drug registration standard lauromacrogol 400 injection (JX20120149), the test results are shown in Table 1 below.

[0122] Table 1

[0123] name

preparation example 2

[0124] Preparation Example 2: Preparation of Lauryl Alcohol Purification Sample 2

[0125] Add 350g of lauryl alcohol and 350g of toluene into the reaction kettle, stir and mix well, then slowly raise the temperature to reflux state, control the temperature to keep the mixture in azeotropic state, and collect the distillation product under reduced pressure. The distillation product is first distilled at 100°C and controlled pressure ≤ -0.1Mpa until no liquid flows out, and then gradually heated up to 150°C-160°C and -0.1Mpa to continue vacuum distillation for 4-5 hours. Toluene is recovered and reused until the lauryl alcohol is completely distilled off.

[0126] According to the requirements of related substances in the imported drug registration standard lauromacrogol 400 injection (JX20120149), the test results are shown in Table 2 below.

[0127] Table 2

[0128] name

preparation example 3

[0129] Preparation Example 3: Preparation of Lauryl Alcohol Purification Sample 3

[0130] Add 11kg of lauryl alcohol and 11kg of toluene into the reaction kettle, stir and mix well, then slowly raise the temperature to reflux state, control the temperature to keep the mixture in azeotropic state, and collect the distillation product under reduced pressure. The distillation product is first distilled at 100°C and controlled pressure ≤ -0.1Mpa until no liquid flows out, and then gradually heated up to 150°C-160°C and -0.1Mpa to continue vacuum distillation for 4-5 hours. Toluene is recovered and reused until the lauryl alcohol is completely distilled off.

[0131] According to the requirements of related substances in the imported drug registration standard lauromacrogol 400 injection (JX20120149), the test results are shown in Table 3 below.

[0132] table 3

[0133]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com