Method for comprehensively recovering aluminum, silicon and titanium from pyrite tailings

A technology for pyrite and aluminum recovery, applied in chemical instruments and methods, silicon oxide, silicon dioxide, etc., can solve problems such as hidden dangers to public safety, environmental pollution, land occupation, etc., to shorten synthesis time, excellent performance, The effect of speeding up the generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

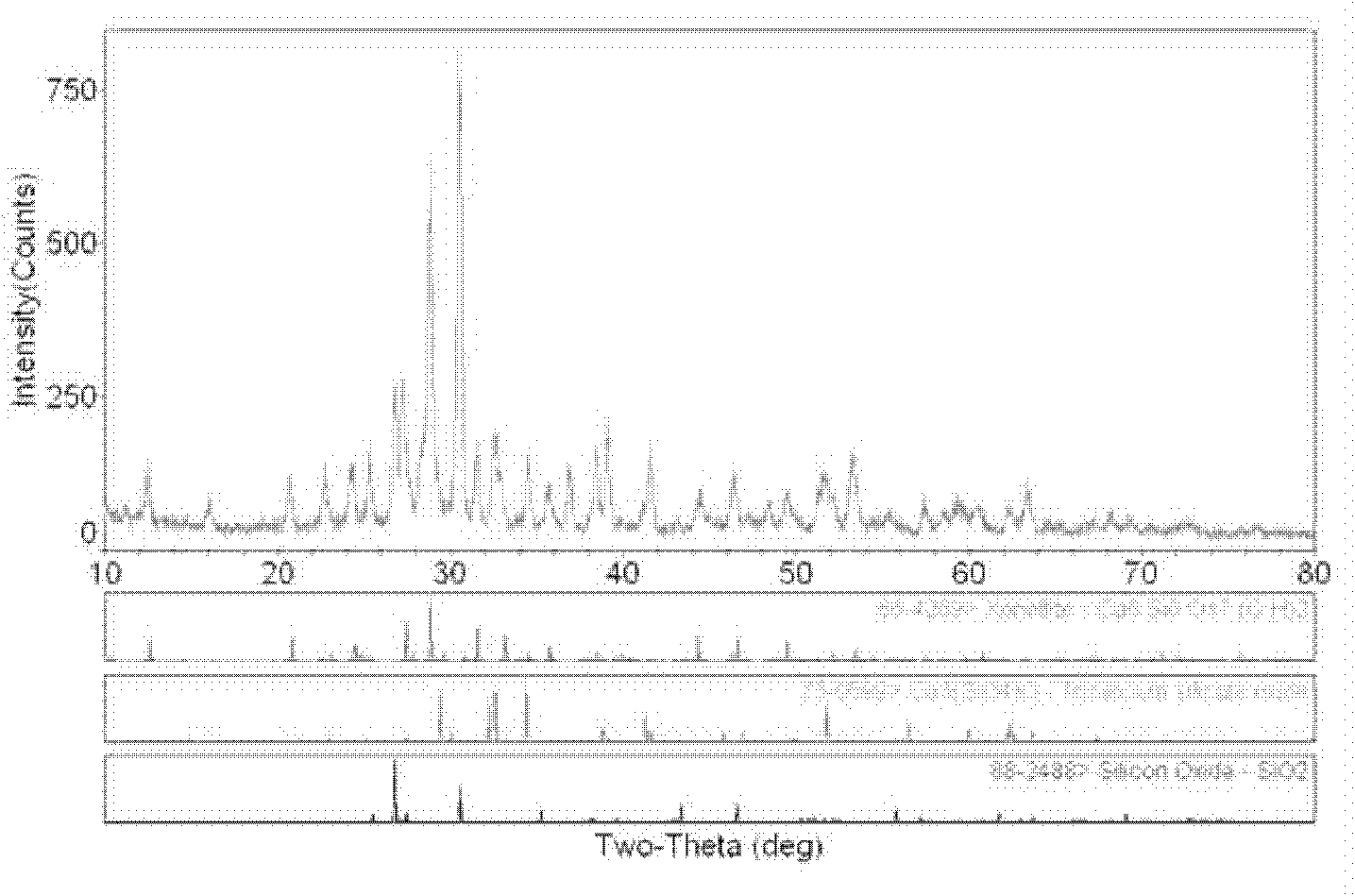

[0033] The flotation tailings are first oxidized and calcined, the calcining temperature is 1050°C, and the calcining time is 15 minutes. The flue gas generated during the calcining process is discharged after desulfurization; The temperature is 140°C, the dissolution time is 30min, the concentration of dissolved sodium hydroxide is 140g / L, and the mass ratio of dissolved liquid to solid is 10:1. Under these conditions, the dissolution rate of silicon dioxide is 53.67%. It is obtained by solid-liquid separation Al in alumina concentrate 2 o 3 The content is 62.43%, Al 2 o 3 with SiO 2 The mass percentage ratio A / S is 3.46.

Embodiment 2

[0035]The flotation tailings are first oxidized and calcined, the calcining temperature is 1100°C, and the calcining time is 15 minutes. The flue gas generated during the calcining process is discharged after desulfurization; The temperature is 140°C, the dissolution time is 30min, the concentration of dissolved sodium hydroxide is 140g / L, and the mass ratio of dissolved liquid to solid is 10:1. Under these conditions, the dissolution rate of silicon dioxide is 70.99%. It is obtained by solid-liquid separation Al in alumina concentrate 2 o 3 The content is 68.60%, Al 2 o 3 with SiO 2 The mass percentage ratio A / S is 5.51.

Embodiment 3

[0037] The flotation tailings are first oxidized and calcined, the calcining temperature is 1150°C, and the calcining time is 15 minutes. The flue gas generated during the calcining process is discharged after desulfurization; The temperature is 140°C, the dissolution time is 30min, the concentration of dissolved sodium hydroxide is 140g / L, and the mass ratio of dissolved liquid to solid is 10:1. Under these conditions, the dissolution rate of silicon dioxide is 72.97%. It is obtained by solid-liquid separation Al in alumina concentrate 2 o 3 The content is 69.49%, Al 2 o 3 with SiO 2 The mass percentage ratio A / S is 5.93.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com