Isopropanolamine production method

A technology of isopropanolamine and its production method, which is applied in chemical instruments and methods, preparation of organic compounds, chemical industry, etc., and can solve problems such as the influence of product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

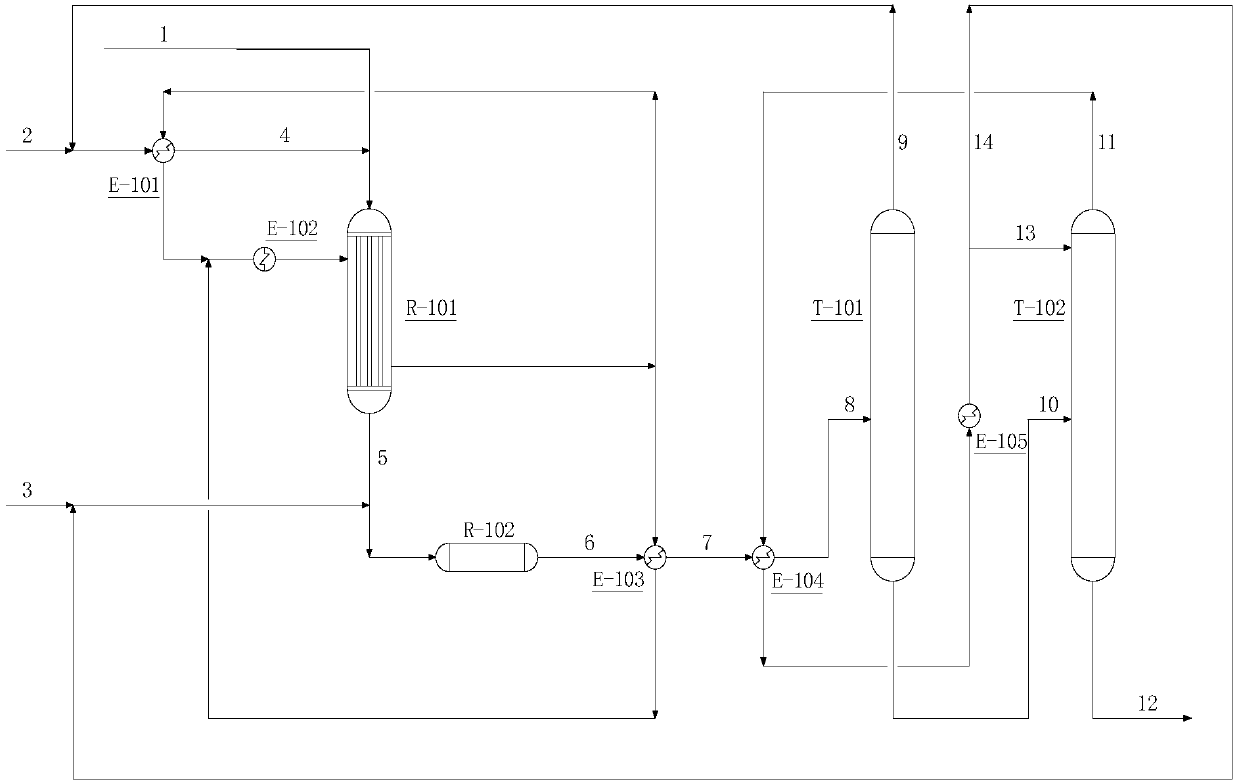

[0037] Fresh liquid ammonia feed 2 is mixed with circulating liquid ammonia 9 and sent to E-101. After being preheated by circulating hot water in reactor R-101, liquid ammonia feed 4 is mixed with propylene oxide feed 1 and sent to R-101 , to obtain the primary reaction product flow 5, after mixing with fresh water 3 and circulating ammonia water 14, send it to R-102, the outlet of R-102 is decompressed, and the depressurized reaction product 6 is first preheated in E-103 by circulating hot water , 7 is sent to E-104, after 11 preheating, 8 is sent to ammonia recovery tower T-101, the top of T-101 gets circulating liquid ammonia 9 returns to E-101, and the tower kettle gets isopropanolamine containing water and a small amount of ammonia 10 and 10 are sent to the dehydration tower T-102, and after the dehydration tower top gas 11 is condensed in E-104 and E-105, part of it returns to the top of the dehydration tower T-102 as the dehydration tower reflux 13, and part of it retur...

Embodiment 2

[0046] Fresh liquid ammonia feed 2 is mixed with circulating liquid ammonia 9 and sent to E-101. After being preheated by circulating hot water in reactor R-101, liquid ammonia feed 4 is mixed with propylene oxide feed 1 and sent to R-101 , to obtain the primary reaction product flow 5, after mixing with fresh water 3 and circulating ammonia water 14, send it to R-102, the outlet of R-102 is decompressed, and the depressurized reaction product 6 is first preheated in E-103 by circulating hot water , 7 is sent to E-104, after 11 preheating, 8 is sent to ammonia recovery tower T-101, the top of T-101 gets circulating liquid ammonia 9 returns to E-101, and the tower kettle gets isopropanolamine containing water and a small amount of ammonia 10 and 10 are sent to the dehydration tower T-102, and after the dehydration tower top gas 11 is condensed in E-104 and E-105, part of it returns to the top of the dehydration tower T-102 as the dehydration tower reflux 13, and part of it retur...

Embodiment 3

[0055] Fresh liquid ammonia feed 2 is mixed with circulating liquid ammonia 9 and sent to E-101. After being preheated by circulating hot water in reactor R-101, liquid ammonia feed 4 is mixed with propylene oxide feed 1 and sent to R-101 , to obtain the primary reaction product flow 5, after mixing with fresh water 3 and circulating ammonia water 14, send it to R-102, the outlet of R-102 is decompressed, and the depressurized reaction product 6 is first preheated in E-103 by circulating hot water , 7 is sent to E-104, after 11 preheating, 8 is sent to ammonia recovery tower T-101, the top of T-101 gets circulating liquid ammonia 9 returns to E-101, and the tower kettle gets isopropanolamine containing water and a small amount of ammonia 10 and 10 are sent to the dehydration tower T-102, and after the dehydration tower top gas 11 is condensed in E-104 and E-105, part of it returns to the top of the dehydration tower T-102 as the dehydration tower reflux 13, and part of it retur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com