Diesel exhaust fluid production method

A production method and technology of urea for vehicles, applied in chemical instruments and methods, preparation of urea derivatives, preparation of organic compounds, etc., can solve the problems of increasing energy exchange steps, high content, reducing energy utilization efficiency, etc., to achieve reduction Risk and Cost Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

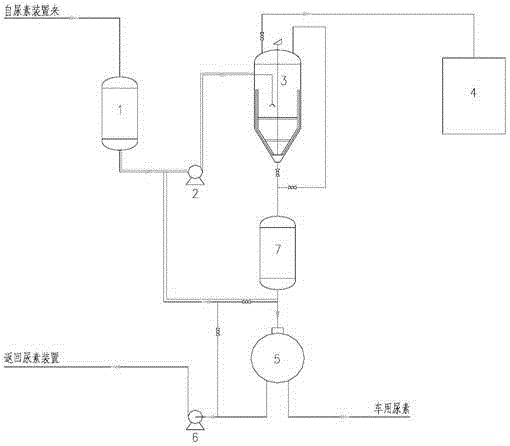

Image

Examples

Embodiment 1

[0028] Send 460kg of urea synthesis reaction liquid from the urea synthesis plant, which has desorbed unreacted ammonia and carbon dioxide, into the urine tank 1; the temperature of the urea liquid is 90°C, the pressure is 0.05MPa (table), and the concentration is 73wt%.

[0029] The urea solution in the urine tank 1 is sent to the vacuum flash crystallization tank 3 through the delivery pump 2, and the outlet pressure of the delivery pump is 0.8MPa (table); in order to prevent the cooling and crystallization of the urea solution during the delivery process, the pipeline should be shortened as much as possible. The transportation distance of the pipeline, or adopt heat preservation and heat tracing measures to prevent the temperature of the urea solution from dropping; in order to facilitate the discharge of urea crystals, the bottom of the vacuum flash crystallization kettle 3 is designed as a cone-bottom structure, and its cone angle is 40-60°. A frame-type stirring is arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com