Preparation method of MWW structure molecular sieve

A molecular sieve and slurry technology, applied in the direction of crystalline aluminosilicate zeolite, etc., can solve the problems of miscellaneous crystal formation, impurity accumulation, high energy consumption, etc., and achieve the effect of reducing the probability of miscellaneous crystal formation and avoiding environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

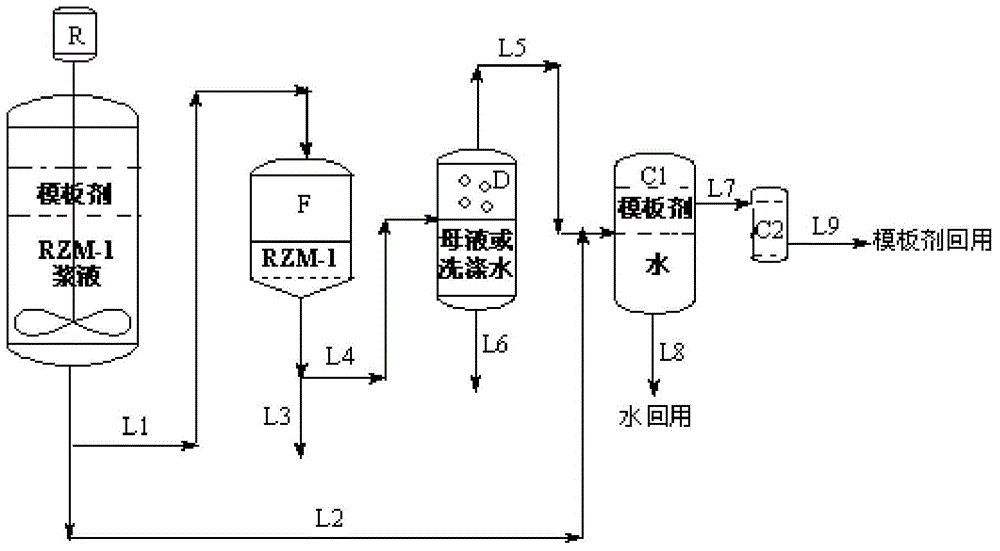

[0017] The present invention provides a kind of preparation method of molecular sieve of MWW structure, and this method comprises the following steps:

[0018] (1) Mix silicon source, aluminum source, alkali agent, templating agent and water, crystallize the glue solution obtained after mixing, and then cool to obtain a layered system in which the upper layer is an organic phase and the lower layer is a molecular sieve slurry, wherein , the template contains hexamethyleneimine and aniline;

[0019] (2) separating the layered system to obtain an organic phase and a molecular sieve slurry;

[0020] (3) The molecular sieve slurry is filtered, the obtained filter cake is washed, dried and roasted successively, and the obtained filtrate is distilled or rectified to reclaim the azeotrope of hexamethyleneimine and water and aniline Azeotrope with water.

[0021] In the present invention, the aluminum source can be various conventional soluble aluminum salts used in the preparation ...

Embodiment 1

[0059] This example is used to illustrate the preparation method of the molecular sieve with MWW structure of the present invention.

[0060] In the reaction unit R, dissolve a certain amount of sodium metaaluminate and sodium hydroxide in deionized water, stir until completely dissolved, then add solid silica gel, then add an appropriate amount of hexamethyleneimine and aniline, and stir evenly , the amount of the above raw materials is such that in the obtained glue, the molar ratio of sodium hydroxide, silicon source, aluminum source, HMI, AN and water is 0.18:1:0.033:0.10:0.20:15. The glue solution was crystallized at 145° C. and autogenous pressure for 72 hours at a stirring speed of 24 revolutions per minute. Then, the temperature was lowered to 20° C. with cooling water, and the stirring was stopped for 5 minutes to obtain a layered system in which the upper layer was the organic phase and the lower layer was the molecular sieve slurry.

[0061] Turn on the reaction un...

Embodiment 2

[0065] This example is used to illustrate the preparation method of the molecular sieve with MWW structure of the present invention.

[0066] According to the method of Example 1, the raw materials are mixed, crystallized and cooled in the reaction unit R, the difference is that the washing water in Example 1 is used as the water source, and the mixture recovered in the template storage tank C2 of Example 1 is used As a template, the amount of raw materials used is such that the molar ratio of sodium hydroxide, silicon source, aluminum source, HMI, AN and water in the resulting glue is 0.18:1:0.033:0.10:0.20:15.

[0067] Turn on the reaction unit R, send the molecular sieve slurry to the filter washing unit F, when the molecular sieve slurry is taken out of the organic phase, the organic phase is transported to the liquid-liquid separation container C1 through the fourth pipeline L4 to stand for phase separation, and the separated The template agent is sent to the template age...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com