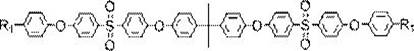

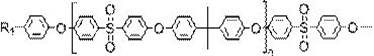

Preparation method of double-terminated polysulfone

A technology of double end-capping polymerization and end-capping agent, applied in the field of polymer materials, can solve the problems of flammability and explosion, easy to depolymerize, and difficult to remove end-capping agent.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] With condensing, N 2 4.34Kg bisphenol A, 5.74Kg 4,4'-dichlorodiphenylsulfone and 2.90Kg Kg 2 CO 3 Add 47L of N,N-dimethylacetamide, gradually raise the temperature from room temperature to 120°C, add p-hydroxyacetophenone according to the water content in the reaction system, test the water content of the reaction system in the first 1h to 1.0235%, the reaction process Add 6.09g of p-hydroxyacetophenone, 2-3h test reaction system water content is 0.44568%, need to add 3.43g of p-hydroxyacetophenone, 3-4h test reaction system water content is 0.29324%, need to add p-hydroxyacetate Acetophenone 0.90 g. At the same time, during the reaction process, the effluent was produced at a rate of 5 L / h for 4 hours (the water content in the final produced solution was less than 0.5%), and the temperature was continued to rise to 160°C for 6 hours, and then the concentration of 1.8mol / 5 L of N,N-dimethylacetamide solution of p-aminophenol (completely added in half an hour). Add ...

Embodiment 2

[0040] With condensing, N 2 4.34Kg bisphenol A, 5.74Kg 4,4'-dichlorodiphenylsulfone and 2.90Kg Kg 2 CO 3 Add 47L of N,N-dimethylacetamide, gradually raise the temperature from room temperature to 120°C, add p-nitrophenol according to the water content in the reaction system, test the water content of the reaction system in the first 1h to 1.13400%, during the reaction process Add 5.55g of p-nitrophenol, 2-3h test reaction system water content 0.53251%, need to add 3.64g p-nitrophenol, 3-4h test reaction system water content is 0.30511%, need to add p-nitrophenol 1.38 g. At the same time, during the reaction process, the effluent was produced at a rate of 5 L / h for 4 hours (the water content in the final produced solution was less than 0.5%), and the temperature was continued to rise to 160°C for 6 hours, and then the concentration of 1.8mol / 5L of N,N-dimethylacetamide solution of L-p-aminophenol (completely added in half an hour). Add 15L of N,N-dimethylacetamide to dilut...

Embodiment 3

[0042] With condensing, N 2 4.34Kg bisphenol A, 5.74Kg 4,4'-dichlorodiphenylsulfone and 2.90Kg Kg 2 CO 3 Add 47L of N,N-dimethylacetamide, gradually raise the temperature from room temperature to 120°C, add p-hydroxybenzenesulfonic acid according to the water content in the reaction system, test the water content of the reaction system in the first 1h to 1.03460%, the reaction process Add 7.70g of p-hydroxybenzenesulfonic acid, 2-3h test reaction system water content is 0.48921%, need to add 4.14g p-hydroxybenzenesulfonic acid, 3-4h test reaction system water content is 0.28911%, need to add p-hydroxybenzenesulfonic acid Benzenesulfonic acid 1.52g. At the same time, during the reaction process, the effluent was produced at a rate of 5 L / h for 4 hours (the water content in the final produced solution was less than 0.5%), and the temperature was continued to rise to 160°C for 6 hours, and then the concentration of 1.8mol / L N-(4-hydroxyphenyl)acetamide in N,N-dimethylacetamid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com