Sphere-like silver powder with particle size capable of being accurately controlled and preparation method thereof

A technology with precise control and spherical shape, which is applied in metal processing equipment, transportation and packaging, etc., can solve the problems that are not suitable for large-scale industrial production, the particle size cannot be precisely controlled, and the adjustable range of particle size is narrow, so as to achieve easy scale-up and industrialization. Chemical application, wide controllable range of particle size and uniform shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

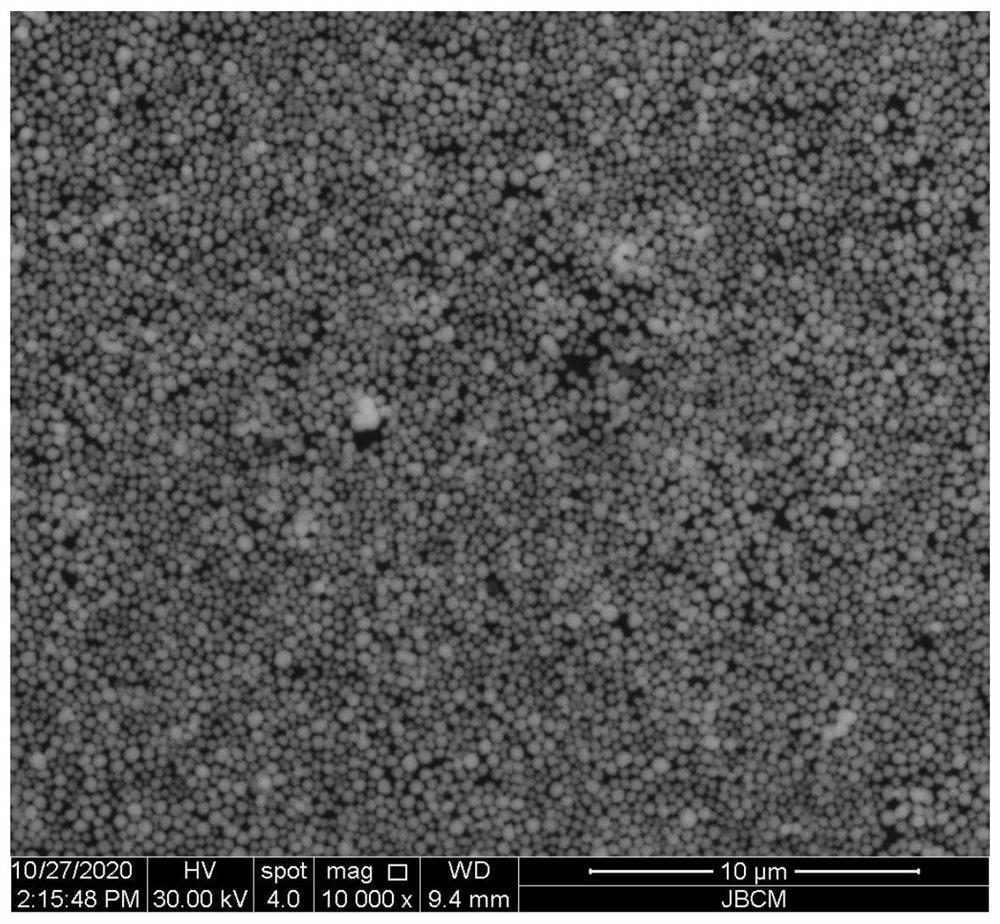

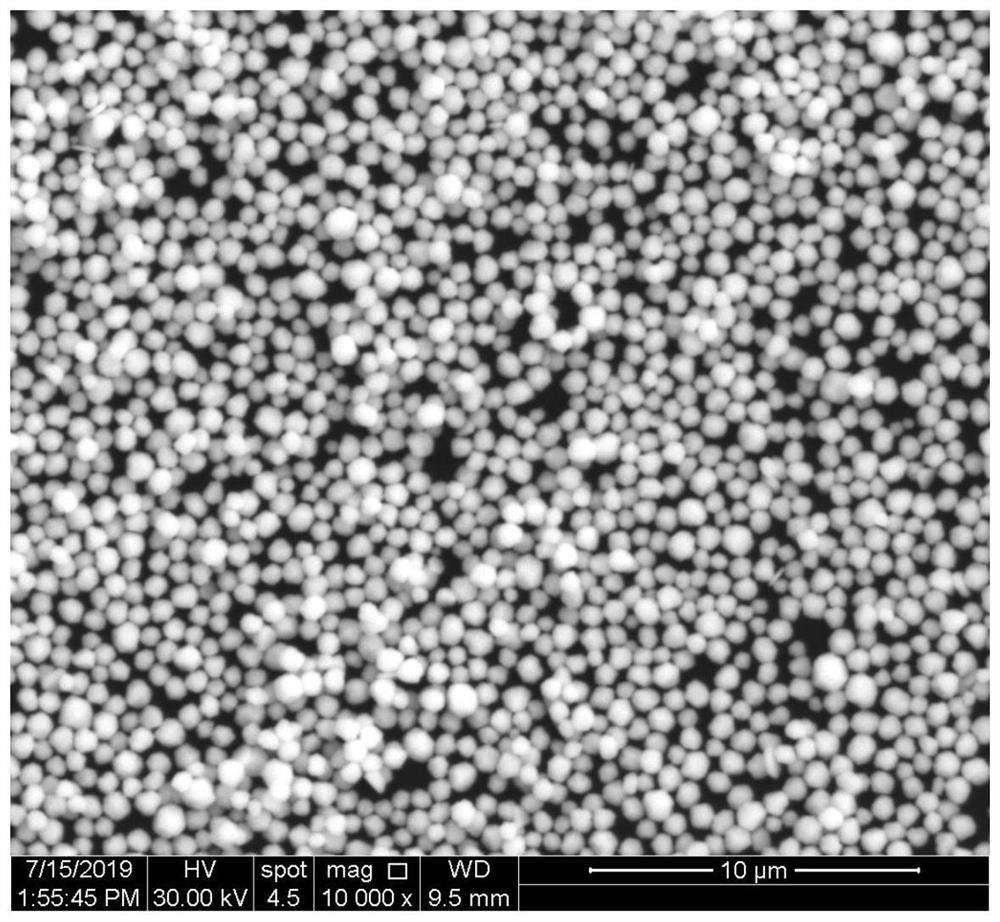

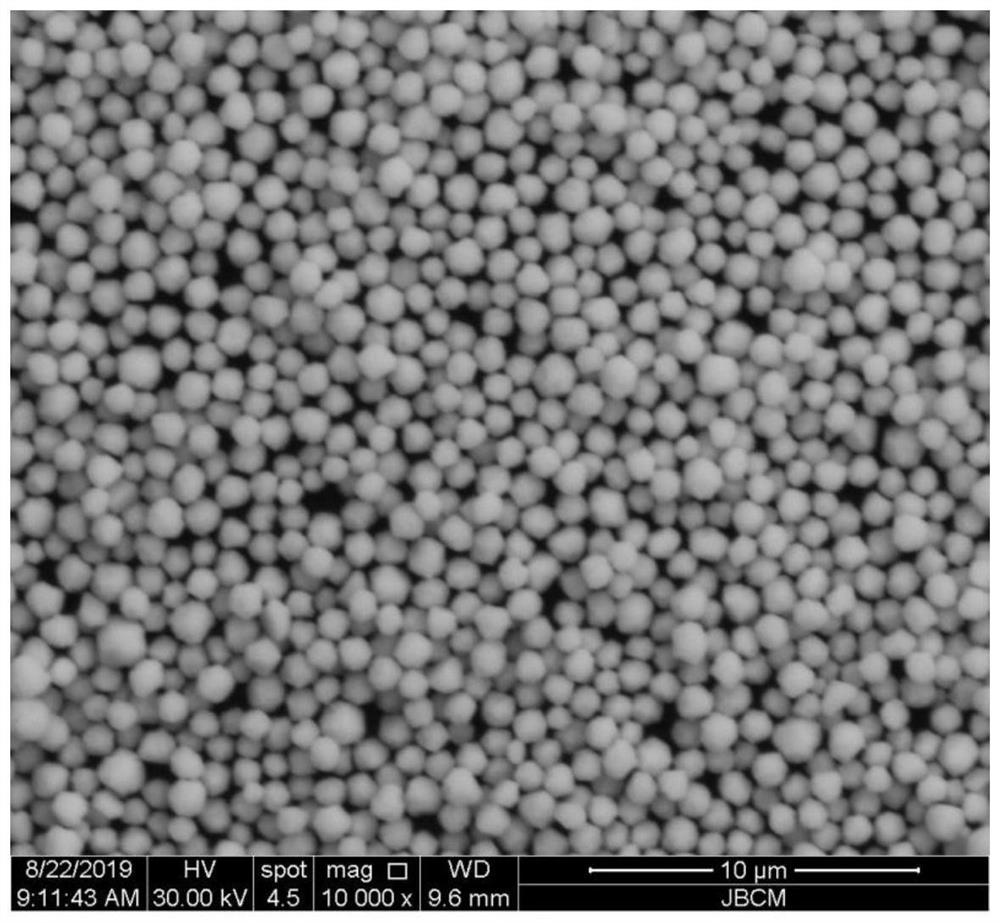

Image

Examples

preparation example Construction

[0041] The present application uses nano-silver colloid as a seed crystal. The particle size of silver particles in the nano-silver colloid is 50-300nm, the content of silver particles is 0.5-4%, and the silver particles have a hydrophilic surface. As long as the nano-silver colloids meeting the above conditions can be used as the seed crystals of this application. Specifically, the nano-silver glue used in the following examples refers to the patent CN102407342B, and the preparation method of the nano-silver glue specifically includes the following steps:

[0042] (1) Preparation of seed crystals

[0043]The polymer is calculated as a monomer. Dissolve the dispersant I and silver nitrate in water at a molar ratio of 1 to 100:1 to form a mixed solution I with a silver nitrate concentration of 0.01 to 20.0 mmol / L, and then add the reducing agent I under stirring. solution, continue to stir and react to form nano-silver seeds;

[0044] Wherein, the dispersant I is one or a com...

Embodiment 1

[0057] Embodiment 1 preparation target particle diameter D50 is the spherical silver powder 1# of 0.5 μ m

[0058] The specific preparation method of described quasi-spherical silver powder comprises the following steps:

[0059] (1) Take by weighing 4.5Kg silver nitrate solid, be mixed with the silver nitrate solution A of 1mol / L and add nitric acid, adjust to pH to 2; Take 5Kg ascorbic acid as reducing agent, be mixed with reducing agent solution B of 1.5mol / L And add ammonia water to adjust the pH to 5; weigh 3.2Kg polyvinylpyrrolidone, and prepare a dispersant solution C with a concentration of 250g / L.

[0060] (2) take by weighing 300g particle diameter and be the above-mentioned seed crystal of 50nm (wherein silver particle content is 1.0%, and silver particle has hydrophilic surface), after adding in the dispersant solution C and stirring, keep the reaction kettle temperature to be 15 ℃, The stirring speed is 200r / min, and the silver nitrate solution A and the reducing...

Embodiment 2

[0065] Embodiment 2 Preparation target particle diameter D50 is the spherical silver powder 2# of 0.8 μ m

[0066] The specific preparation method of described quasi-spherical silver powder comprises the following steps:

[0067] (1) Take by weighing 4.5Kg silver nitrate solid, be mixed with the silver nitrate solution A of 1mol / L and add nitric acid, adjust to pH to 2; Take 5Kg glucose and make reducing agent, be mixed with reducing agent solution B of 2mol / L and Add sodium hydroxide to adjust the pH to 5; weigh 3.2Kg of polyvinylpyrrolidone, and prepare a dispersant solution C with a concentration of 250g / L.

[0068] (2) take by weighing 300g particle diameter and be the above-mentioned seed crystal of 100nm (wherein silver particle content is 1.5%, and silver particle has hydrophilic surface), after adding in the dispersant solution C and stirring, keep the reaction kettle temperature to be 20 ℃, The stirring speed is 200r / min, and the silver nitrate solution A and the red...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com