Preparation method for AlSi10Mg aluminum alloy superfine powder for 3D printing

A 3D printing, aluminum alloy technology, applied in the direction of additive processing, etc., can solve the problem of not finding the preparation method of AlSi10Mg aluminum alloy ultrafine powder, etc., and achieve the effect of low oxygen content, accurate particle size control and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0010] The present invention will be described in further detail below. A method for preparing AlSi10Mg aluminum alloy ultrafine powder for 3D printing, the weight percentage of each component of the prepared AlSi10Mg aluminum alloy ultrafine powder is: Si: 9% to 11%; Mg: 0.25% to 0.45%; Al: Yu The content of impurity elements is: O: ≤0.12%; Fe: ≤0.55%; Ti: ≤0.15%; Zn: ≤0.10%; Cu: ≤0.05%; Ni: ≤0.05%; Mn: ≤0.45%; : ≤0.05%; Sn: ≤0.05%; characterized in that, the preparation steps are as follows:

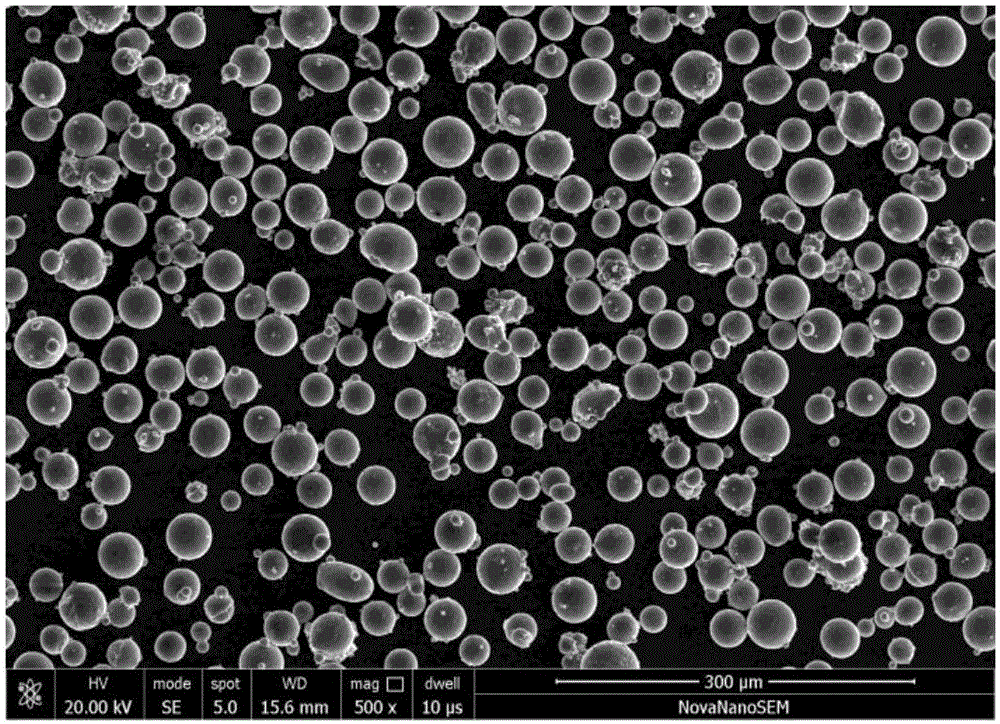

[0011] 1. Supersonic gas atomization: According to the ingredients, refined aluminum ingots, primary magnesium ingots, and aluminum-silicon intermediate alloy ingots are used to prepare furnace charges. Using a vacuum atomization furnace, the charge is smelted in an atmosphere that is first vacuumed and protected by high-purity nitrogen. After sufficient smelting, use high-purity nitrogen to atomize the alloy melt. The atomization temperature is 740°C-820°C, and the atomization pres...

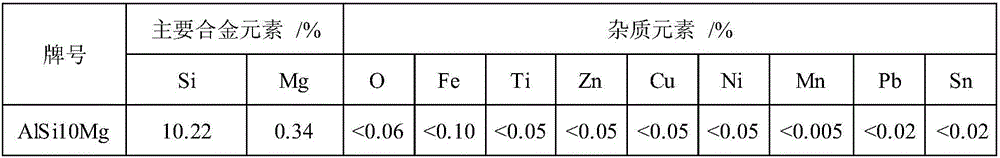

Embodiment 1

[0014] According to the ingredients, refined aluminum ingots (purity ≥ 99.99%), primary magnesium ingots (purity ≥ 99.95%) and AlSi12A intermediate alloy ingots (Si content 12%) are used to prepare charge. Using a vacuum atomization furnace, the charge is smelted in an atmosphere that is first vacuumed and protected by high-purity nitrogen. After sufficient smelting, use high-purity nitrogen to atomize the alloy melt. The atomization temperature is 800°C, and the atomization pressure is 2.5MPa. Thereby obtaining the atomized original powder of AlSi10Mg aluminum alloy ultrafine powder.

[0015] After the atomization is completed, the atomized raw powder of AlSi10Mg aluminum alloy ultrafine powder is screened by ultrasonic vibration screening equipment. According to the user's requirements for powder particle size, select 300-mesh and 500-mesh stainless steel screens, and install the screens in the order that the 500-mesh screen is on the bottom and the 300-mesh screen is on t...

Embodiment 2

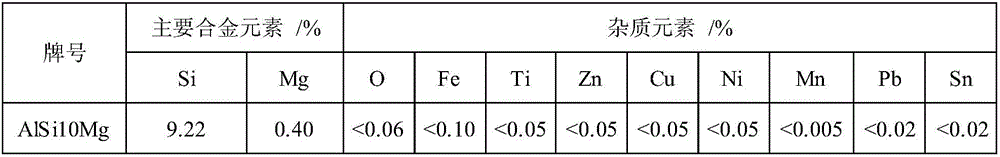

[0023] According to the ingredients, refined aluminum ingots (purity ≥ 99.99%), primary magnesium ingots (purity ≥ 99.95%) and AlSi12A intermediate alloy ingots (Si content 12%) are used to prepare charge. Using a vacuum atomization furnace, the charge is smelted in an atmosphere that is first vacuumed and protected by high-purity nitrogen. After sufficient smelting, use high-purity nitrogen to atomize the alloy melt. The atomization temperature is 740°C, and the atomization pressure is 1.5MPa. Thereby obtaining the atomized original powder of AlSi10Mg aluminum alloy ultrafine powder.

[0024] After the atomization is completed, the atomized raw powder of AlSi10Mg aluminum alloy ultrafine powder is screened by ultrasonic vibration screening equipment. According to the user's requirements for powder particle size, select 250-mesh and 500-mesh stainless steel screens, and install the screens in the order that the 500-mesh screen is on the bottom and the 250-mesh screen is on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com