Method for detecting molybdenum element in milk powder

A detection method and milk powder technology, which is applied to the detection of molybdenum in milk powder by ion emission spectrometer, and in the field of detection of molybdenum in milk powder. To achieve the effect of avoiding damage to the instrument and harm to the testing personnel, stable testing, and accurate and reliable results

Active Publication Date: 2010-08-25

INNER MONGOLIA MENGNIU DAIRY IND (GRP) CO LTD

View PDF0 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Now, the traditional wet digestion manual method is generally used for detection. First, weigh the sample and add a certain amount of concentrated nitric acid to the beaker overnight, then add perchloric acid to catch the acid on the electric heating plate, and add water many times. During this process, it is easy to burn dry. The final acidity can't be controlled

When acid and water are added during the acid removal process, it is easy to bring other interferences into the sample, and the sample will be turbid if the sampling volume is too large (that is, there is a problem of incomplete digestion)

The traditional wet digestion manual method is not only time-consuming and labor-intensive, pollutes the environment, but also has certain harm to the testing personnel

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

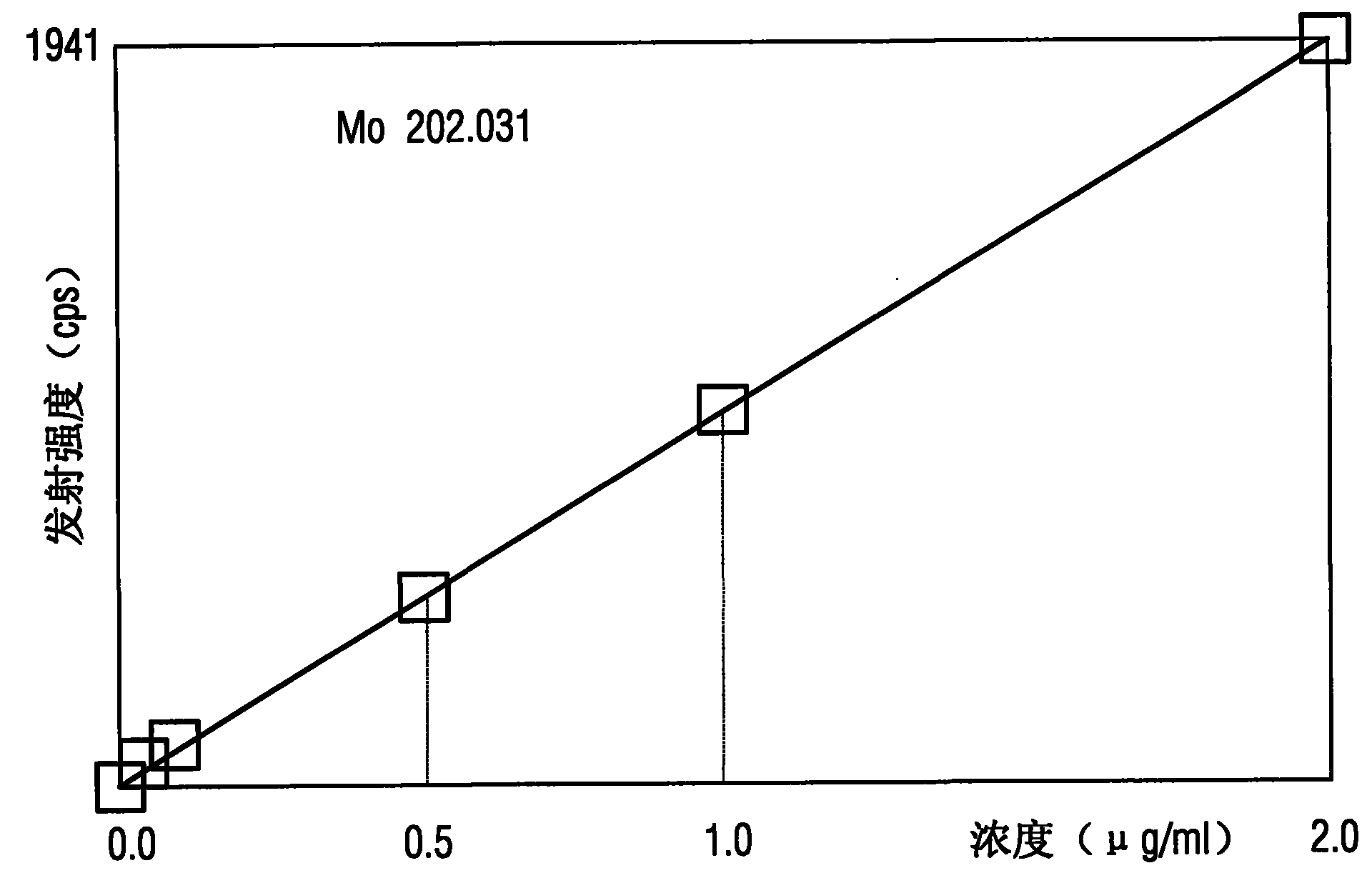

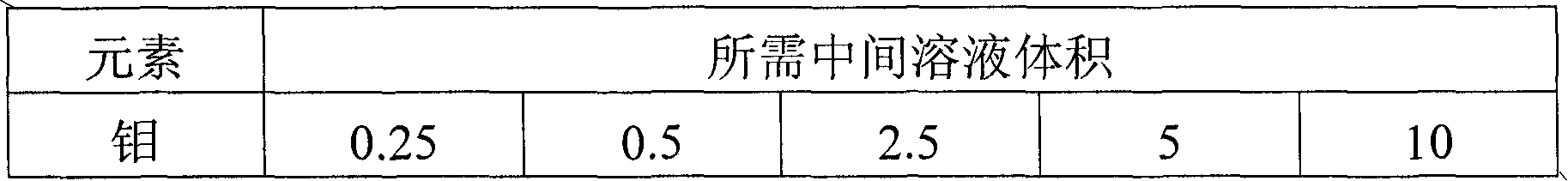

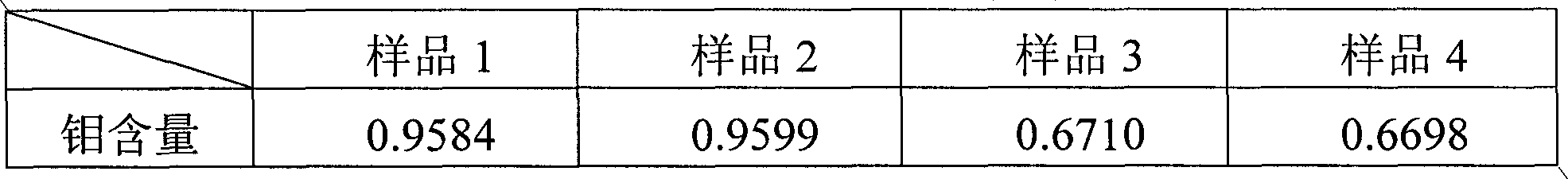

The invention relates to a method for detecting molybdenum element in milk powder. The used equipment is an inductively coupled plasma atomic emission spectrometer. The method has the following steps of: 1) preparing molybdenum element standard solution and making a standard curve according to the standard solution; 2) oxidizing a milk powder sample to be tested by using peroxide, performing acid treatment by using nitric acid, digesting in a microwave digestion system, and detecting by using equipment parameters same as the standard solution to obtain a detection result of the sample to be tested; and 3) comparing the detection result of the sample to be tested with the standard curve to determine the content of the molybdenum element in the sample to be tested. The instrument detection limit of the method is 0.0071 mu g / ml, and in an element linear range, the related coefficient r is over 0.999, and the recovery rate is 92.0 to 101.8 percent. The method can quickly and accurately detect the content of the molybdenum element in the milk powder, and has the advantages of low element loss and pollution probability in the sample preparing process, accurate and reliable result, good repeatability and high sensitivity.

Description

technical field The invention relates to a method for detecting molybdenum element in milk powder, in particular to a method for detecting molybdenum element in milk powder by using an inductively coupled plasma emission spectrometer, and belongs to the technical field of chemical composition detection. Background technique Molybdenum is an essential trace element for human body. The content of molybdenum in the human body is very small, accounting for only one ten-millionth of the body weight. Although the content of molybdenum is very small, it plays an important role that cannot be ignored in human life. It is known that the human heart muscle contains a relatively high proportion of molybdenum, and molybdenum and some enzymes maintain the energy metabolism of the heart muscle. Someone analyzed the hearts of dozens of patients who died of myocardial infarction and found that their molybdenum content was lower than that of healthy people. This shows that the amount of m...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N21/73G01N1/44

Inventor 其其格高娃乌尼尔常建军李梅刘卫星

Owner INNER MONGOLIA MENGNIU DAIRY IND (GRP) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com