Oily wastewater treatment method

A waste water treatment and waste water technology, applied in the direction of oxidized water/sewage treatment, etc., can solve the problems of long cycle and large investment, and achieve the effect of enhanced pollution holding capacity, low consumption and large reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

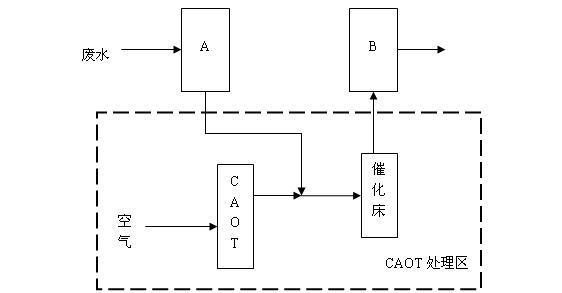

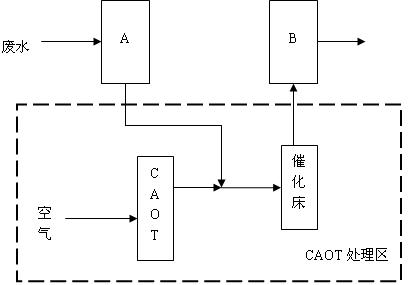

[0041] Such as figure 1 shown.

[0042] A kind of oily waste water treatment method, it is to install between any two processing equipment A, B of conventional waste water treatment process and can produce OH - The advanced oxidation treatment device CAOT of the activated gas makes the waste water flowing out of the first treatment equipment A and the OH-containing water produced by the advanced oxidation treatment device CAOT - The activated gas is mixed with air to generate CAOT activated water in the wastewater, and then the wastewater containing CAOT activated water enters the catalytic bed for catalytic reaction with the catalyst and then enters the second treatment equipment B to improve the second treatment equipment B purification and separation ability to control the OH - The volume ratio of the activated gas to the waste water is between 1% and 20%, and the residence time of the waste water on the catalytic bed is controlled between 2 and 1500 seconds.

[0043] Amon...

Embodiment 2

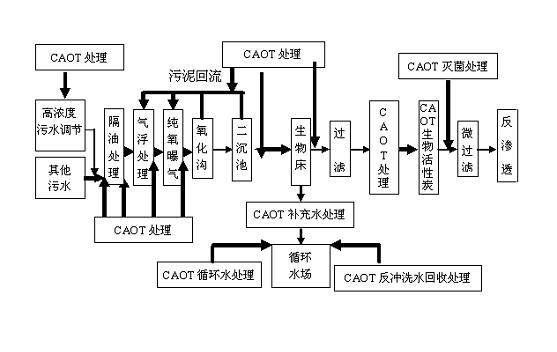

[0045] Such as figure 2 shown.

[0046] This embodiment is a typical refinery wastewater treatment process, from figure 2 It can be seen from the figure that OH-activated gas treated by CAOT can be added in any step of the whole treatment process to generate activated water to improve the treatment effect and reduce the load on the original equipment. The activation gas effect is the best, but the corresponding investment is also large. If only an advanced oxidation treatment device CAOT is installed in the air flotation treatment device, it can also meet the emission requirements and improve the treatment efficiency and purification level of the entire treatment process. If the wastewater treated by the sewage treatment device needs to be further treated as domestic water, the final step is to install an advanced oxidation treatment device CAOT in the filter equipment after the biological bed, see Example 3 for details.

[0047] Specific application examples:

[0048] ex...

example 2

[0055] Take the 20,000-ton tap water plant as an example

[0056] 2.1 Install CAOT equipment before the water intake pump, connect the suction port to the inlet of the CAOT equipment, and connect the outlet of the CAOT equipment to the delivery pipeline;

[0057] 2.2 Install CAOT equipment before the purification process, connect the incoming water pipeline to the inlet of the CAOT equipment, and connect the outlet of the CAOT equipment to the purification process equipment;

[0058] 2.3 When the purification equipment is flotation, a part or another water body is taken to be treated by CAOT equipment, and the treated water merges and diffuses with the large water body;

[0059] 2.4 Collect the sewage discharged from each process section of the waterworks, and send it to the CAOT equipment for treatment after being lifted. The outlet of the CAOT equipment is connected to the water supply pipeline of the waterworks or the water source buffer pool;

[0060] Example 3.

[0061]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com