Complex-phase ceramic material with stress irradiance and electroluminescence characters and preparation thereof

A technology of stress luminescence and composite ceramics, which is applied in the direction of luminescent materials, color-changing fluorescent materials, chemical instruments and methods, etc. It can solve the problems of limited luminescence spectrum, hindering the application of wider fields, and insufficient luminous intensity, and achieves low cost. , less pollution and side effects, simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

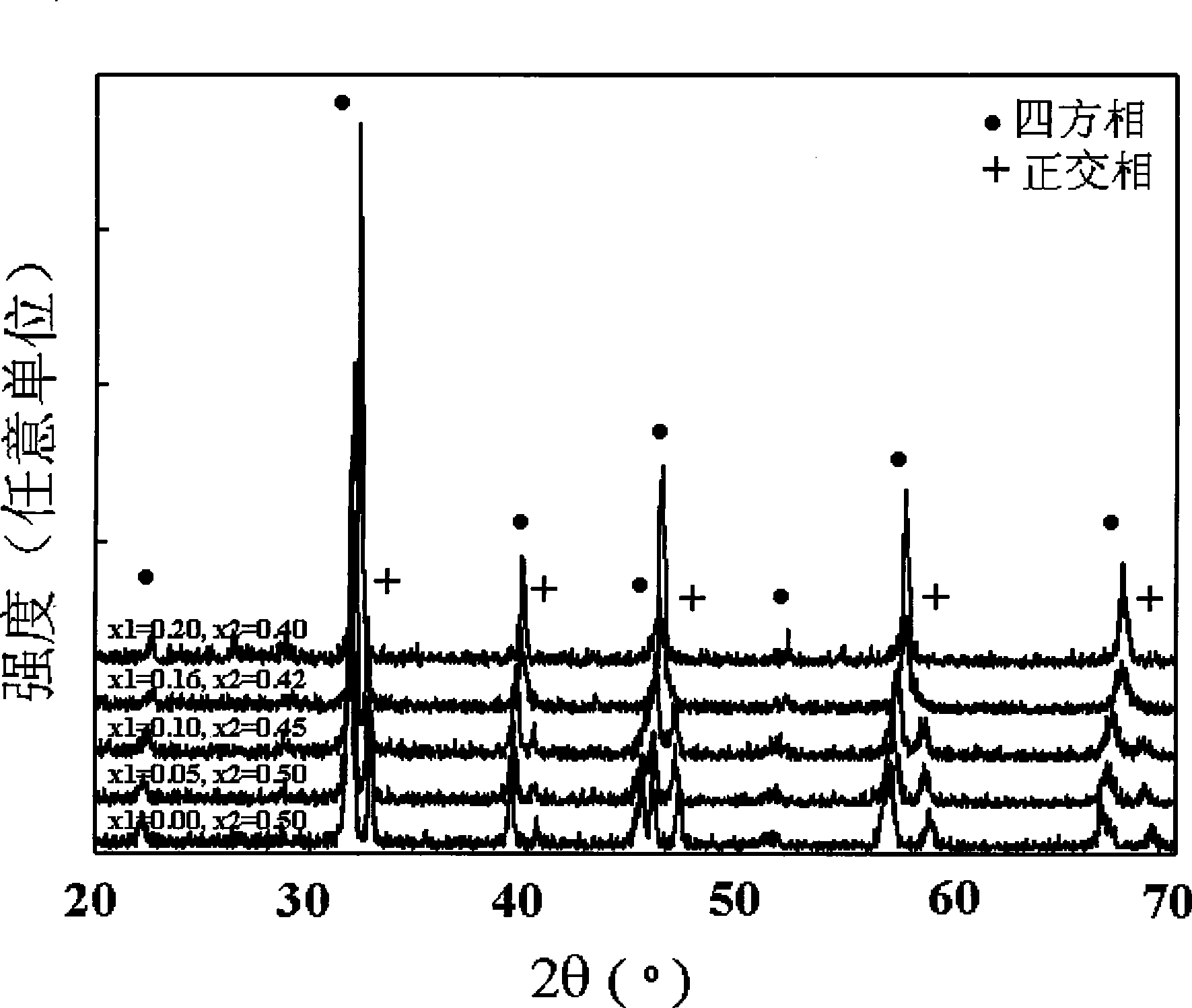

[0026] The proportioning of embodiment 1#-7# sample and each raw material weight are as shown in table 1.

[0027] Table 1.Ba 1-x1-x2-x3-y Sr x1 Ca x2 A x3 R y Ti 1-z m z o 3 Proportion and performance of composite ceramic powder

[0028]

Raw material (g)

phase structure

PL (Strong

Spend)

(612nm) ML (Strong

Spend)

(1000N) EL (strength)

(25kv / cm,

60Hz) 1 # (x1=0,

x2=0.898,

x3=0,

y=0.002,

z=0) BaCO 3 =0.7910

CaCO 3 =3.5956

PR 6 o 11 =0.0136

TiO 2 =3.1992

barium rich

(Ba, Ca)TiO 3 -

calcium rich

(Ba, Ca)TiO 3

30

10

8

2 # (x1=0.1,

x2=0.45,

x3=0,

y=0.002,

z=0) BaCO 3 =3.5436

SrCO 3 =0.5911

CaCO 3 =1.8018

PR 6 o 11 =0.0136

TiO 2 =3.1992 barium rich

(Ba,Sr,Ca)TiO 3 -

calcium rich

(Ba,Sr,Ca)TiO 3

136

23

18

3 # (x1=0,

x2=0.898,

x3=0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com