Titanium dioxide hollow nanospheres and preparation method thereof

A technology of titanium dioxide and hollow spheres, applied in the direction of titanium dioxide, chemical instruments and methods, titanium oxide/hydroxide, etc., can solve the problems of not being suitable for large-scale production, insufficient photocatalytic performance, and insufficient specific surface area, etc., to achieve improved Adsorption capacity and capture capacity, enhanced photocatalytic efficiency, uniform particle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0068] The preparation method of the titanium dioxide nano hollow spheres of the present invention is simple in operation, good in repeatability, does not need high-temperature sintering, is suitable for large-scale production, avoids agglomeration of titanium dioxide powder, has little process pollution, high product yield and low production cost.

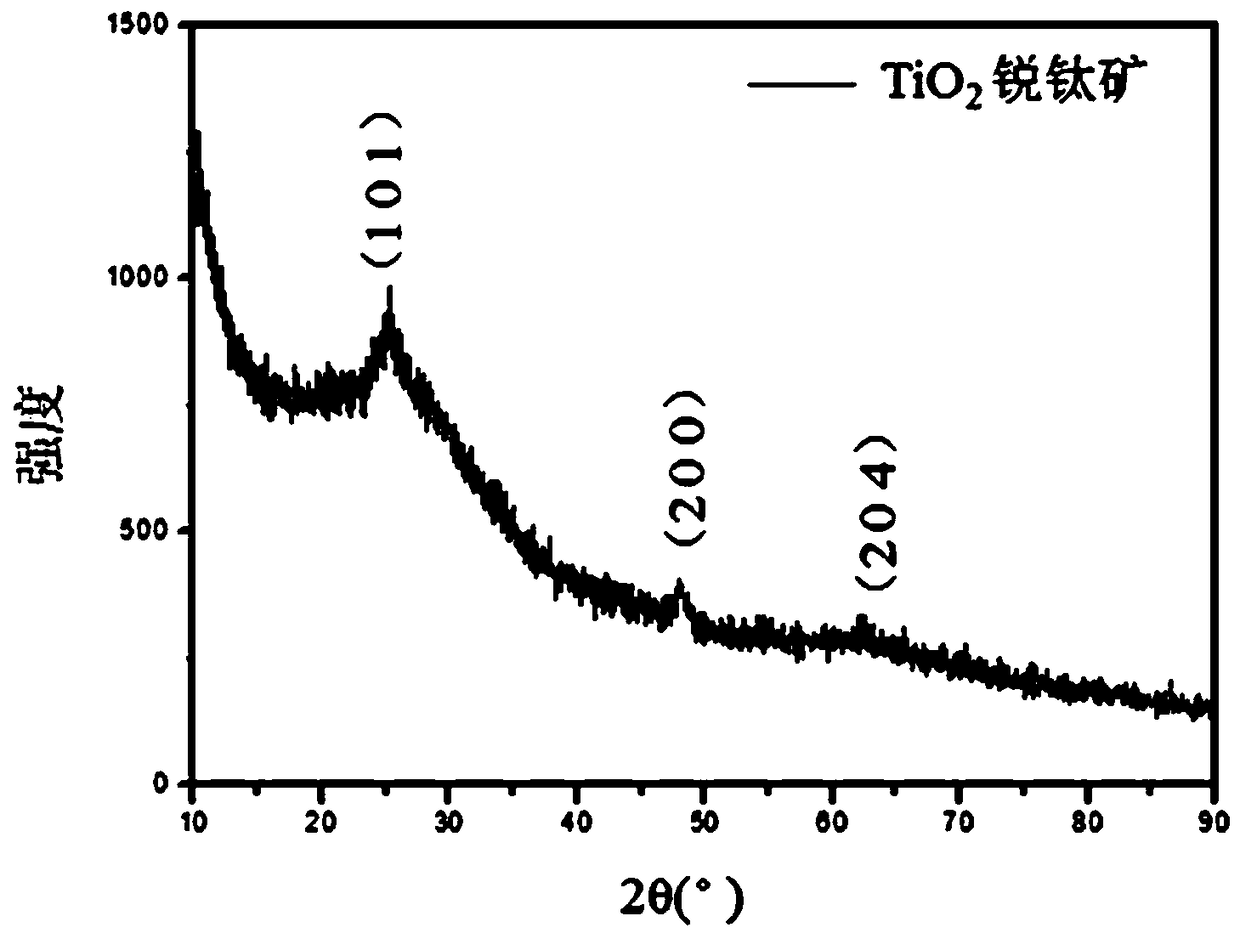

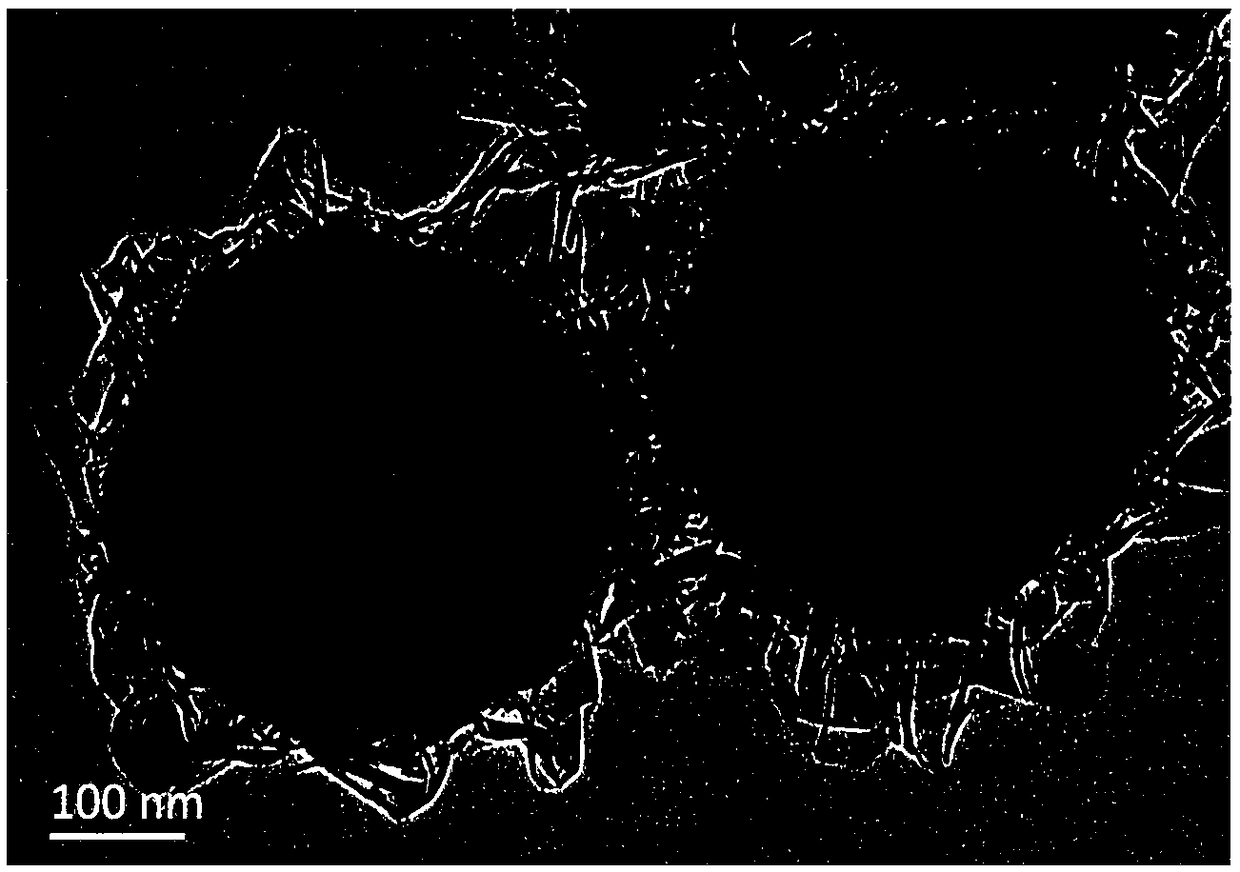

[0069] The titanium dioxide nano hollow spheres prepared by the method of the present invention have high purity, uniform particles, good crystallization, controllable crystal form, good dispersion, and many lamellar branches on the surface, which can increase the specific surface area, improve the adsorption capacity and capture of pollutants ability to enhance the photocatalytic efficiency.

Embodiment 1

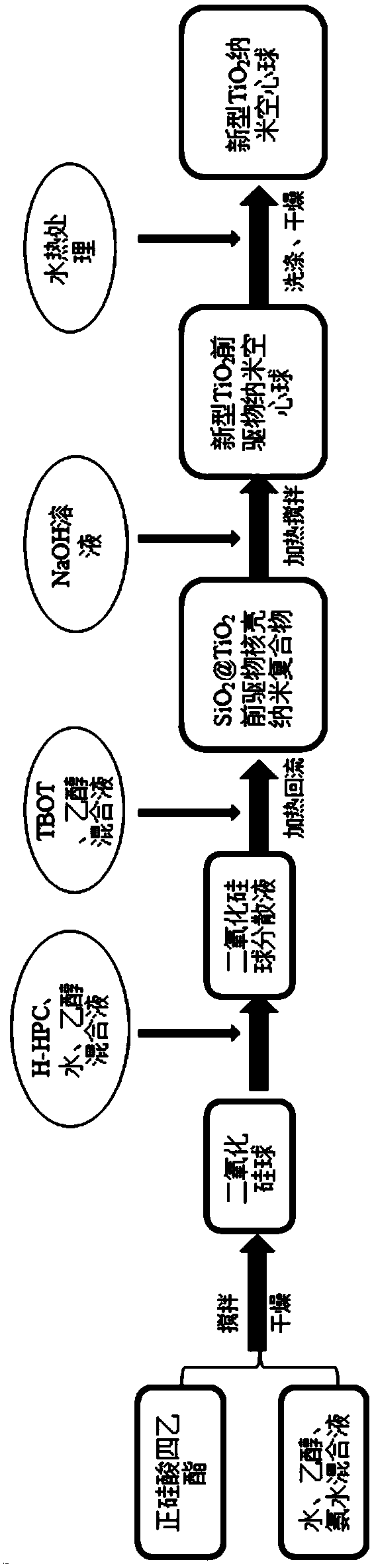

[0072] Such as figure 1 As shown, embodiment 1 proposes a kind of preparation method of titanium dioxide nano hollow sphere, specifically comprises the following steps:

[0073] 1. SiO2 2 ball preparation

[0074] 1.1. Mix water, ethanol and ammonia water according to the volume ratio of 5:37:1 to prepare solvent liquid I;

[0075] 1.2. Slowly add 0.8ml tetraethyl orthosilicate to the above solvent solution I, stir at room temperature for 8 hours, carry out hydrolysis reaction, then wash with ethanol several times, and dry at 60°C to obtain dispersed SiO 2 ball.

[0076] 2. TiO2 2 Precursor coating

[0077] 2.1. Mix water and ethanol at a volume ratio of 1:80 to prepare solvent solution II;

[0078] 2.2. Add 80 mg of highly substituted hydroxypropyl cellulose dropwise into the above solvent solution II. After fully dissolving, add 0.18g of SiO prepared in step 1 2 The balls were fully dissolved to obtain a uniform mixed solution, which was recorded as solution A;

[0...

Embodiment 2

[0090] Embodiment 2 proposes a kind of preparation method of titanium dioxide nanometer hollow sphere, specifically comprises the following steps:

[0091] 1. SiO2 2 ball preparation

[0092] 1.1. Mix water, ethanol and ammonia water according to the volume ratio of 5:38:1 to prepare solvent liquid I;

[0093] 1.2. Slowly add 1.0ml tetraethyl orthosilicate to the above solvent solution I, stir at room temperature for 10 hours, carry out hydrolysis reaction, then wash with ethanol several times, and dry at 50°C to obtain dispersed SiO 2 ball.

[0094] 2. TiO2 2 Precursor coating

[0095] 2.1. Mix water and ethanol according to the volume ratio of 1:130 to prepare solvent liquid II;

[0096] 2.2. Add 100 mg of highly substituted hydroxypropyl cellulose dropwise into the above solvent solution II. After fully dissolving, add 0.25g of SiO prepared in step 12 The balls were fully dissolved to obtain a uniform mixed solution, which was recorded as solution A;

[0097] 2.3. Mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com