Five-freedom-degree automobile seat vibration test table

A technology of vibration test bench and car seat, which is applied in vibration testing, testing of machine/structural components, measuring devices, etc. It can solve the problems of high maintenance cost, low precision, high cost, etc., and achieve environmental pollution and low noise , Simple and reasonable installation, extremely low maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

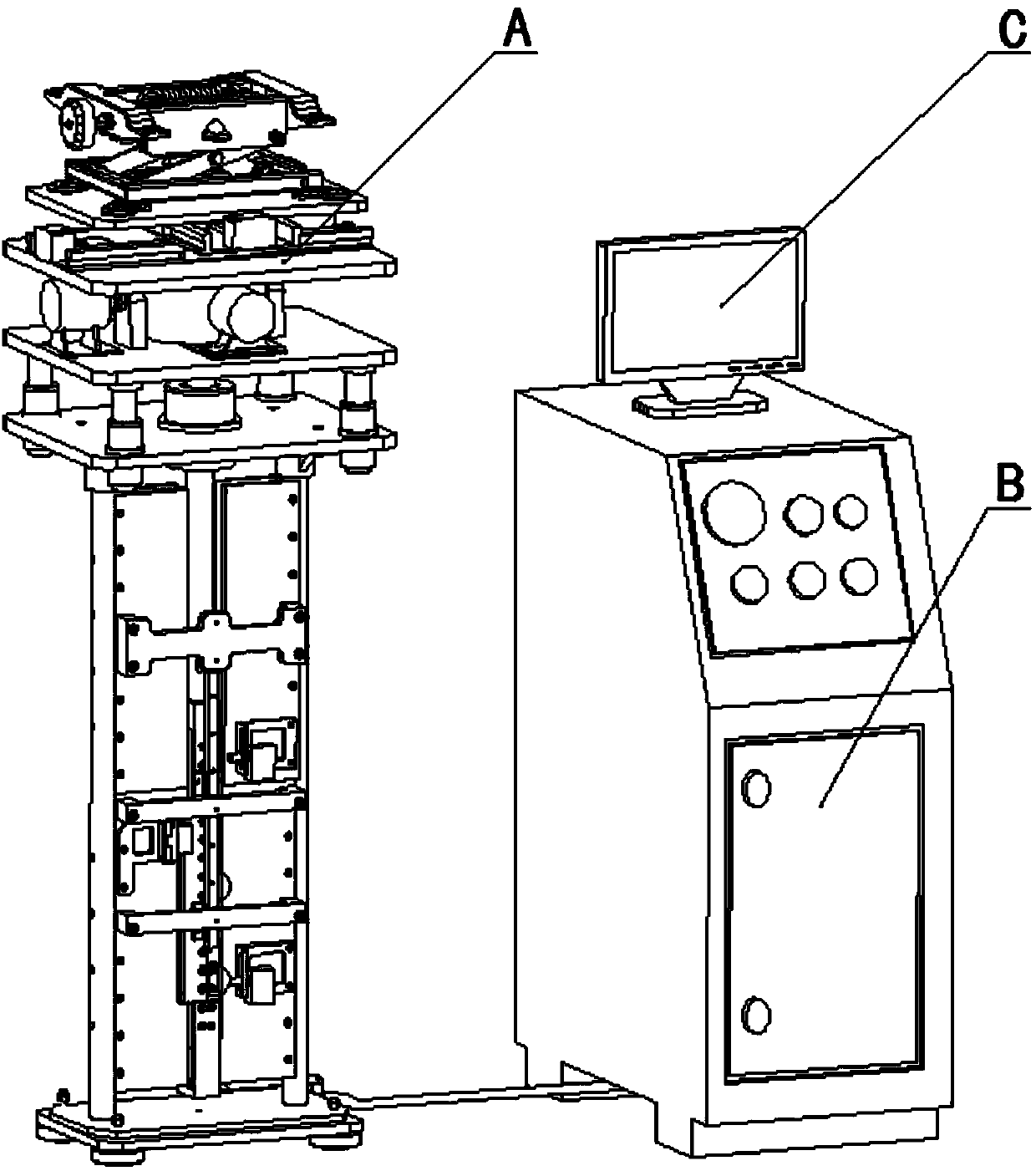

[0029] as attached figure 1 Shown: The test bench includes body part A, control system B connected to body part A, and host computer C connected to control system B.

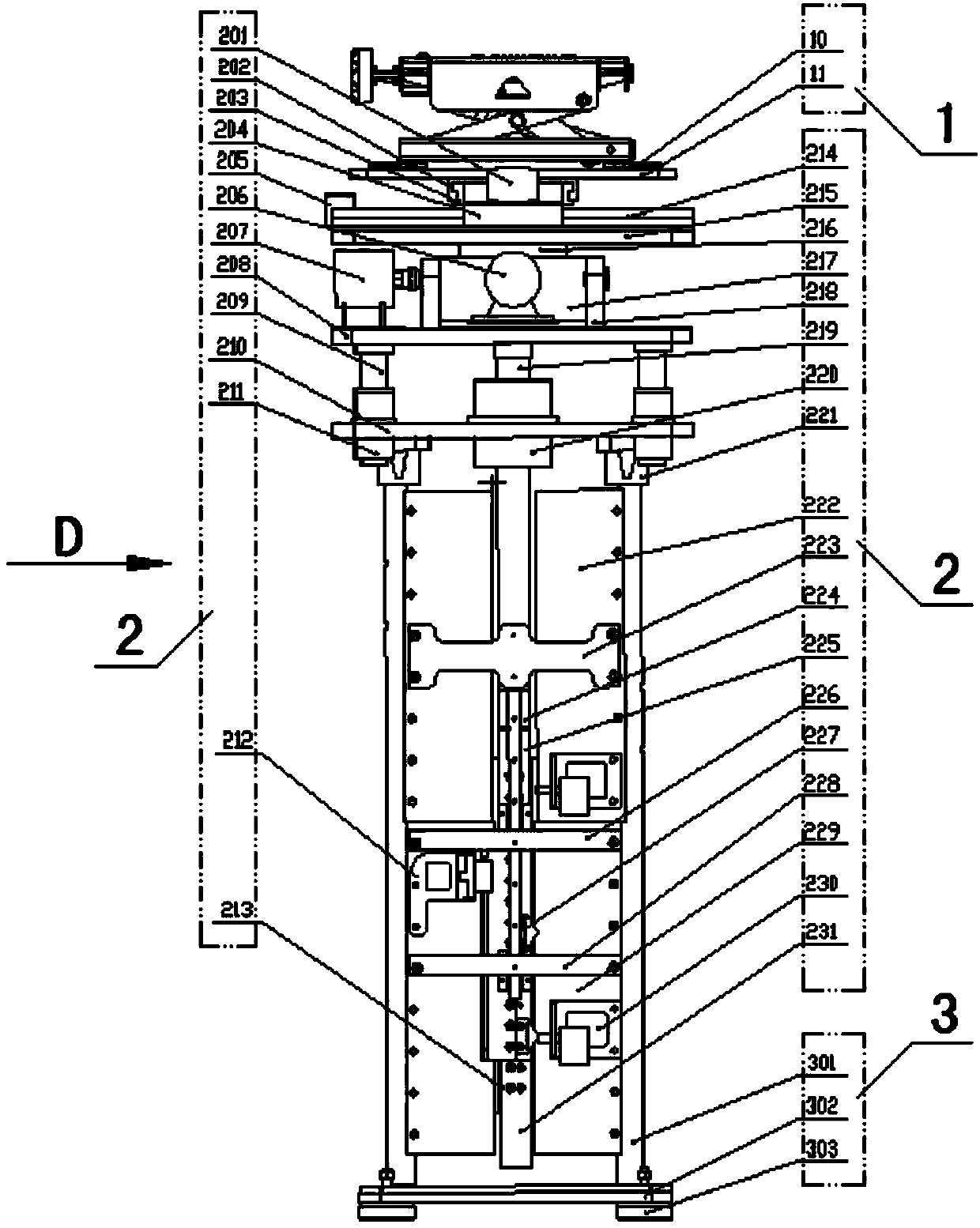

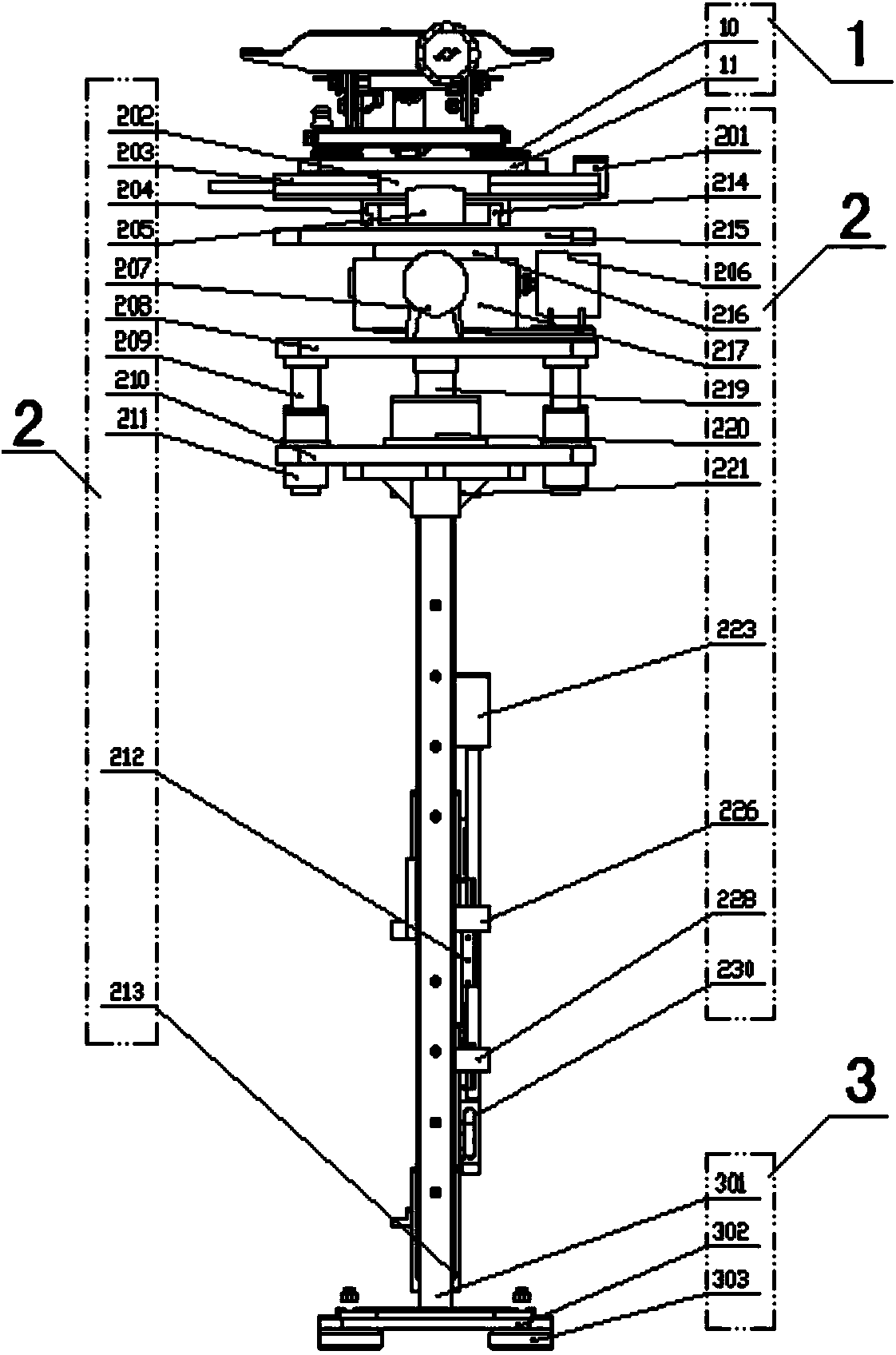

[0030] as attached figure 2 , 3 , 7 and 8: the body part A includes a clamp module 1 , a power module 2 arranged under the clamp module 1 and a bottom support module 3 arranged under the power module 2 .

[0031] The clamp module 1 is composed of a seat mounting bracket 10 and an actuating plate 11, wherein the test seat frame 10 is connected with the seat moving plate 11 through bolts, and the seat moving plate 11 is connected with the longitudinal direction of the power module 2 through bolts. Rail sliders 202 are coupled.

[0032]The power module 2 includes a longitudinal push rod motor 201, a coupling 2011, a ball screw 2012, a longitudinal guide rail slider 202, a longitudinal guide rail 203, a transverse guide rail slider 204, a transverse push rod motor 205, and a coupling 2051 , ball screw 2052, rol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com