Gas burner

A technology for gas stoves and burners, which is applied to burners, combustion methods, combustion types, etc., can solve the problems of high noise affecting personal health, poor combustion effect, and high use costs, and ensure personal health, environmental pollution and low noise. , the effect of reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] Describe in detail below in conjunction with accompanying drawing and embodiment:

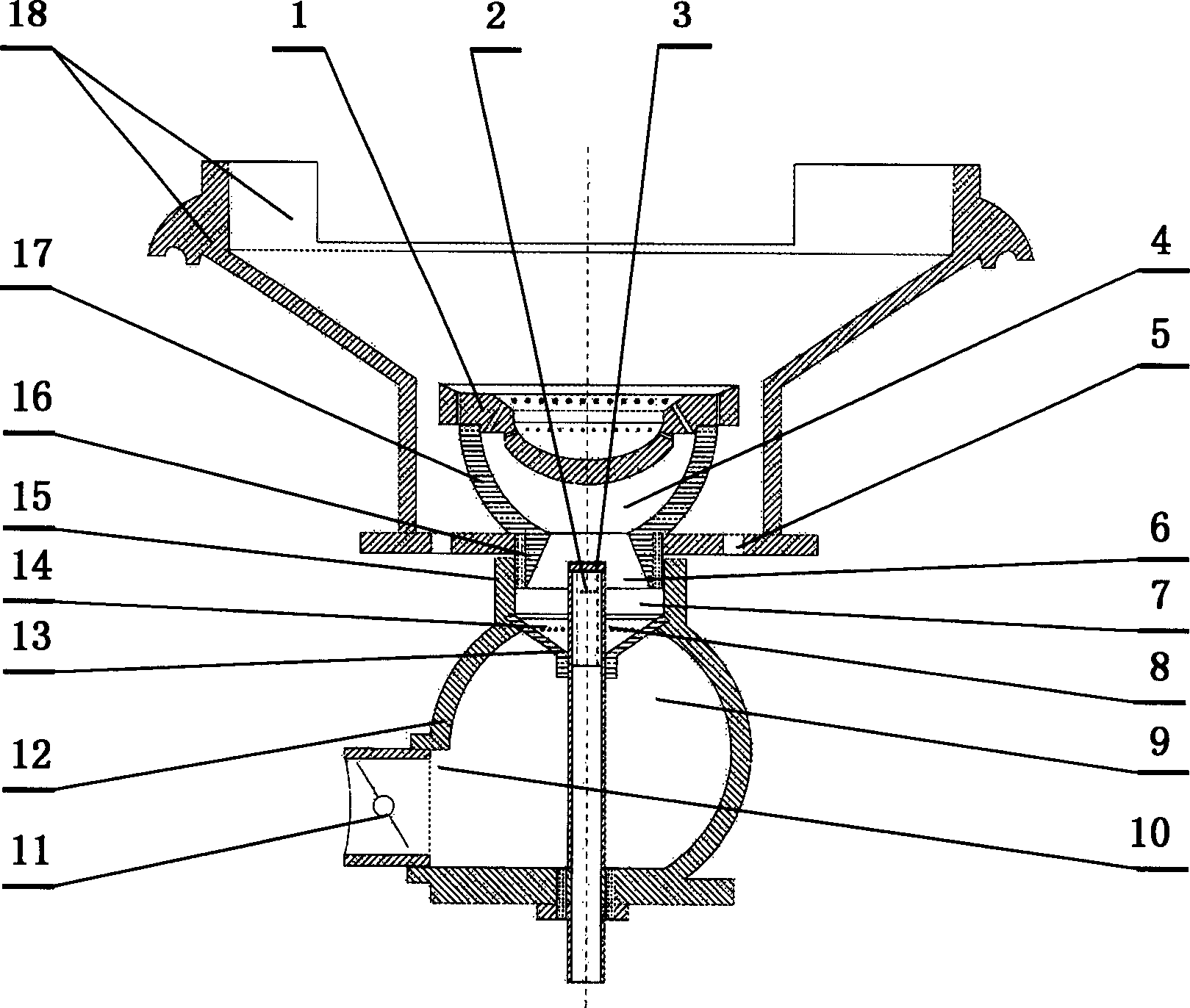

[0009] In the figure is a gas burner using a blower to blow air, which not only includes a double spherical gap flat-bottomed diffusion chamber 4, a conical truncated air injection chamber 6, and a mixing chamber 7, which are sequentially arranged in the burner body and communicated in sequence, and also includes a top The center communicates with the circular body wind collecting chamber 9 on the bottom of the mixing chamber 7, and the side of the circular body wind collecting chamber 9 is provided with an air inlet 10. The air inlet 10 provided on the side of the circular air collecting chamber 9 is connected to the blower, and the wind energy blown by the blower is gathered together through the provided circular air collecting chamber 9, and the gas is collected through the cylindrical mixing chamber 7 and The air outlet hole 2 of the pipe is set in the cylindrical mixing chamber 2 so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com