Special modified calcium carbonate for caking prevention of fertilizer and preparation method of modified calcium carbonate

A calcium carbonate and anti-caking technology, which is applied in the fields of application, organic fertilizers, inorganic fertilizers, etc., can solve the problems of poor powder modification effect, large amount of anti-caking agent, and increased fertilizer costs, etc., to achieve inhibition of diffusion, contact Effects of Angle Enlargement, Lifting Wrapping and Modification Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

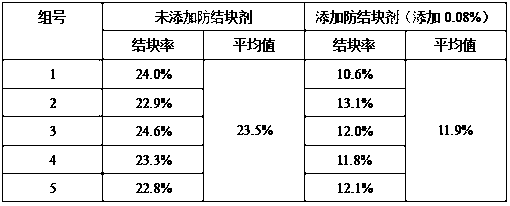

Embodiment 1

[0017] After crushing, grinding and grading natural marble to obtain 1000-mesh calcium carbonate; 65% of 1000-mesh calcium carbonate is first stirred with 22% liquid paraffin at high speed and constant temperature for 2 hours, that is, primary modified calcium carbonate is obtained by dry mixing; Then 10% water-soluble natural polysaccharide is dissolved in hot water at 50°C to obtain a 20wt% water-soluble natural polysaccharide solution, and further the primary modified calcium carbonate, 20wt% water-soluble natural polysaccharide solution, and 3% surfactant are added in sequence Go to the ball milling equipment with heat preservation device, and wet ball mill for 3 hours under the heat preservation condition of 50°C; finally, after drying, depolymerization, and packaging processes, the modified calcium carbonate specially used for anti-caking of chemical fertilizers is obtained.

[0018] The indicators of the special modified calcium carbonate for preventing caking of chemica...

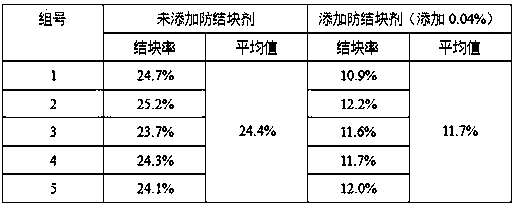

Embodiment 2

[0028] After the natural marble is crushed, ground and classified to obtain 1000 mesh calcium carbonate; 55% of the 1000 mesh calcium carbonate is first stirred with 25% liquid paraffin at high speed and constant temperature for 3 hours, that is, the primary modified calcium carbonate is obtained by dry mixing; Then 15% water-soluble natural polysaccharide is dissolved in hot water at 60°C to obtain a 25wt% water-soluble natural polysaccharide solution, and the primary modified calcium carbonate, 25wt% water-soluble natural polysaccharide solution, and 5% surfactant are added in sequence Go to the ball milling equipment with heat preservation device, and wet ball mill for 5 hours under the heat preservation condition of 60°C; finally, after drying, depolymerization, and packaging processes, the modified calcium carbonate specially used for anti-caking of chemical fertilizers is obtained.

[0029] The indicators of the special modified calcium carbonate for preventing caking of ...

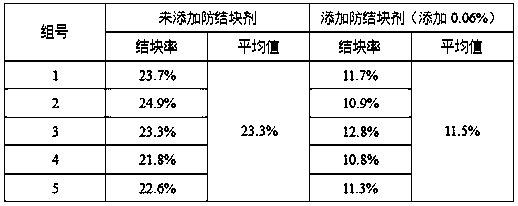

Embodiment 3

[0039]After crushing, grinding and grading natural marble to obtain 1000-mesh calcium carbonate; 60% of 1000-mesh calcium carbonate is first stirred with 23% liquid paraffin at high speed and constant temperature for 2.3 hours, that is, primary modified calcium carbonate is obtained by dry mixing Then 13% water-soluble natural polysaccharide is dissolved in 53 ℃ of hot waters, obtains 22wt% water-soluble natural polysaccharide solution, further described primary modified calcium carbonate and 22wt% water-soluble natural polysaccharide solution, 4% tensio-active agent Add it to the ball milling equipment with heat preservation device, and wet ball mill for 4 hours under the heat preservation condition of 53°C; finally, after drying, depolymerization, and packaging processes, the modified calcium carbonate specially used for anti-caking of chemical fertilizers is obtained.

[0040] The indicators of the special modified calcium carbonate for preventing caking of chemical fertiliz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com