Method for reducing supercooling degree of alkane phase change microcapsule by using different shell materials, microcapsule prepared by method and application of microcapsule

A technology of phase change microcapsules and alkanes, which is applied in the field of microcapsules, can solve the problems of uneven distribution of nucleating agents, reduction of enthalpy value of phase change microcapsules, reduction of supercooling degree, etc., to achieve uniform particle size and low cost , the effect of reducing supercooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

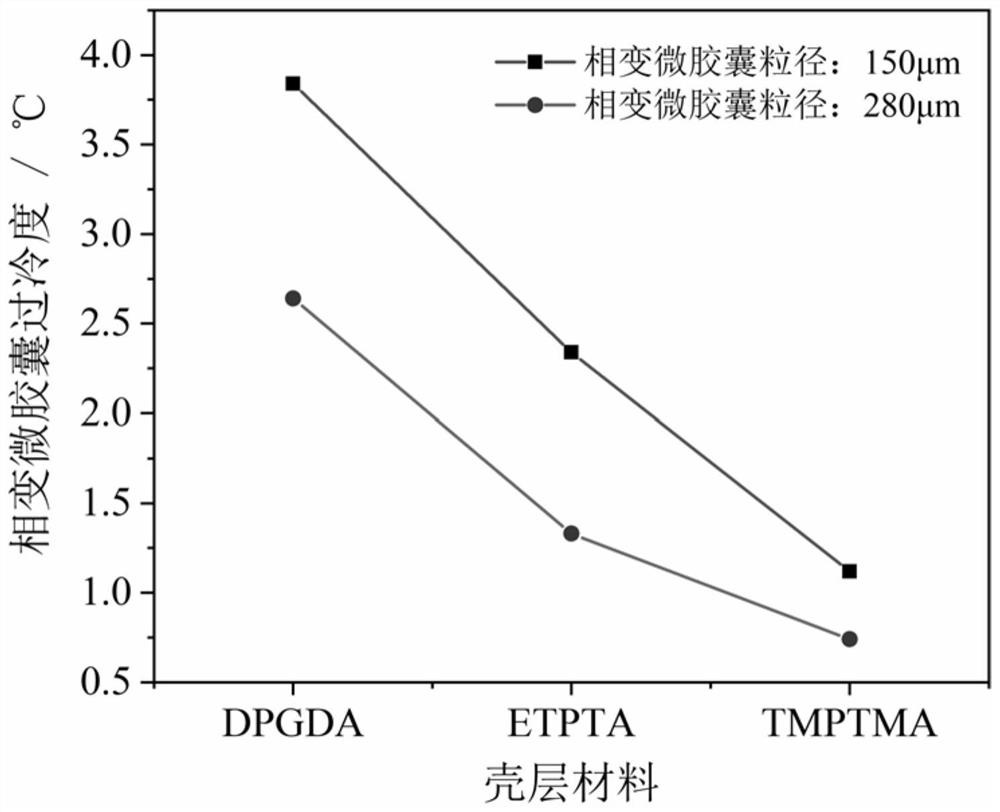

[0029] (1) Preparation of dispersed phase: 5 g of purchased high-purity octadecane was weighed as the dispersed phase.

[0030] (2) Preparation of intermediate phase: Weigh 0.2g of Span 80, 0.4g of 2-hydroxy-2-methyl-1-phenyl-1-propanone and 19.4g of dipropylene glycol diacrylate (DPGDA) in In a 50ml beaker, under the conditions of 25°C and 500r / min, stir continuously for 30min to ensure uniform stirring, as the intermediate phase.

[0031] (3) Preparation of continuous phase and collection phase: Weigh 10g of polyvinyl alcohol (PVA) and pour it into 490ml of deionized water, and keep stirring for 30min at 70°C and 800r / min to ensure that PVA is evenly dispersed in deionized water. In water, the mixed solution obtained by stirring evenly was used as the continuous phase and the collection phase.

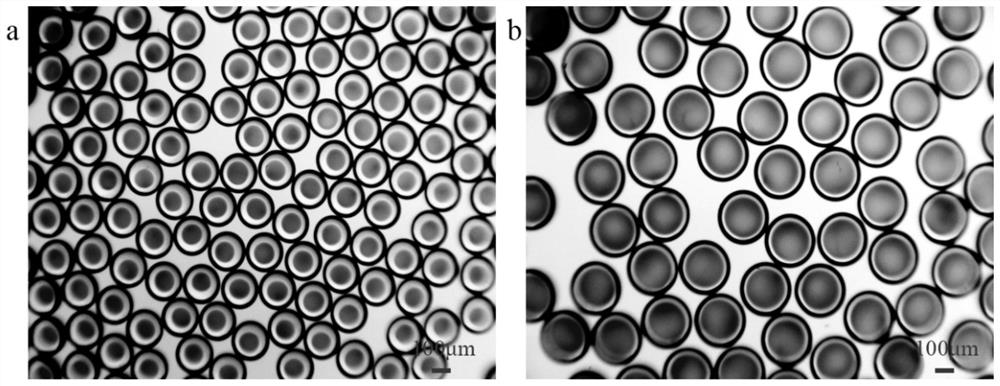

[0032] (4) Using the double-emulsified glass capillary microfluidic chip in the Chinese invention patent application number 201811008829.0 as the microfluidic chip, the octadecane d...

Embodiment 2

[0036] (1) Preparation of dispersed phase: 5 g of purchased high-purity octadecane was weighed as the dispersed phase.

[0037] (2) Preparation of intermediate phase: Weigh 0.2g of Span 80, 0.4g of 2-hydroxy-2-methyl-1-phenyl-1-propanone and 19.4g of dipropylene glycol diacrylate (DPGDA) in In a 50ml beaker, under the conditions of 25°C and 500r / min, stir continuously for 30min to ensure uniform stirring, as the intermediate phase.

[0038] (3) Preparation of continuous phase and collection phase: Weigh 10g of polyvinyl alcohol (PVA) and pour it into 490ml of deionized water, and keep stirring for 30min at 70°C and 800r / min to ensure that PVA is evenly dispersed in deionized water. In water, the mixed solution obtained by stirring evenly was used as the continuous phase and the collection phase.

[0039] (4) Using the double-emulsified glass capillary microfluidic chip in the Chinese invention patent application number 201811008829.0 as the microfluidic chip, the octadecane d...

Embodiment 3

[0043] (1) Preparation of dispersed phase: 5 g of purchased high-purity octadecane was weighed as the dispersed phase.

[0044] (2) Preparation of the intermediate phase: Weigh 0.2g Span 80, 0.4g 2-hydroxy-2-methyl-1-phenyl-1-propanone and 19.4g trimethylolpropane triacrylate (TMPTA ) placed in a 50ml beaker, under the conditions of 25°C and 500r / min, continuously stirred for 30min to ensure uniform stirring, as the intermediate phase.

[0045] (3) Preparation of continuous phase and collection phase: Weigh 10g of polyvinyl alcohol (PVA) and pour it into 490ml of deionized water, and keep stirring for 30min at 70°C and 800r / min to ensure that PVA is evenly dispersed in deionized water. In water, the mixed solution obtained by stirring evenly was used as the continuous phase and the collection phase.

[0046] (4) Using the double-emulsified glass capillary microfluidic chip in the Chinese invention patent application number 201811008829.0 as the microfluidic chip, the octadeca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com