Graphene oxide nano inorganic phase-change material and preparation method thereof

A technology of phase change materials and graphene, which is applied in the field of phase change energy storage, can solve problems such as the stability of nano phase change materials, and achieve good cycle stability, reduce supercooling, and promote the effect of specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

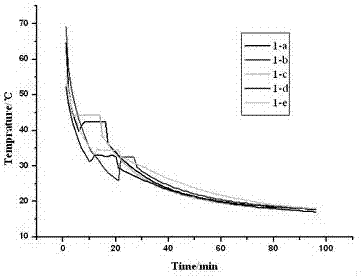

Embodiment 1

[0020] 1) Dissolve graphene oxide in distilled water, disperse with low-temperature ultrasonic for 120 minutes, disperse into a graphene oxide aqueous solution with a concentration of 0.015g / ml, and seal it for use;

[0021] 2) Add 80 g of CH 3 COONa·3H 2 O is mixed with 2 grams of KCl and heated at 80°C to make the main heat agent. The phase transition temperature range is 40-50°C, the phase transition enthalpy is 180-190j / g, and the supercooling degree is about 15°C;

[0022] 3) Slowly add 1 gram of sodium carboxymethylcellulose into the main heating agent in step 2), and stir evenly under high-speed shearing conditions;

[0023] 4) Add 0.1 g of the ultrasonically dispersed graphene oxide aqueous solution prepared in step 1) to step 3), stir in a water bath ultrasonically, seal and place it, and the product is obtained.

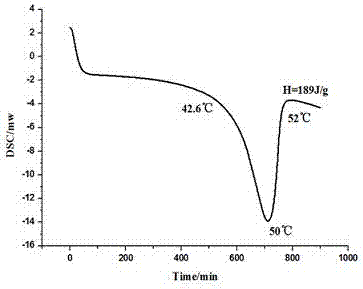

[0024] The phase change temperature range of the nano graphene oxide phase change material is 42~52°C, the degree of supercooling is reduced to 2°C, the ...

Embodiment 2

[0026] 1) Dissolve graphene oxide in distilled water, disperse with low-temperature ultrasonic for 130 minutes, disperse into a graphene oxide aqueous solution with a concentration of 0.015g / ml, and seal it for use;

[0027] 2) Add 82 g of CH 3 COONa·3H 2 O is mixed with 4 grams of KCl and heated at 80°C to make the main heat agent. The phase transition temperature range is 40-50°C, the phase transition enthalpy is 180-190j / g, and the supercooling degree is about 15°C;

[0028] 3) Slowly add 2 grams of sodium carboxymethylcellulose into the main heating agent in step 2), and stir evenly under high-speed shearing conditions;

[0029] 4) Add 0.2 g of the ultrasonically dispersed graphene oxide aqueous solution prepared in step 1) to step 3), stir in a water bath ultrasonically, seal and place it, and the product is obtained.

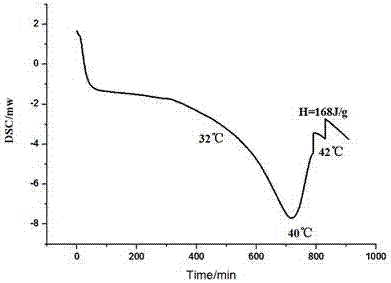

[0030] The phase change temperature range of the nano-graphene oxide phase change material is 32~42°C, the undercooling degree is reduced to 4°C, the ph...

Embodiment 3

[0032] 1) Dissolve graphene oxide in distilled water, disperse with low-temperature ultrasonic for 130 minutes, disperse into a graphene oxide aqueous solution with a concentration of 0.015g / ml, and seal it for use;

[0033] 2) Add 84 g of CH 3 COONa·3H 2 O is mixed with 6 grams of KCl and heated at 80°C to make the main heat agent. The phase transition temperature range is 40-50°C, the phase transition enthalpy is 180-190j / g, and the supercooling degree is about 15°C;

[0034] 3) Slowly add 4 grams of sodium carboxymethylcellulose into the main heating agent in step 2), and stir evenly under high-speed shearing conditions;

[0035] 4) Add 0.3 g of the ultrasonically dispersed graphene oxide aqueous solution prepared in step 1) to step 3), stir in a water bath ultrasonically and place it in a sealed seal to obtain the product;

[0036] The phase change temperature range of the nano-graphene oxide phase change material is 45~52°C, the undercooling degree is reduced to 1°C, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com