Production method for improving insulating property by adding trace elements in oriented silicon steel barrier-coat

A technology of oriented silicon steel and trace elements, which is applied in the field of improving insulation performance and adding trace elements to the isolation coating of oriented silicon steel, can solve the problems of high comprehensive cost, high heating temperature of slab, difficult production in cold rolling process, etc. Magnesium oxide bottom layer quality, good adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] 1. Use a 500 kg vacuum furnace to smelt steel according to the method of step (1) and obtain the two final components of A and B in Table 1, and hot-roll according to the method of step (2). The specific optimal conditions for hot rolling are shown in Table 2:

[0070]Table 1. Steelmaking composition of experimental steel (wt%)

[0071]

[0072] Table 2. Experimental steel hot rolling conditions (°C)

[0073]

[0074] 2. According to step (3) normalization plus pickling step, first normalize annealing at a temperature of 1120°C, normalization annealing time is 5s, then normalization annealing at a temperature of 900°C, normalization annealing time is 60s, normalization annealing Cooling after chemical annealing, the cooling rate is 50°C / s; pickling conditions after normalizing annealing: pickling in 5wt% hydrochloric acid solution, that is, the specific preferred normalizing conditions are: 1120°C×5s+900°C×60s+50°C / s cooldown;

[0075] 3. According to step (4...

Embodiment 2

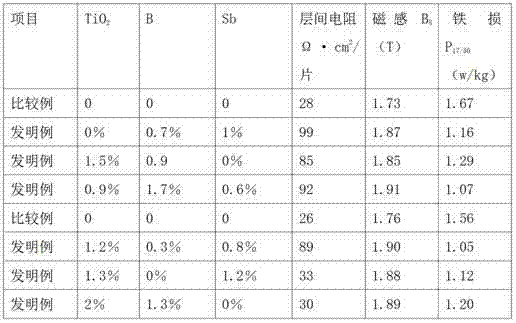

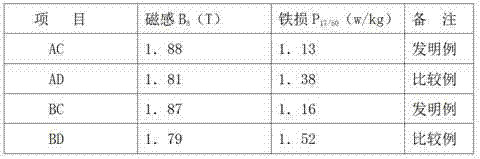

[0080] The steel strip obtained with the A component in the middle of the above table 1 and the C hot rolling condition in the table 2 is carried out the nitriding experiment in the early stage of the high temperature annealing stage according to the above method, after the normalization annealing of the step (3), the nitriding experiment of the step (4) The effects of cold rolling, decarburization annealing in step (5), and the addition of different types and quantities of elements in the magnesium oxide coating on the interlayer resistance of the magnesium silicate bottom layer on the surface of the silicon steel strip are shown in Table 4. The magnesium oxide coating The layer is made of an annealing spacer with magnesium oxide as the main component. The weight of the annealing spacer in Table 4 is 100 kg. The annealing spacer includes MgO, B and TiO 2 , wherein 0.01-0.10wt% of the mass of the annealing spacer is added with B, and 0.01-0.30wt% of the mass of the annealing sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com