Roll crusher

A roller crusher and roller technology, which is applied in the field of mining machinery, can solve the problems of inconvenient operation and inaccurate particle size control, and achieve the effects of convenient operation, precise particle size control and high control accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below in conjunction with accompanying drawing embodiment:

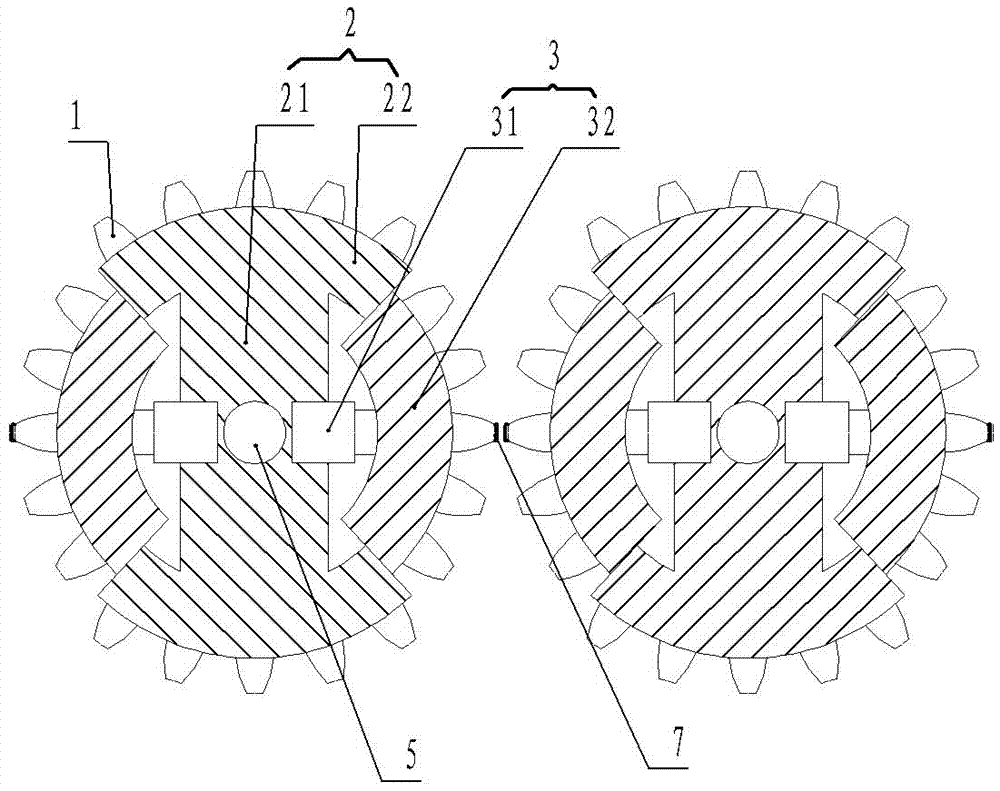

[0012] figure 1 The shown roller crusher includes two rollers side by side, each roller has a sawtooth 1 on its outer wall, and each roller is driven to rotate by its own mandrel 5; each roller includes radial The fixed portion 2 and the radial extension portion 3; the radial fixed portion 2 includes a bearing mounting portion 21 and a first arc portion 22, the mandrel 5 is mounted on the core of the bearing mounting portion 21, and the first arc portion 22 has Two, respectively located at the two outer ends of the bearing mounting part 21; the radial extension part 3 includes two power cylinders 31 and two second arc parts 32, and the fixing parts of the two power cylinders 31 are respectively worn and fixed on On both sides of the bearing installation part 21 facing each other, the protruding ends of the two power cylinders 31 are respectively fixedl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com