Patents

Literature

57results about How to "High precision control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

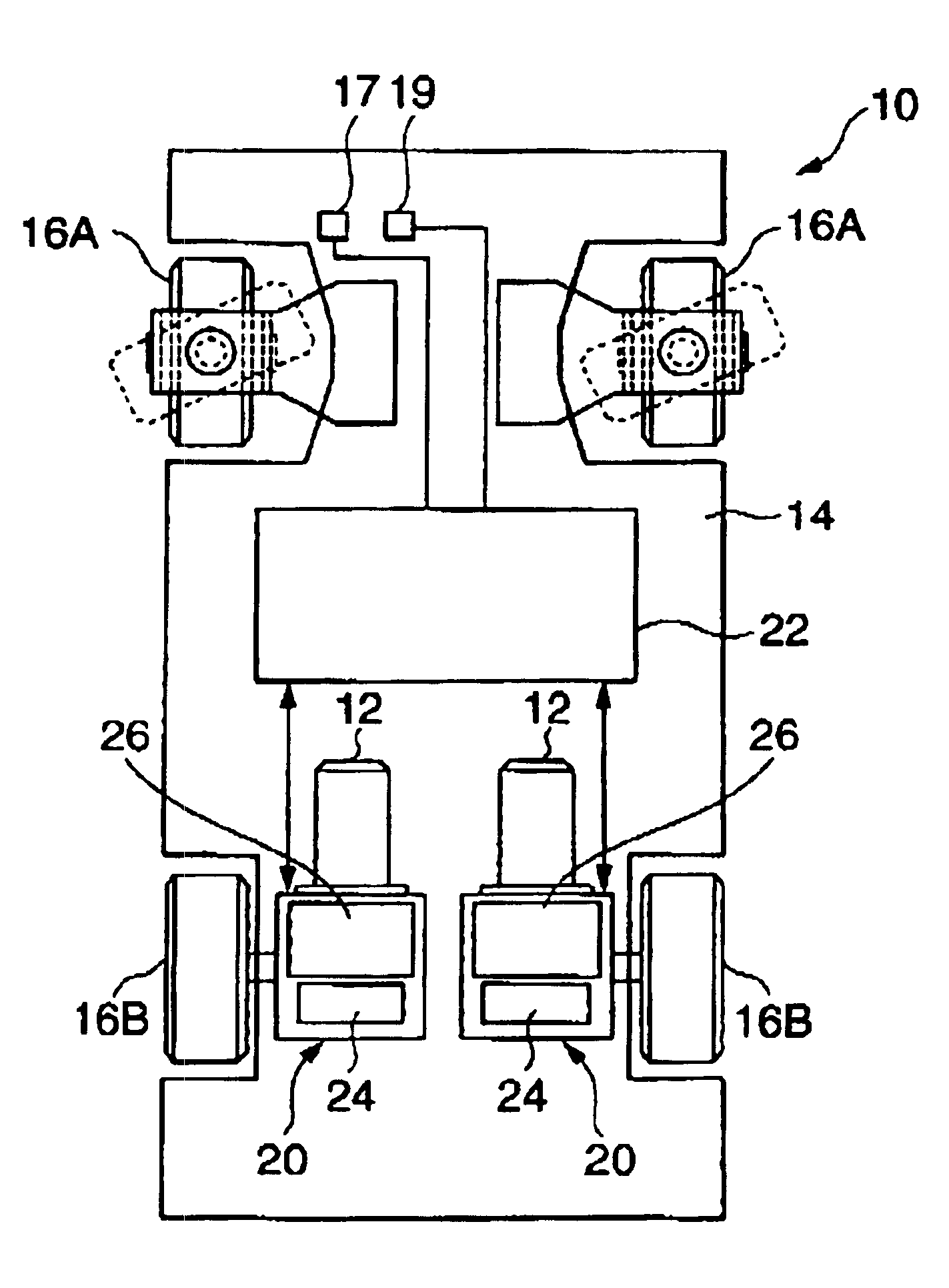

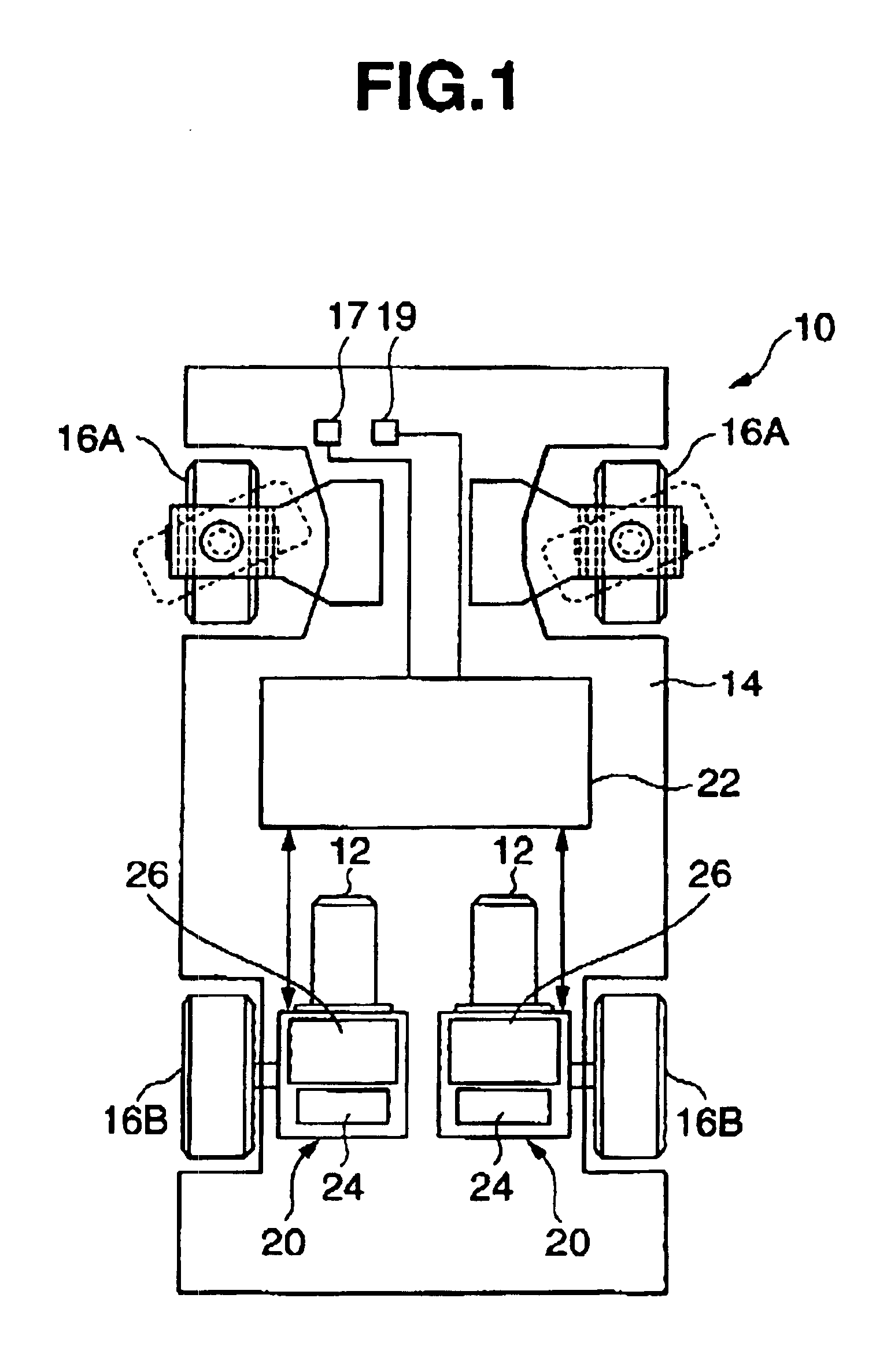

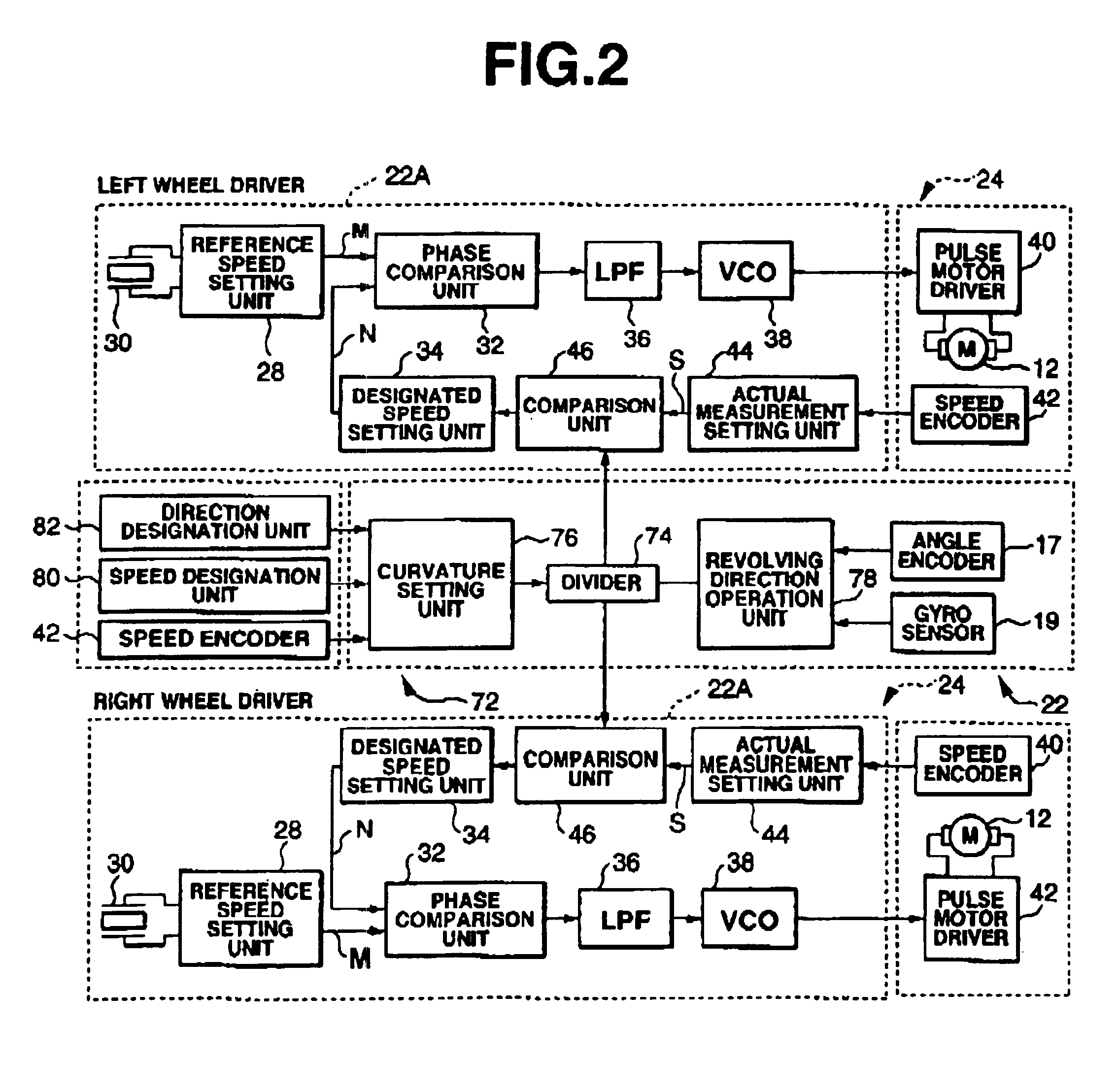

Direction control device of control target

InactiveUS6988570B2Quickly and accurately realizingChange directionSpeed controllerDC motor speed/torque controlDrive wheelControl objective

The left and right rear drive wheels of a vehicle are controlled independently, and the traveling direction of the vehicle is changed by providing a rotational speed difference between each of the left and right rear drive wheel. A vehicle operator merely designates the turning direction by moving an operation stick, e.g., to the left or right, which will in turn enable an automatic turn at an optimum curvature to be performed which frees the vehicle operator from complicated steering operations. A highly precise and responsive turn is achieved when the left and right independent control is implemented with a PLL control circuit.

Owner:PARKSIDE IP LLC

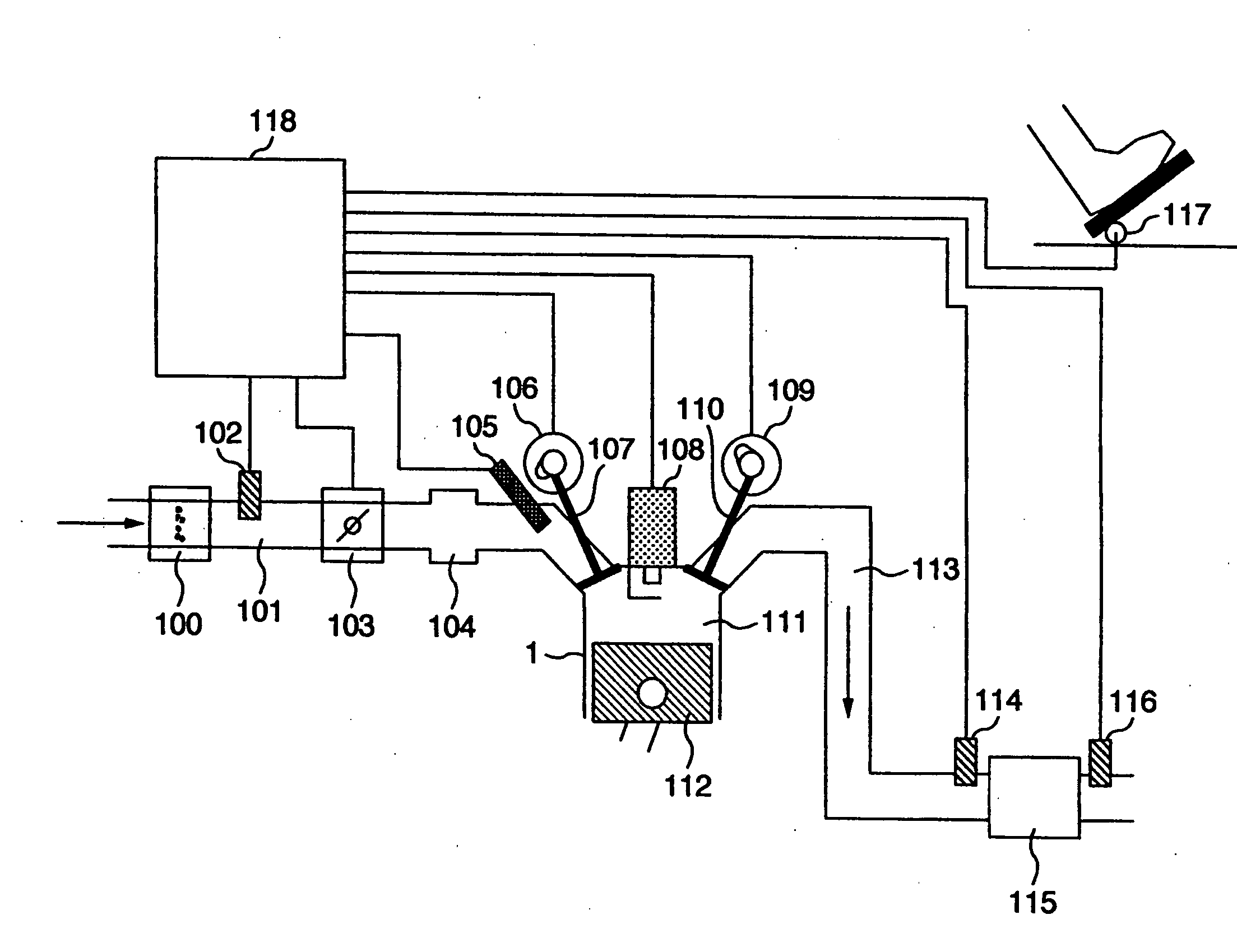

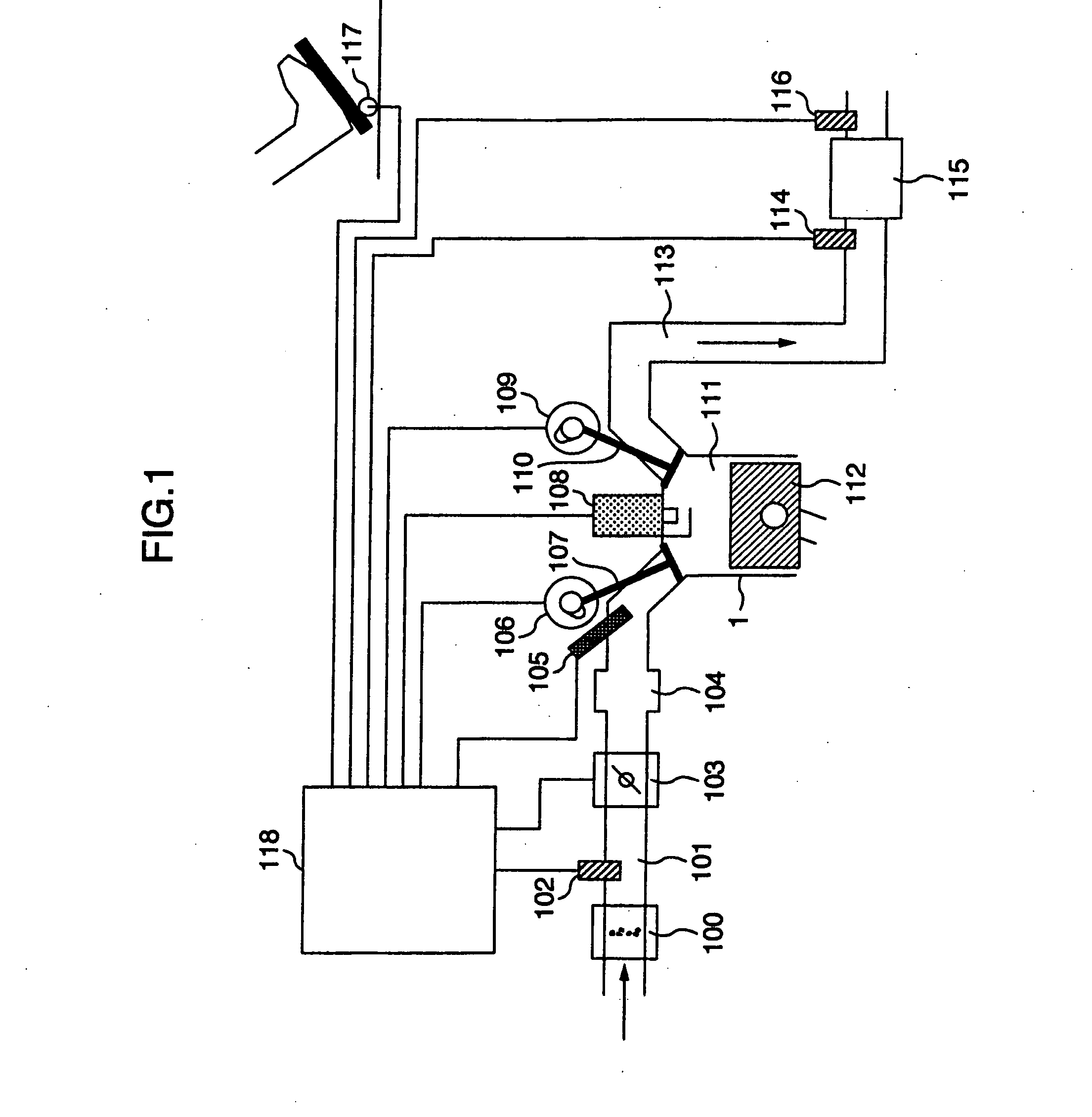

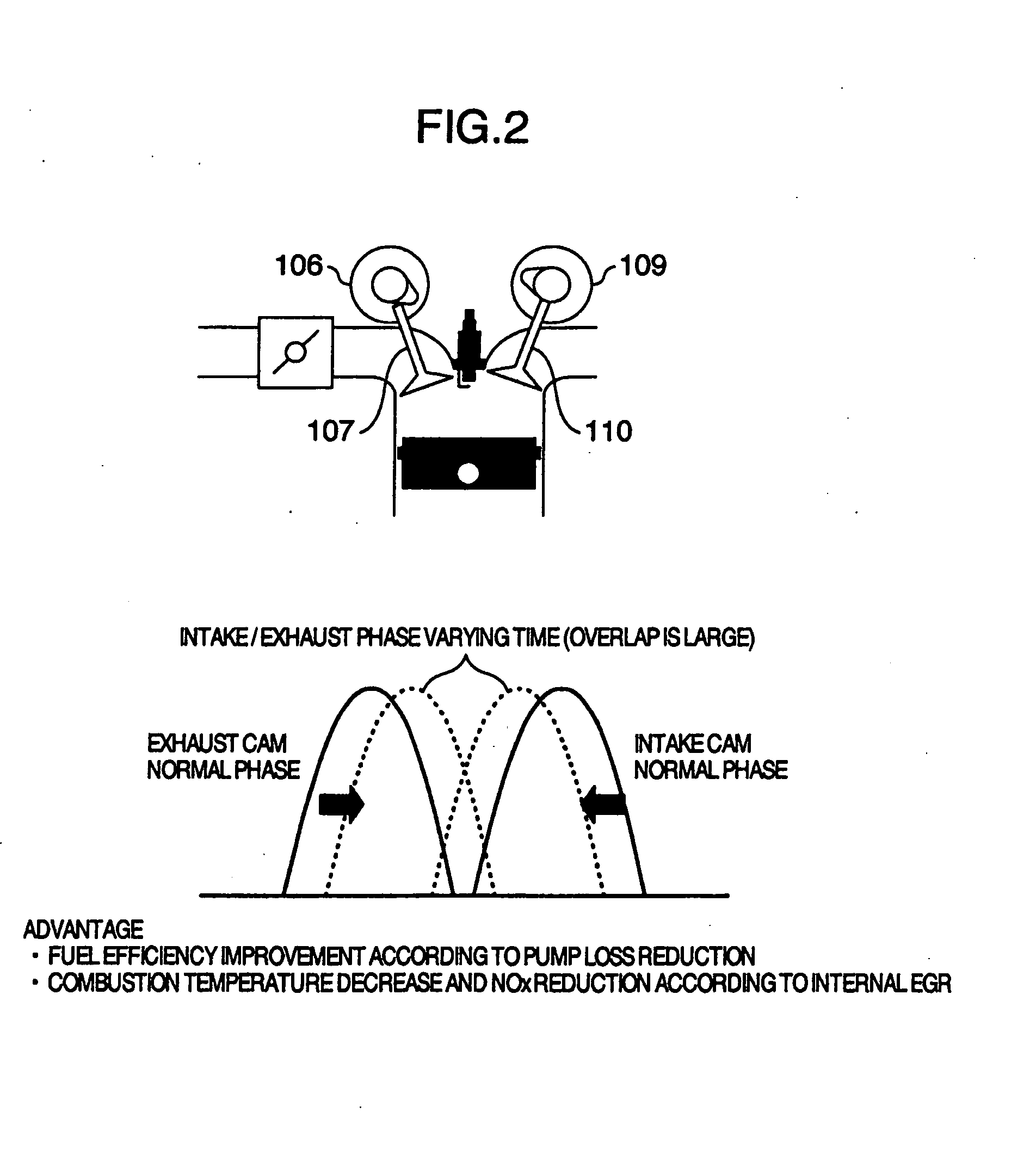

Control Method and Control Device for Engine

InactiveUS20090017987A1High-precise engine torque controlHigh precision controlElectrical controlInternal combustion piston enginesIgnition delayIgnition timing

In a control method and control device for an engine, in order to prevent torque control precision from deteriorating while performing an ignition retard control in a variable valve engine, when a torque down control is carried out by using the ignition retard, combustion duration is calculated in consideration of valve timing or an engine rpm for each driving state, and a characteristic of a reference ignition timing efficiency curve is corrected on the basis of a difference between the combustion duration and a combustion duration reference value which is set in advance.

Owner:HITACHI LTD

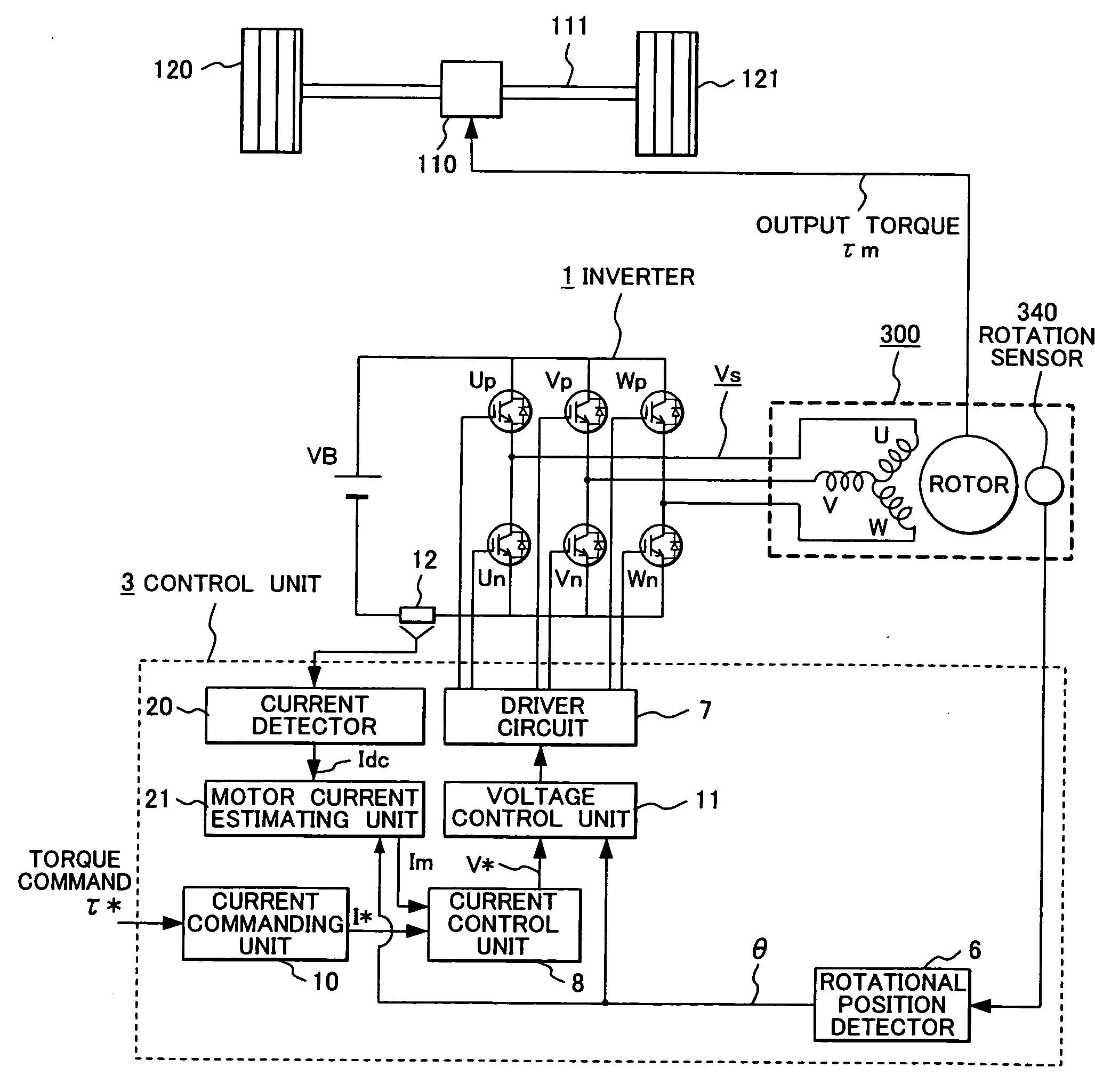

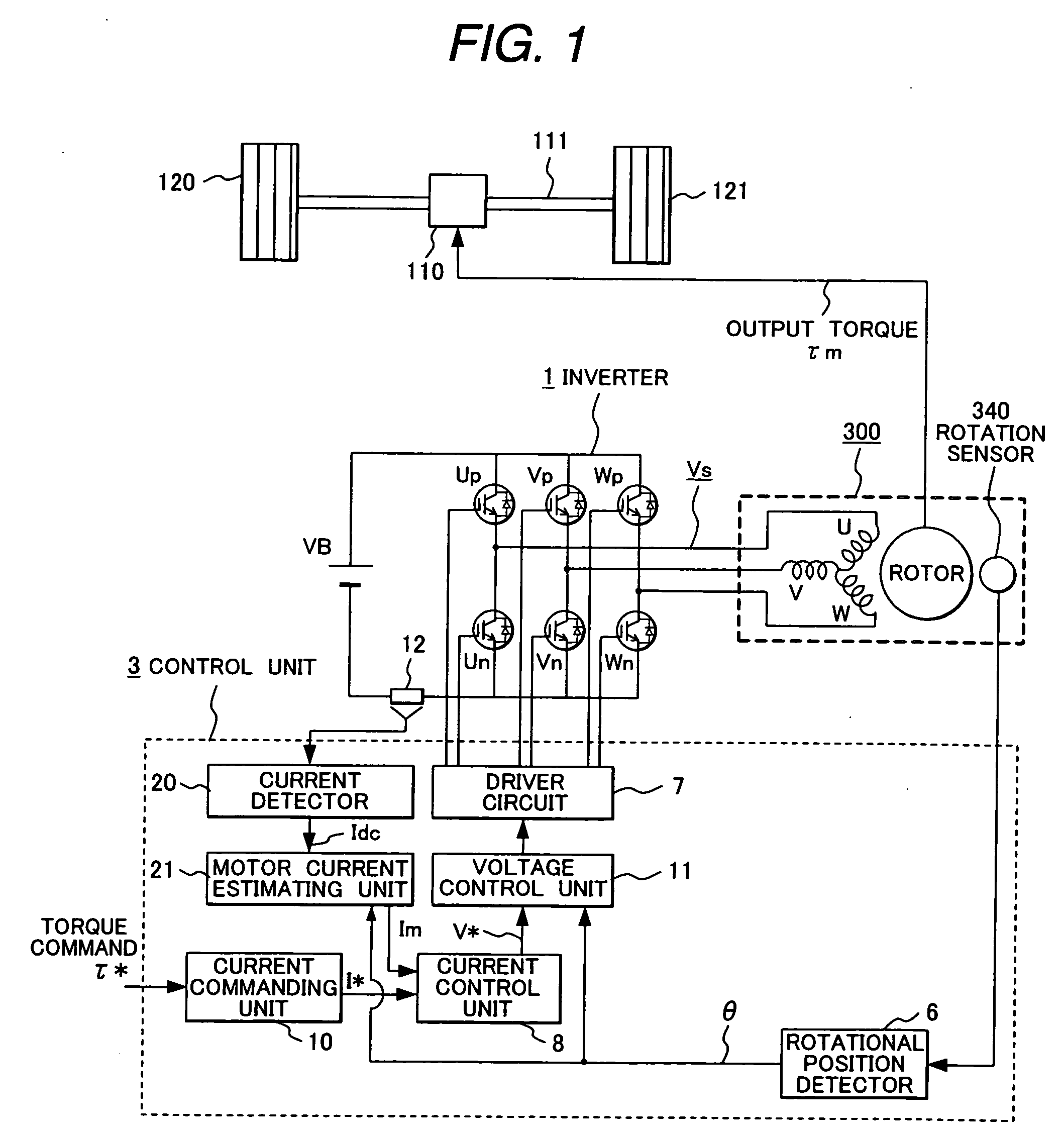

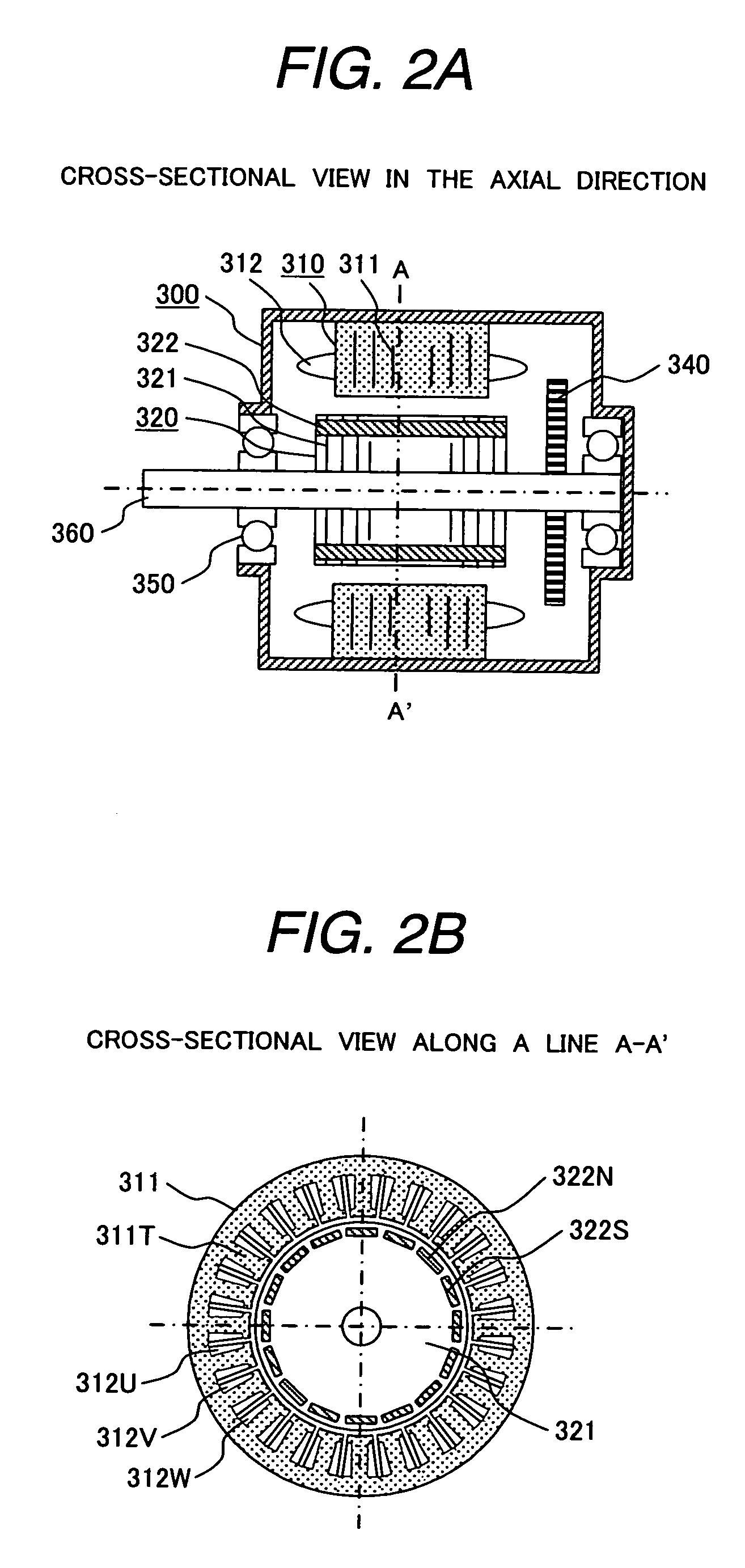

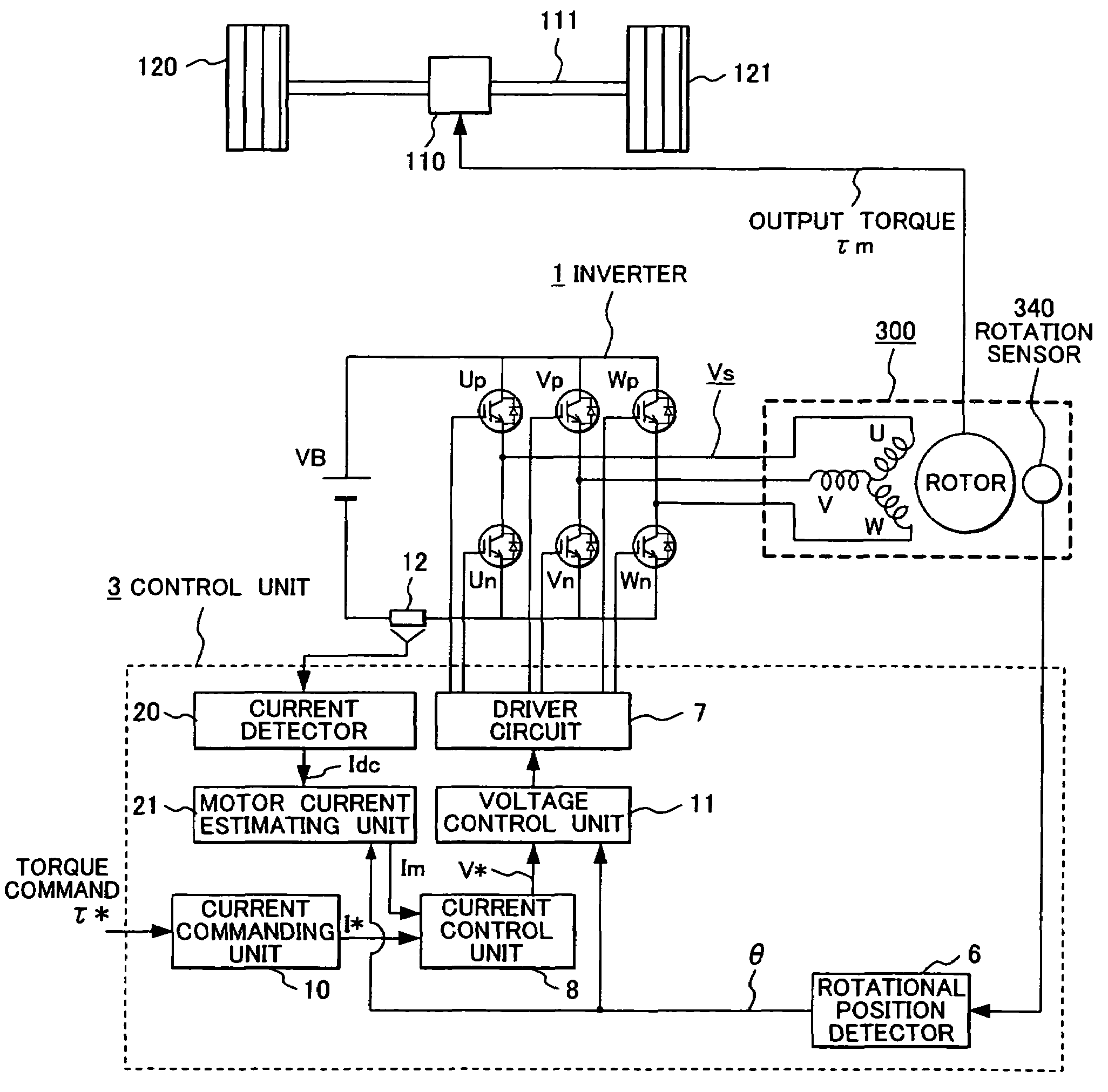

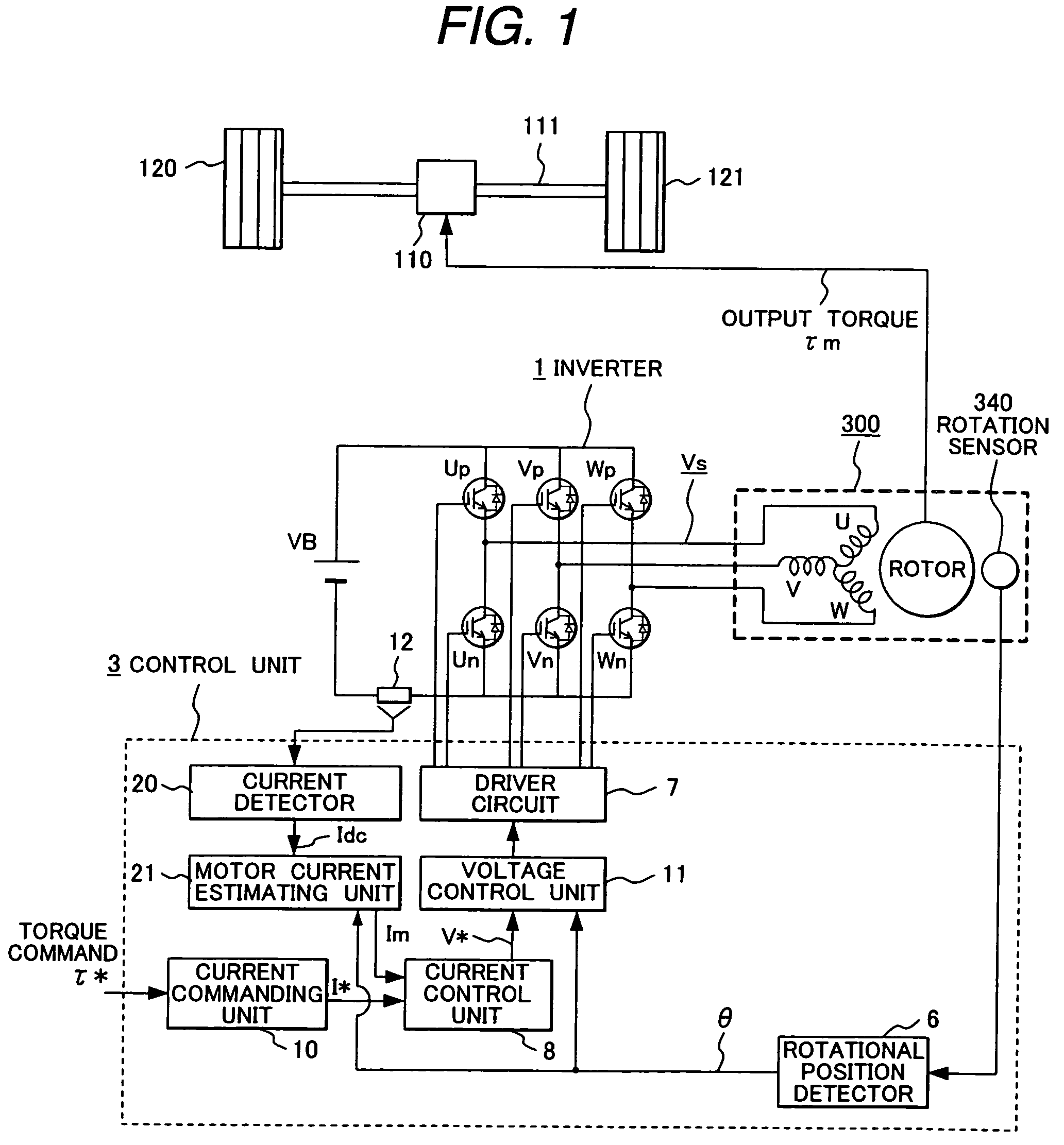

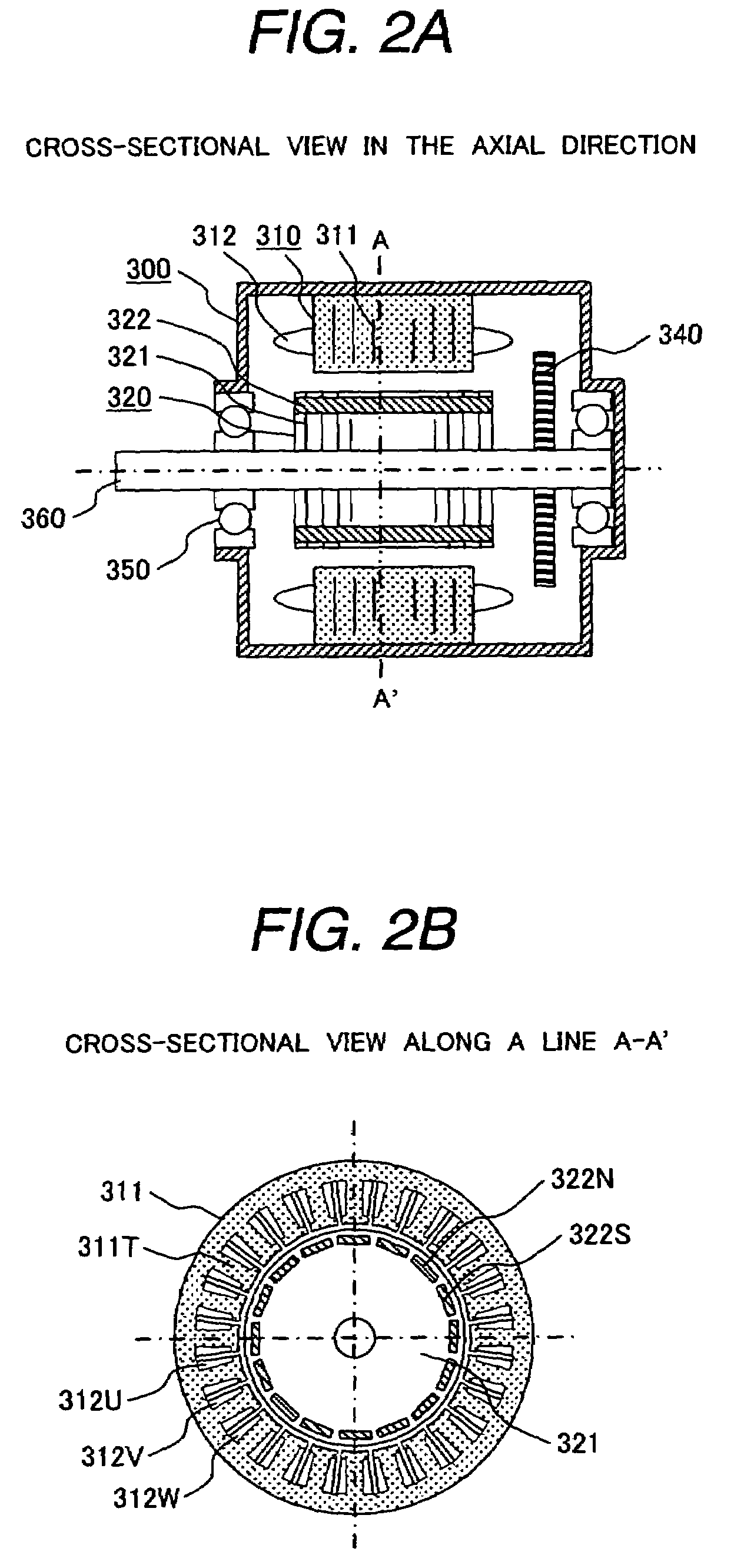

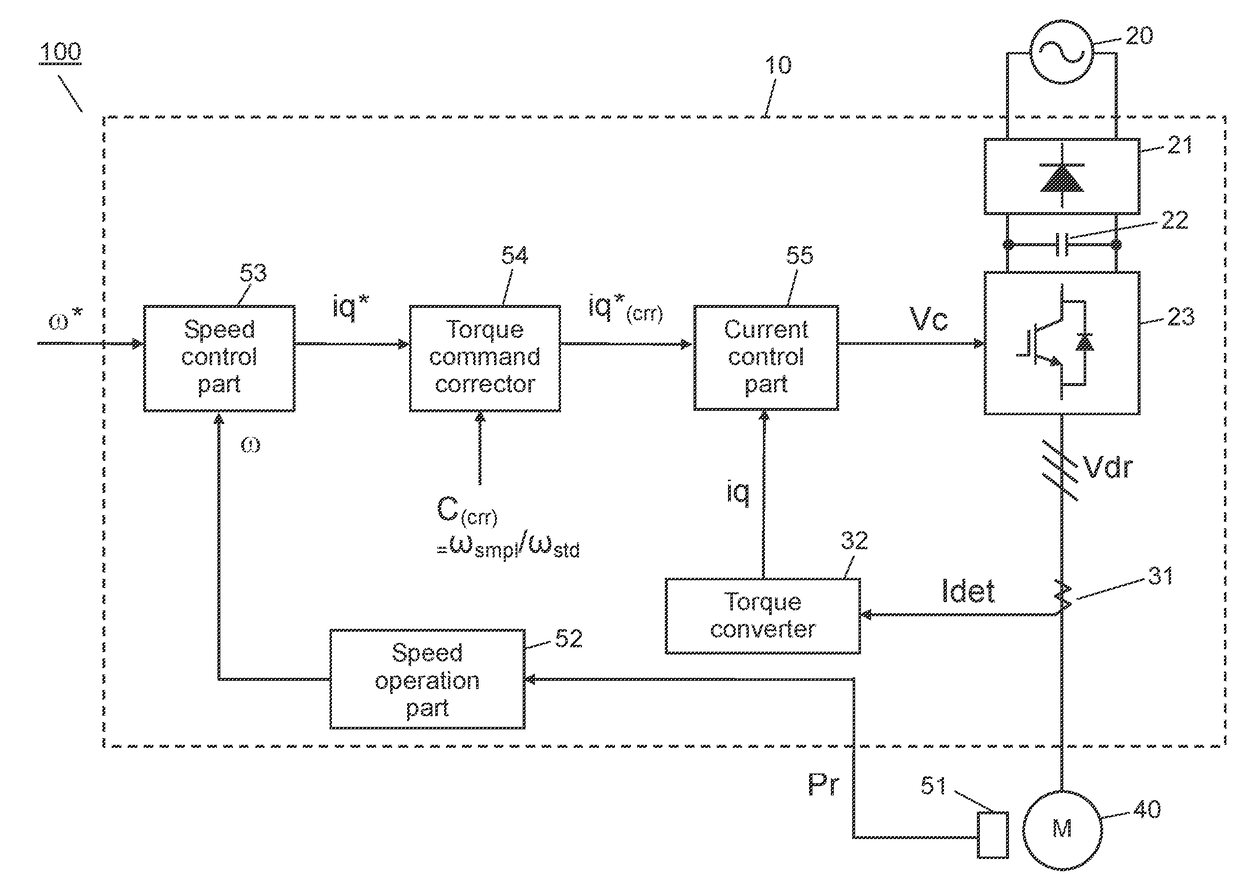

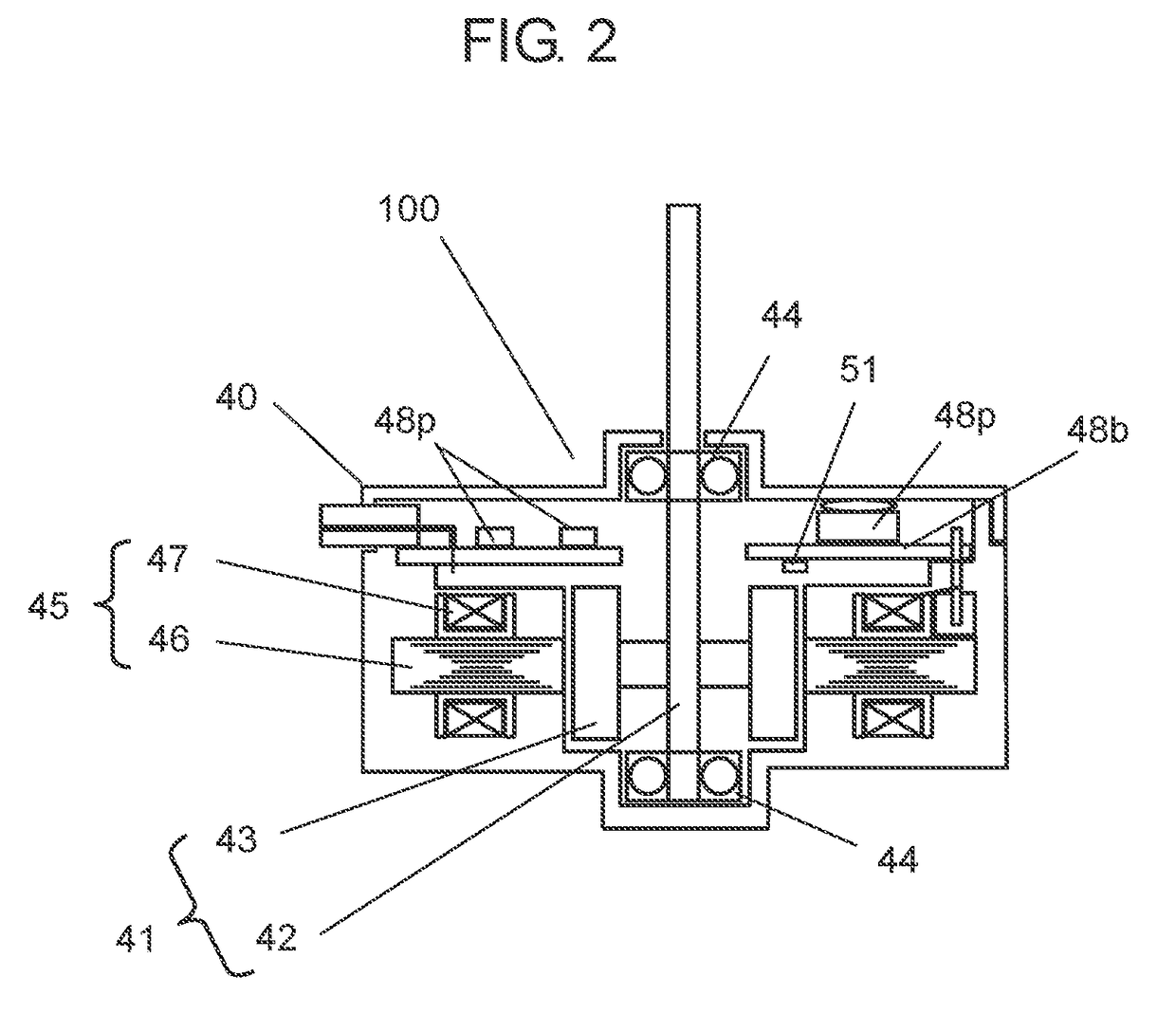

AC motor driving apparatus and method of controlling the same

ActiveUS20070013333A1Low costSave spaceDC motor speed/torque controlSynchronous motors startersPower inverterCurrent sensor

The AC motor driving apparatus comprises an inverter for supplying power to an AC motor, current sensors for detecting current that flows in the motor or inverter, a rotation sensor for detecting the rotation of the rotor in the motor, and a control unit for controlling the driving of the inverter. A current detection value detected by the current sensor and a rotor rotational position are used to estimate three-phase motor current values. The estimated motor current values are used to control the inverter. Thereby, an inexpensive, space-saving AC motor driving apparatus as well as an AC motor controller, electric actuator, or vehicle that can perform highly precise torque control from zero speed to high-speed rotation without depending on the PWM pulse pattern are provided.

Owner:HITACHI ASTEMO LTD

AC motor driving apparatus and method of controlling the same

ActiveUS7271557B2Low costSave spaceSynchronous motors startersDC motor speed/torque controlPower inverterCurrent sensor

The AC motor driving apparatus comprises an inverter for supplying power to an AC motor, current sensors for detecting current that flows in the motor or inverter, a rotation sensor for detecting the rotation of the rotor in the motor, and a control unit for controlling the driving of the inverter. A current detection value detected by the current sensor and a rotor rotational position are used to estimate three-phase motor current values. The estimated motor current values are used to control the inverter. Thereby, an inexpensive, space-saving AC motor driving apparatus as well as an AC motor controller, electric actuator, or vehicle that can perform highly precise torque control from zero speed to high-speed rotation without depending on the PWM pulse pattern are provided.

Owner:HITACHI ASTEMO LTD

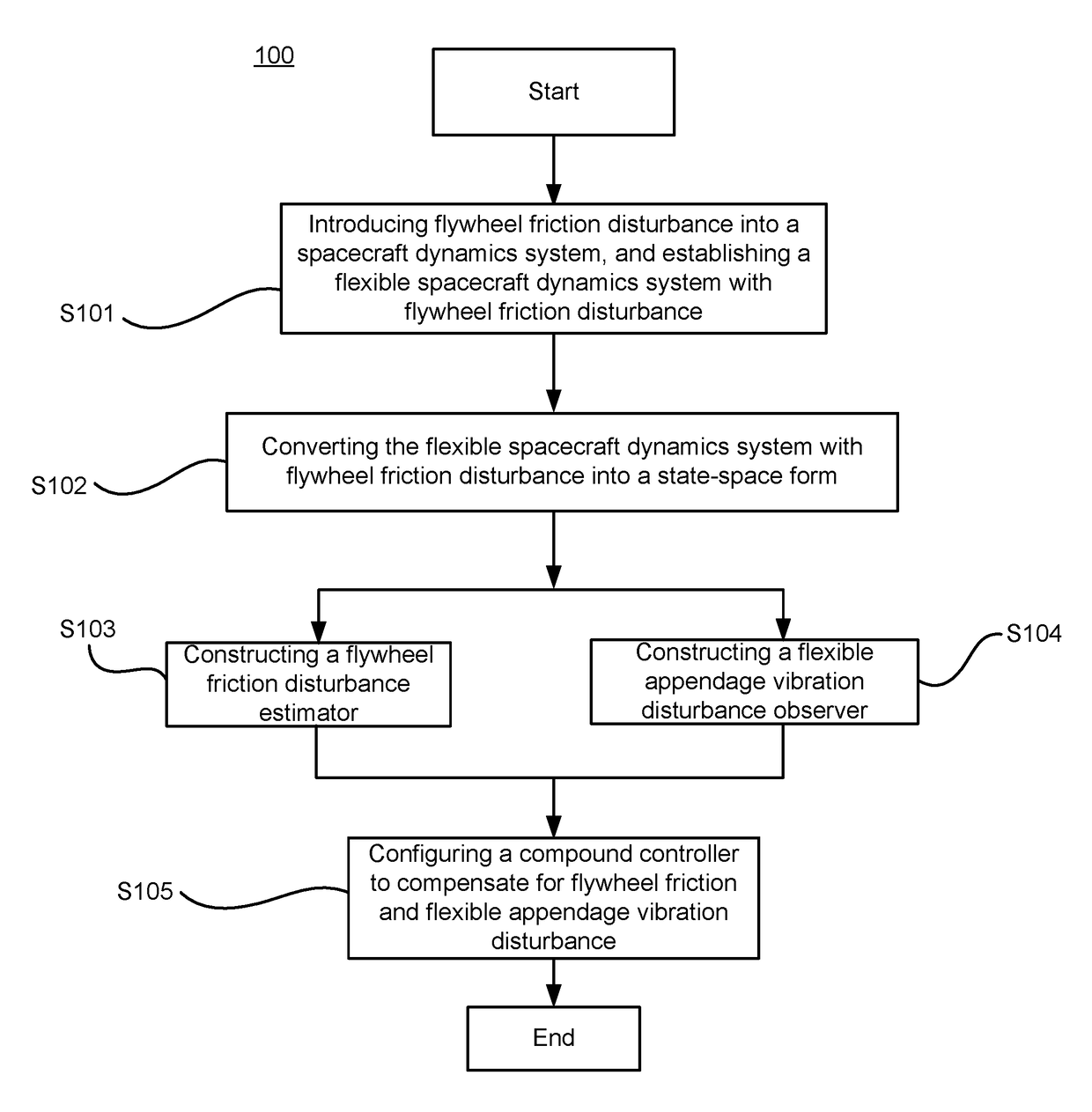

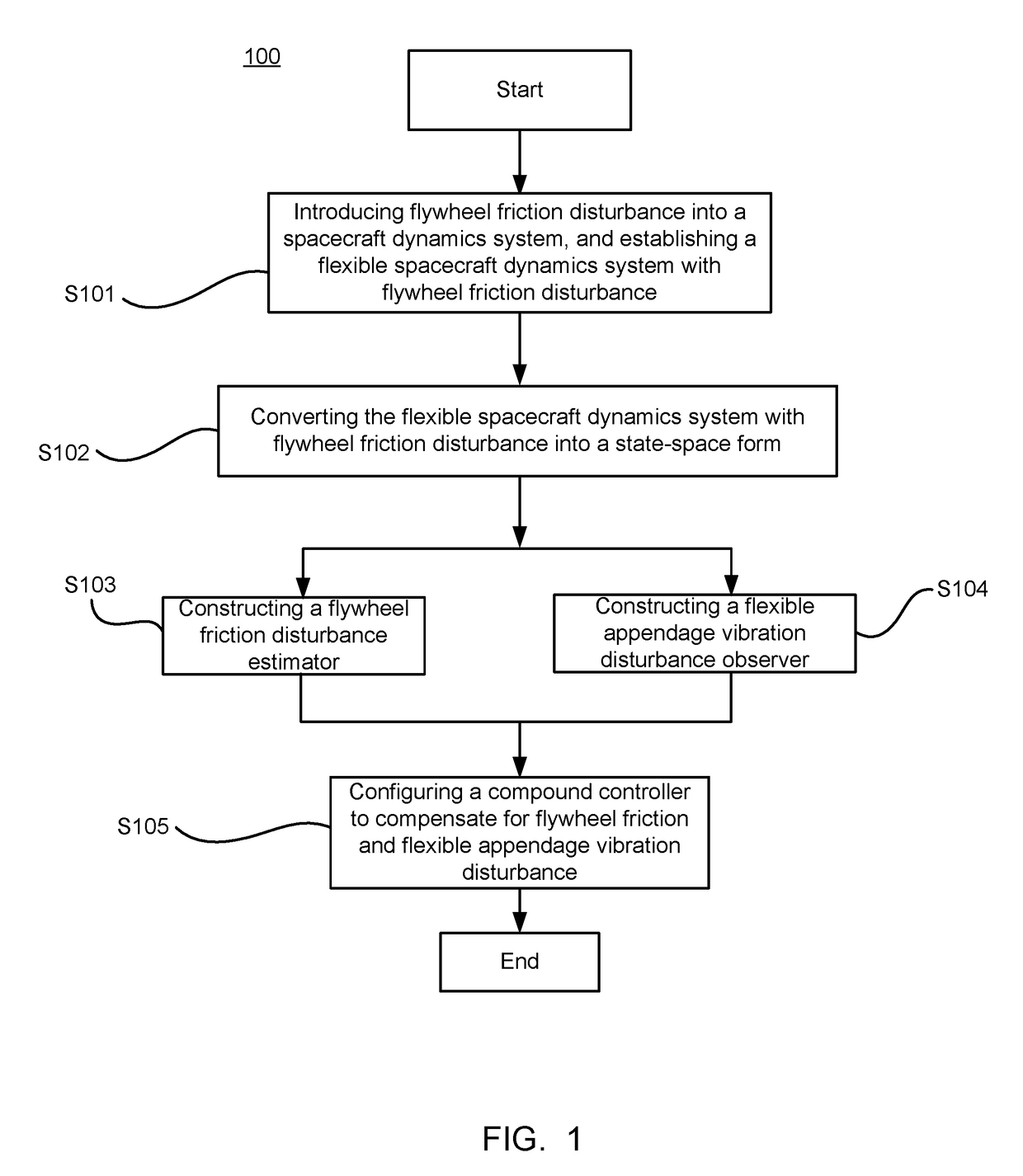

Method for attitude controlling based on finite time friction estimation for flexible spacecraft

ActiveUS9663252B1High precision controlFast trackCosmonautic vehiclesFlywheelsFlexible spacecraftState space

The present invention provides a method for attitude control based on finite time friction estimation for a flexible spacecraft. The control method includes the following steps: a. introducing spacecraft flywheel friction disturbance into a spacecraft dynamics system, and establishing a flexible spacecraft dynamics system with flywheel friction disturbance; b. converting the flexible spacecraft dynamics system with flywheel friction disturbance into a state-space form; c. constructing a flywheel friction disturbance estimator; d. constructing a flexible appendage vibration disturbance observer; and e. combining the flywheel friction disturbance estimator in the step c and the flexible appendage vibration disturbance observer in the step d with a nominal controller to obtain a compound controller; the compound controller compensating for flywheel friction according to an estimated value of a flywheel friction moment; and the compound controller compensating for flexible appendage vibration disturbance according to an estimated value of flexible appendage vibration disturbance.

Owner:BEIHANG UNIV

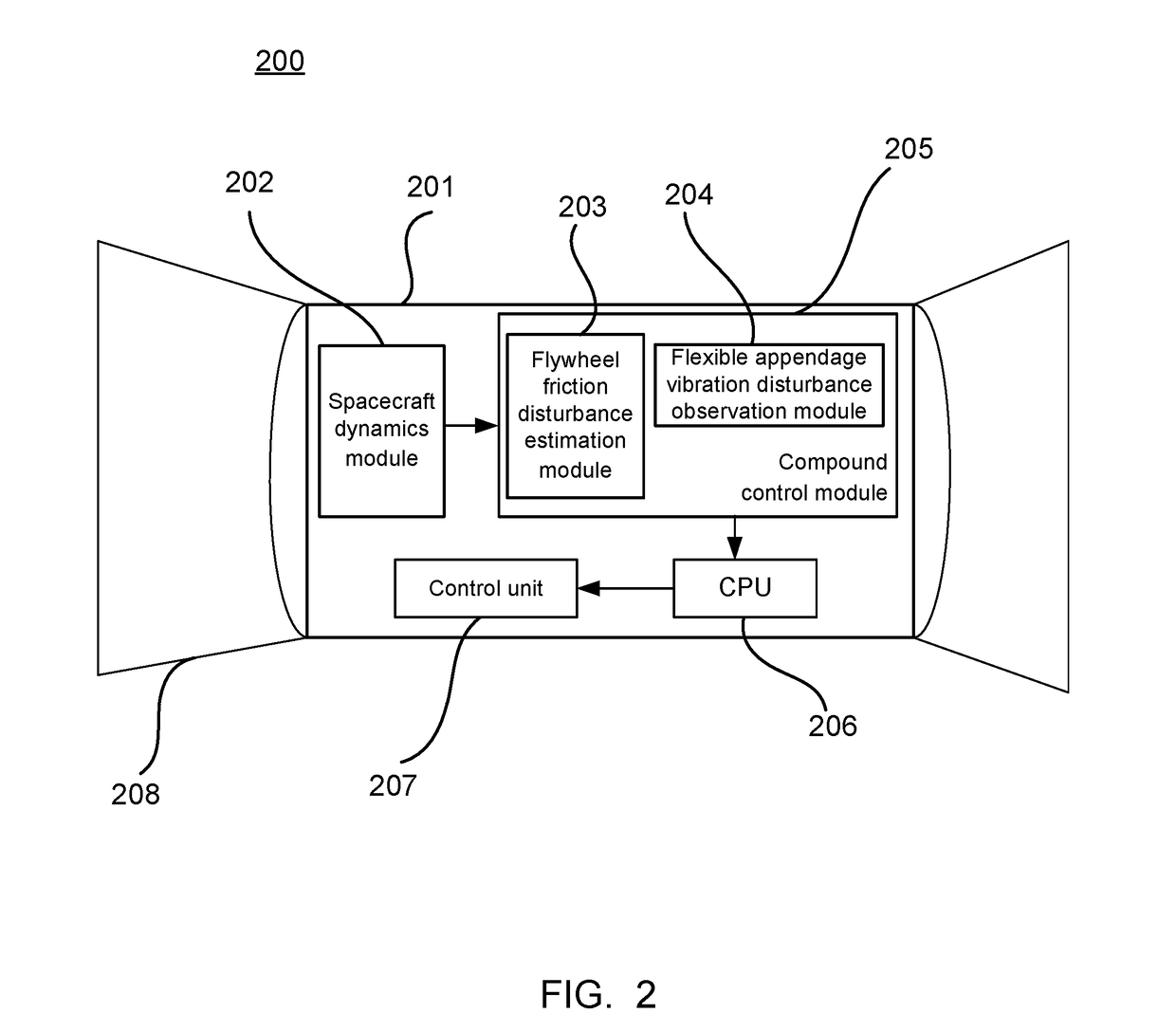

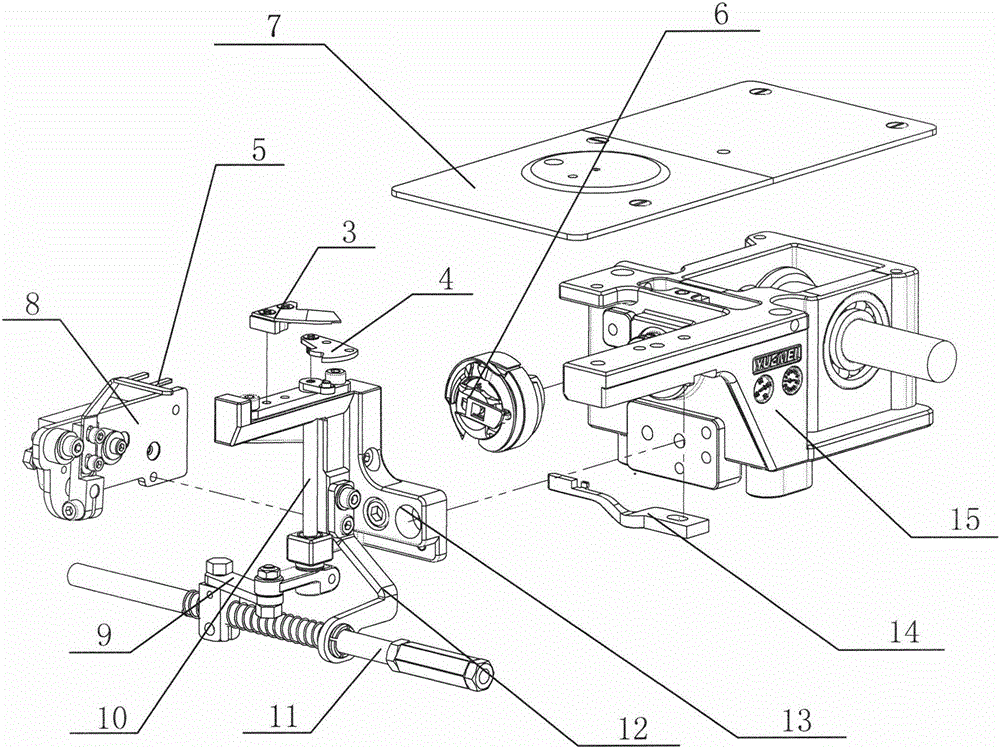

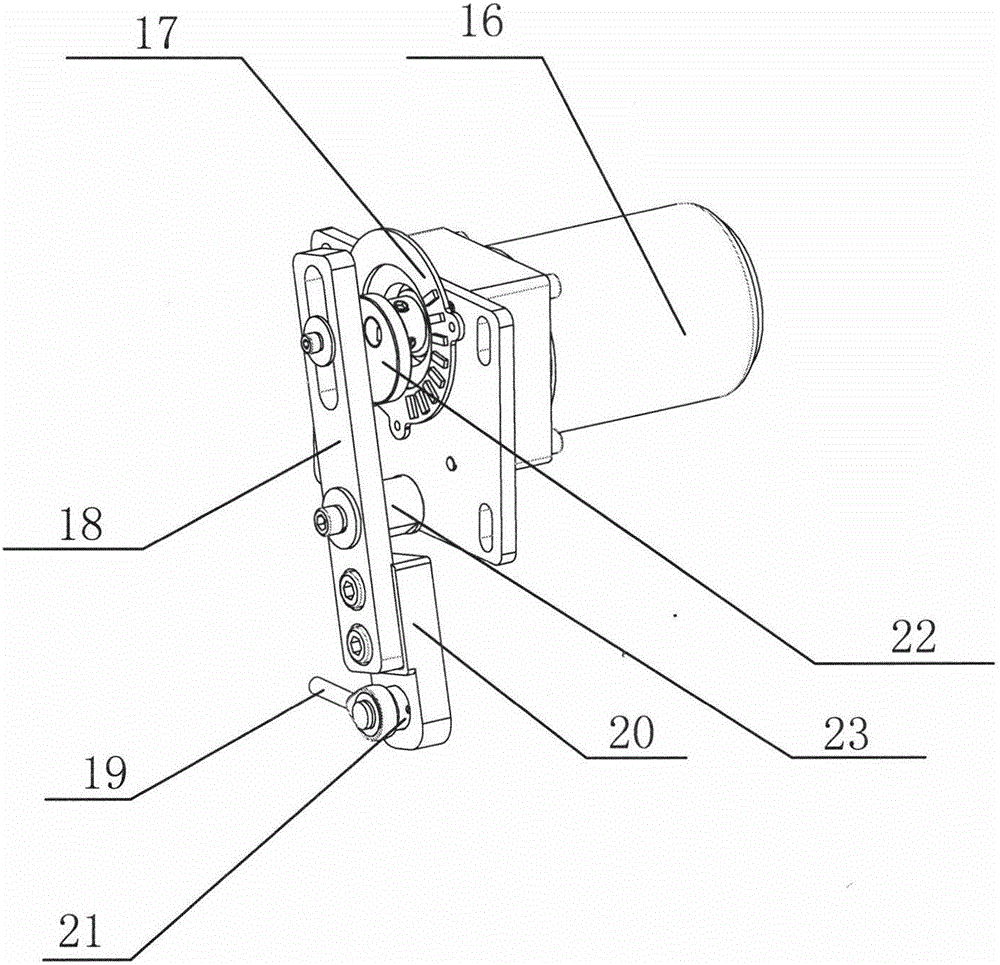

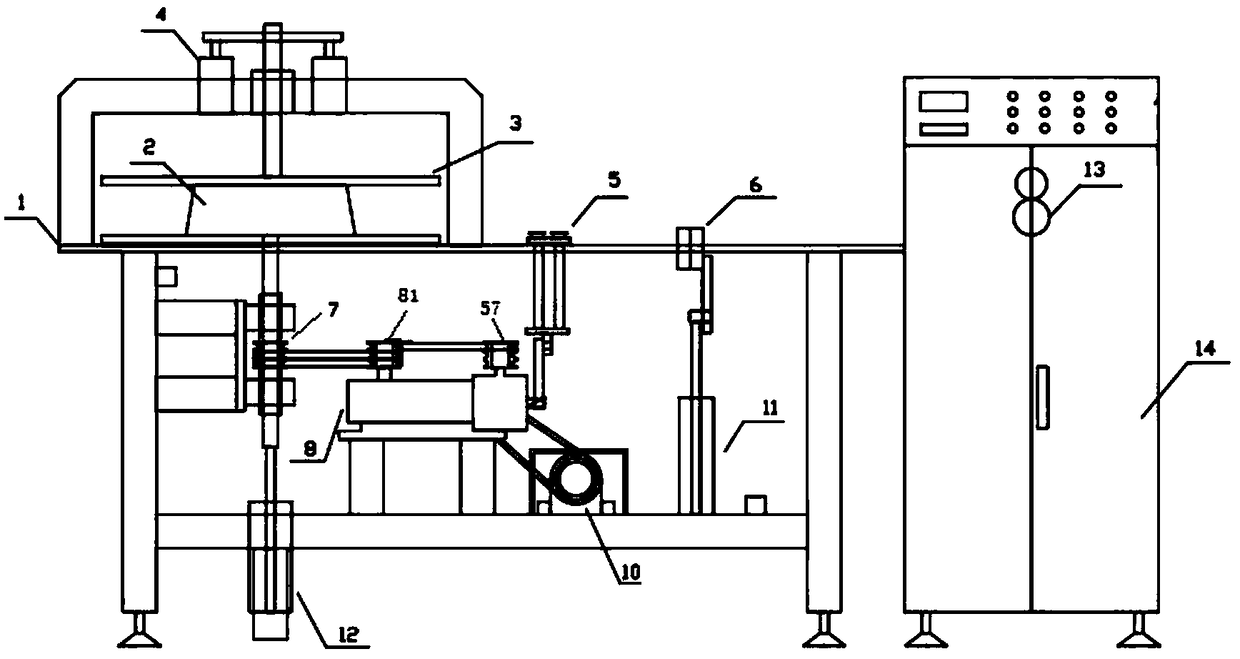

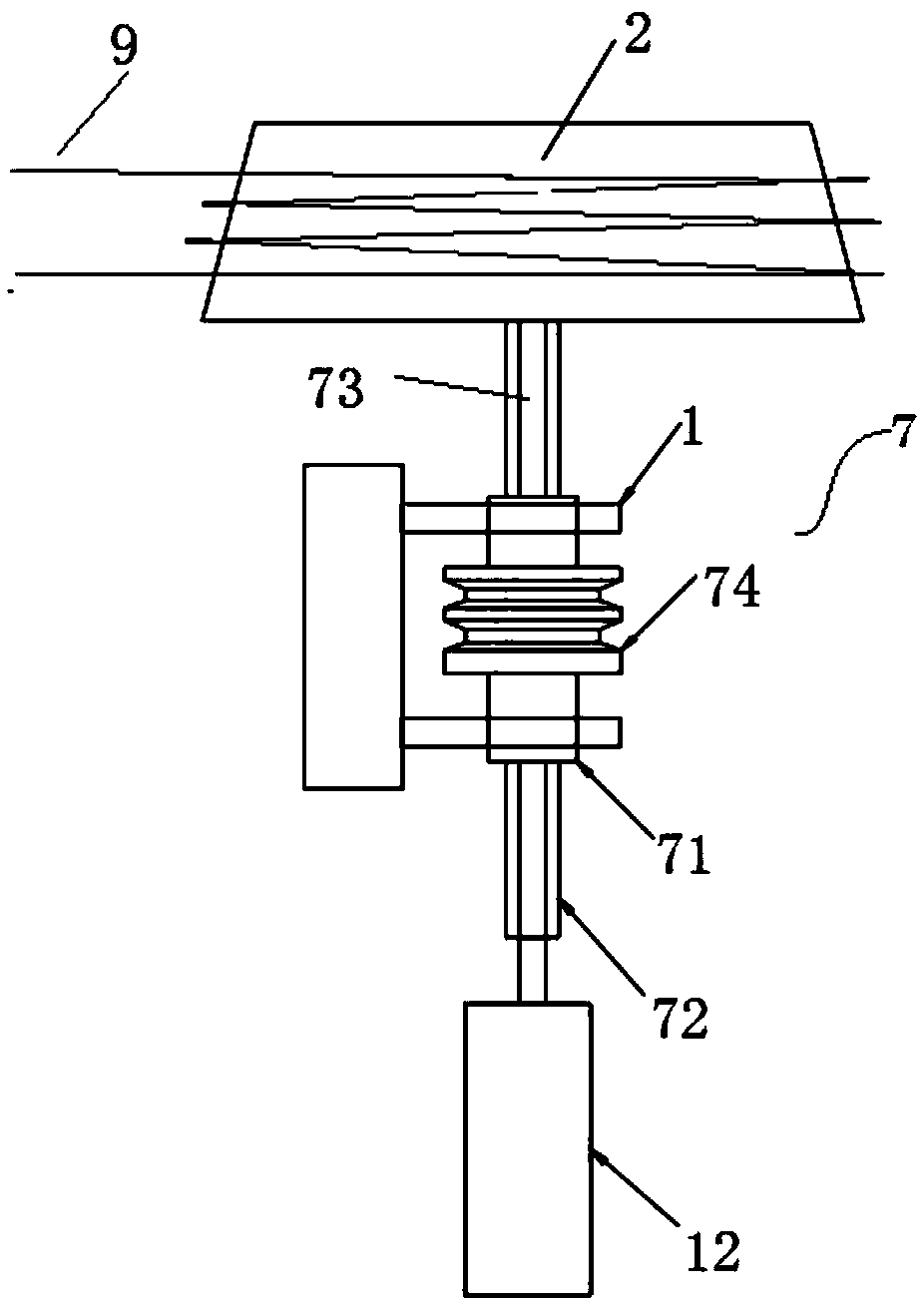

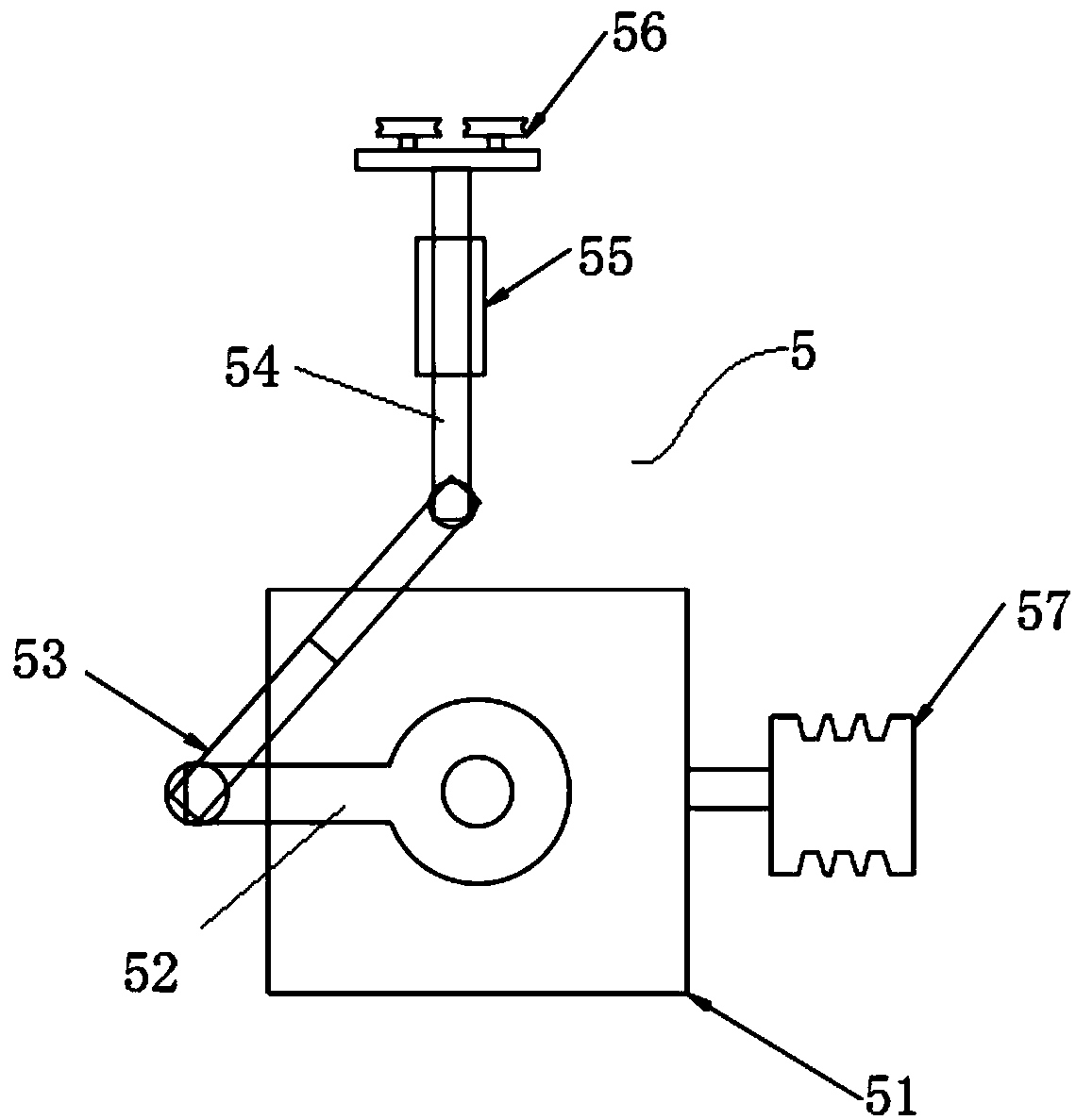

High precision thread trimming device and method for embroidery machine

PendingCN106012362AHigh precision controlAvoid spindle speed fluctuationsEmbroidering machines apparatusTextile disintegration and recoveryEngineeringPosition sensor

The invention discloses a high precision thread trimming device and a high precision thread trimming method for an embroidery machine. The device comprises a plastic cutter driving device and a thread trimming device, wherein the plastic cutter driving device is arranged at the upper side of a faller; the thread trimming device is arranged at the lower side of the faller; the plastic cutter driving device comprises a plastic cutter motor; a position sensor and an eccentric wheel are respectively arranged on the periphery of a drive shaft of the plastic cutter motor; the eccentric wheel is connected with a swing rod with a sliding chute at one end by a pin roller; a stationary shaft connected with a motor base is arranged in the middle of the swing rod; the other end of the swing rod is connected with a pull rod driving a plastic cutter by a connecting rod. The device has the beneficial effects that the exact position of the plastic cutter when going back is determined via the position sensor on the periphery of the drive shaft of the plastic cutter motor, thus achieving high precision control of the thread trimming length and avoiding technical defects caused by main shaft speed fluctuation.

Owner:ZHEJIANG YUELONG SEWING EQUIP

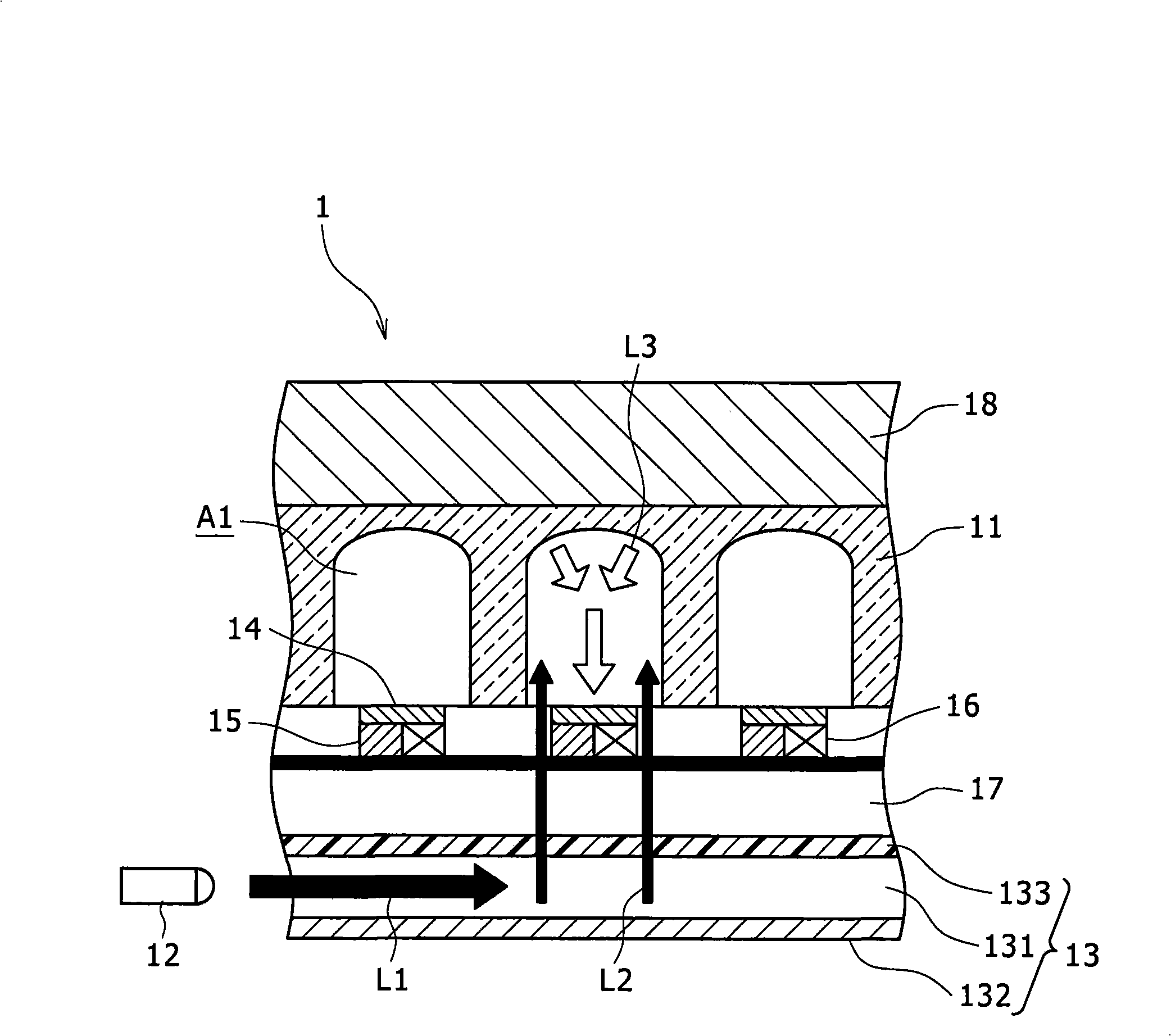

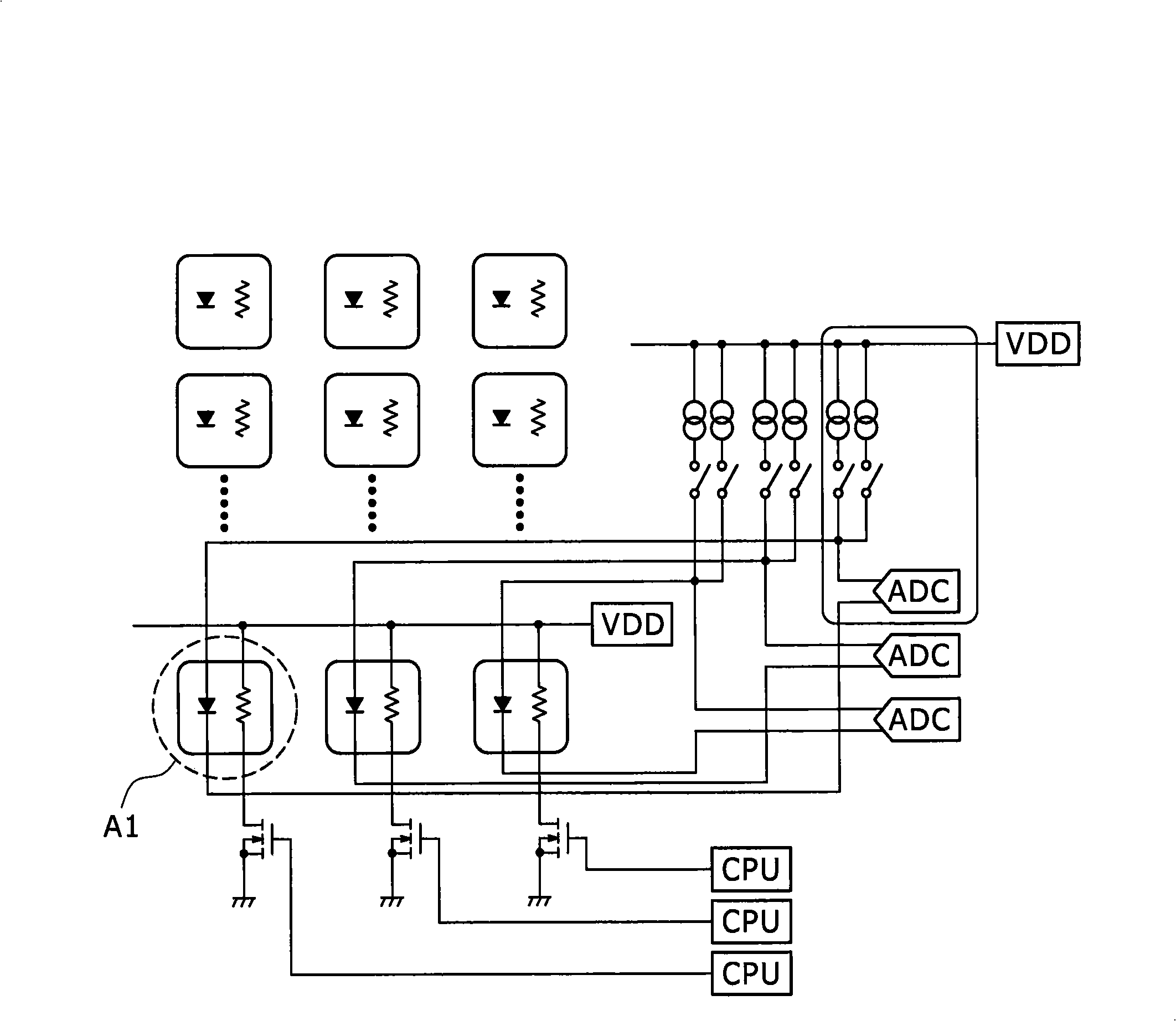

Real-time PCR system

InactiveCN101302473AHigh precision controlControlling Gene Expression LevelsBioreactor/fermenter combinationsHeating or cooling apparatusFluorescenceElectric signal

A real-time PCR system for detecting gene expression levels includes plural reaction regions, a like plural number of heating portions arranged corresponding to the reaction regions and having heat sources, respectively, an optical unit capable of irradiating exciting light of a specific wavelength to all of the plural reaction regions, and a like plural number of fluorescence detecting portions (15) arranged corresponding to the reaction regions, respectively. The heating portions are each provided with a temperature detector for detecting a temperature in a vicinity of the corresponding heat source and converting the temperature into an electrical signal and also with a controller for controlling a thermal dose from the corresponding heat source based on a correlation between electricalsignals and calorific values of the heat source stored beforehand.

Owner:SONY CORP

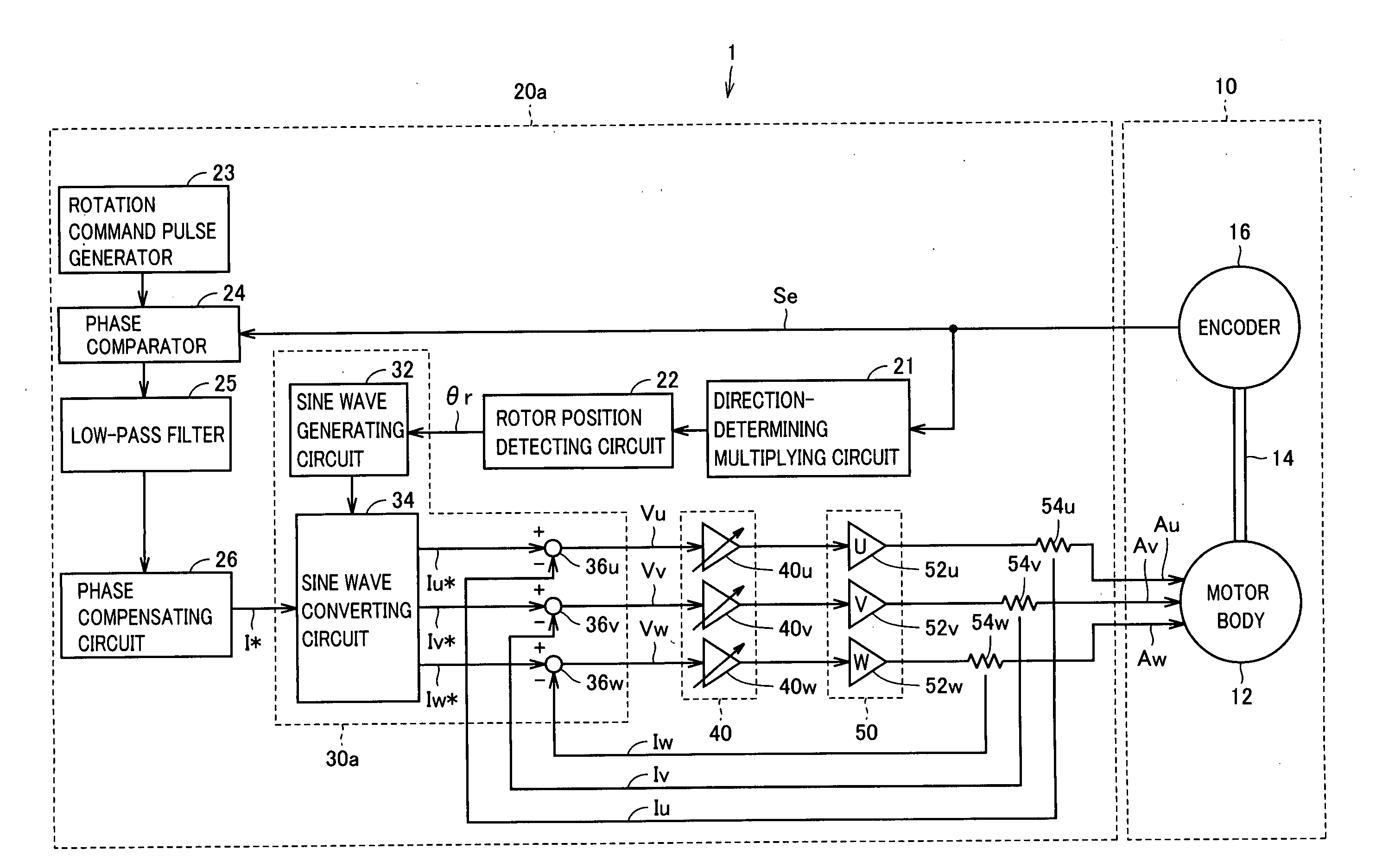

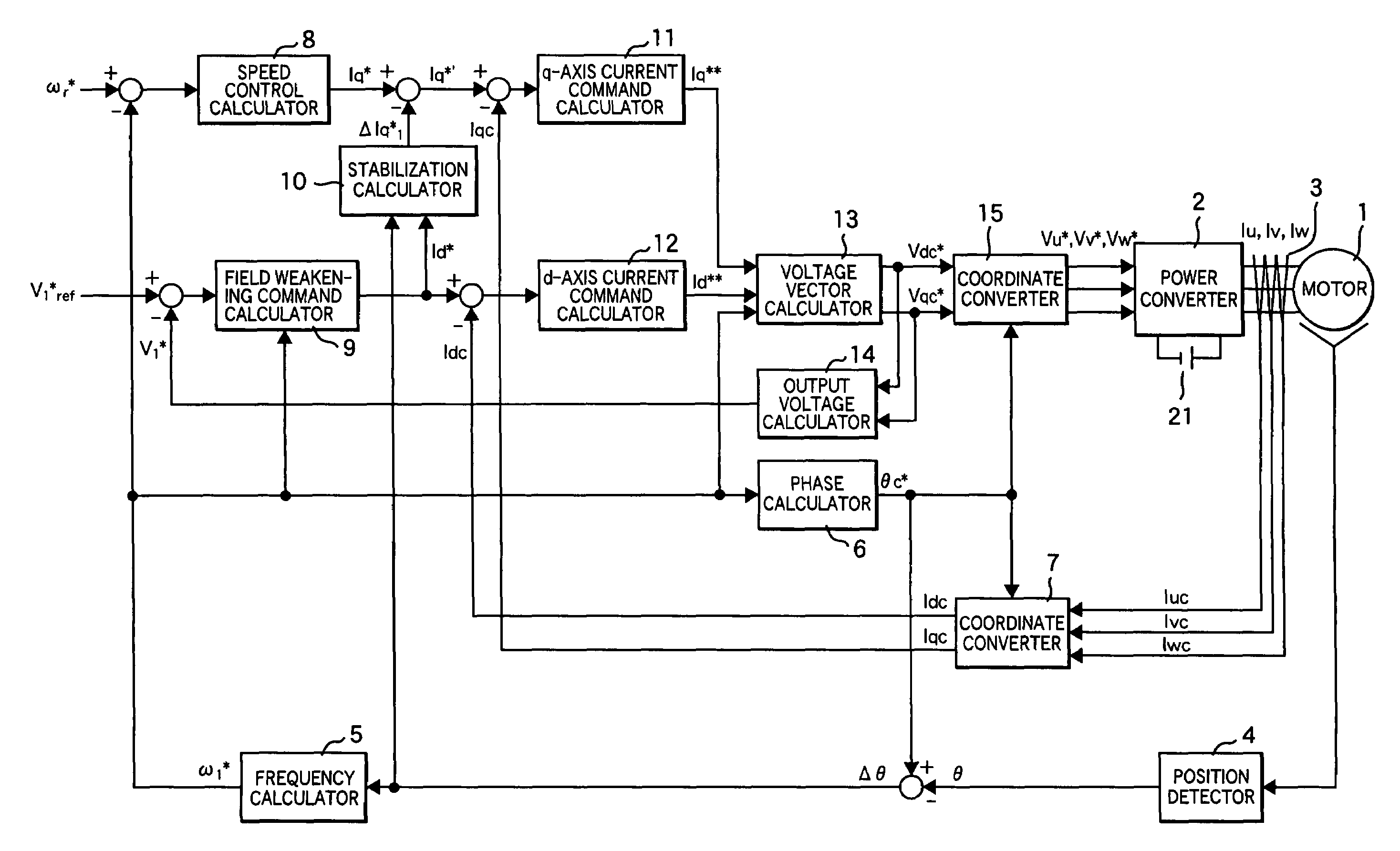

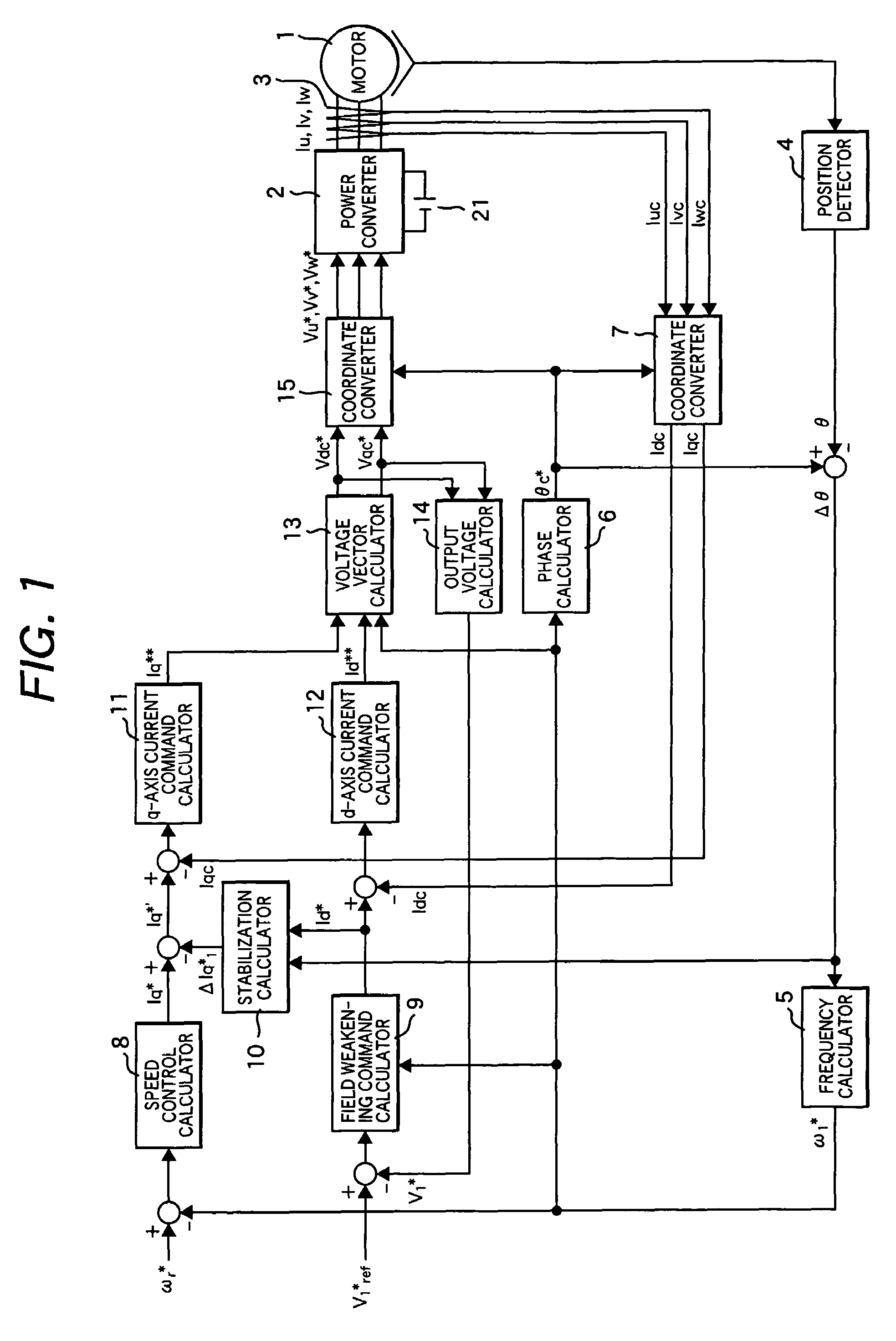

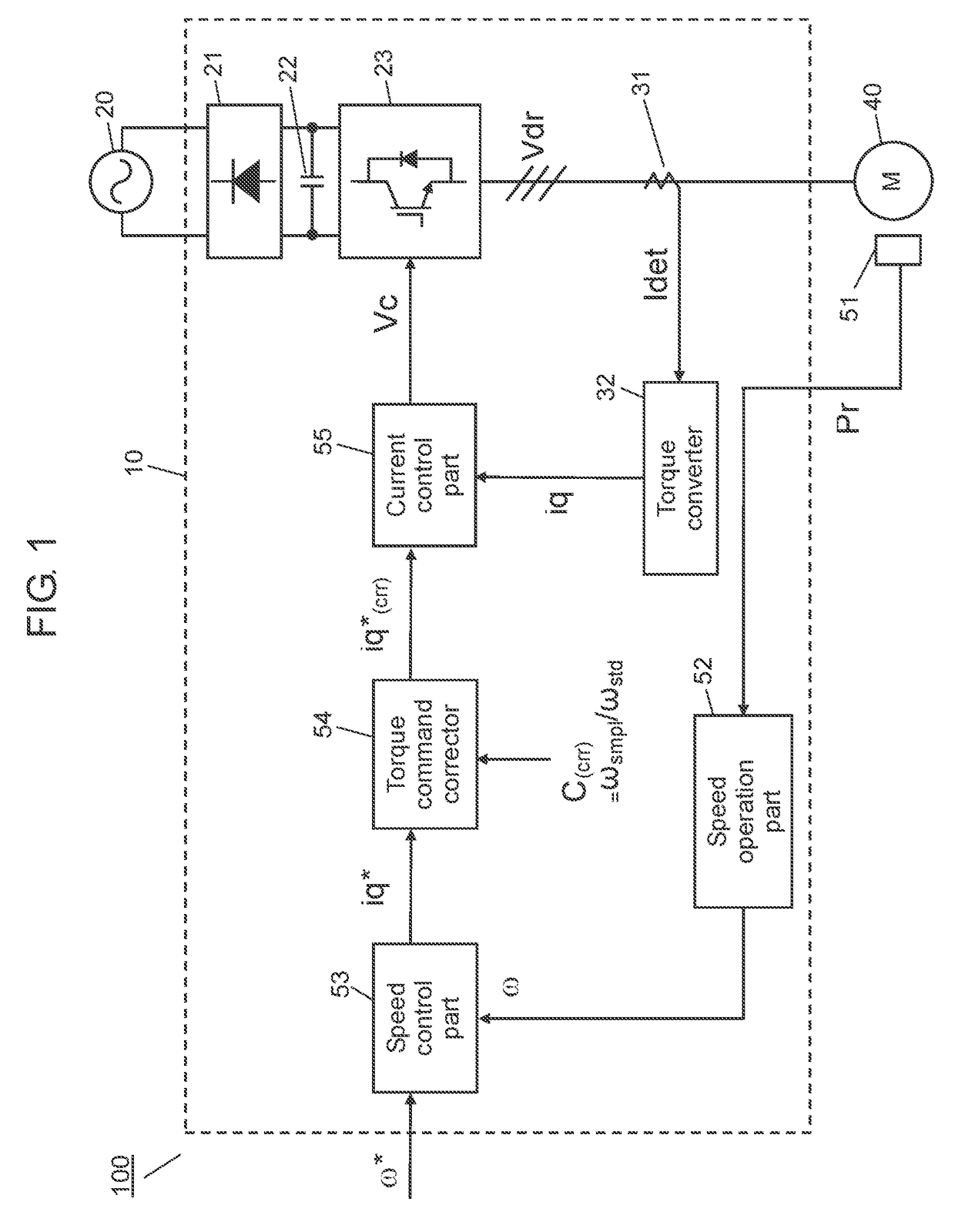

Field weakening vector controller for permanent magnet synchronous motor and control module

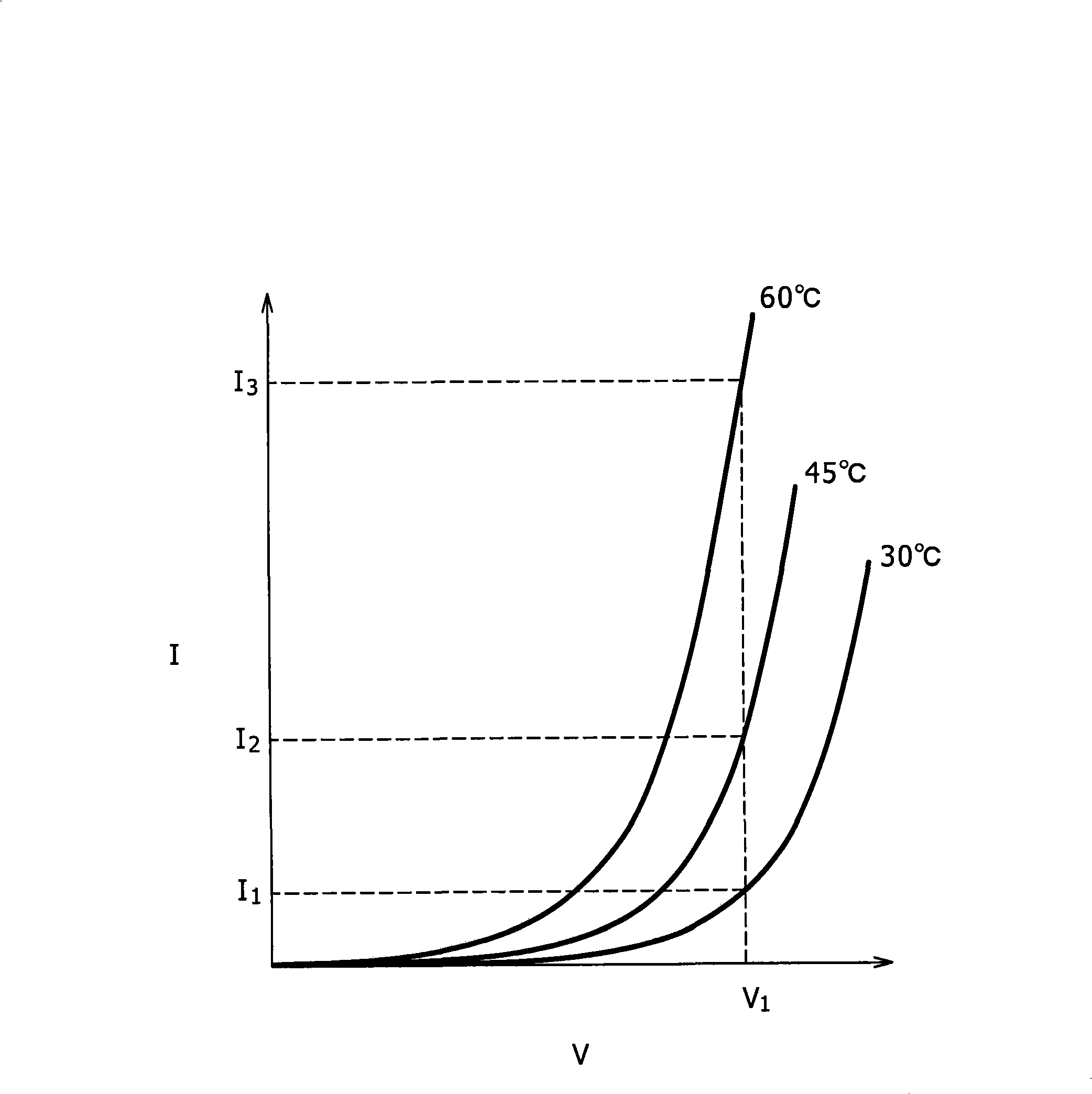

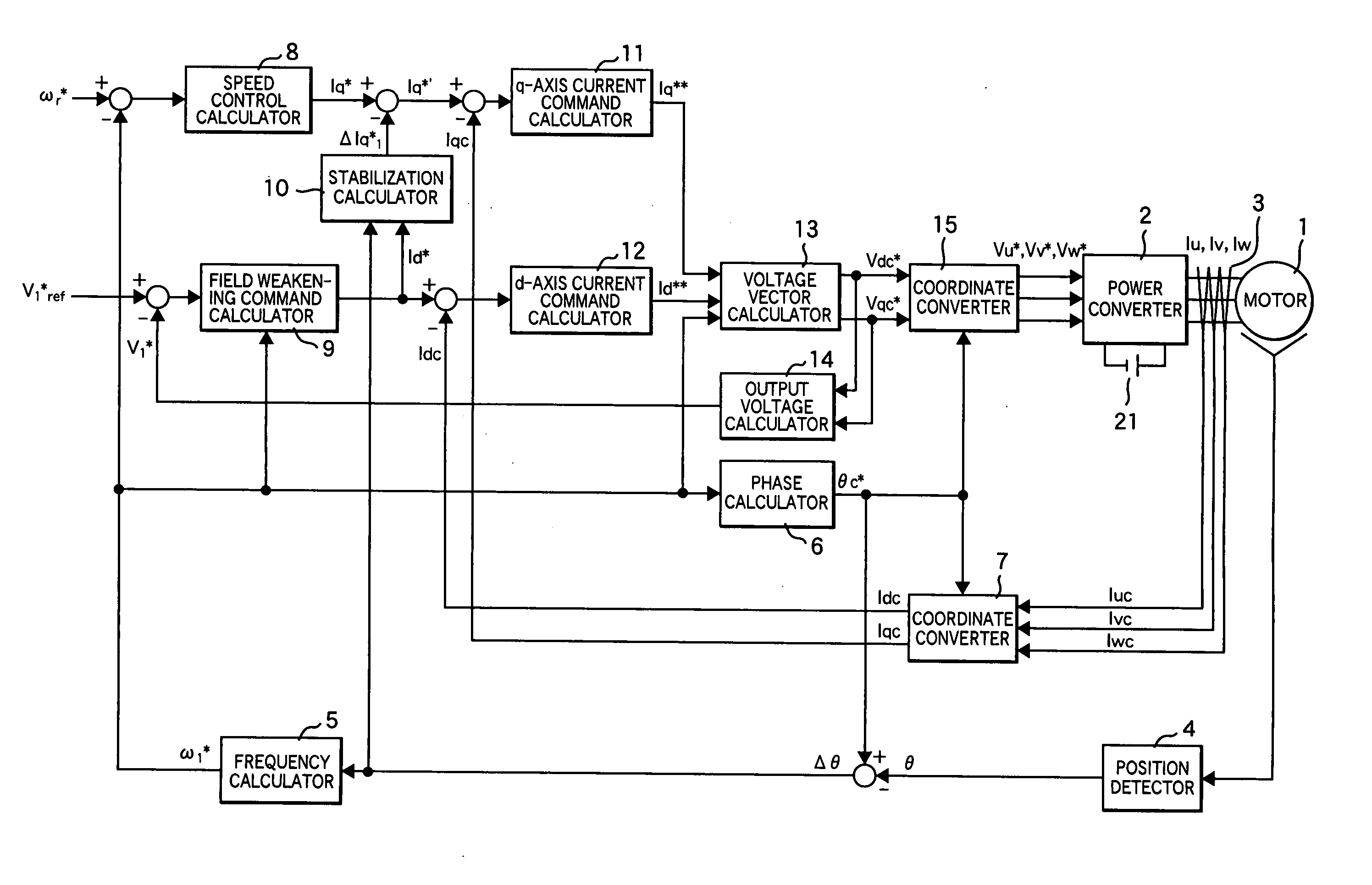

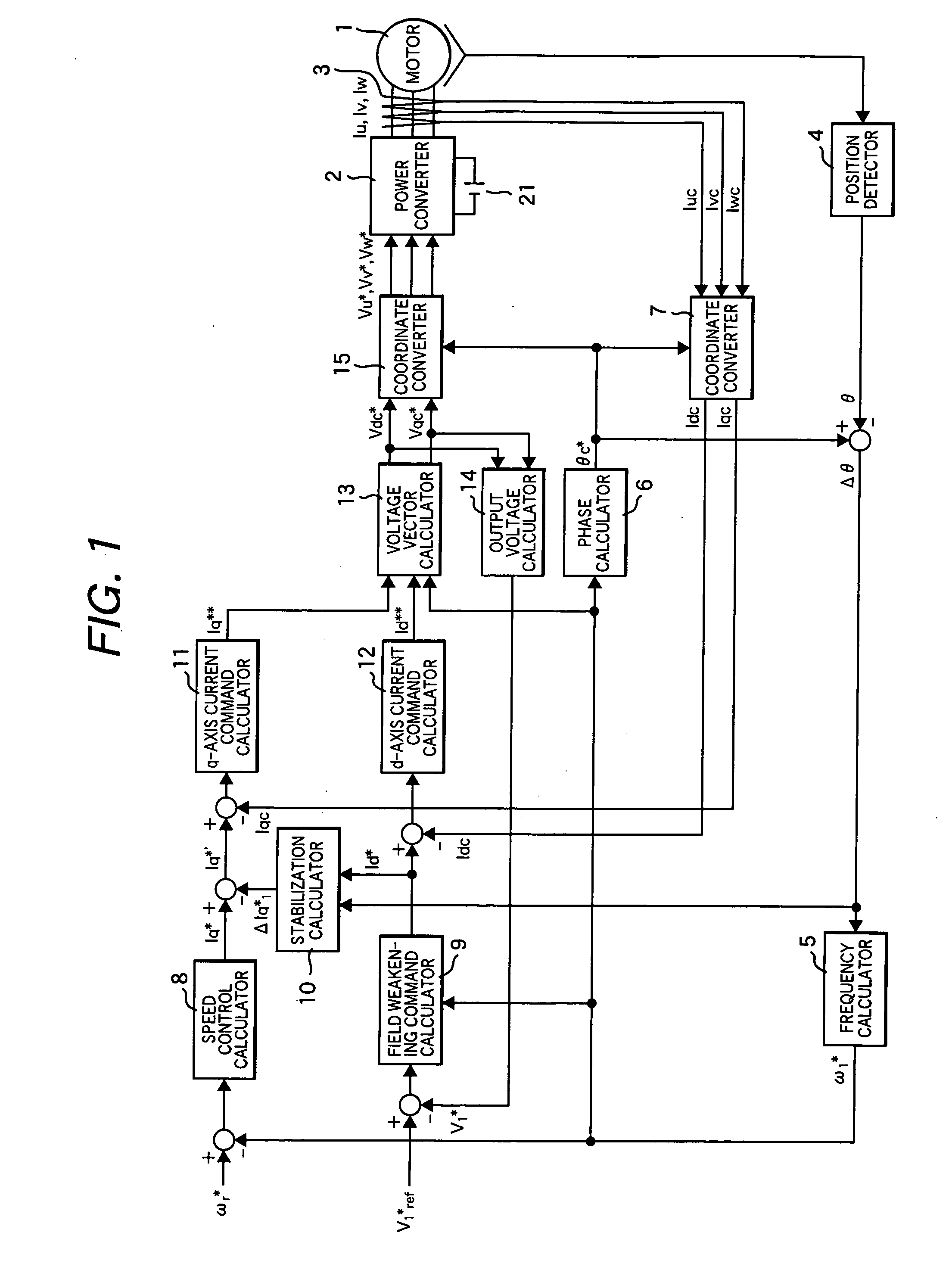

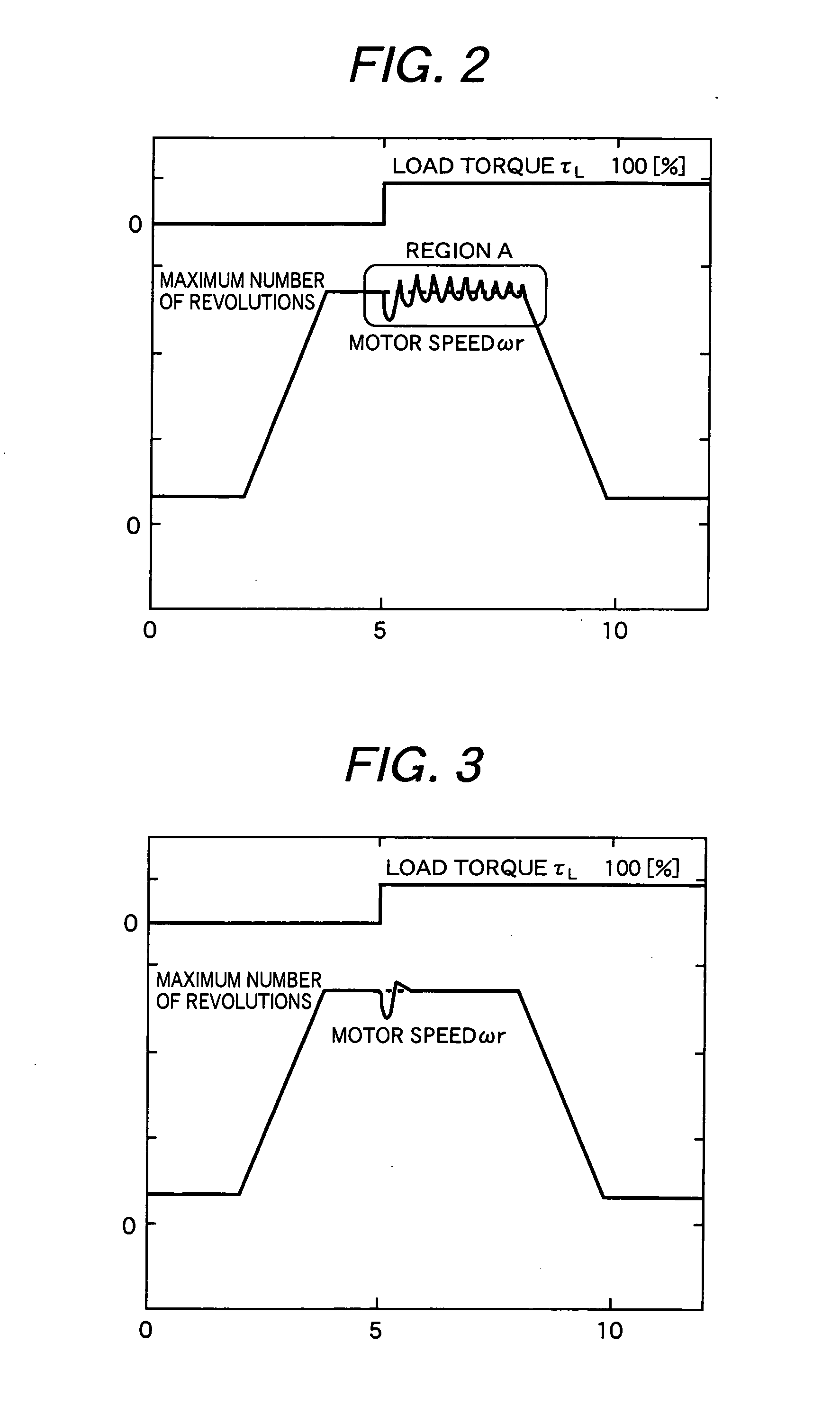

ActiveUS20070085507A1Improve accuracyHigh precision controlTorque ripple controlMotor/generator/converter stoppersPhase differencePermanent magnet synchronous motor

A stable motor control characteristics can be accomplished by correcting a q-axis current command value by a product of a d-axis current command value (or a detected current value) calculated by field weakening control and a sine signal which is a phase difference between the reference axis of control and the reference axis of the motor. Thereby, a “field weakening vector controller for the permanent magnet synchronous motor” which accomplishes a high-precision, high-response, and high-stability motor torque control even in a field weakening region and which is applicable both to an inexpensive current detecting system and to a system without a pole position detector is provided.

Owner:HITACHI LTD

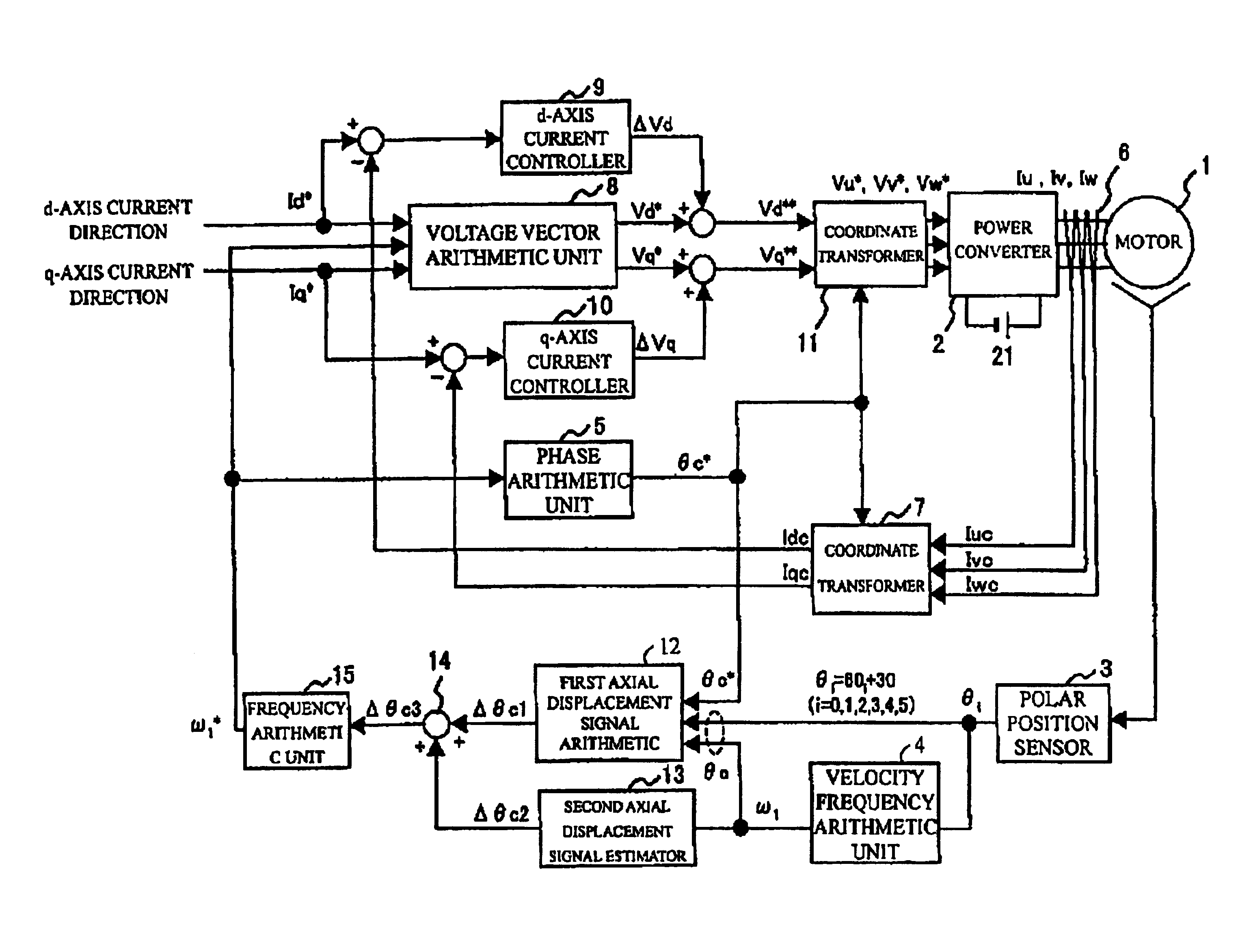

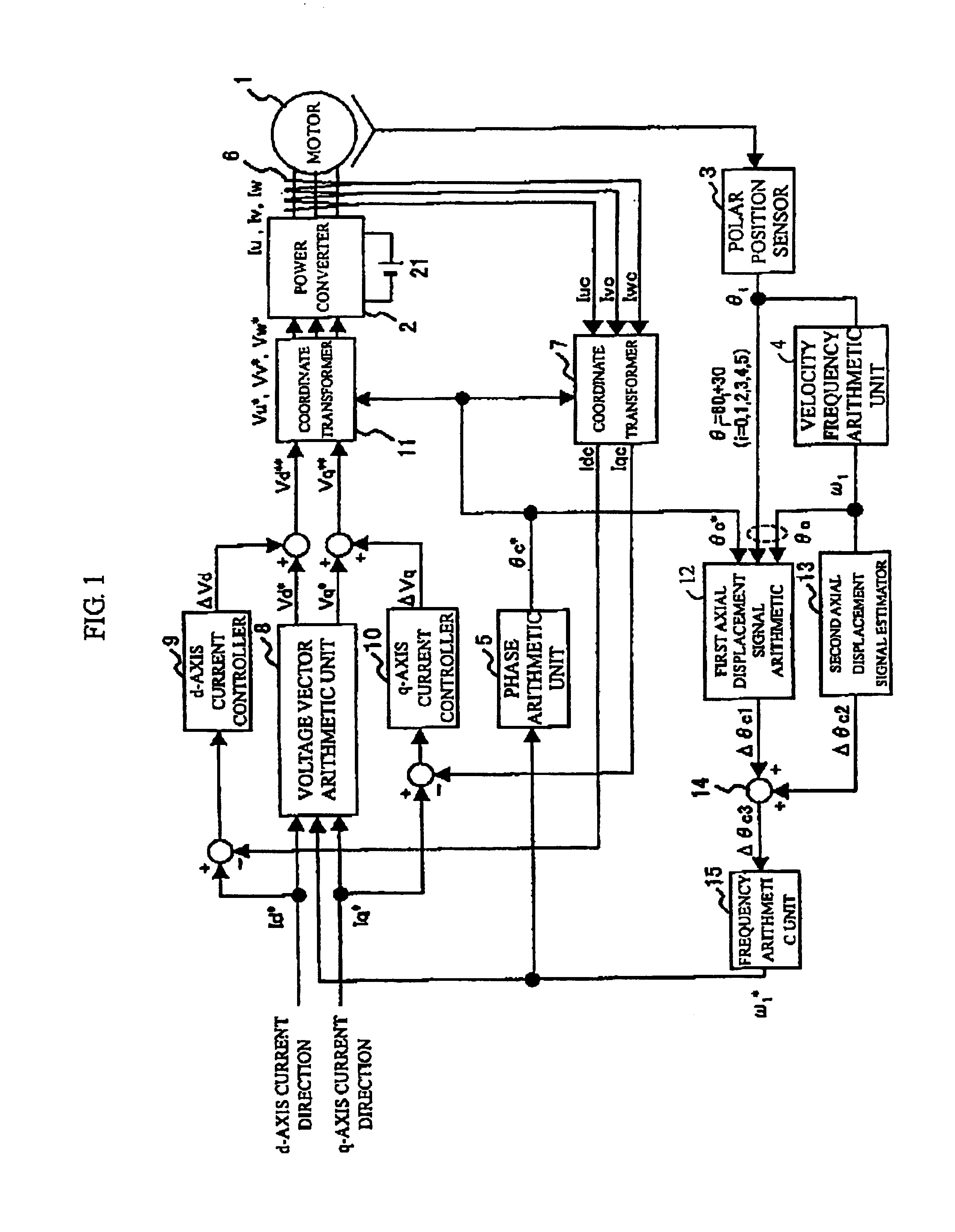

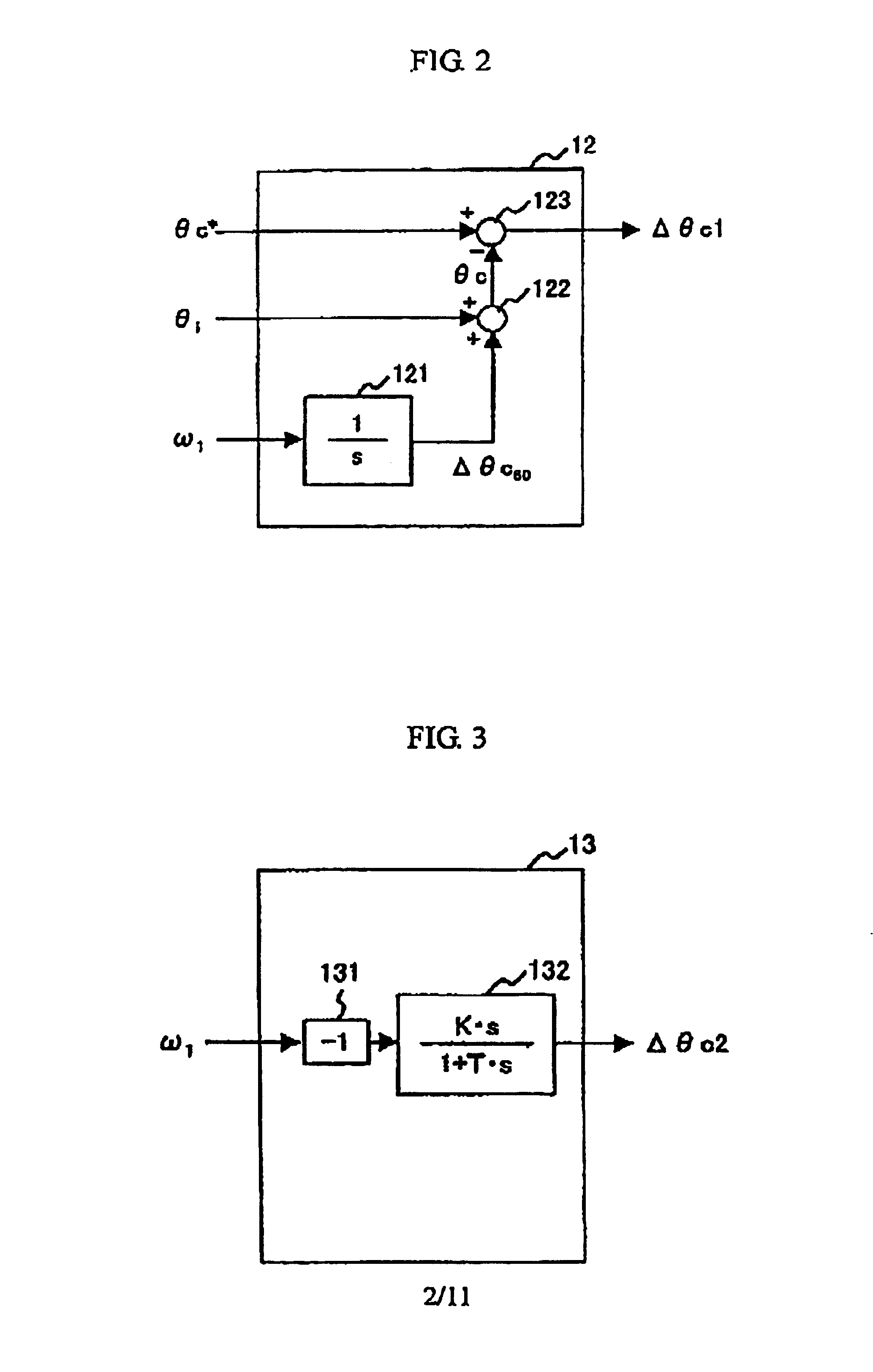

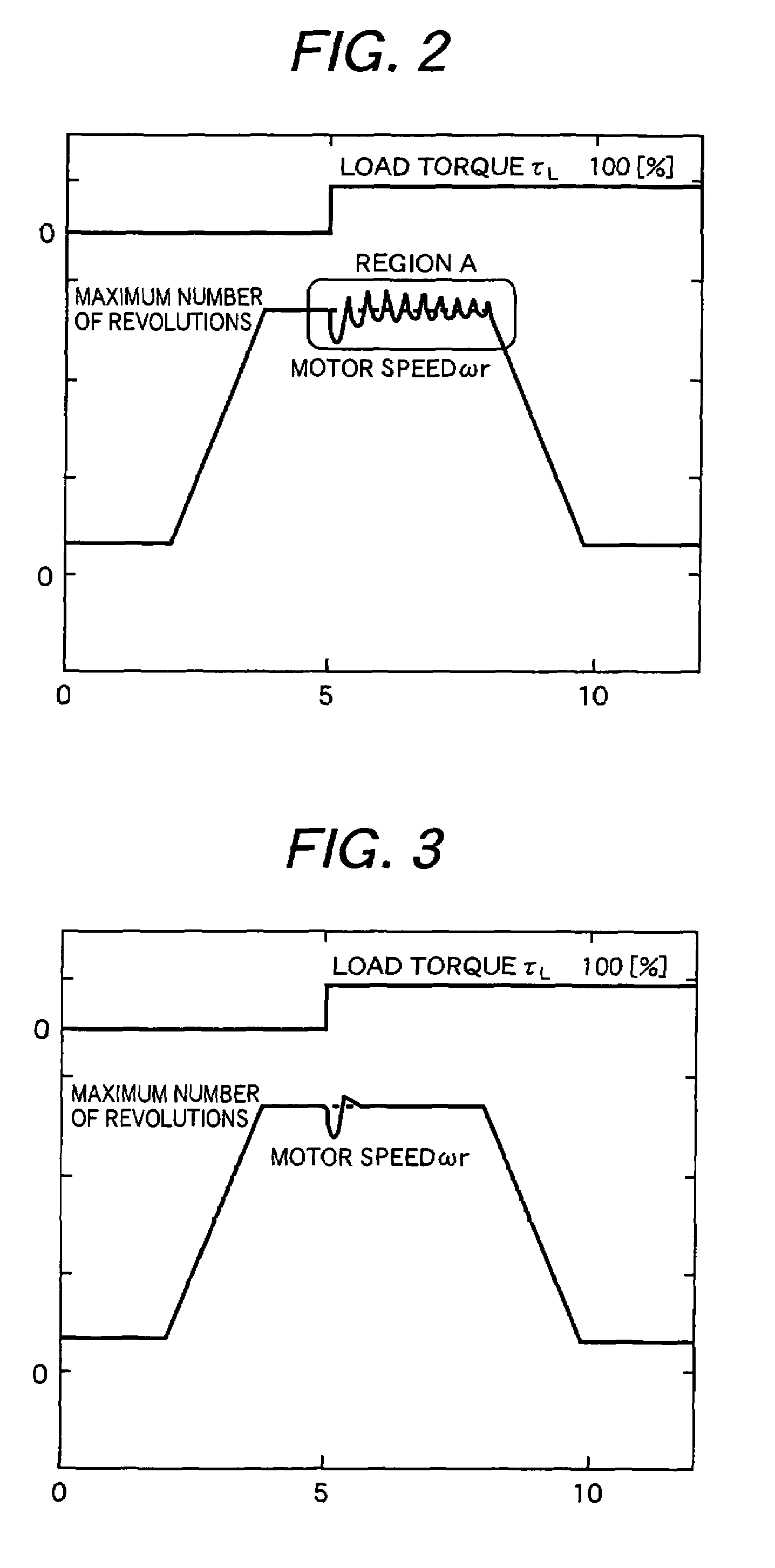

Control method and control device of permanent-magnet type synchronous motor

ActiveUS6954050B2High-precision torque controlHigh precision controlDC motor speed/torque controlSynchronous motors startersSynchronous motorPhysics

The object of the invention is to inhibit the axial displacement caused by the insufficiency of a control response angular frequency of a frequency arithmetic unit of a synchronous motor and realize high-precision torque control also in acceleration / deceleration. To achieve the object, the axial displacement of the synchronous motor caused by the insufficiency of the control response angular frequency of the frequency arithmetic unit is estimated in consideration of the control response angular frequency and input Δθc3 (=Δθc1+Δθc2) including an estimated value Δθc2 in addition to an axial displacement operated value Δθc1 to the frequency arithmetic unit is acquired. Hereby, even if the frequency arithmetic unit has an insufficient control response angular frequency, the quantity of axial displacement which will be caused by the insufficiency is estimated as a second axial displacement signal Δθc2, is added and input. Therefore, actual axial displacement Δθc1 of the synchronous motor is stable at a value substantially close to zero.

Owner:HITACHI LTD +1

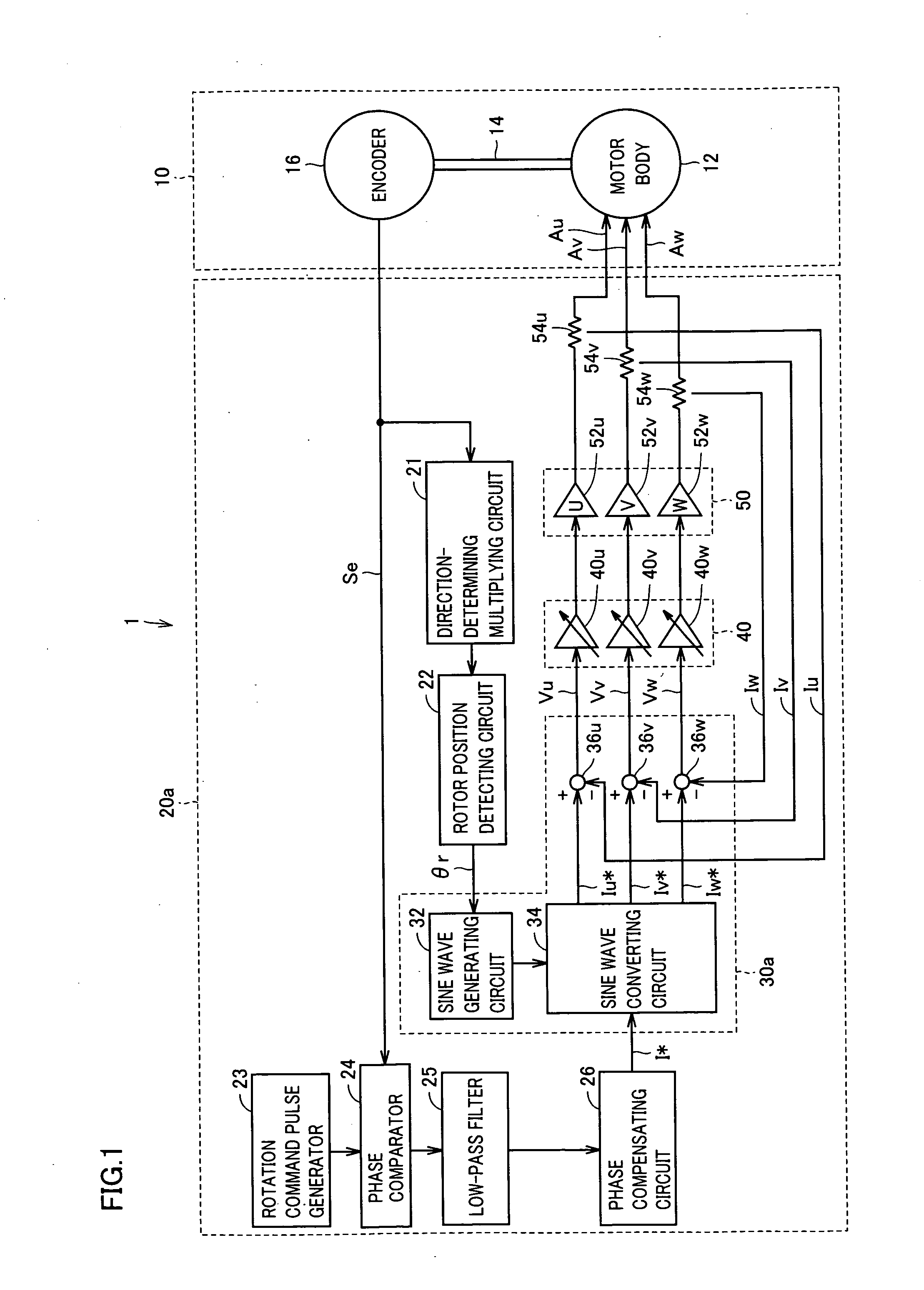

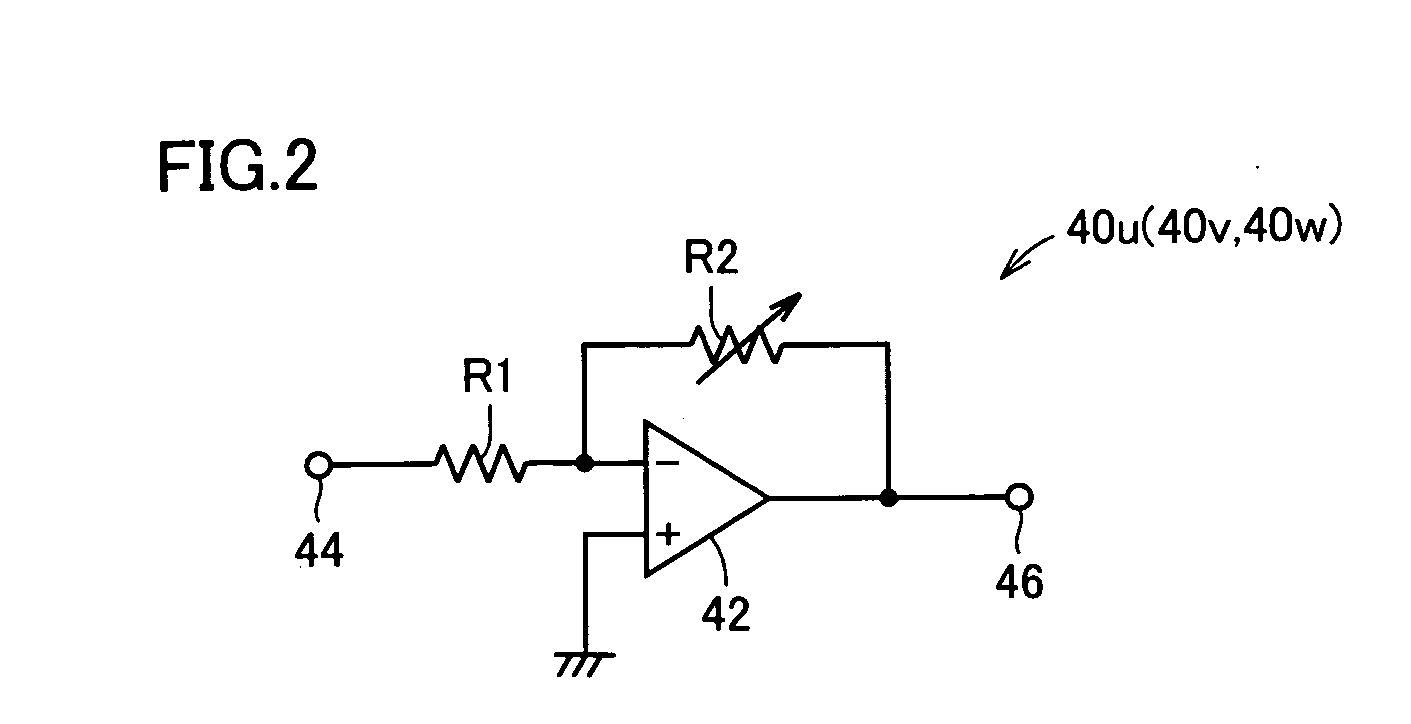

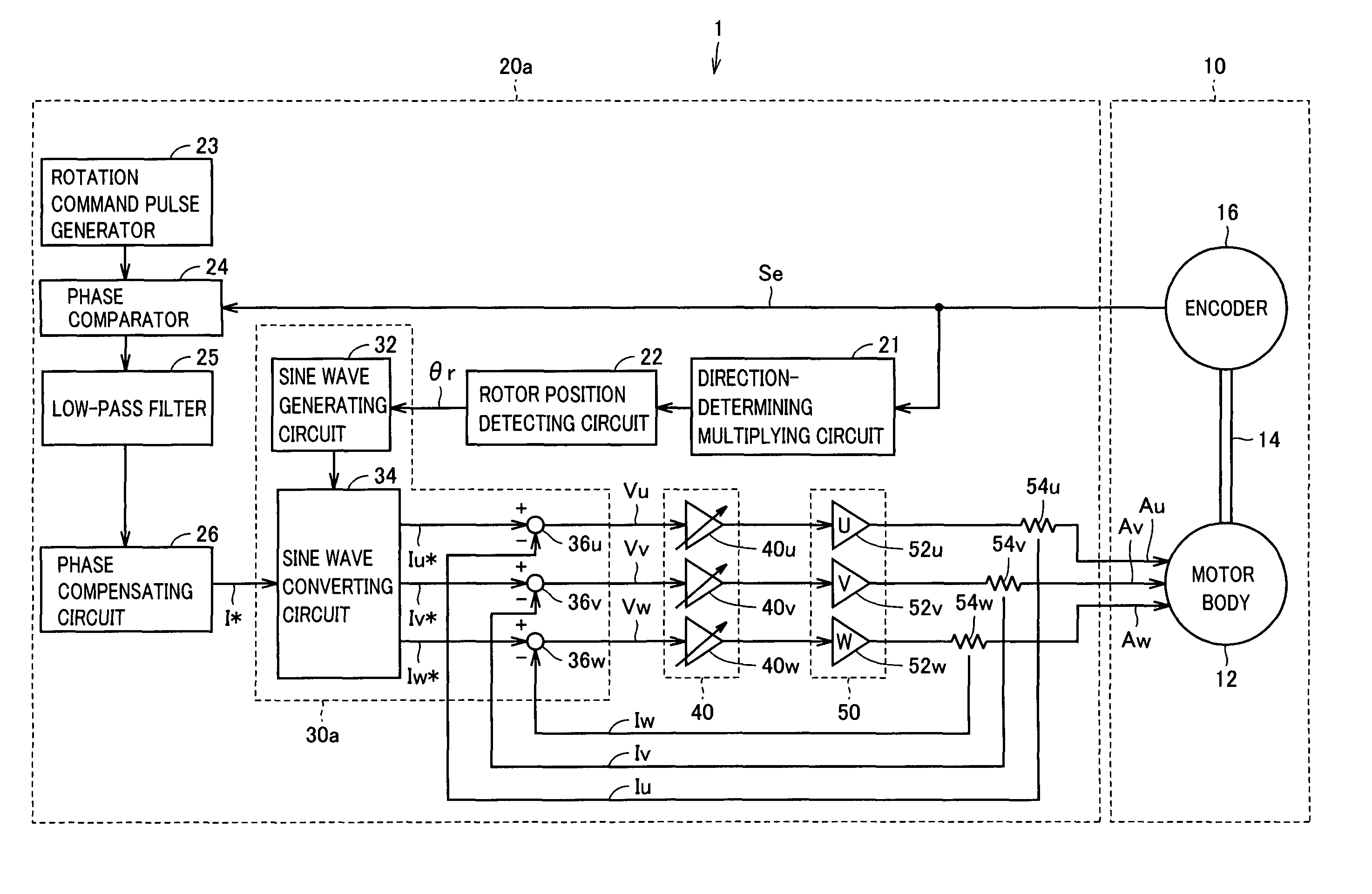

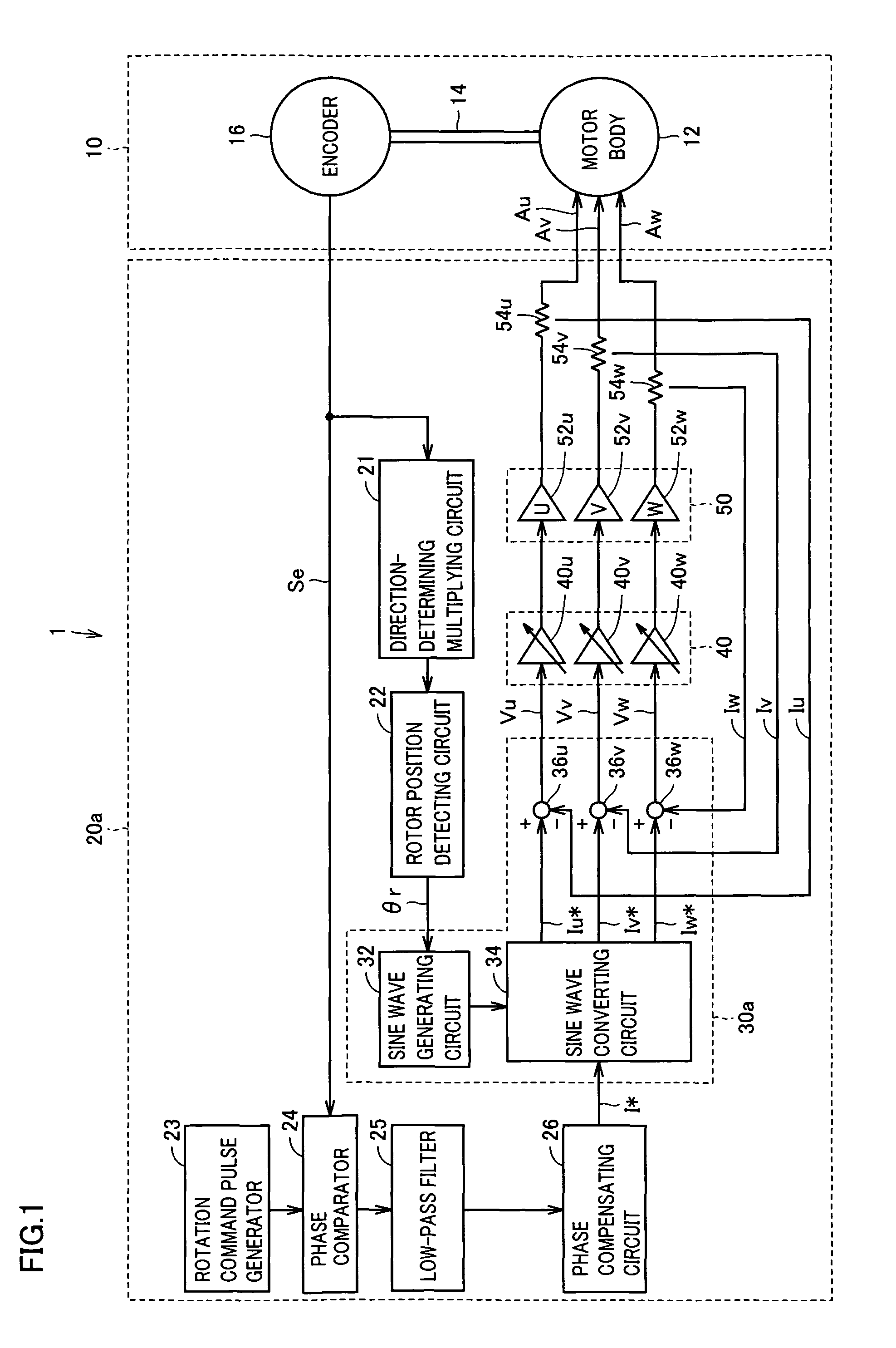

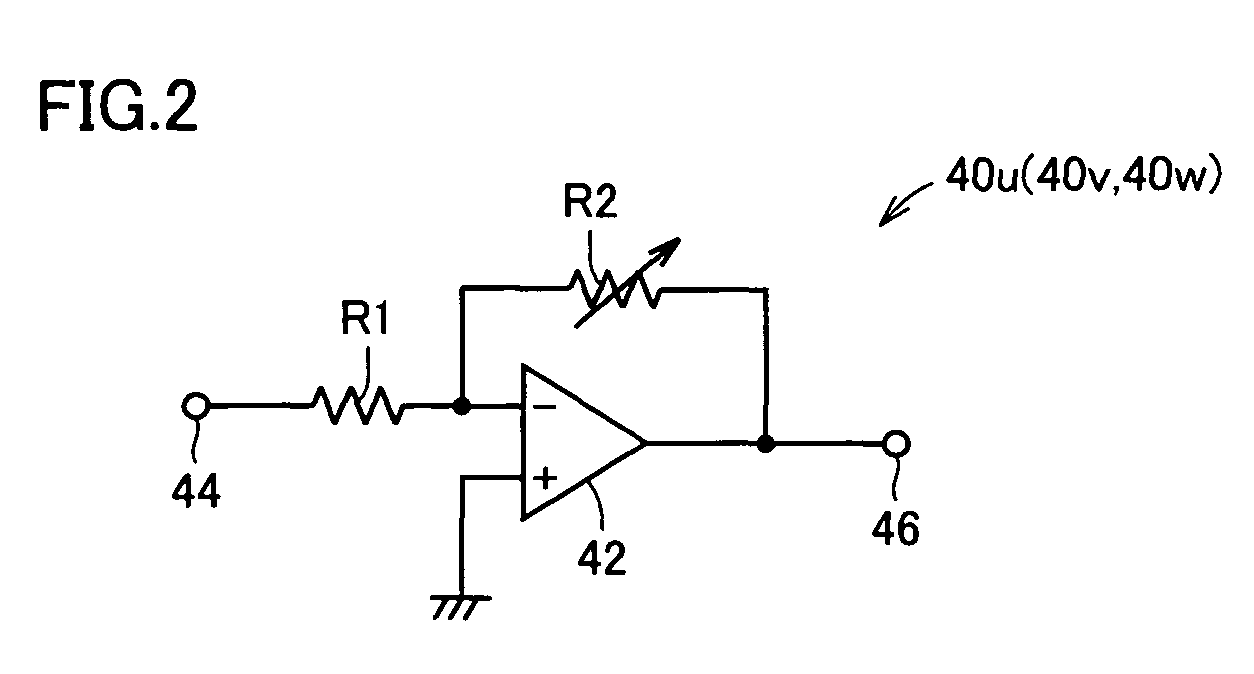

Drive control circuit for polyphase motor capable of reducing variation among armature currents of respective phases, and spindle apparatus using the same

ActiveUS20080297095A1Suppress fluctuationsReduce vibrationTorque ripple controlAC motor controlControl signalAmplitude control

Even when there is some degree of variation in the characteristics among components constituting a polyphase motor and a driving circuit therefor, current control signals of respective phases being input to the drive circuit have their amplitude finely adjusted by an amplitude control circuit, so that amplitude is uniform among armature currents of respective phases that are ultimately output from the drive circuit. The amplitude adjusting circuit is configured by gain variable amplifiers, for example. Thus, rotation fluctuation and vibration of the polyphase motor can be reduced.

Owner:NTN CORP

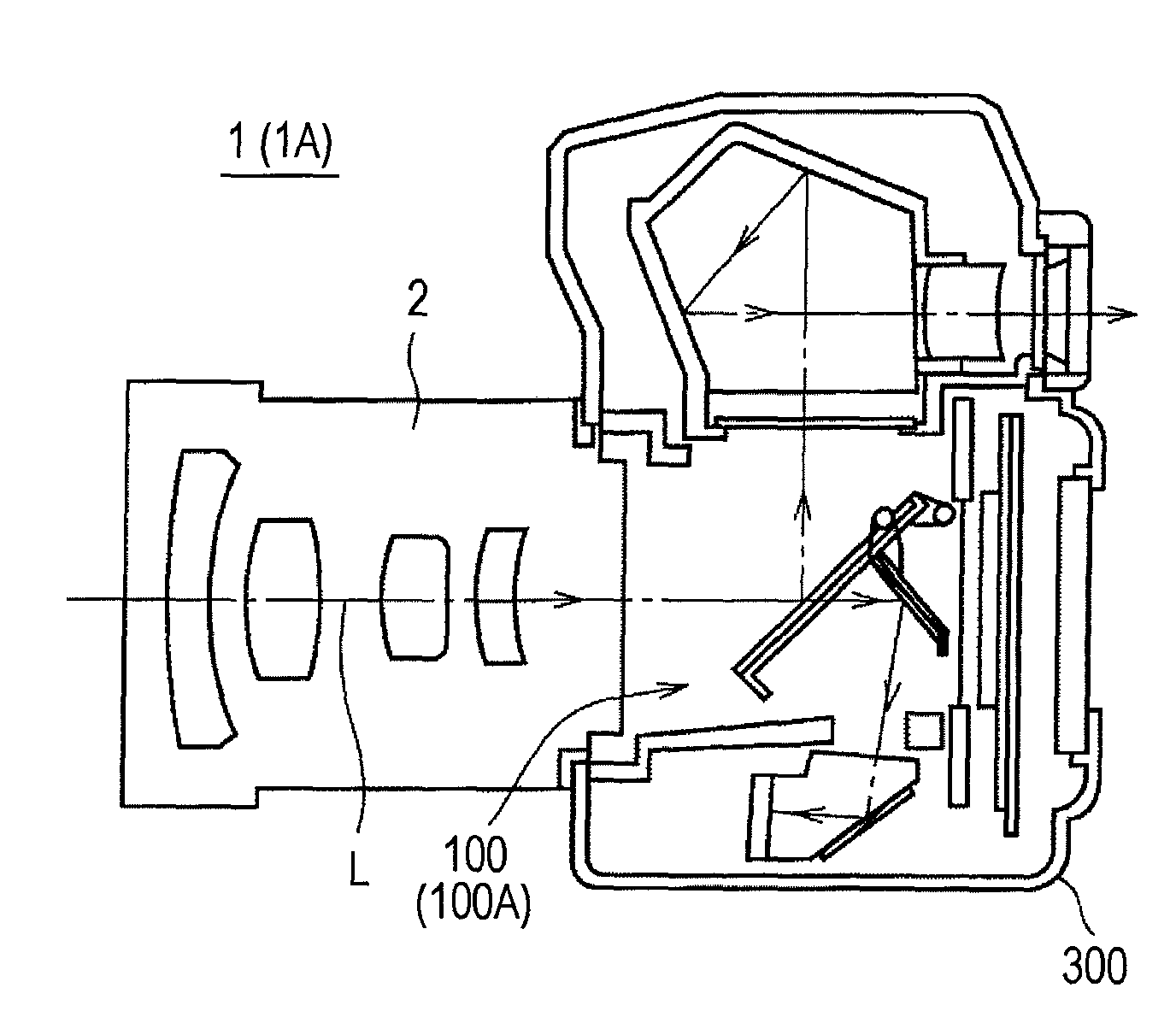

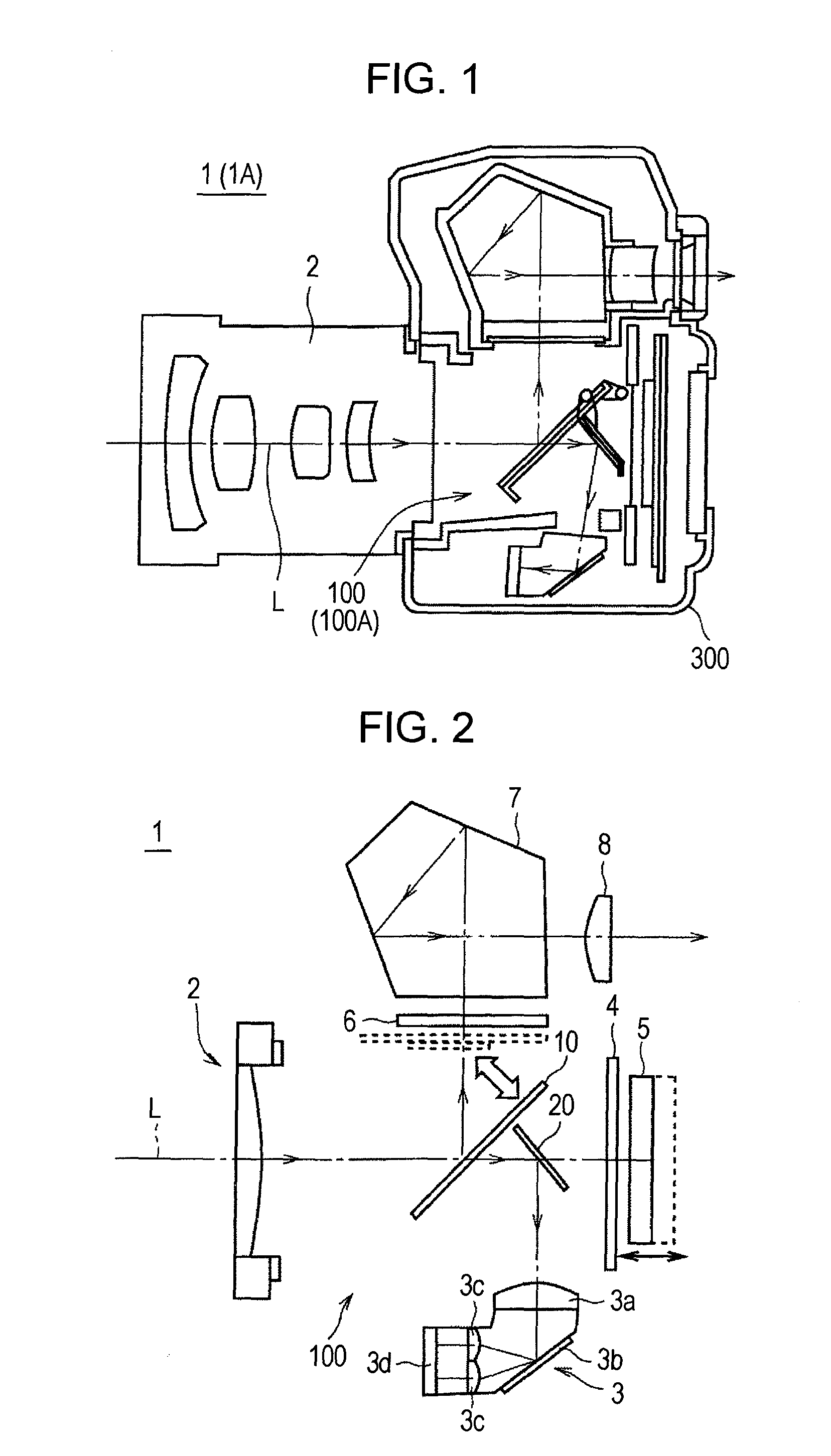

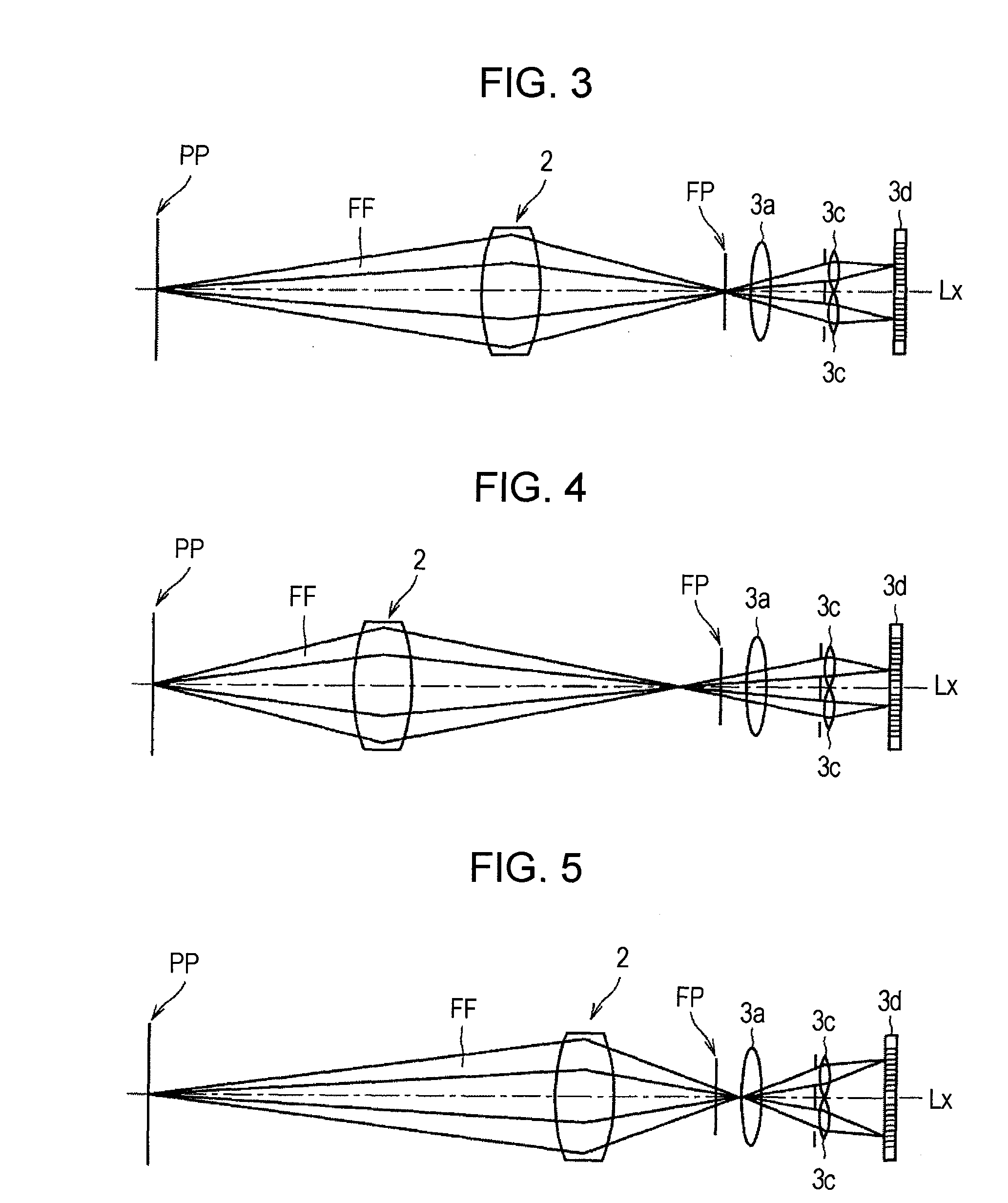

Focus control device and imaging device

InactiveUS20090066830A1High precision focus controlFast and precise focus controlTelevision system detailsColor television detailsCamera lensHigh-pass filter

An auto focus (AF) circuit includes a high-pass filter and band-pass filter having mutually different frequency characteristics. During contrast AF control prior to an actual shooting, AF evaluation values acquired by using the high-pass filter are used most preferentially in detecting the lens focusing position of a focus lens. In this way, the high-pass filter that emphasizes and extracts high frequency band components, which increase in image data when shooting a typical subject, is set to be used preferentially, thereby making it possible to perform high-precision focusing control with respect to various kinds of subjects.

Owner:SONY CORP

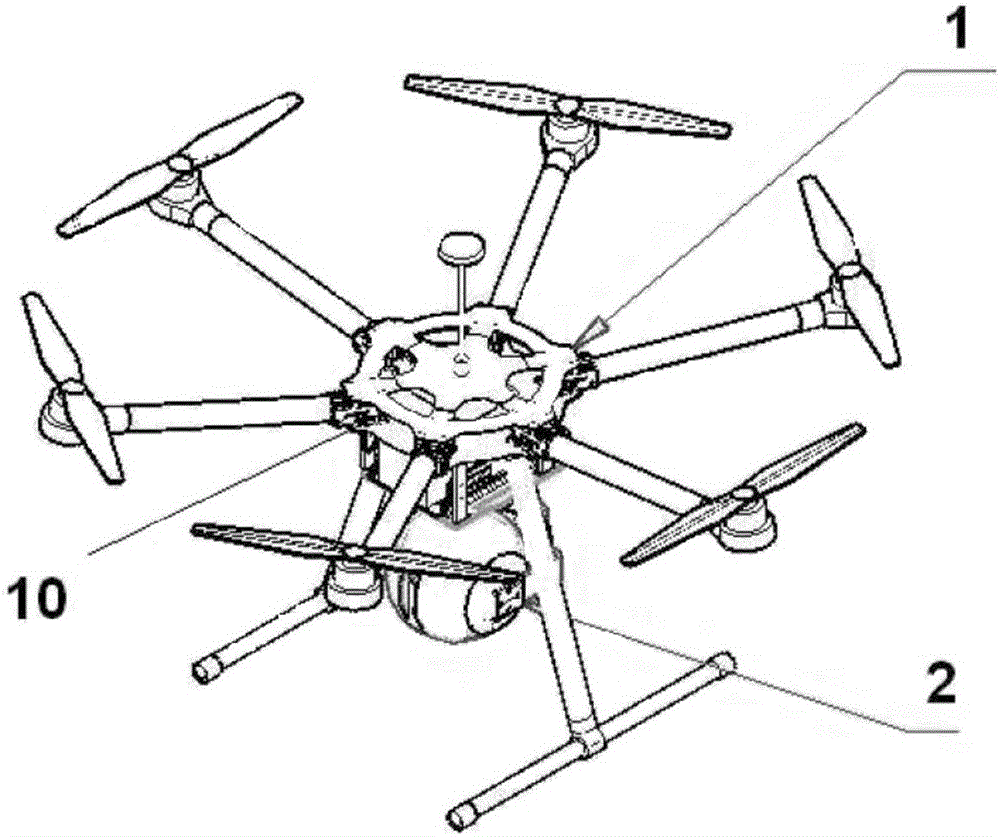

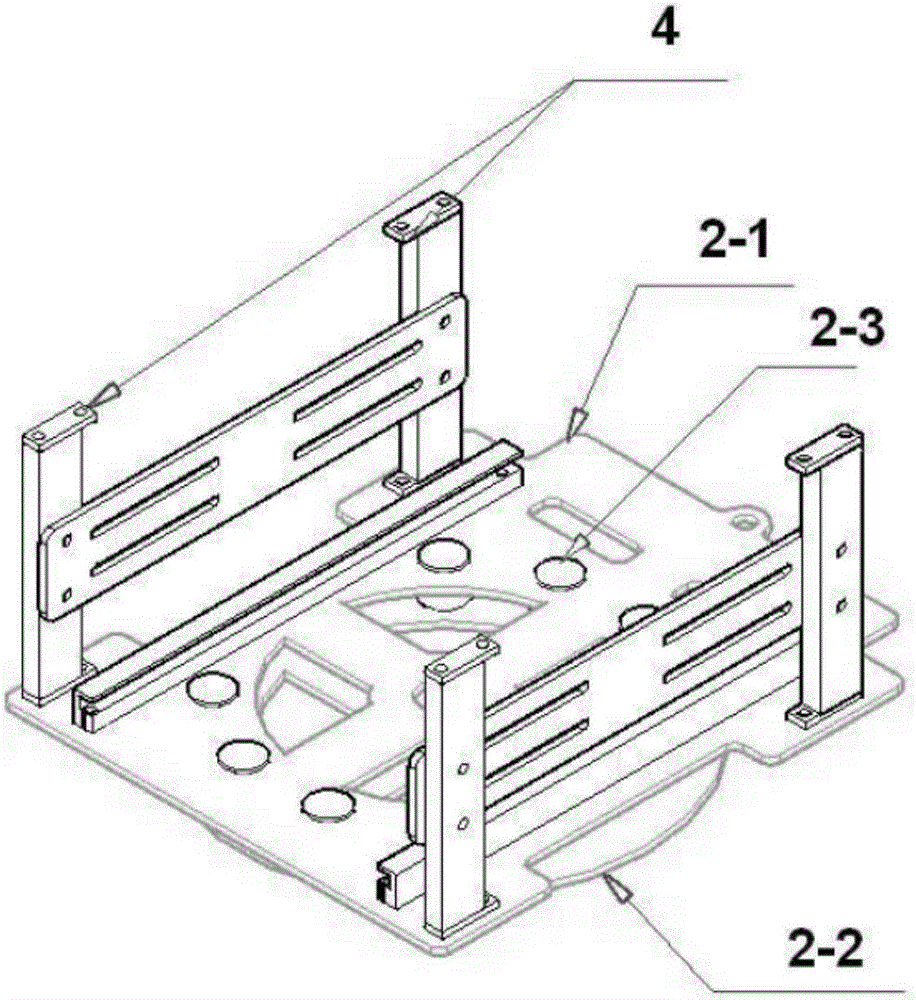

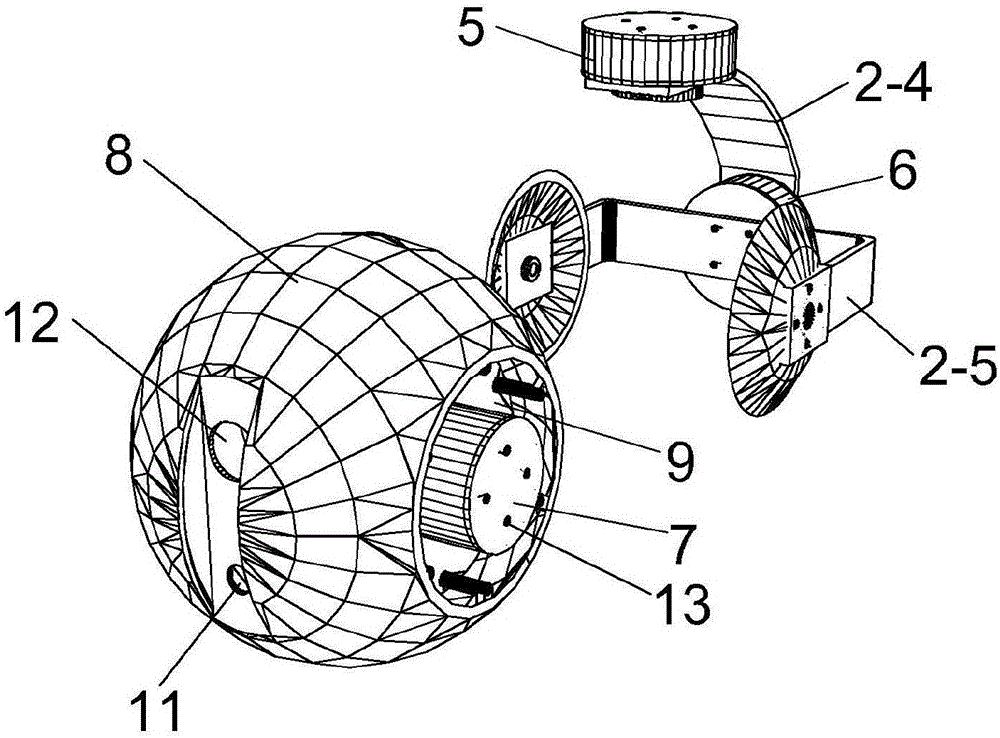

Unmanned aerial vehicle

InactiveCN106586009AGuaranteed stabilityGuaranteed clarityNon-rotating vibration suppressionAttitude controlEngineeringElectric power

The invention relates to an unmanned aerial vehicle, comprising an unmanned aerial vehicle aircraft, a cradle head and a shooting device, wherein the shooting device is installed at the lower part of the cradle head, the cradle head comprises an upper cradle head plate, a cradle head damping ball and a lower cradle head plate, the cradle head damping ball is connected with the upper cradle head plate and the lower cradle head plate respectively, and the lower cradle head plate is connected with a rotary motor. The used unmanned aerial vehicle can better meet requirements of power line inspection and is compatible with multi-functional devices to meet requirements of long-line power line inspection, self-stabilizing multi-angle zooming shot and self protection.

Owner:江苏云端智能科技有限公司

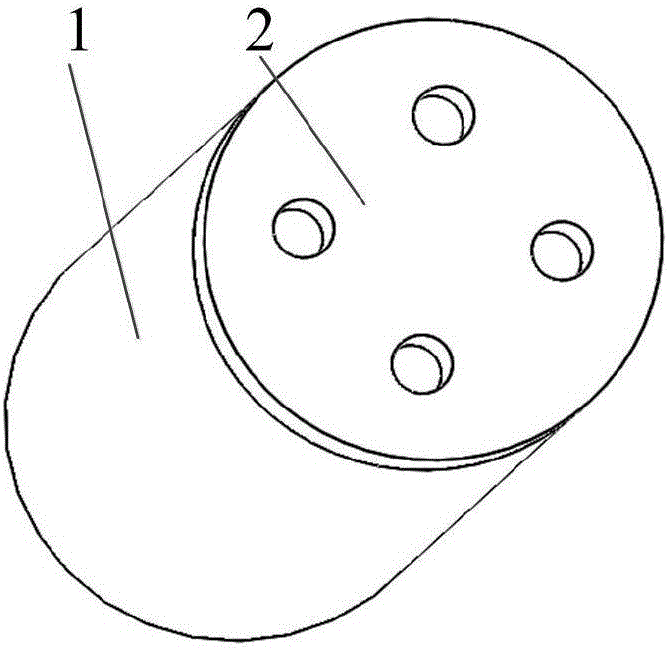

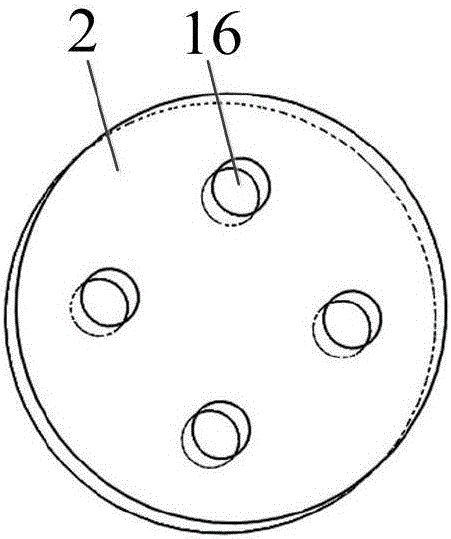

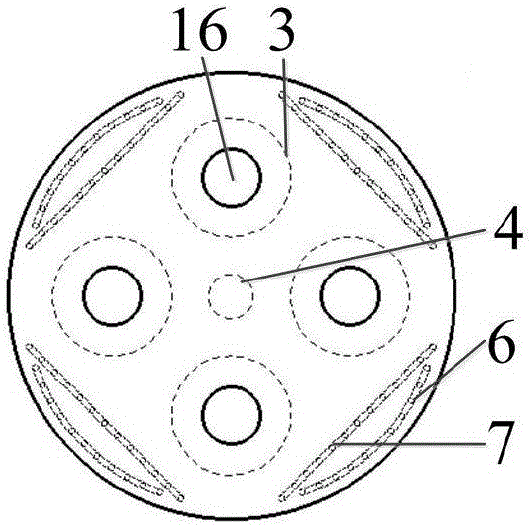

Pneumatic redundancy self-sensing multi-degree-of-freedom flexible nimble finger

PendingCN106695854AUniform forceAvoid breakingProgramme-controlled manipulatorGripping headsEngineeringMulti degree of freedom

A pneumatic redundancy self-sensing multi-degree-of-freedom flexible nimble finger comprises a cylindrical flexible finger base body and a circular-truncated-cone-shaped flexible connecting base body. The flexible finger base body is provided with four pneumatic cavities distributed circumferentially and evenly in the axial direction. A bent inner core is arranged at the axis of the flexible finger base body, and tube connectors are arranged at the end of the flexible finger base body. Four micro sensitive channels distributed circumferentially and evenly are formed in the peripheries of the pneumatic cavities. Each micro sensitive channel comprises an arc sensitive channel body and a linear sensitive channel body and is filled with gallium-indium-tin liquid alloy or a liquid sensitive piezoresistive element. Four rubber tube connectors are arranged at the finger root of the flexible nimble finger and correspond to the pneumatic cavities. The pneumatic redundancy self-sensing multi-degree-of-freedom flexible nimble finger has the advantages of being simple in structure, low in weight, clean, safe, large in working space, high in control precision and the like, the effect that the multi-degree-of-freedom flexible mechanical finger has high precision during operation can be ensured, and the finger can be widely applied to the multiple fields such as industrial and agricultural production, national defense security and medical rehabilitation.

Owner:YANSHAN UNIV

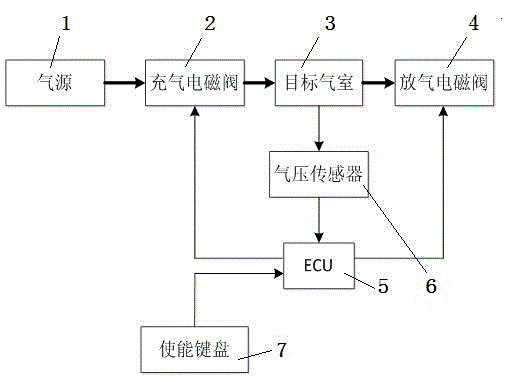

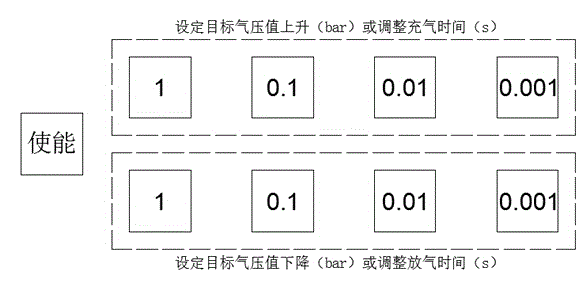

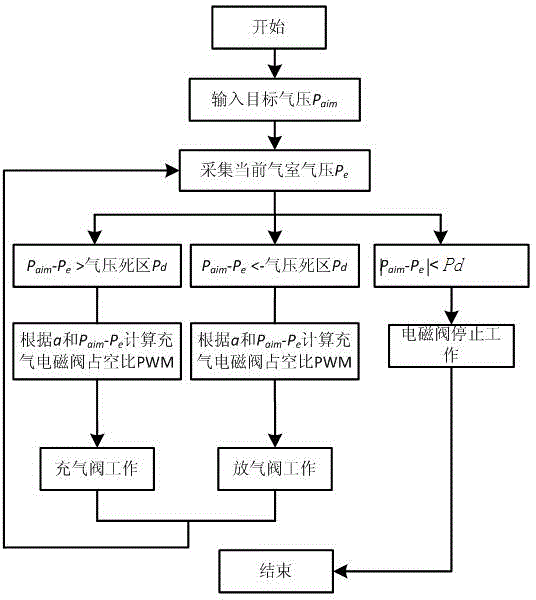

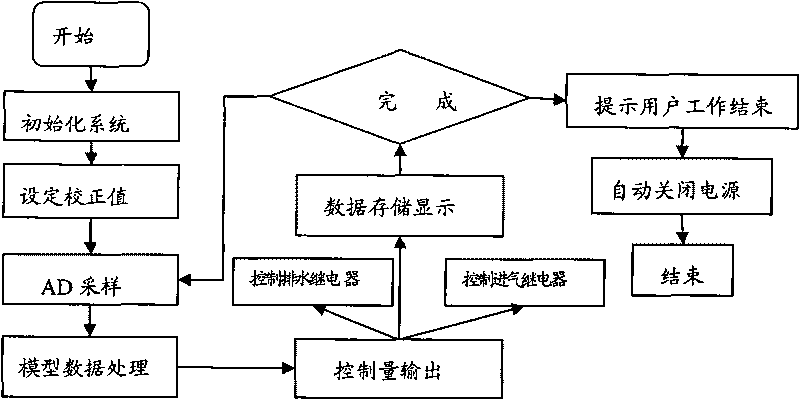

Method for charging and discharging air as well as maintaining and controlling air pressure

InactiveCN104309415AEasy to operateMeet different needsTyre measurementsStopped workAutomatic control

The invention discloses a method for charging and discharging air as well as maintaining and controlling air pressure. The method comprises the steps of inputting the needed target air pressure value Paim into an electronic control unit (ECU) control system by an enable keyboard; subtracting the Paim and current air pressure value Pe of a target air chamber to obtain difference, and comparing the obtained difference with the air pressure dead zone value Pd; if the difference of Paim and Pe is larger than Pd, controlling an air charging electromagnetic valve to charge air by the ECU control system which generates the corresponding pulse signal according to the duty ratio; if the difference of Paim and Pe is less than Pd, controlling an air discharging electromagnetic valve to discharge air by the ECU control system according to the duty ratio; when the absolute value of the difference of the target air pressure value Paim and the current air pressure value Pe is less than the air pressure dead zone value Pd, controlling the electromagnetic valves to stop working by the ECU control system according to the duty ratio at the moment. After the method is adopted, air charging and discharging can be carried out on the closed air chamber with any form; when the air chamber with the unknown pressure value reaches the needed air pressure value after being manually adjusted, the air chamber can be switched into an automatic control mode at any time, and the current air pressure value is maintained to be constant; the method is simple in operation and high in controllable degree.

Owner:JIANGSU UNIV

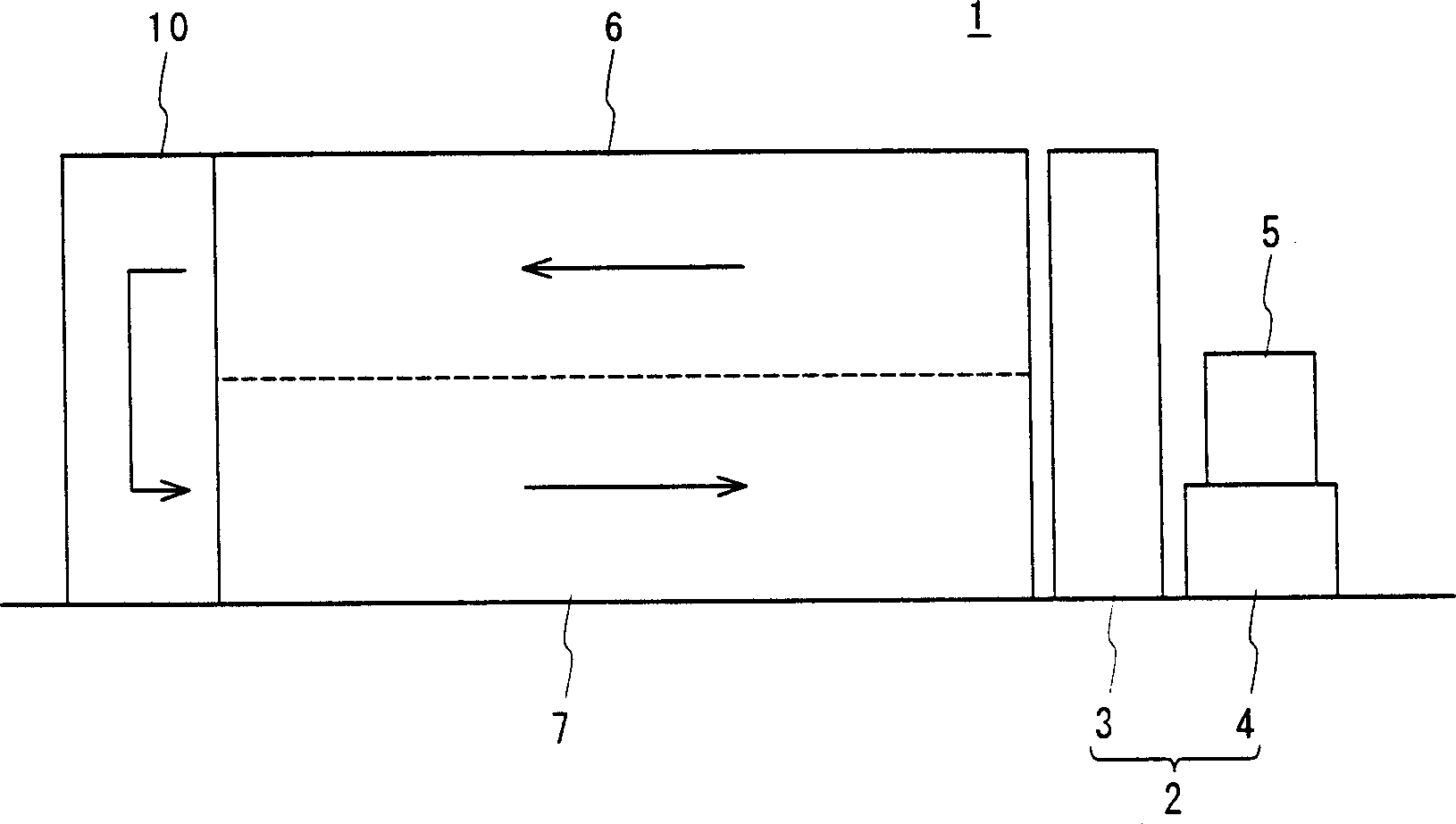

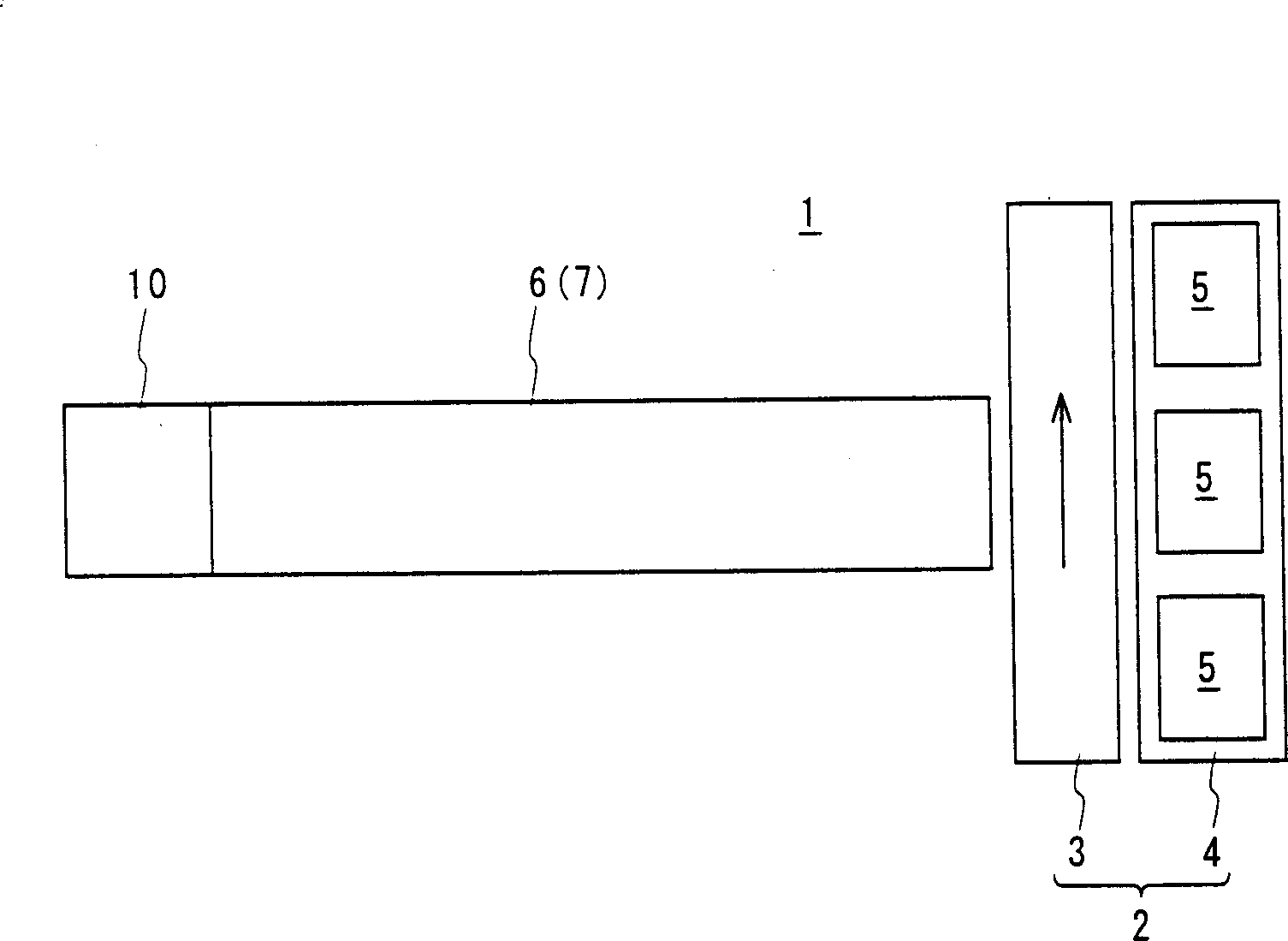

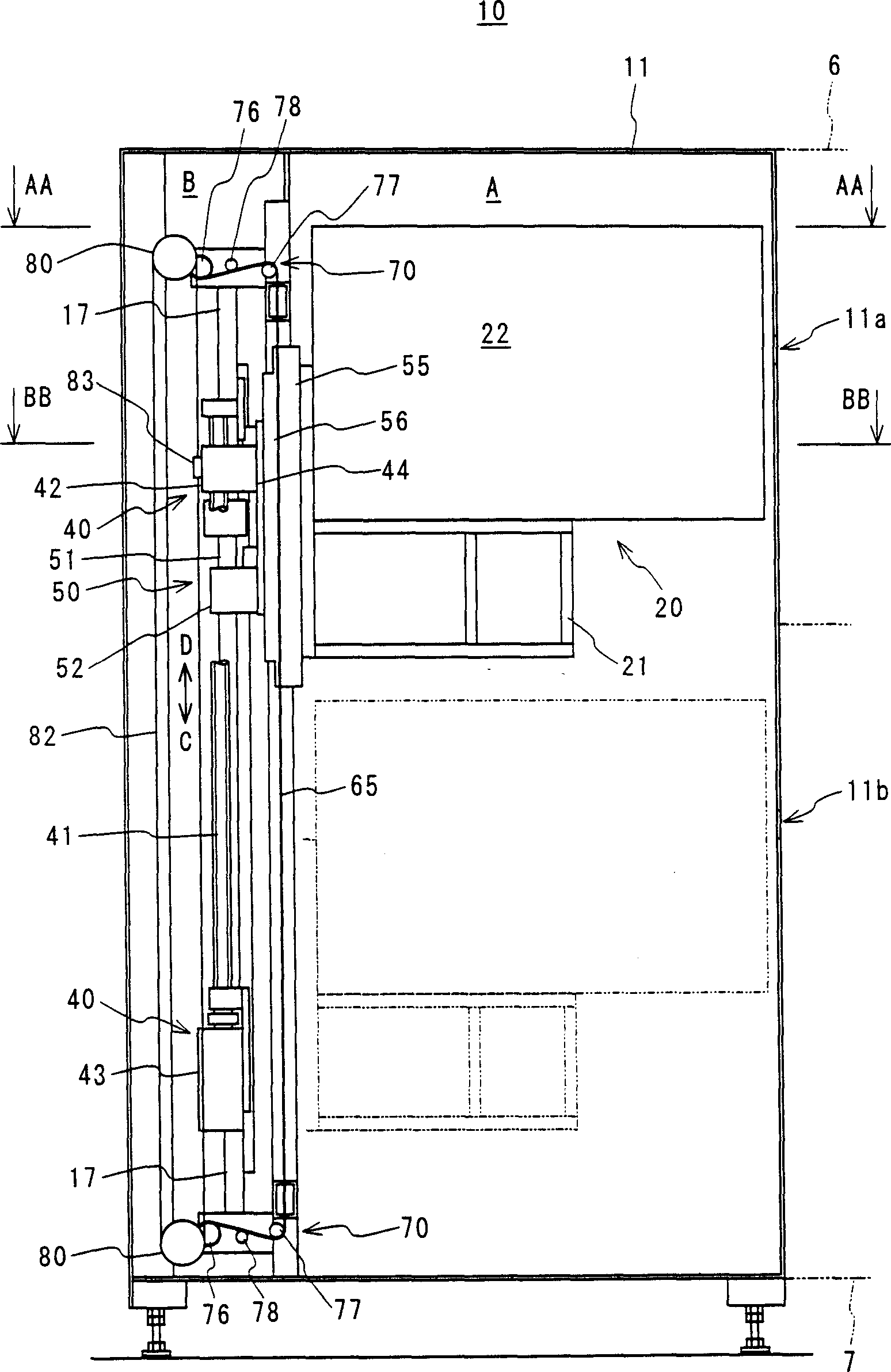

Lifting/lowering type substrate proless device and substrate process system having same

InactiveCN1484279AFlexible speed controlHigh precision controlSemiconductor/solid-state device manufacturingNon-linear opticsProcess systemsElectrical and Electronics engineering

The substrate treatment apparatus 10 includes a housing shape cover 11 having a substrate input port 11a and a substrate discharge port 11b provided in parallel in a vertical direction, and a treatment mechanism 20 mounted in the cover 11. The apparatus 10 further includes the treatment mechanism 20 having a conveying / supporting means for receiving and supporting the substrate conveyed from the input port 11a and discharging the substrate from the port 11b, a support substrate 21 for supporting the conveying / supporting means, a substrate inclining means for inclining the substrate supported by the conveying / supporting means, and a treatment fluid discharge means arranged above the substrate / supporting means to discharge a treatment fluid on the substrate inclined by the substrate inclining means, and a lifting means 40 for supporting the treatment mechanism 20, lifting the treatment mechanism 20 in a vertical direction and making the treatment mechanism 20 pass via the port 11a and the port 11b.

Owner:SUMITOMO PRECISION PROD CO LTD

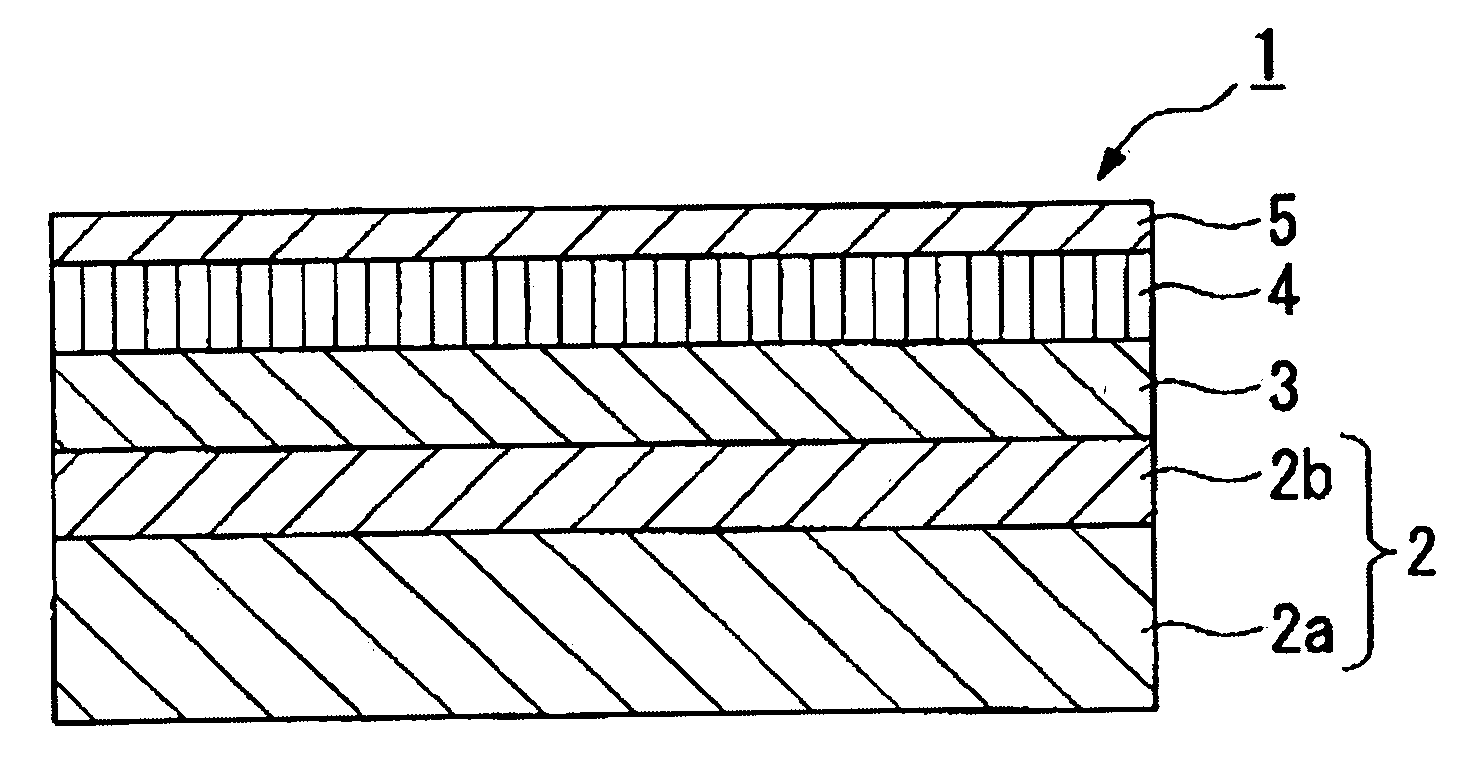

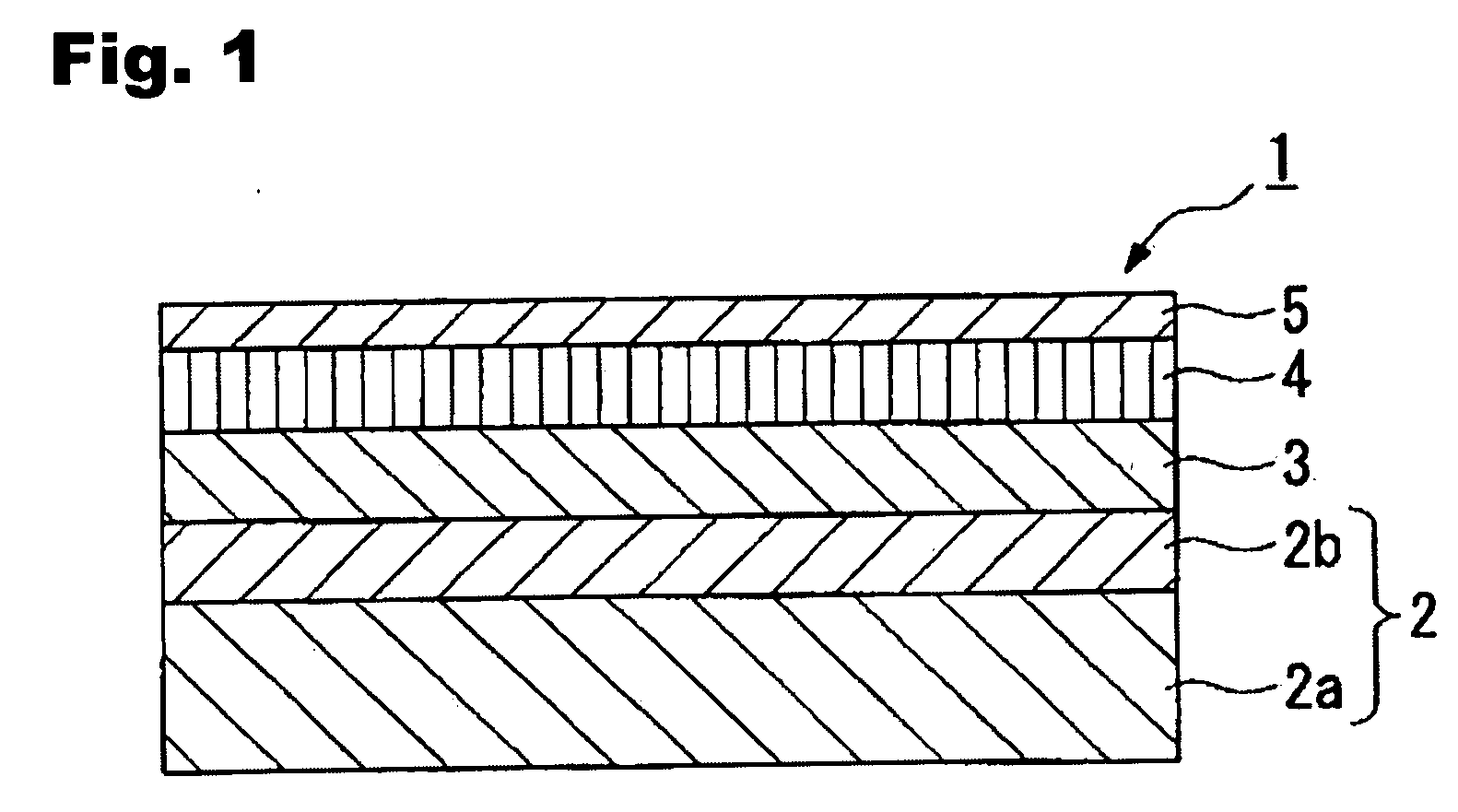

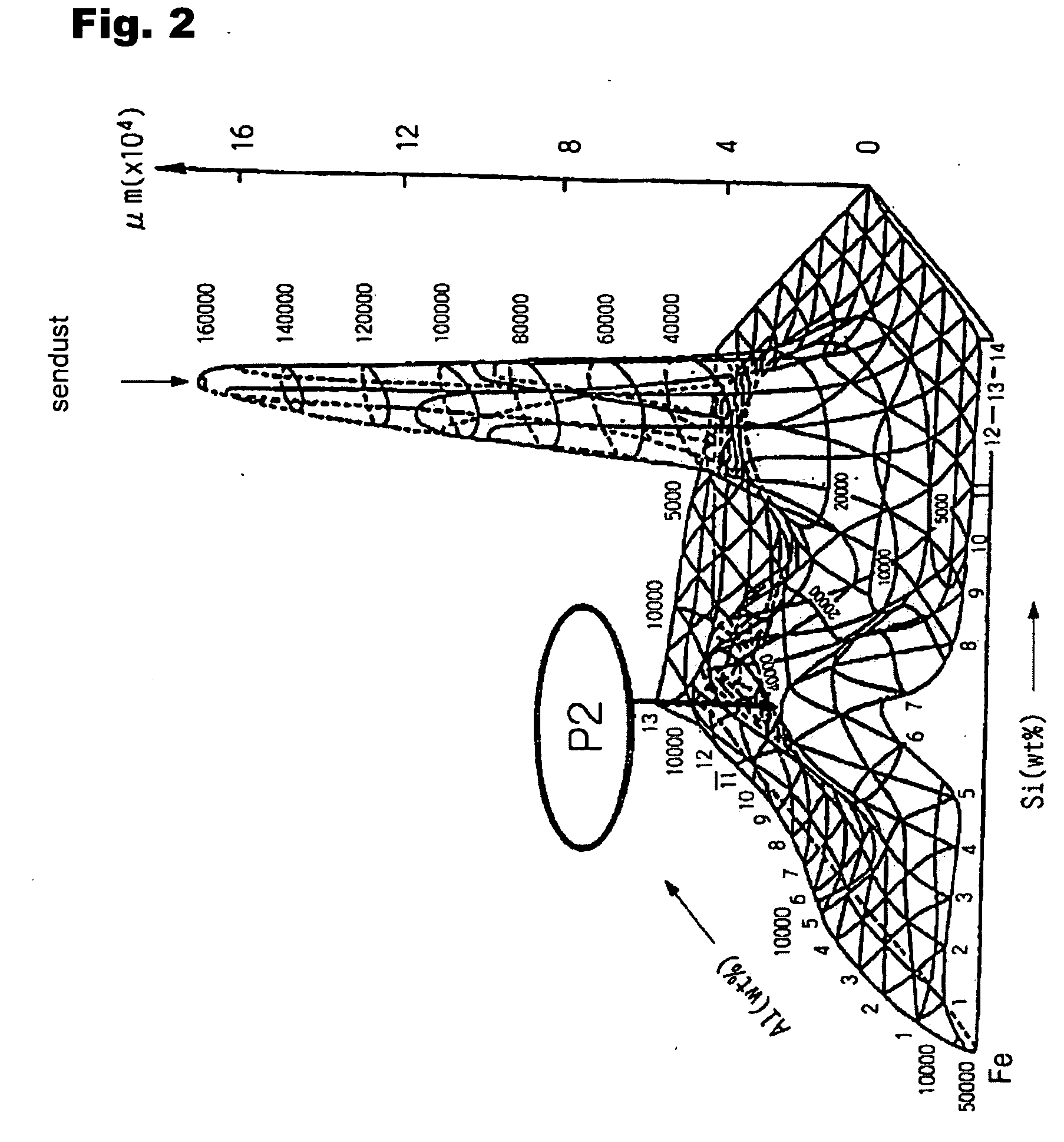

Vertical magnetic recordding medium magnetic recorder having same vertical magnetic recording medium manufacturing method and vertical magnetic recording medium manufacturing apparatus

InactiveUS20050158585A1High precisionHigh-precision controlBase layers for recording layersRecord information storageCrystalline materialsPermalloy

A vertical magnetic recording medium has a low-noise characteristic compared to media of a permalloy or sendust crystalline material, including a high-flatness soft magnetic backing layer, and enabling recording / reproduction of information at high recording density, a magnetic recorder provided with the vertical magnetic recording medium, a vertical magnetic recording medium manufacturing method and apparatus. The vertical magnetic recording medium has a multilayer structure on a substrate, in which a soft magnetic backing layer, a vertical recording layer of a ferromagnetic body, and a protective layer are formed. The soft magnetic backing layer is formed of an FeSiAlN film of a soft magnetic material. The atom % of each element of Fe, Si, Al, and N of the FeSiAlN film can be changed by changing the flow rate of N2 gas in a mixture gas of N2 gas and Ar gas introduced into the chamber.

Owner:CANON ANELVA CORP +3

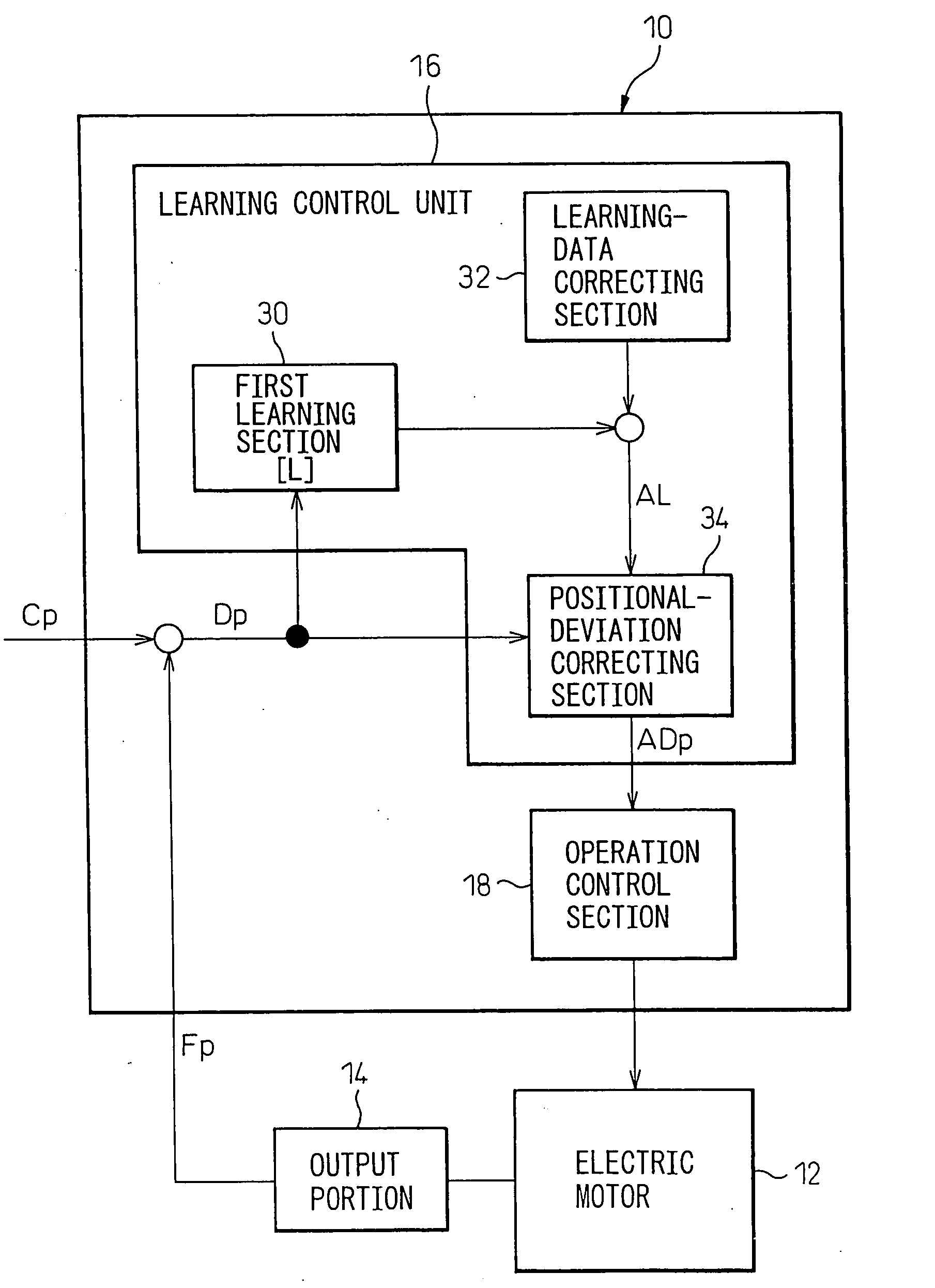

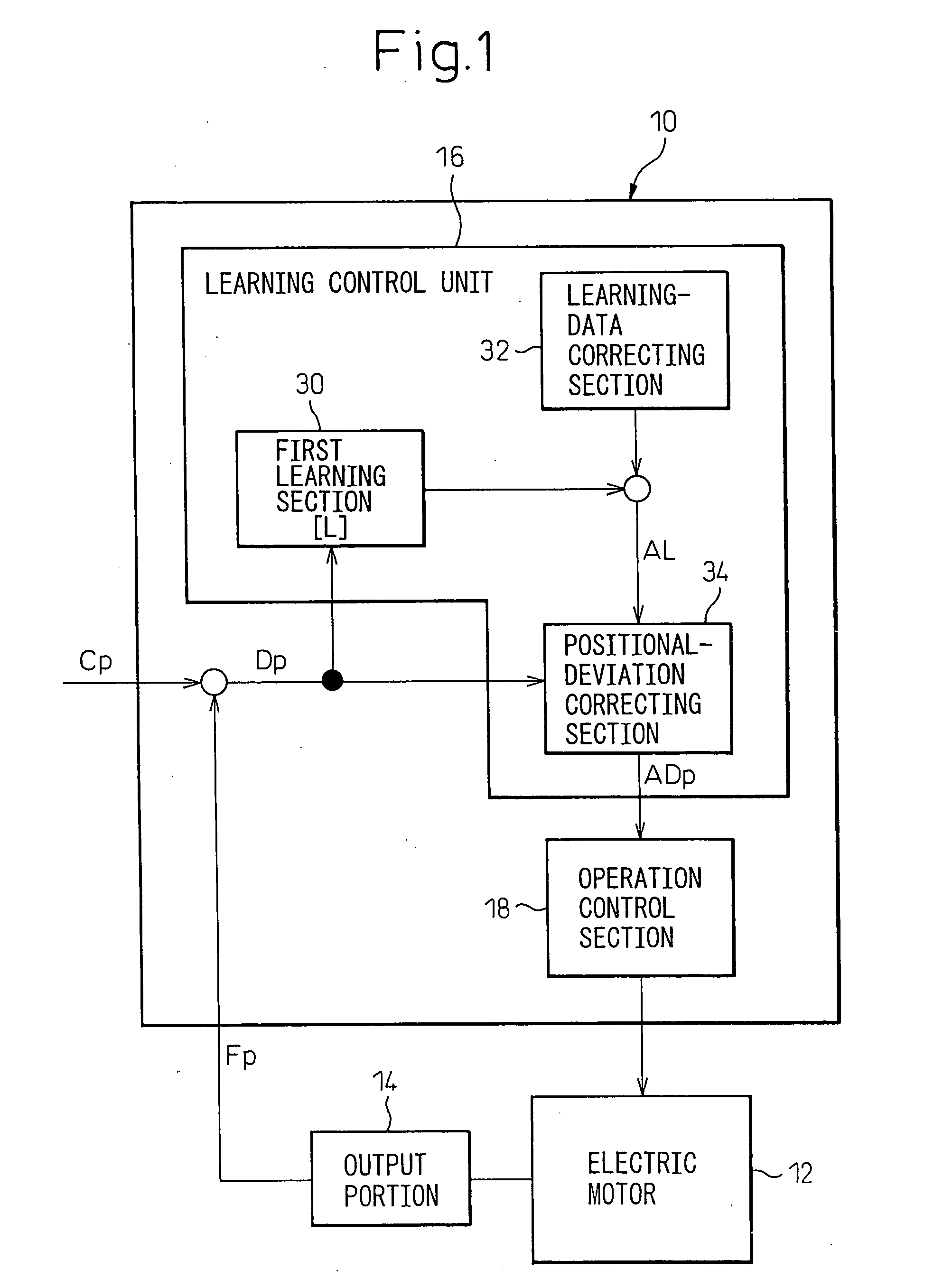

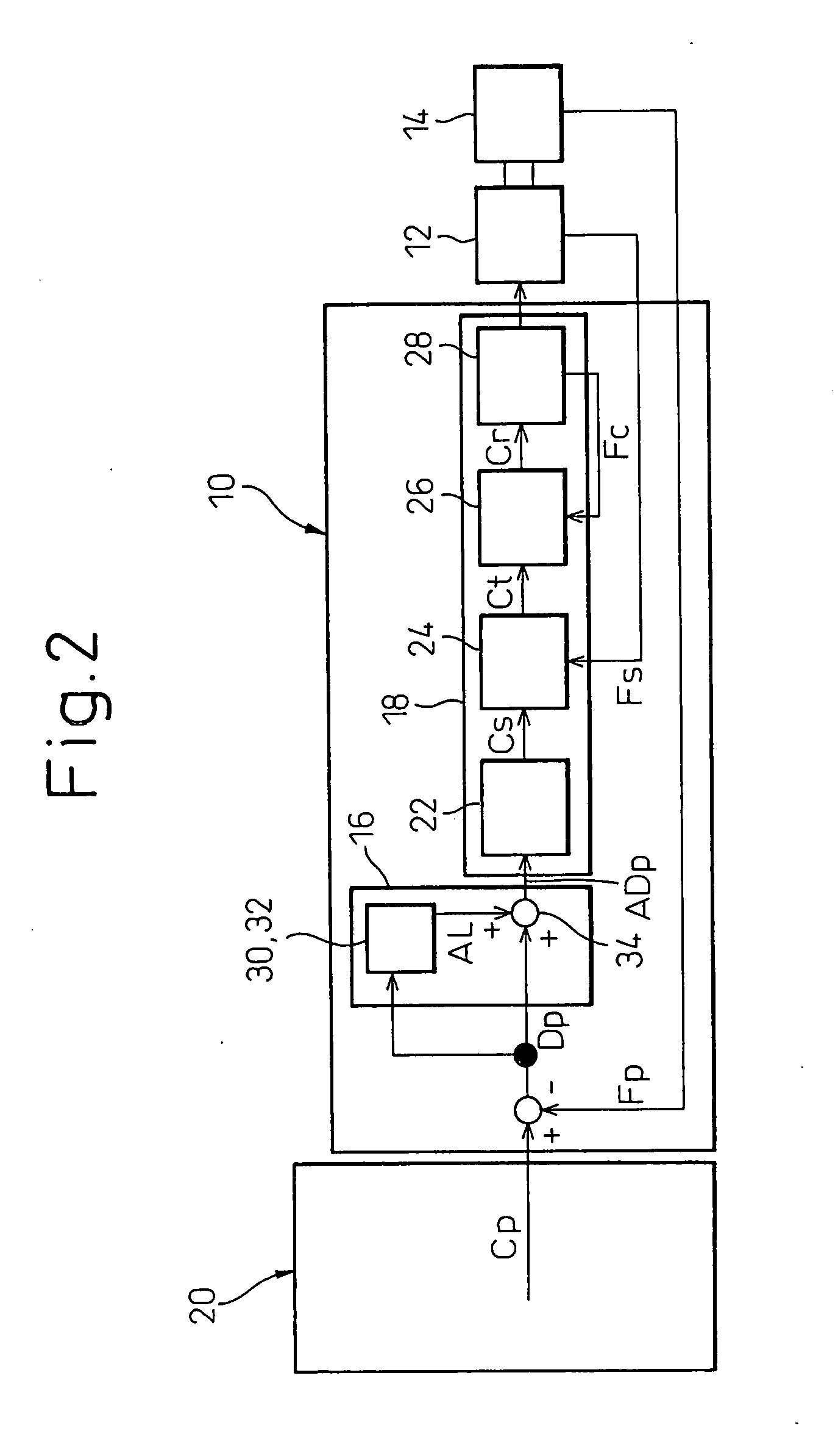

Controller for electric motor

ActiveUS20070205738A1High-precision controlImprove precision controlProgramme-controlled manipulatorComputer controlEngineeringControl unit

A controller including a learning control unit for determining learning data based on a positional deviation between a target-position command commanding superimposed-type motion including repetitive motion and a positional fed-back variable obtained from an output portion of an electric motor; and an operation control section for controlling the electric motor based on a corrected positional deviation. The learning control unit includes a first learning section for periodically determining, based on the positional deviation, and storing, first learning data according to a first learning period; a learning-data correcting section for correcting the first learning data to eliminate an influence of a local change included in the target-position command or the positional fed-back variable and periodically arising according to a period different from the first learning period; and a positional-deviation correcting section for correcting the positional deviation by using corrected learning data.

Owner:FANUC LTD

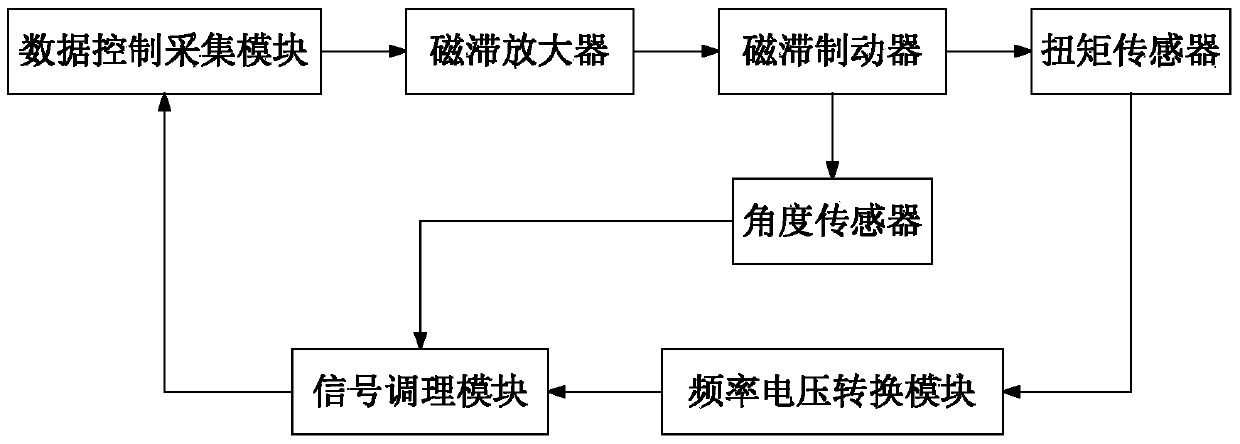

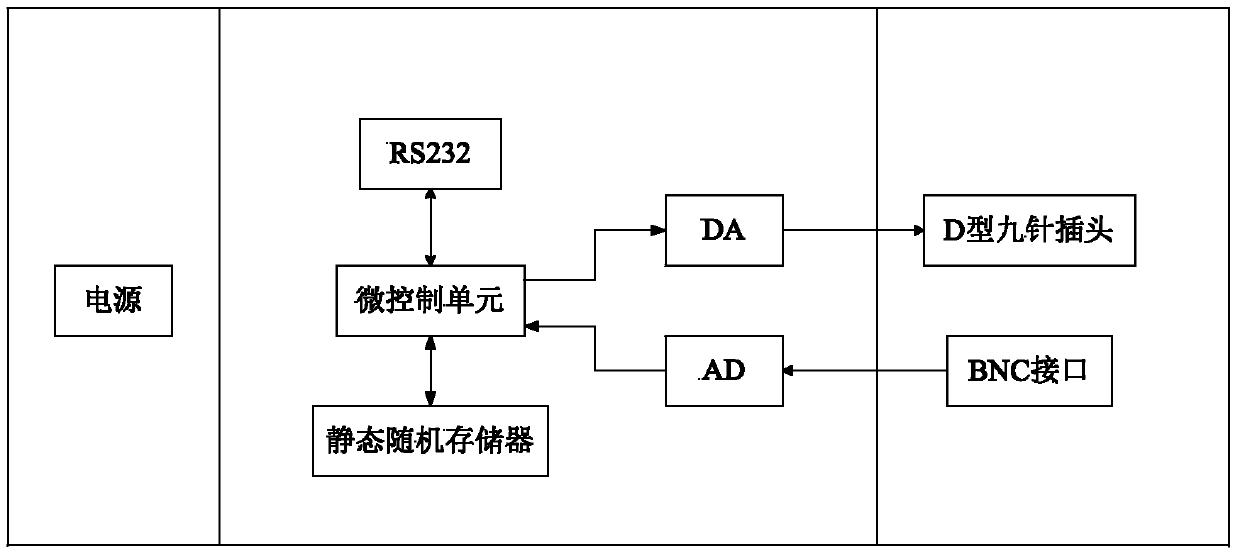

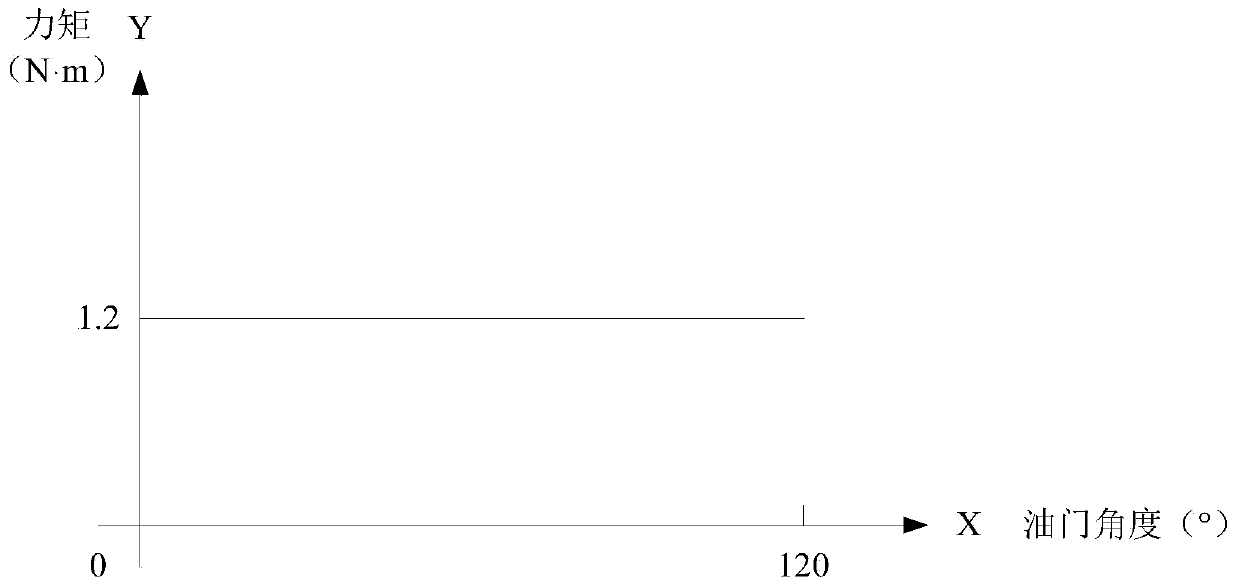

Anti-interference torque simulator

ActiveCN103991558AEfficient mobilizationImprove simulation accuracyAircraft components testingData controlHysteresis

The invention discloses an anti-interference torque simulator, and relates to a method for simulating the torque of a main pump of an engine in a ground test. The anti-interference torque simulator is characterized by comprising a data control collecting module, a hysteresis amplifier, a hysteresis brake, a torque transducer, an angular transducer, a frequency voltage conversion module and a signal conditioning module. According to the anti-interference torque simulator, the combination of the hysteresis amplifier and the hysteresis brake is adopted as the torque signal generating mode, the response time is short, the good linear relation exists between the control quantity and torque signals, control precision is high, and the anti-interference capacity is improved in the design.

Owner:SHENYANG AIRCRAFT DESIGN INST AVIATION IND CORP OF CHINA

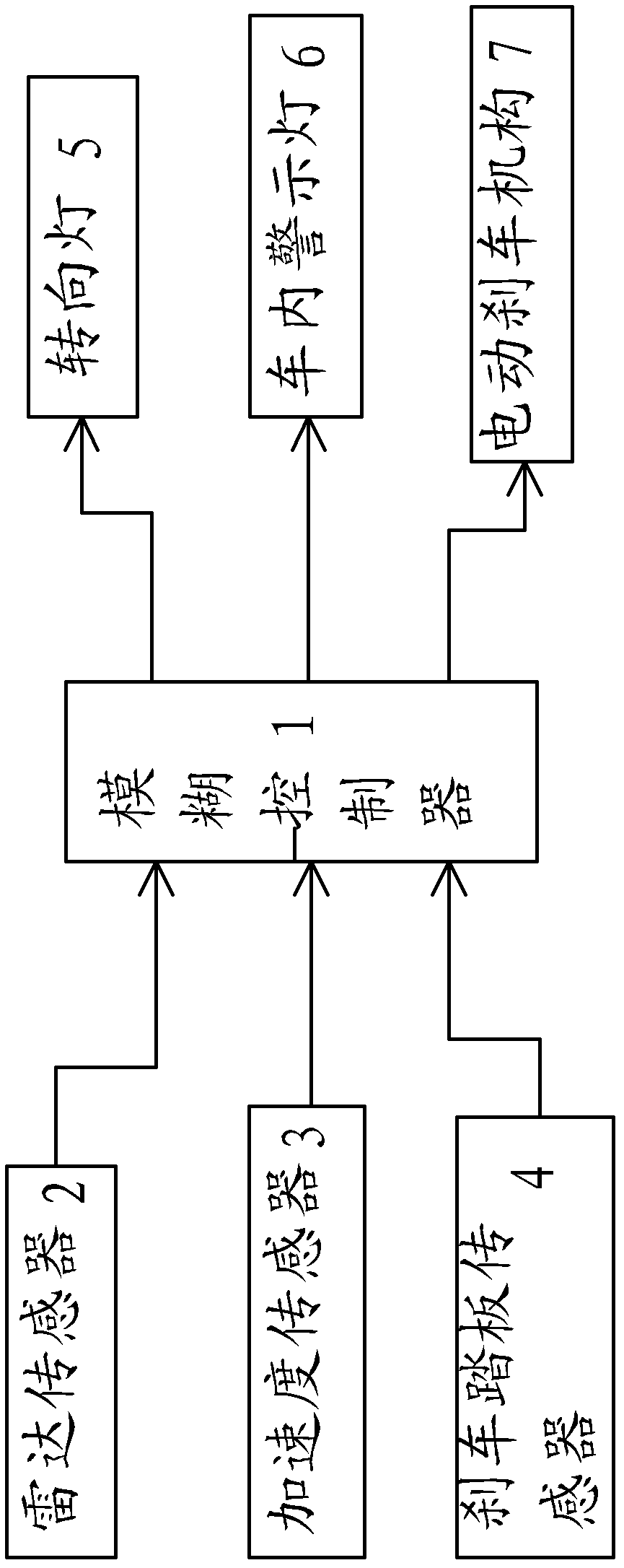

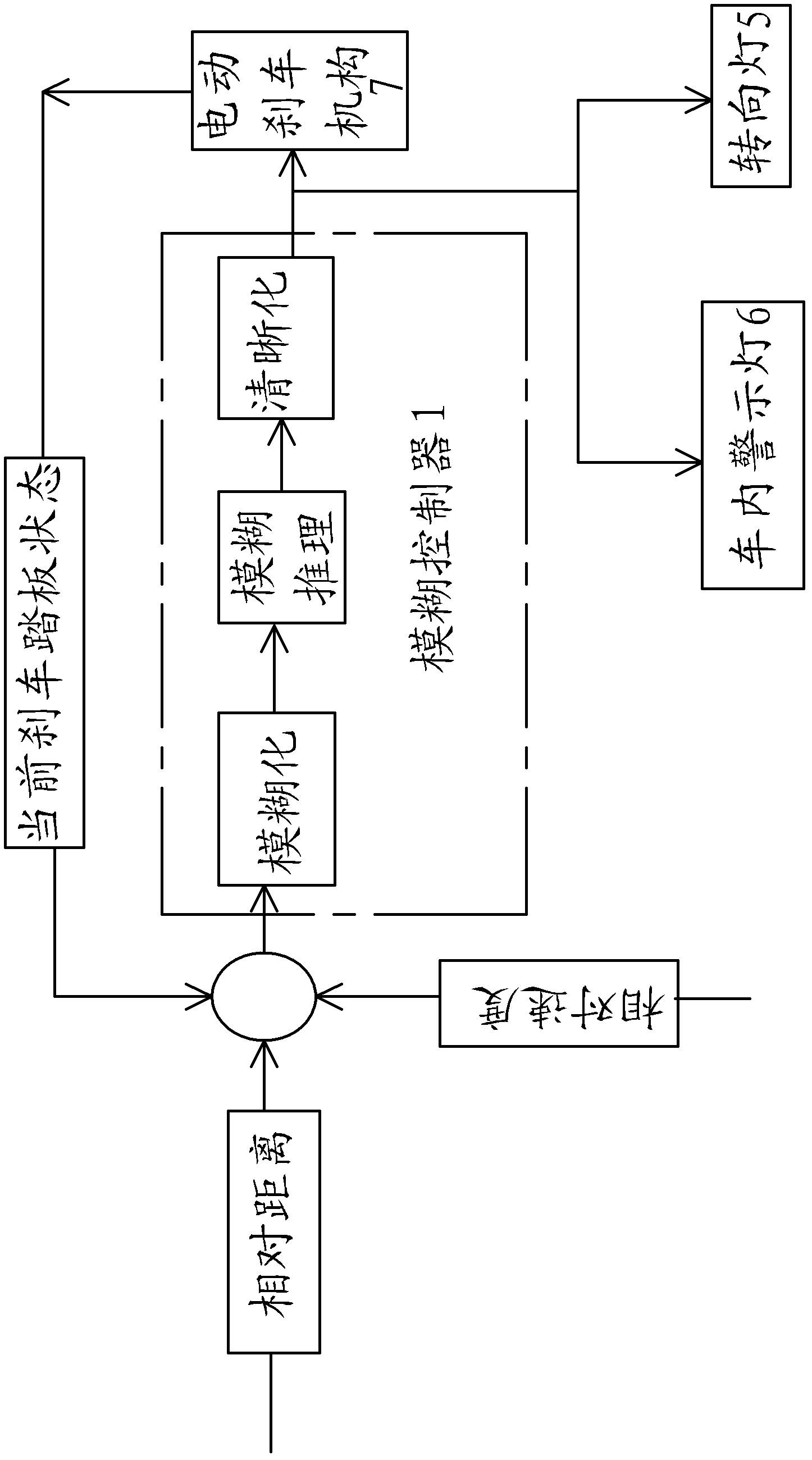

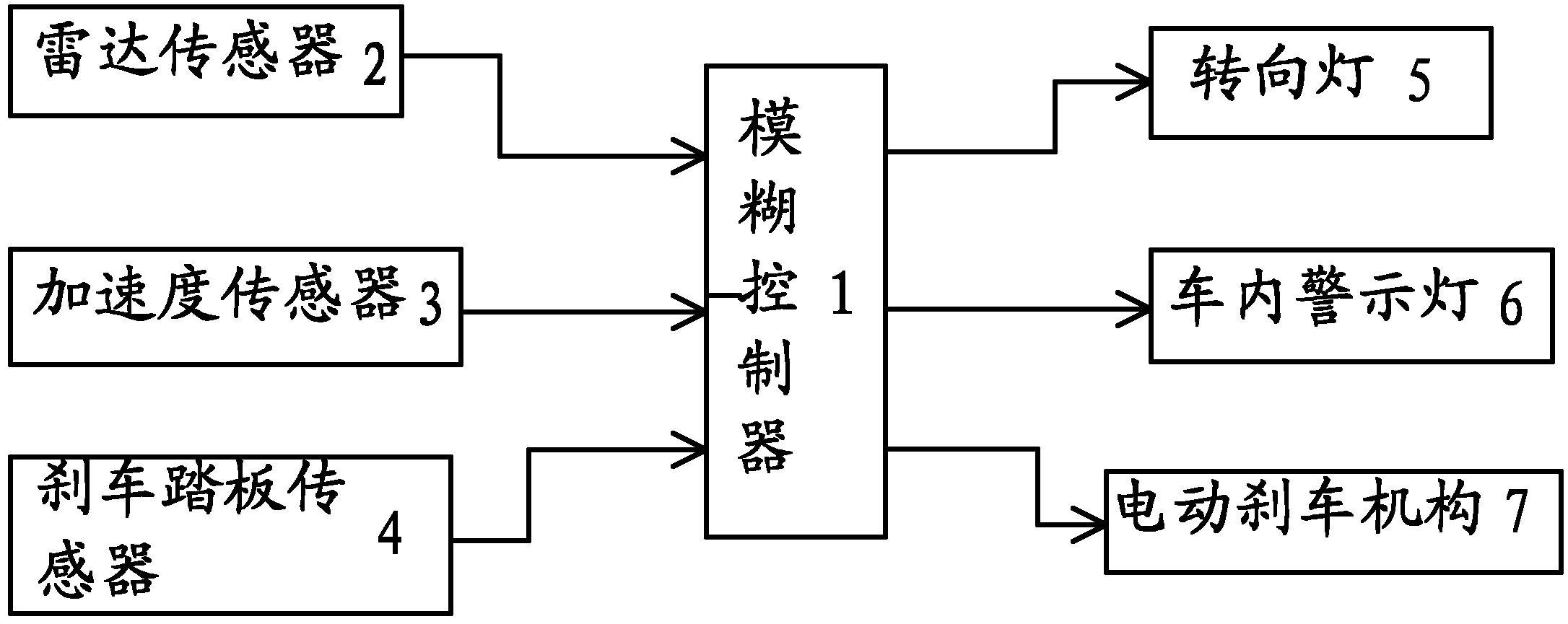

Intelligent brake control device and control method thereof

InactiveCN102556022AImprove intelligenceReduce the chance of misjudgmentAutomatic initiationsRadarFuzzy control system

The invention provides an intelligent brake control device and an intelligent brake control method of the intelligent brake control device, belongs to the technical field of automobiles and solves the problems that the automobile automatic brake is not intelligent, and the control precision is low. The device comprises a fuzzy controller, an electric brake mechanism, a radar sensor, an acceleration sensor and a brake pedal sensor, wherein the electric brake mechanism, the radar sensor, the acceleration sensor and the brake pedal sensor are connected with the fuzzy controller, the fuzzy controller receives precise acceleration signals transmitted by the acceleration sensor and precise relative distance signals transmitted by a radar and carries out scattering and fuzzy processing when brake signals are not received, meanwhile, corresponding fuzzy brake braking force signals are output according to a meta-rule base set in the fuzzy controller, and in addition, the fuzzy brake braking force signals are converted into precise braking force signals for controling the electric brake mechanism to realize the brake. The control method comprises the following steps of: A, obtaining the input quantity; B, obtaining fuzzy input variables through fuzzy processing; C, carrying out clearing processing. The device and the method have the advantages that high intelligence of the automatic brake is realized, and the erroneous judgment probability is reduced.

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

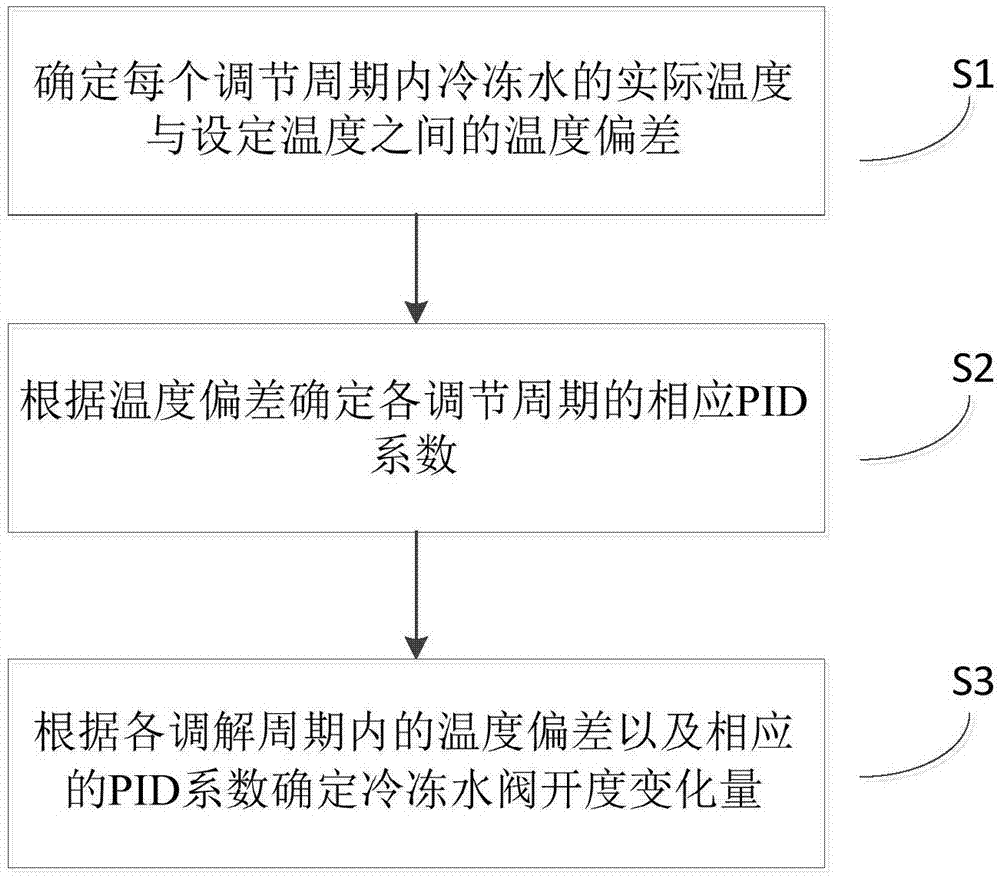

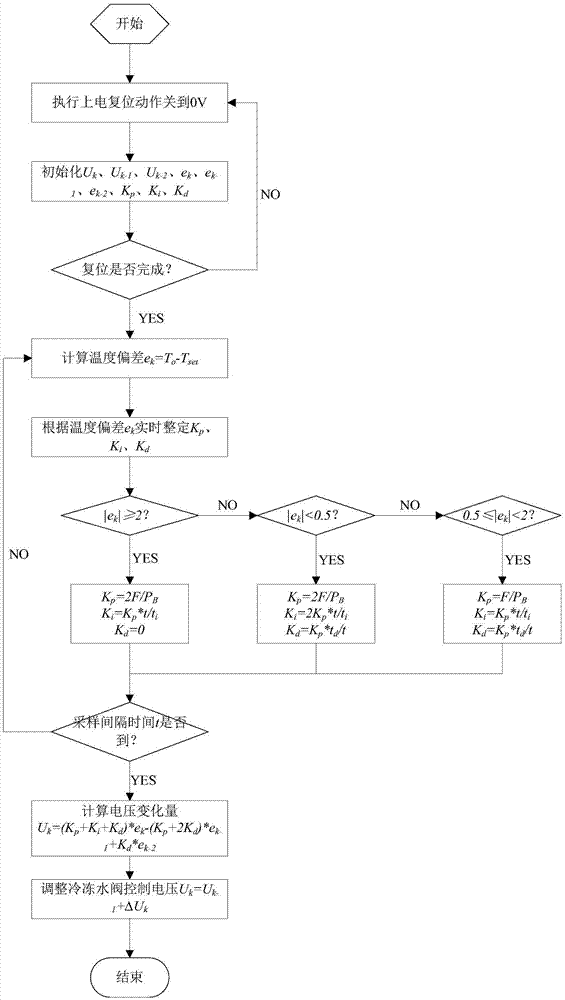

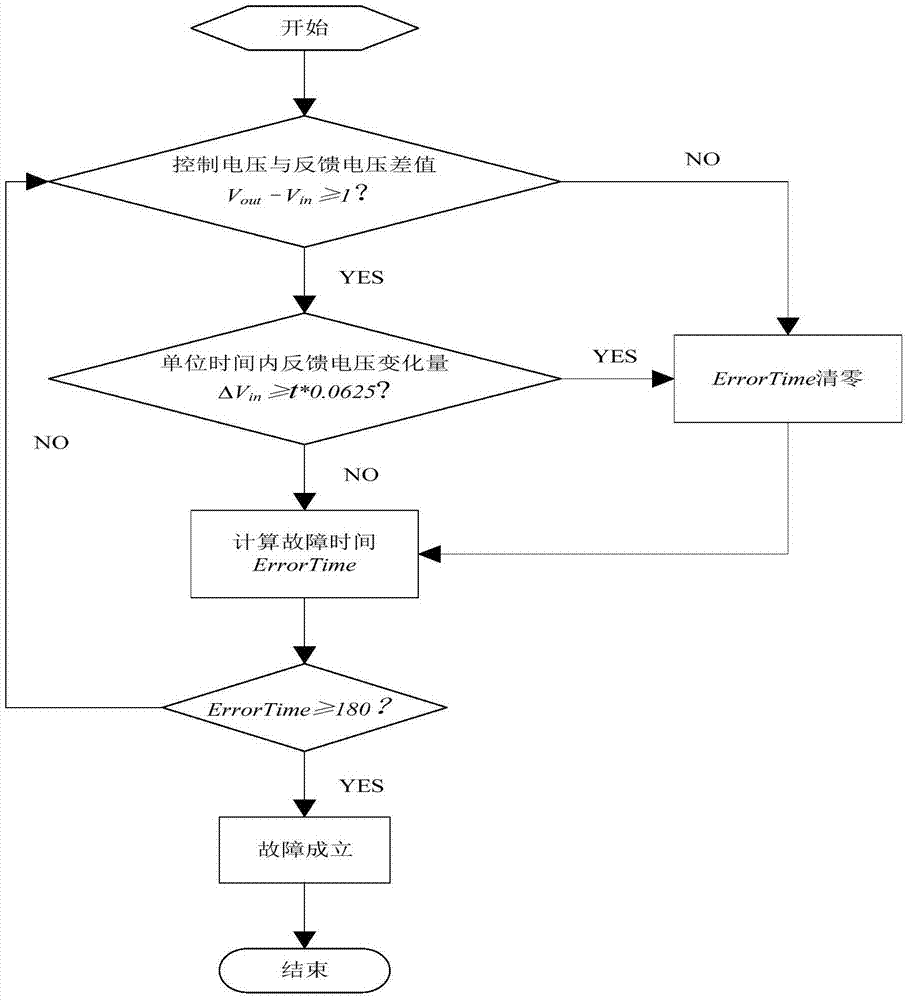

Control method for chilled water valve

InactiveCN107014028AHigh precision controlGuaranteed uptimeMechanical apparatusSpace heating and ventilation safety systemsEngineeringChilled water

The invention discloses a control method for a chilled water valve. The control method for the chilled water valve comprises the following steps: step S1, determining the temperature deviation between an actual temperature and a set temperature of chilled water in every regulation period; step S2, determining the corresponding PID coefficient of every regulation period according to the temperature deviation; and step S3, determining the changes of the opening degree of the chilled water valve according to the temperature deviation and the corresponding PID coefficient in every regulation period. The control method for the chilled water valve, disclosed by the invention, can solve the problems that the chilled water valve in the prior art is low in regulation speed and low in regulation precision.

Owner:GREE ELECTRIC APPLIANCES INC

Drive control circuit for polyphase motor capable of reducing variation among armature currents of respective phases, and spindle apparatus using the same

ActiveUS8198852B2Suppress fluctuationsReduce vibrationTorque ripple controlAC motor controlControl signalAmplitude control

Even when there is some degree of variation in the characteristics among components constituting a polyphase motor and a driving circuit therefor, current control signals of respective phases being input to the drive circuit have their amplitude finely adjusted by an amplitude control circuit, so that amplitude is uniform among armature currents of respective phases that are ultimately output from the drive circuit. The amplitude adjusting circuit is configured by gain variable amplifiers, for example. Thus, rotation fluctuation and vibration of the polyphase motor can be reduced.

Owner:NTN CORP

Field weakening vector controller for permanent magnet synchronous motor and control module

ActiveUS7443120B2High precision controlTorque ripple controlMotor/generator/converter stoppersPermanent magnet synchronous motorPermanent magnet synchronous generator

A field weakening vector controller is disclosed which calculates a d-axis current command value for a power converter to drive a permanent magnet synchronous motor. The field weakening vector controller includes a stabilization calculator, a d-axis current command calculator, a q-axis current command calculator, and a phase calculator. The d-axis current command calculator corrects the d-axis current command value, while the stabilization calculator calculates a product of the phase error and the d-axis command value. The q-axis current command calculator corrects the q-axis current command value using this product.

Owner:HITACHI LTD

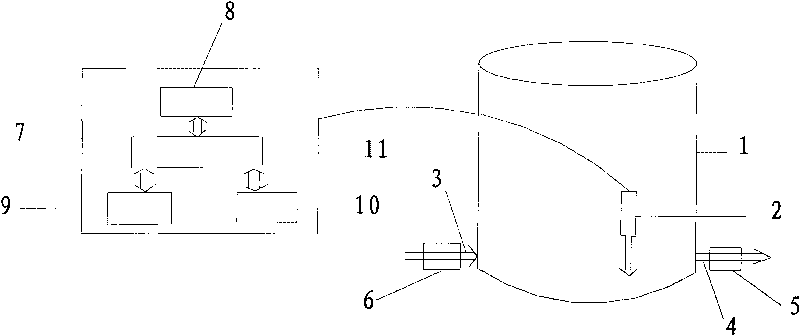

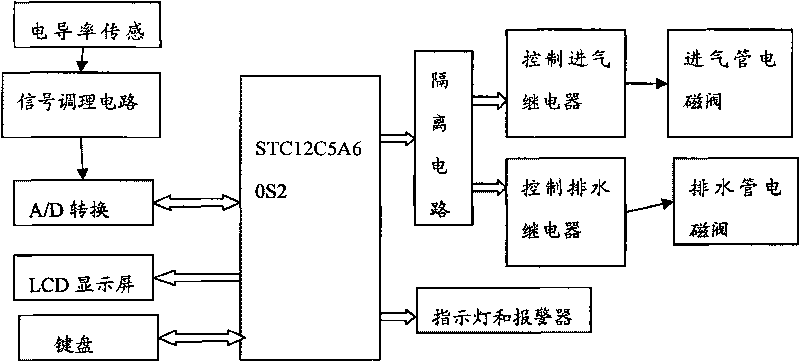

Picked vegetable salted pehtze automatic desalter and method

InactiveCN101700109AHigh precision controlAccurate calculationComputer controlSimulator controlControl parametersDesalination

The invention discloses a picked vegetable salted pehtze automatic desalter which comprises a salted pehtze bleaching and diluting liquid container, a brinishness conductivity sensor, an air inlet pipe, a drain pipe, an air inlet solenoid valve, a drain pipe solenoid valve and a control cabinet; wherein the air inlet pipe and the drain pipe are arranged at the bottom of the salted pehtze bleaching and diluting liquid container and controlled by the solenoid valves to open or close; the solenoid valves are controlled by the control cabinet; the brinishness conductivity sensor is attached to the inner wall of the salted pehtze bleaching and diluting liquid container; the distance between the brinishness conductivity sensor and the port of the air inlet pipe is at least 5cm; the invention also discloses a picked vegetable salted pehtze automatic desalting method which is as follows: controlling control parameters according to requirements, figuring out the salinity content according to the relationship between the conductivity and the salinity content and comparing the salinity content and the setting value so as to decide whether the desalting process is over, thus realizing the intelligent operation of the picked vegetable salted pehtze desalination. Compared with the traditional picked vegetable salted pehtze desalting method, the device provided by the invention not only can accurately work out, appropriately control, but also can greatly reduce the working efficiency of the picked vegetable salted pehtze desalination and saves the labor force.

Owner:ZHEJIANG UNIV

Rotary double-station positioning machine for welding

ActiveCN106695230ARealize free switchingAdapt to the needs of welding processingWelding/cutting auxillary devicesAuxillary welding devicesElectric machineEngineering

The invention relates to a rotary double-station positioning machine for welding. The rotary double-station positioning machine for welding comprises a U-shaped support and supporting shafts, wherein the supporting shafts are fixed on the upper part and the lower part of the U-shaped support; axes of the supporting shafts are superposed; a lifting ring which are matched with the two supporting shafts through bearings respectively is arranged in a U-shaped recess formed in the U-shaped support; a motor, a speed reducer and a driving gear are mounted at the bottom of the lifting ring; the speed reducer is fixed on the motor; the driving gear is mounted on the speed reducer; a driven gear which is engaged with the driving gear is arranged on the upper part of the lower supporting shaft; a supporting table is mounted at the upper end of the upper supporting shaft; and a two-degree-of-freedom adjusting device is mounted at the upper end of the supporting table and is in sliding fit with the lifting ring. The rotary double-station positioning machine for welding has the advantages of reasonable structural design, high automation degree, high control precision and the like. Free switching of double stations in a welding process is realized, a two-degree-of-freedom position adjusting function is fulfilled, and therefore, requirements of welding of different workpieces are met.

Owner:芜湖柯埔智能装备有限公司

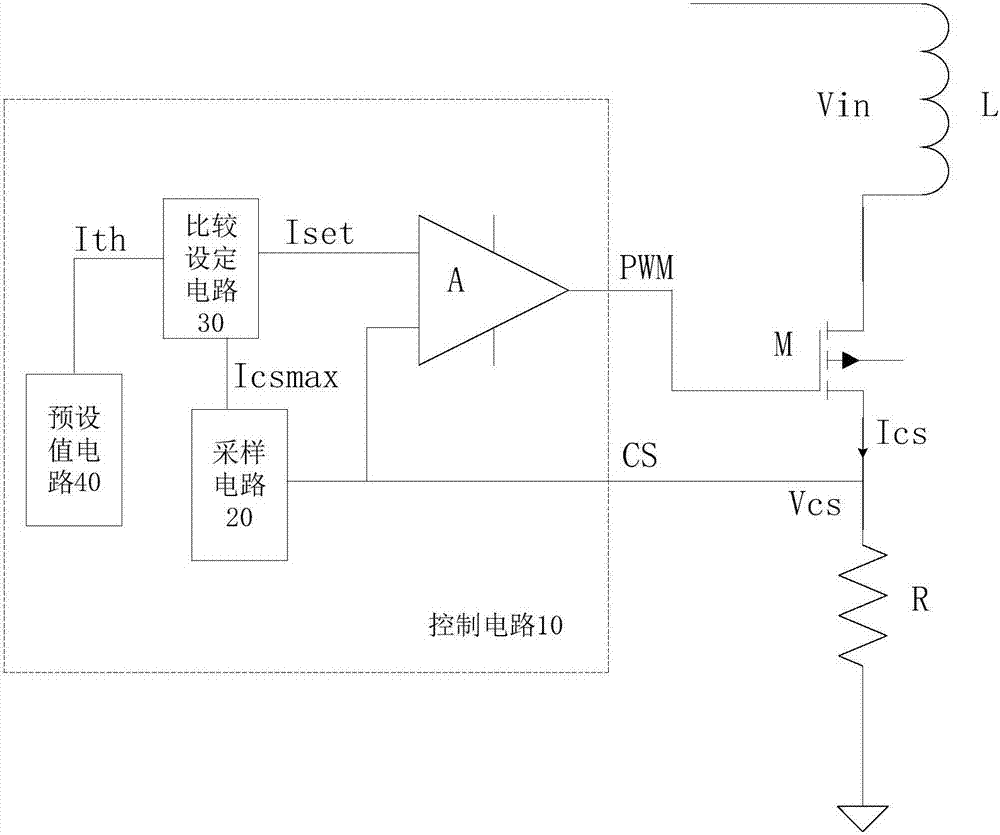

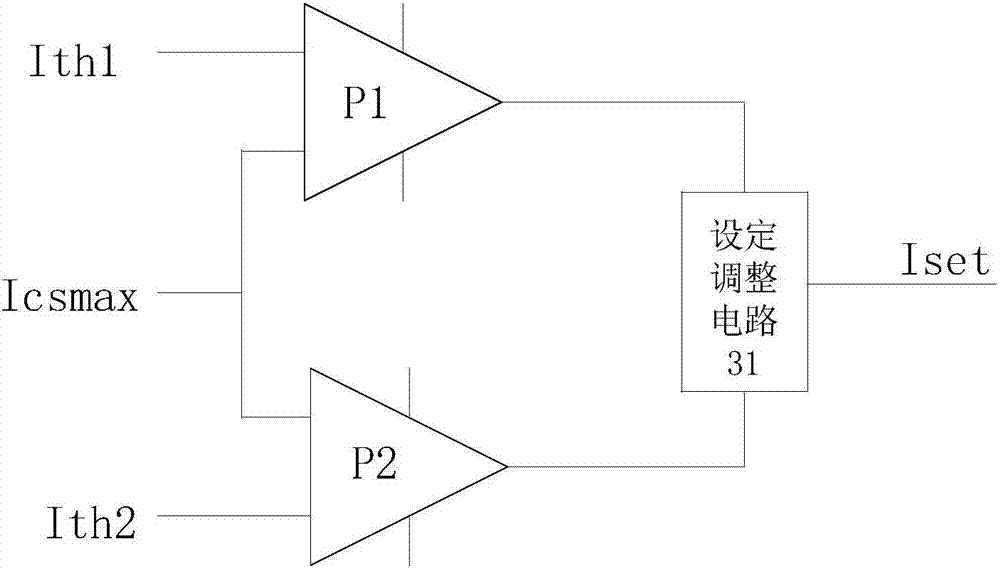

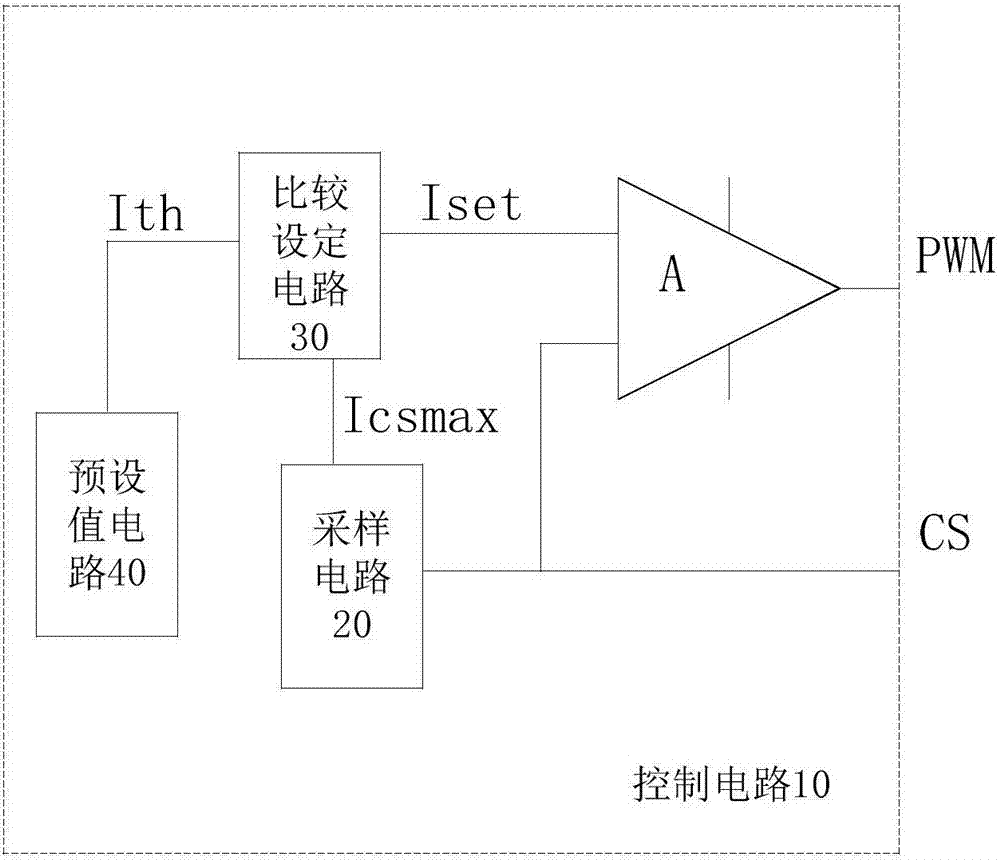

High-precision peak current control method for switching power supply and circuits

PendingCN107026569AHigh precision controlImprove power supply accuracyDc-dc conversionElectric variable regulationInductorPeak value

The invention discloses a high-precision peak current control method for a switching power supply. The high-precision peak current control method comprises the steps of S1, detecting a current I<cs> which flows through an inductive coil in the current cycle of the switching power supply, and recording a current peak value I<csmax>; S2, making a comparison between the current peak value I<csmax> in the current cycle with a preset value I, and adjusting an inductive threshold value current value I<set> of a next cycle according to a first comparison result; and S3, outputting a control signal according to a second comparison result between the current I<cs> of the current cycle and the inductive threshold value current value I<set> of the current cycle. The invention also discloses a high-precision peak current circuit, control circuit and adjusting circuit of the switching power supply. High-precision control of the peak current of the switching power supply is realized, and power supply precision is improved.

Owner:SHAANXI REACTOR MICROELECTRONICS

Motor control device, and method for correcting torque constant in such motor control device

ActiveUS20170163194A1Suppress mutationHigh-precision torque controlTorque ripple controlAC motor controlMotor speedMotor control

A motor control device at least includes a speed control part for controlling a motor rotation speed. The motor control device includes a torque correction means for suppressing variation in torque constant due to individual differences of motors. In addition, the motor control device corrects the torque constant by using a correction torque coefficient calculated based on an unloaded speed when a fixed voltage is applied. Alternatively, the torque constant is corrected using the correction torque coefficient calculated based on the motor applied voltage when the motor speed is fixed.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

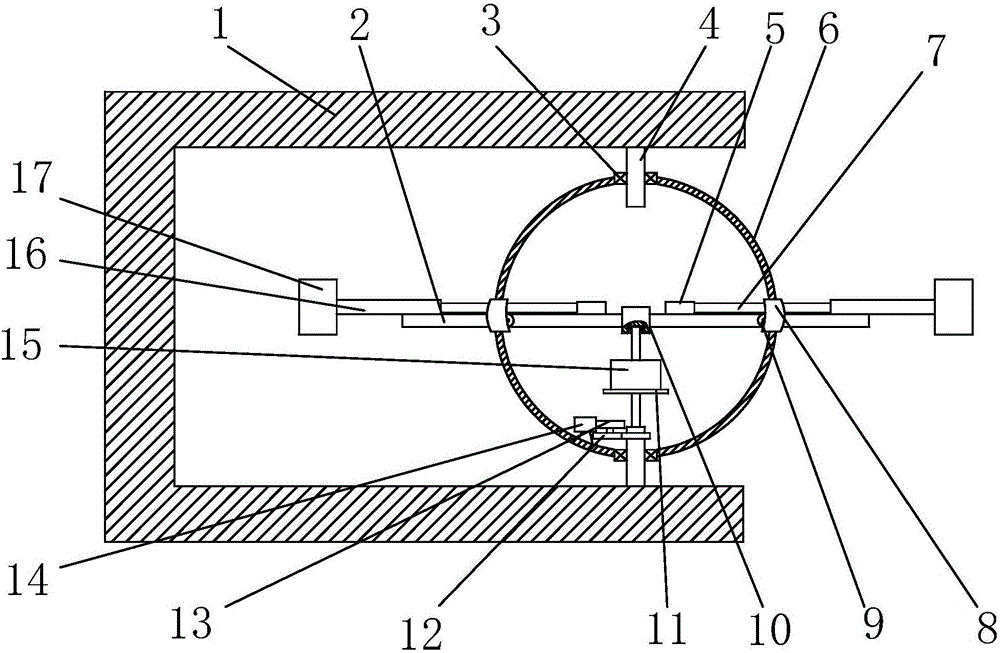

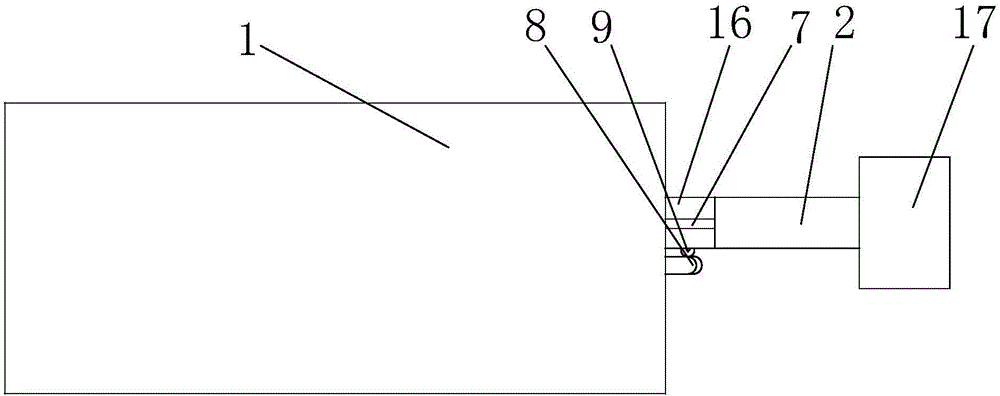

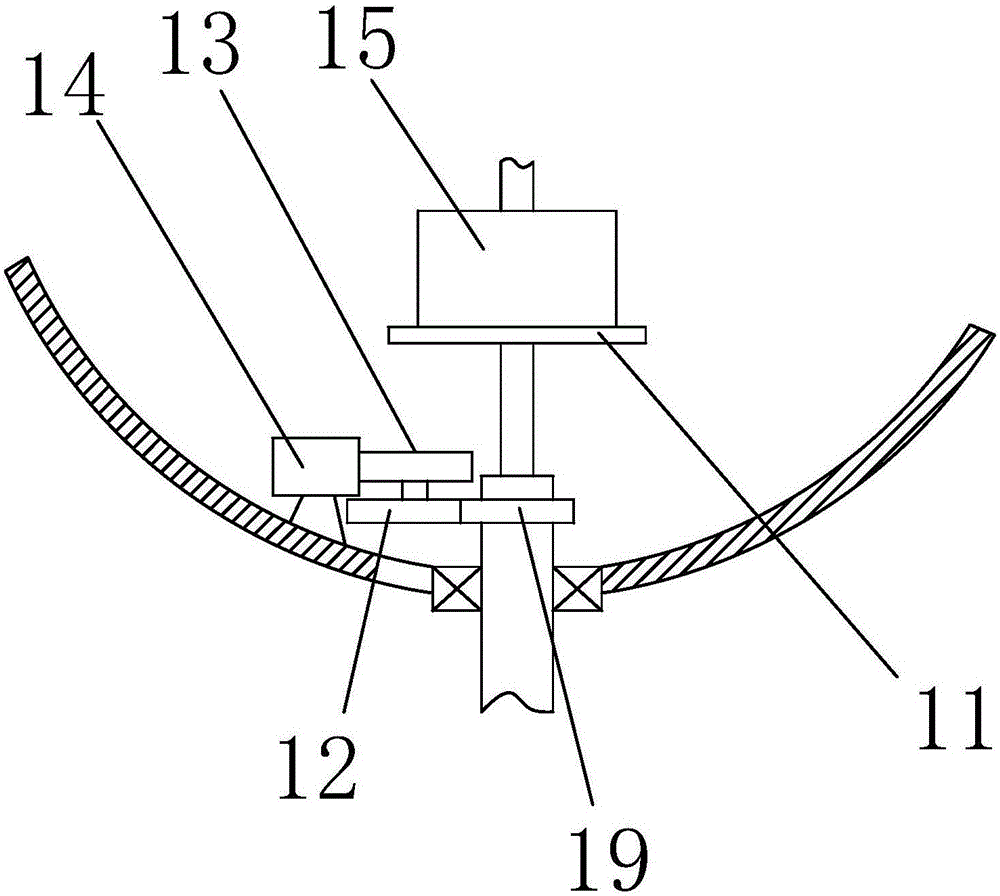

Steel wire rope length measurement and blanking device and steel wire rope length measurement and blanking method

PendingCN108861858AHigh precision controlEasy to straightenFilament handlingLength measurementEngineering

The invention discloses a steel wire rope length measurement and blanking device and a steel wire rope length measurement and blanking method. The steel wire rope length measurement and blanking device comprises a support, a measurement assembly, a cutting mechanism and a rolling mechanism, wherein the measurement assembly, the cutting mechanism and the rolling mechanism are arranged on the support. In the steel wire rope length measurement and blanking process, after measurement and length recording are conducted through an electronic meter gauge, a steel wire rope is wound on a roller and isin the tensioned state; when the length, measured through the electronic meter gauge, of the steel wire rope reaches the set length, the steel wire rope is cut off through the cutting mechanism, andat the moment, the length of the steel wire rope wound on the roller is the set length; then, the roller is driven by a piston rod of a first piston cylinder to move downwards, the steel wire rope wound on the roller is separated from the roller, an at the moment, measurement and blanking of the steel wire rope are completed. After being unwound, the steel wire rope is wound on the roller; the roller is driven by a motor to rotate for secondary rolling, and the steel wire rope is easy to straighten; and the length of the steel wire rope is measured through the electronic meter gauge, the length control precision of the steel wire rope is high, and the error of every 100 meters does not exceed one centimeter.

Owner:JIANGSU LIDA ELEVATOR +1

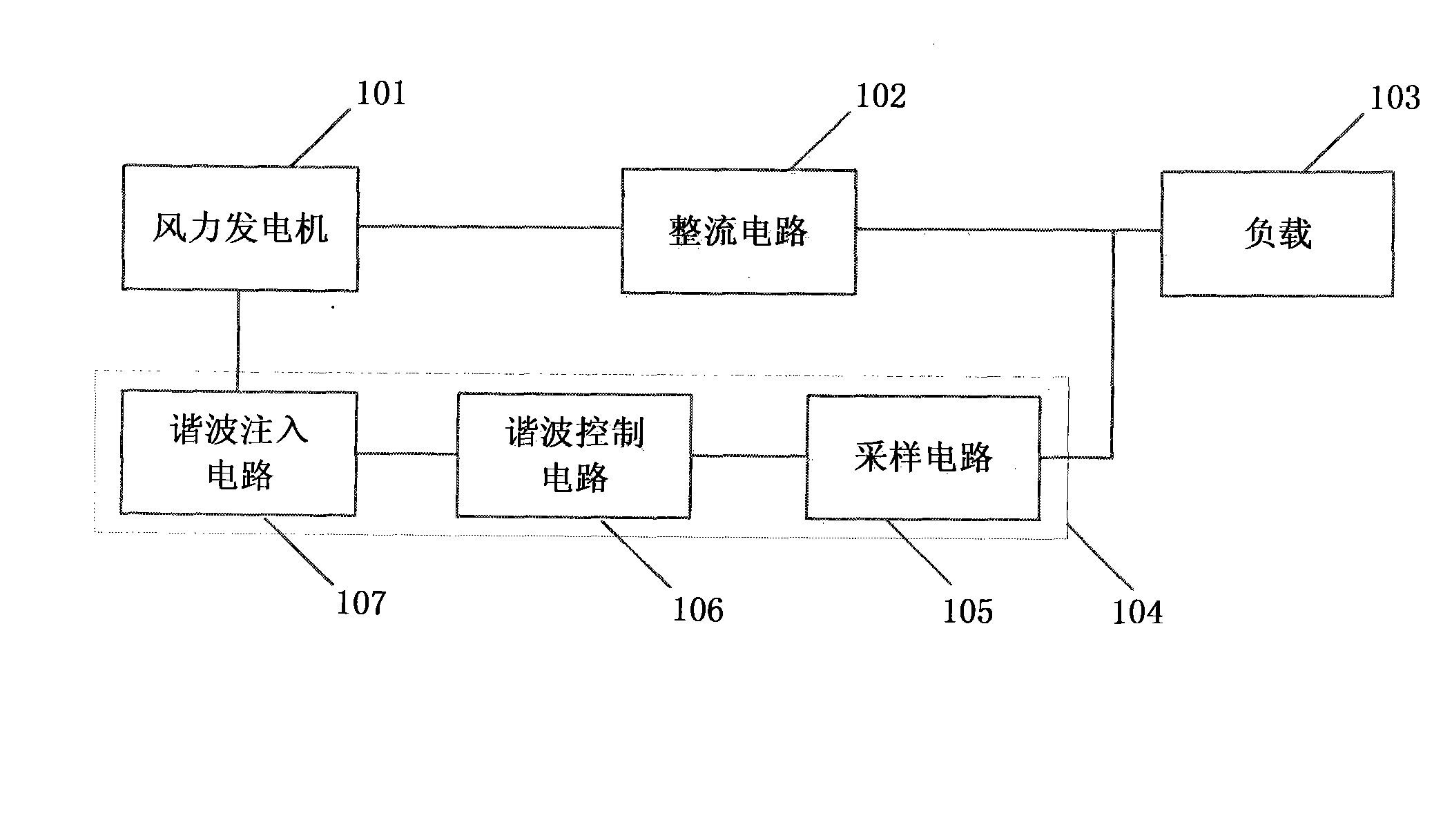

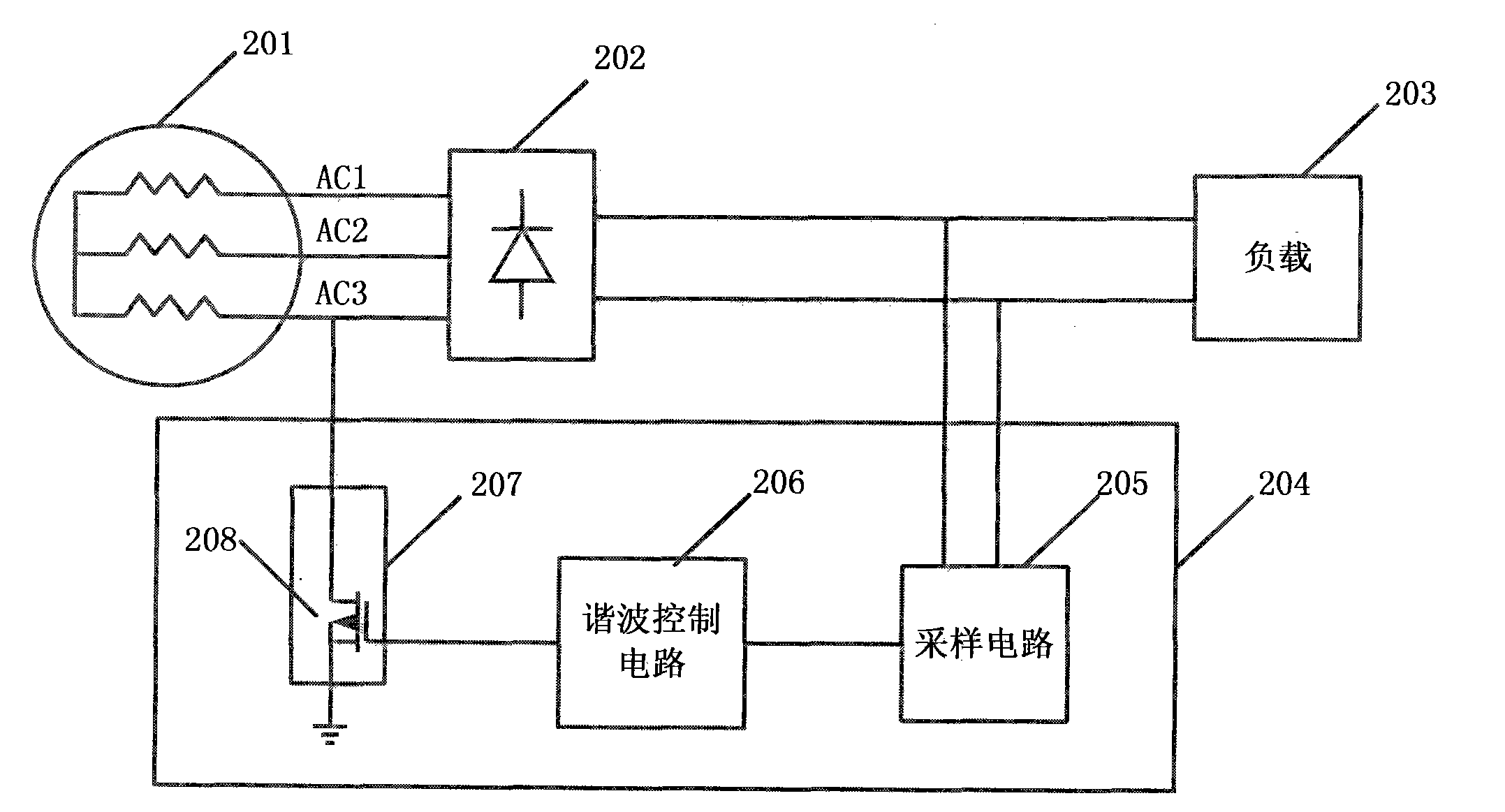

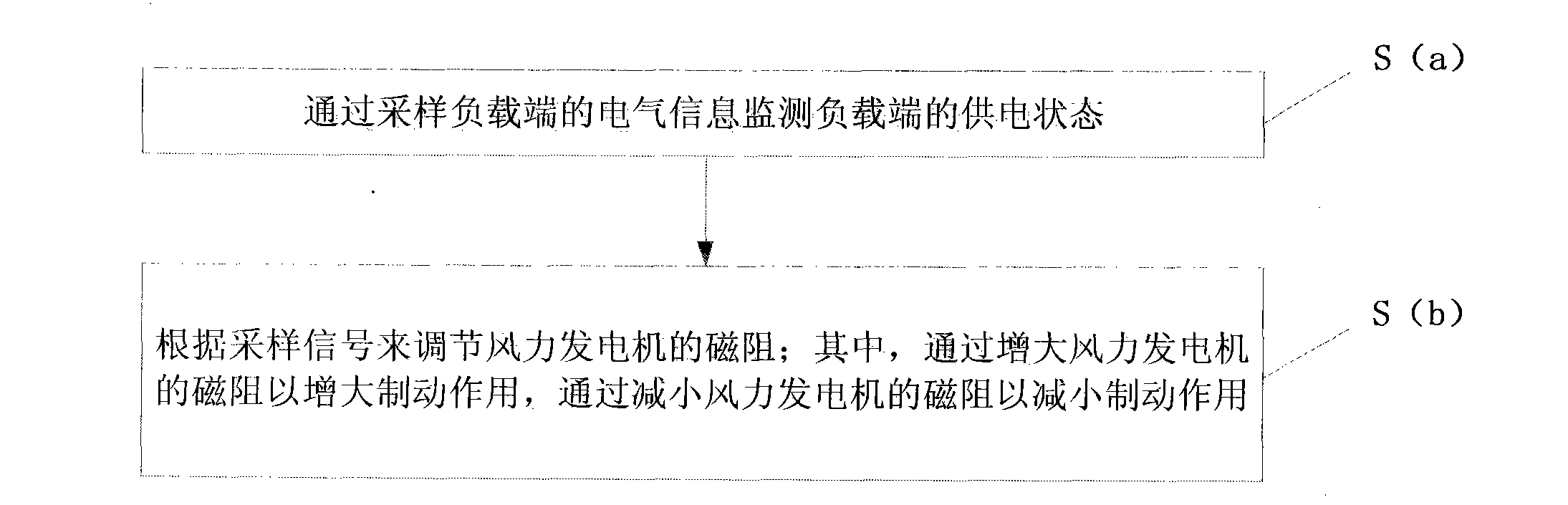

Aerogenerator controller and control method

ActiveCN102694384AHigh precision controlHigh control precisionElectric generator controlHarmonic reduction arrangementSampling circuitsDynamo

The invention discloses an aerogenerator controller and a control method, which solvethe problem of controlling accuracy of output power of an aerogenerator. The aerogenerator controller includes: a sampling circuit, which samples an electrical information from a load end and sends a sampling signal to a harmonic wave control circuit; aharmonic wave control circuit, which receives the sampling signal from the sampling circuit, monitors a power supply state of a load according to the sampling signal and outputs a harmonic wave control signal to a harmonic wave injected circuit; wherein the harmonic wave injected circuit is coupled to a winding of the aerogenerator, receives the harmonic wave control signal from the harmonic wave control circuit, and adjusts a harmonic wave injected into the aerogenerator winding according to the said harmonic wave control signal. This invention can control the output voltage and power of the aerogenerator at a high accurate level and do not need an unload device with a huge volume.

Owner:JINAN DEMING POWER EQUIP

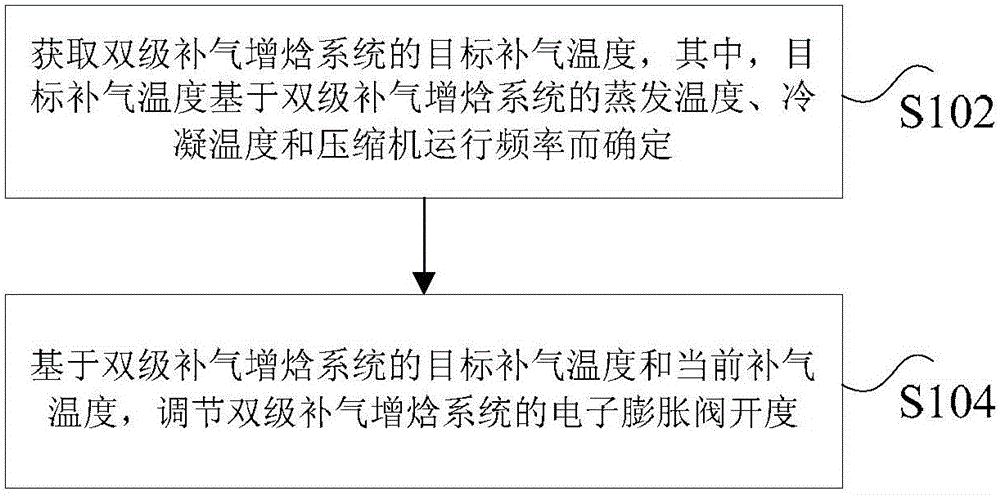

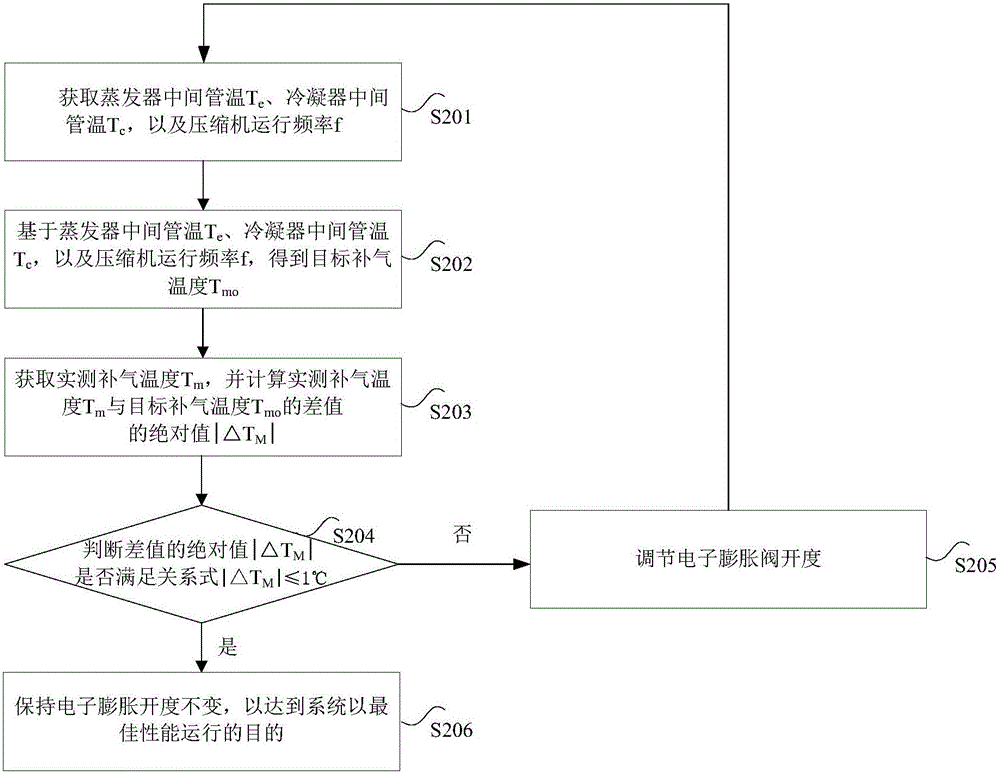

Control method and control device for two-stage gas replenishing and enthalpy increasing system

ActiveCN105953386AHigh precision controlSolve the problem of low control accuracyMechanical apparatusSpace heating and ventilation safety systemsCondensation temperatureEngineering

The invention discloses a control method and a control device for a two-stage gas replenishing and enthalpy increasing system. The control method comprises the following steps of acquiring a target gas replenishing temperature of the two-stage gas replenishing and enthalpy increasing system, wherein the target gas replenishing temperature is determined on the basis of evaporation temperature and condensation temperature of the two-stage gas replenishing and enthalpy increasing system and operation frequency of a compressor; and adjusting the opening degree of an electronic expansion valve of the two-stage gas replenishing and enthalpy increasing system based on the target gas replenishing temperature and current gas replenishing temperature of the two-stage gas replenishing and enthalpy increasing system. According to the control method and the control device disclosed by the invention, the technical problem of low control accuracy of the two-stage gas replenishing and enthalpy increasing system in the prior art is solved.

Owner:GREE ELECTRIC APPLIANCES INC

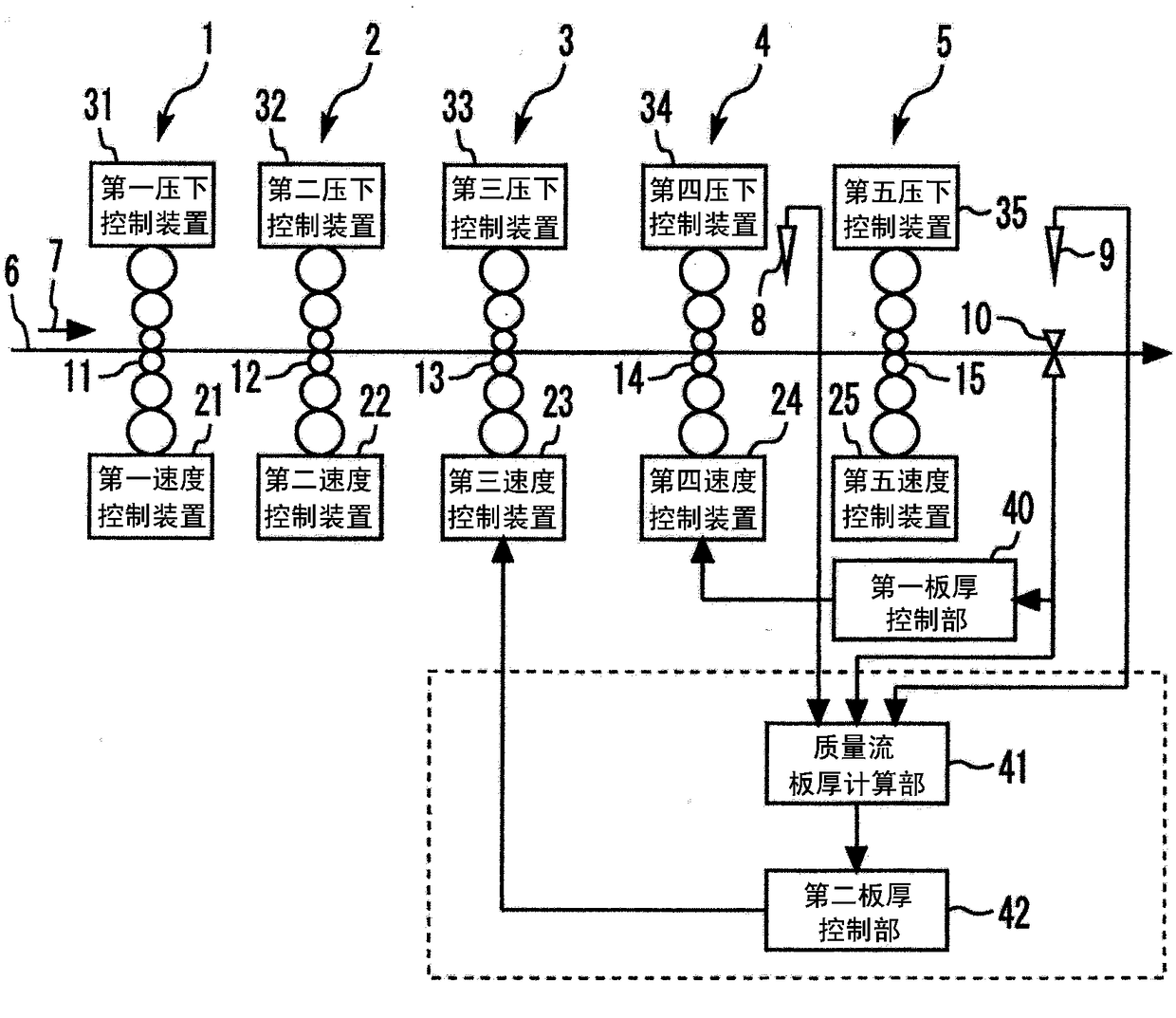

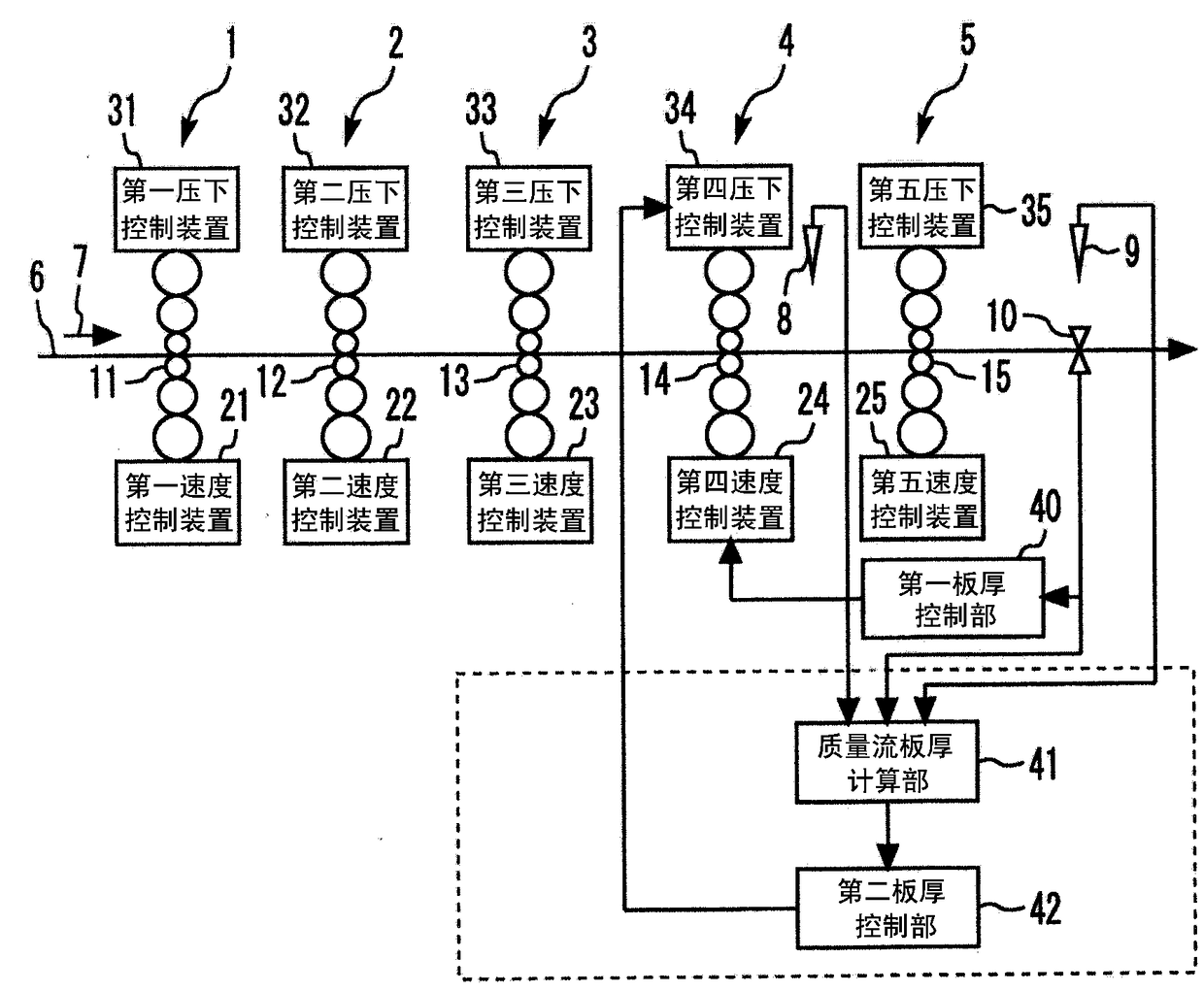

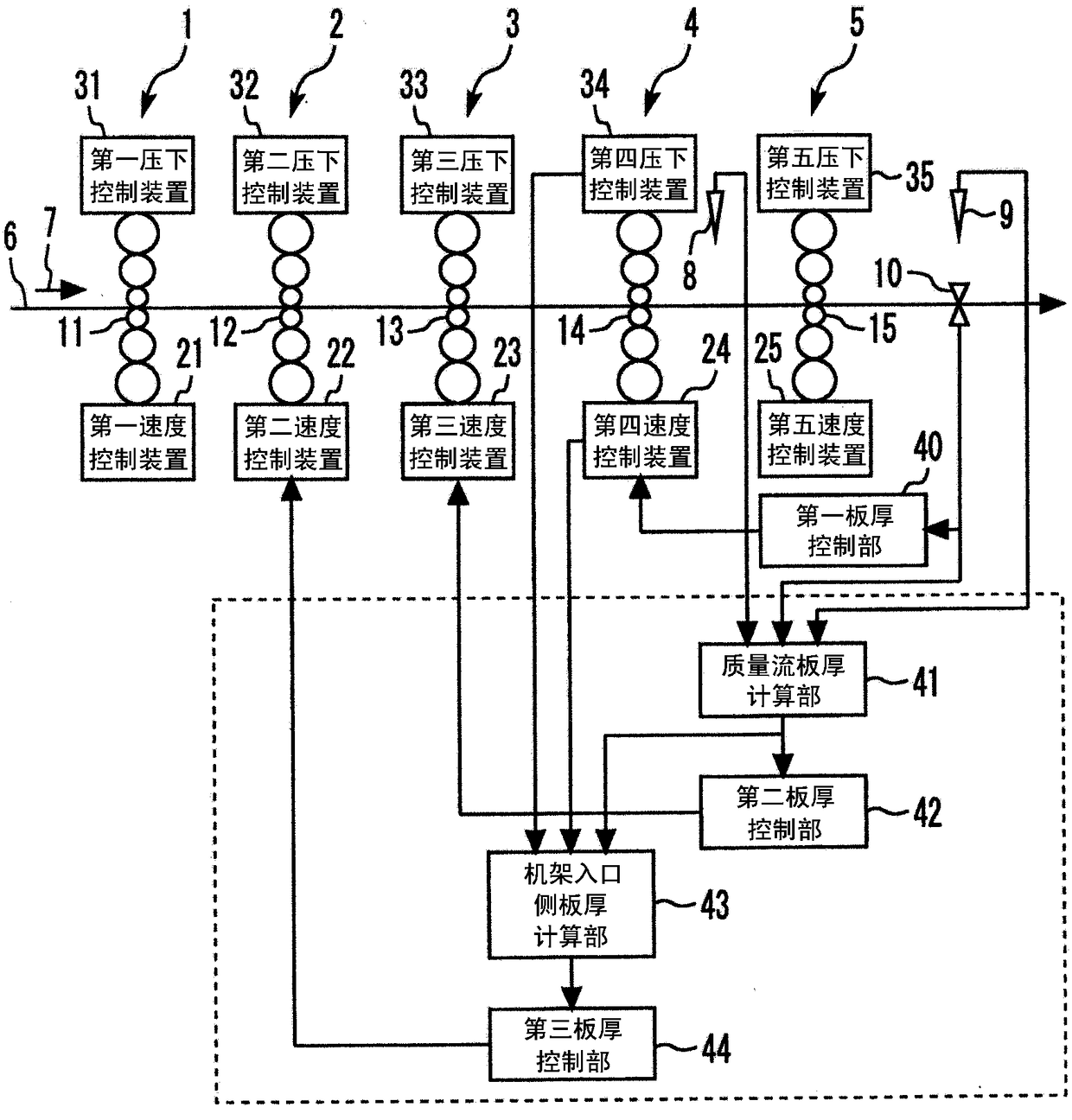

Plate thickness control device of tandem cold mill

ActiveCN108202085ASuppression of plate thickness variationHigh precision controlRoll mill control devicesMetal rolling arrangementsAccuracy improvementEngineering

The invention provides a plate thickness control device for a tandem cold mill. Even when a plate thickness gauge is not arranged on an inlet side of a final frame, thickness variation of the inlet side of the final frame can be suppressed, so as to seek accuracy improvement of thickness of a product. The plate thickness control device of the tandem cold mill includes a mass flow plate thickness calculating unit (41) and a second plate thickness control unit (42). The mass flow plate thickness calculating unit (41) calculates mass flow plate thickness of the inlet side of the nth frame (5) based on a measured value of outlet side plate thickness measured by the outlet side plate thickness gauge (10), a measured value of outlet side plate speed measured by an outlet side plate speedometer (9), and a measured value of inlet side plate speed measured by an inlet side plate speedometer (8). The second plate thickness control unit (42) controls rolling load in the (n-1)th frame (4) so thatmass flow plate thickness calculated by the mass flow plate thickness calculating unit (41) and a target value of the inlet side plate thickness of the nth frame (5) are the consistent.

Owner:TOSHIBA MITSUBISHI-ELECTRIC IND SYST CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com