Picked vegetable salted pehtze automatic desalter and method

The technology of desalting device and salt blank is applied to the automatic desalting device and field of pickled salt blank, which can solve the problems of high application difficulty and complex model, and achieve the effects of accurate calculation, reduced bacterial intervention and labor saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

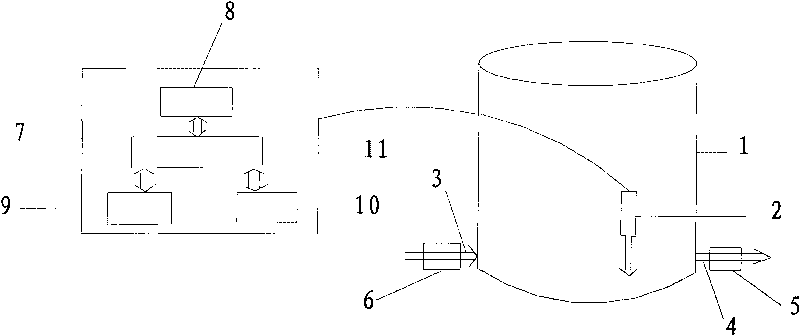

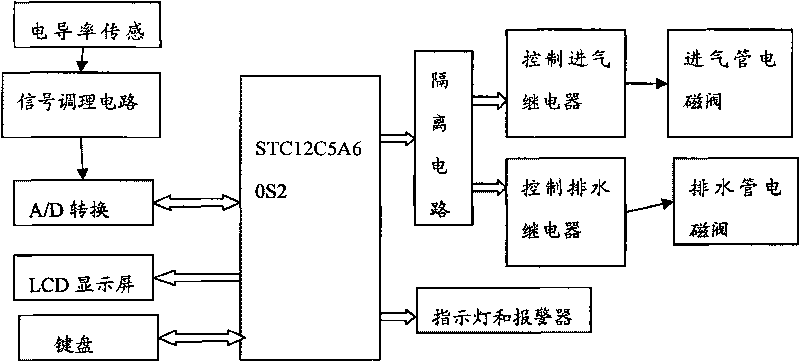

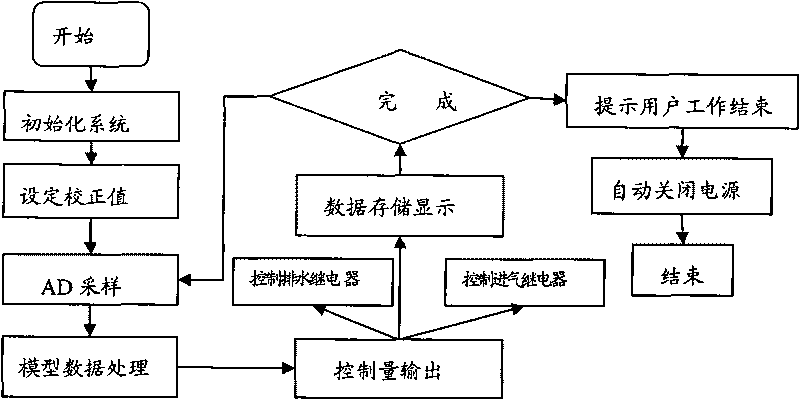

[0029] as attached figure 1 As shown, the air intake pipe 3 is installed on one side of the bottom of the salt billet bleaching liquid container 1, the drain pipe 4 is installed on the other side of the bottom of the salt billet bleaching liquid container 1, the air intake pipe solenoid valve 6 and the drain pipe solenoid valve 5 are respectively Installed on the intake pipe 3 and the drain pipe 4, the control cabinet 7 is composed of a LCD screen 8, a control cabinet main board 11, a relay 9, and a relay 10. The LCD screen 8 and the control cabinet main board 11 are connected to realize the control friendly display function, and control the drainage relay 9 1. Control the air intake relays 10 are respectively connected with the main board 11 of the control cabinet to realize the control of the relays by the main board. The control drainage relay 9 and the air intake relay 10 are respectively connected with the drain pipe solenoid valve 5 and the intake pipe solenoid valve 6 t...

Embodiment 2

[0036] Using the same device and method as in Example 1, the initial salt content of the salt slab is 29.7%, the multiple of water addition is 3, the set value of the salt content of the salt slab is 12.0%, and the correction coefficient is set to 0.87. When the drain pipe starts to drain At that time, the measured blanched salt content was 8.9%, and the salt content of the salt base was 12.03%.

Embodiment 3

[0038] Using the same device and method as in Example 1, the initial salt content of the salt billet is 25.8%, the multiple of water addition is 3, the salt content of the salt billet is set to 9.0%, and the correction coefficient is set to 0.64. When the drain pipe starts to drain At that time, the measured blanched salt content was 6.4%, and the salt content of the salt base was 9.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com