Steel wire rope length measurement and blanking device and steel wire rope length measurement and blanking method

A wire rope and length counting technology, which is applied in the field of elevator wire ropes, can solve the problems of wire ropes and traction wheels being easily worn, inaccurate length control of wire ropes, adhesion of dust and sand, etc., to achieve high length, accurate length, and extended service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

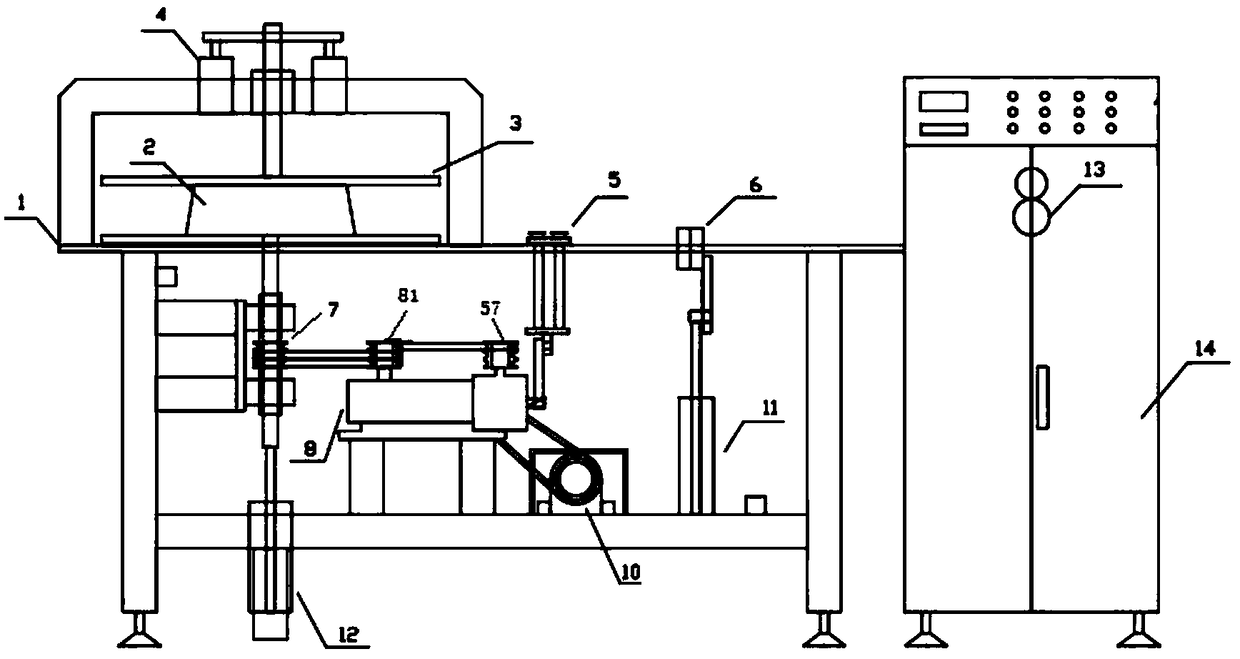

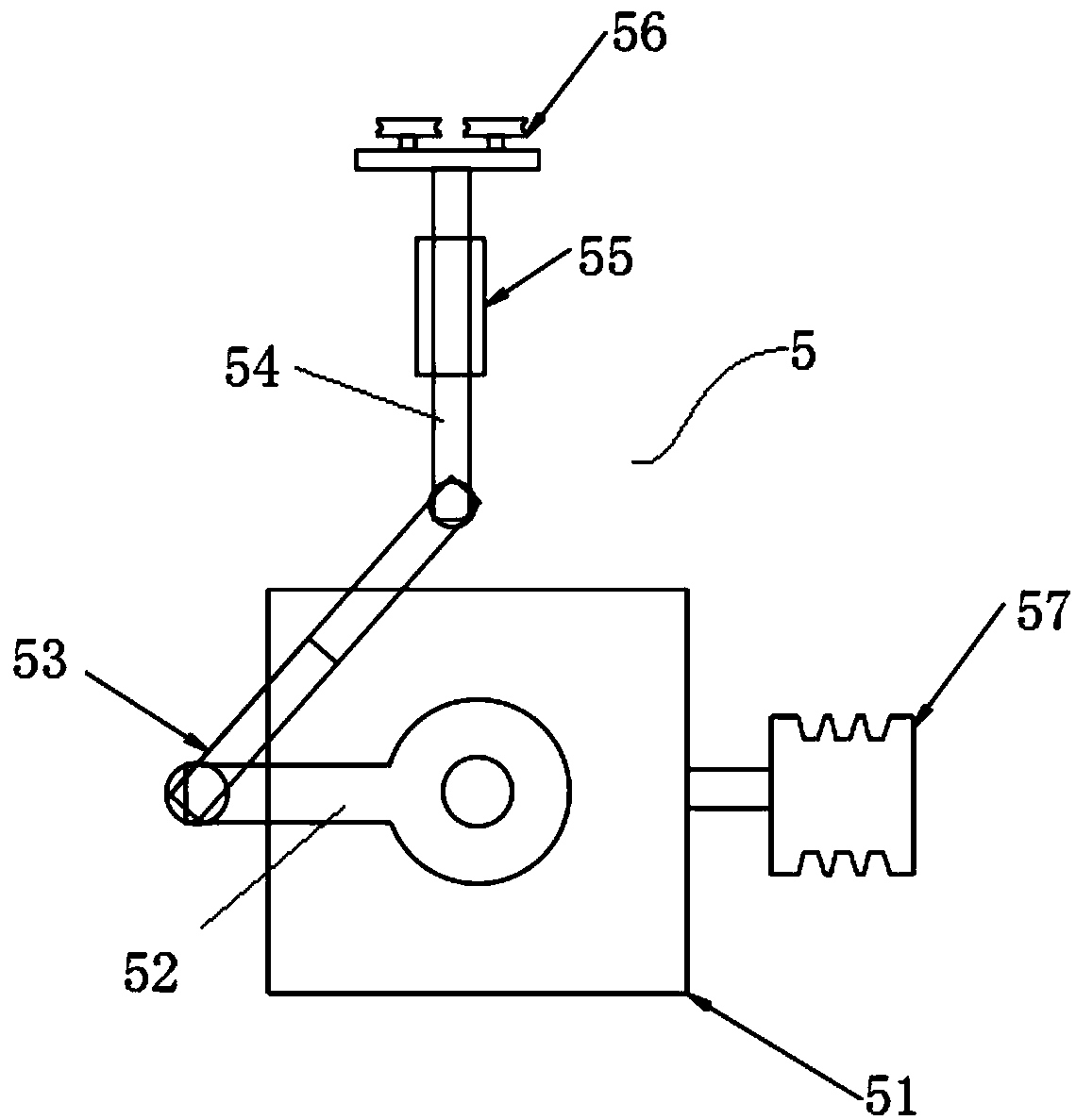

[0036] Such as Figure 1-4 As shown, a wire rope length gauge and feeding device includes a bracket 1, a measuring assembly arranged on the bracket 1, a guiding mechanism 5, a shearing mechanism 6 and a winding mechanism.

[0037] The measuring component is an electronic meter counter 13; the model of the electronic meter counter is HB961, purchased from Shanghai Renzhong Instrument Electric Co., Ltd.

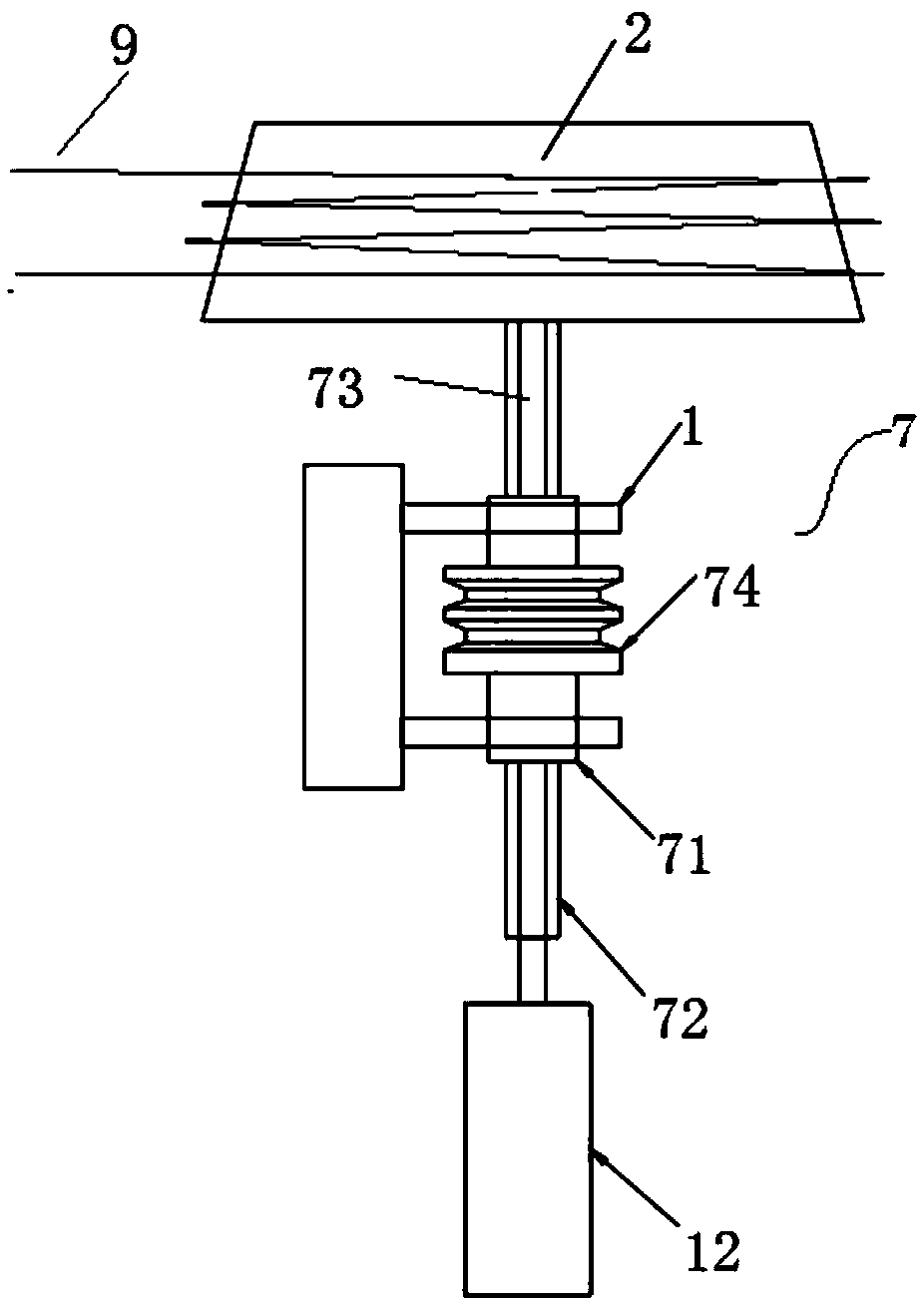

[0038] The winding mechanism includes a driving motor 10, a first reducer 8, a rotating sliding device 7 and a drum 2. The motor 10 drives the first sliding sleeve 71 to rotate by driving the first reducer 8, and the first sliding sleeve 71 passes through the bearing Rotationally connected with the bracket 1; the inner wall of the first sliding sleeve 71 is provided with a first limiter, the first sliding sleeve 71 is set on the sliding shaft 72, and the outer surface of the sliding shaft 72 is provided with a second limiter 73 along its length direction , the second limiter i...

Embodiment 2

[0052] The length counting and blanking method based on the above-mentioned steel wire rope length counting and blanking device comprises the following steps:

[0053] Step 1. Place the entire wire rope on the turntable, take out the tap of the wire rope, pass through the electronic meter, the shear ring of the shear mechanism, and the two rollers, and then fix it on the drum;

[0054] Step 2. Start the motor to drive the drum to rotate. The wire rope is wound on the drum after the length is measured and recorded by the electronic meter counter. The wire rope is in a tensioned state; When moving, the steel wire rope is driven by the two rollers to wind upwards from the lower end of the drum. After winding one layer to the upper end of the drum, the drive assembly drives the slide bar to move down, and the steel wire rope is driven by the two rollers to wind evenly downwards from the upper end of the drum. repeat;

[0055] Step 3: When the length of the wire rope is measured b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com