Plate thickness control device of tandem cold mill

A technology of tandem cold rolling mill and control device, applied in rolling mill control device, metal rolling, metal rolling, etc., can solve the problems of plate thickness fluctuation, high rolling load, inability to ensure plate thickness, etc., and achieve high-precision control , The effect of suppressing plate thickness deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0042]

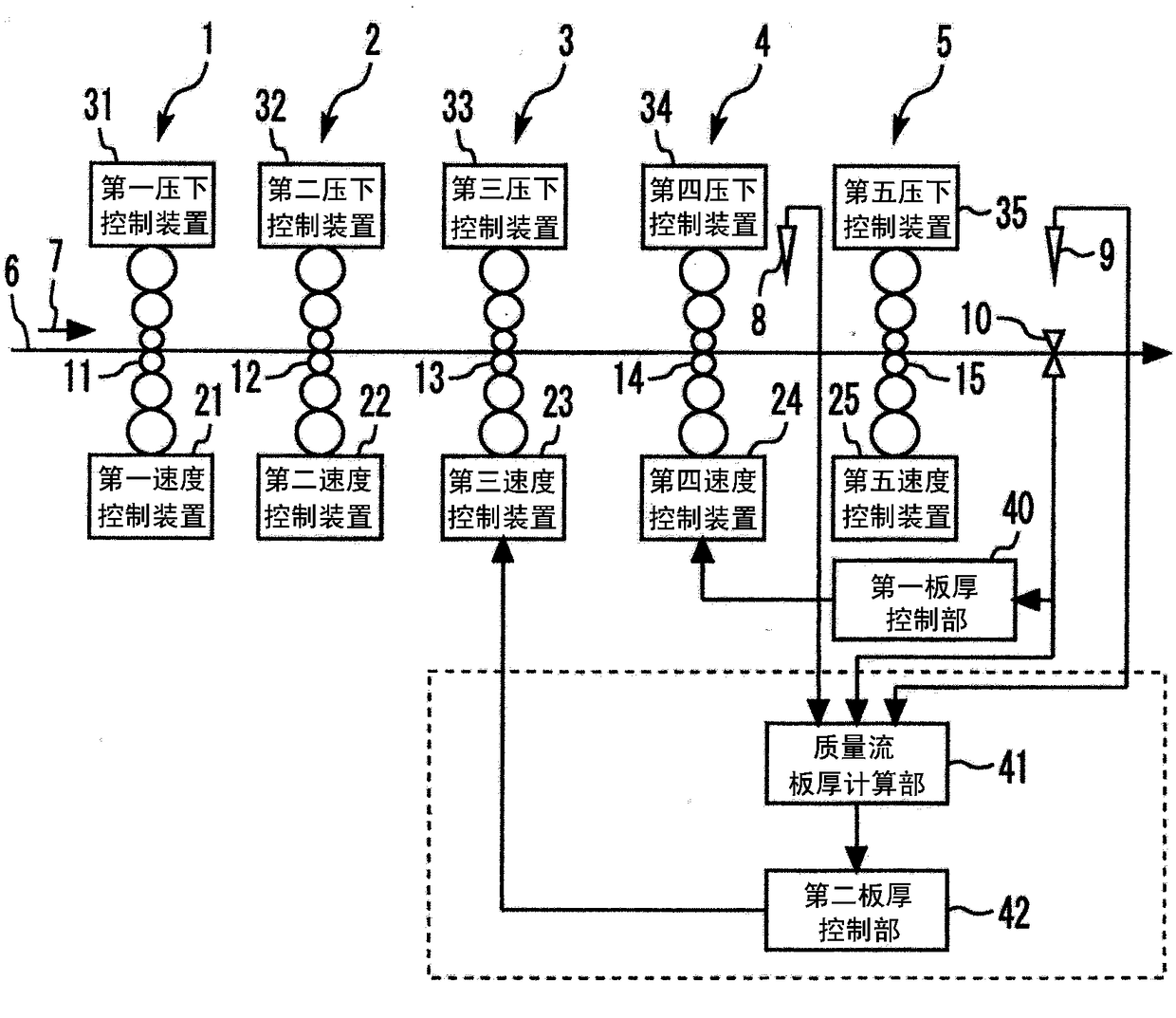

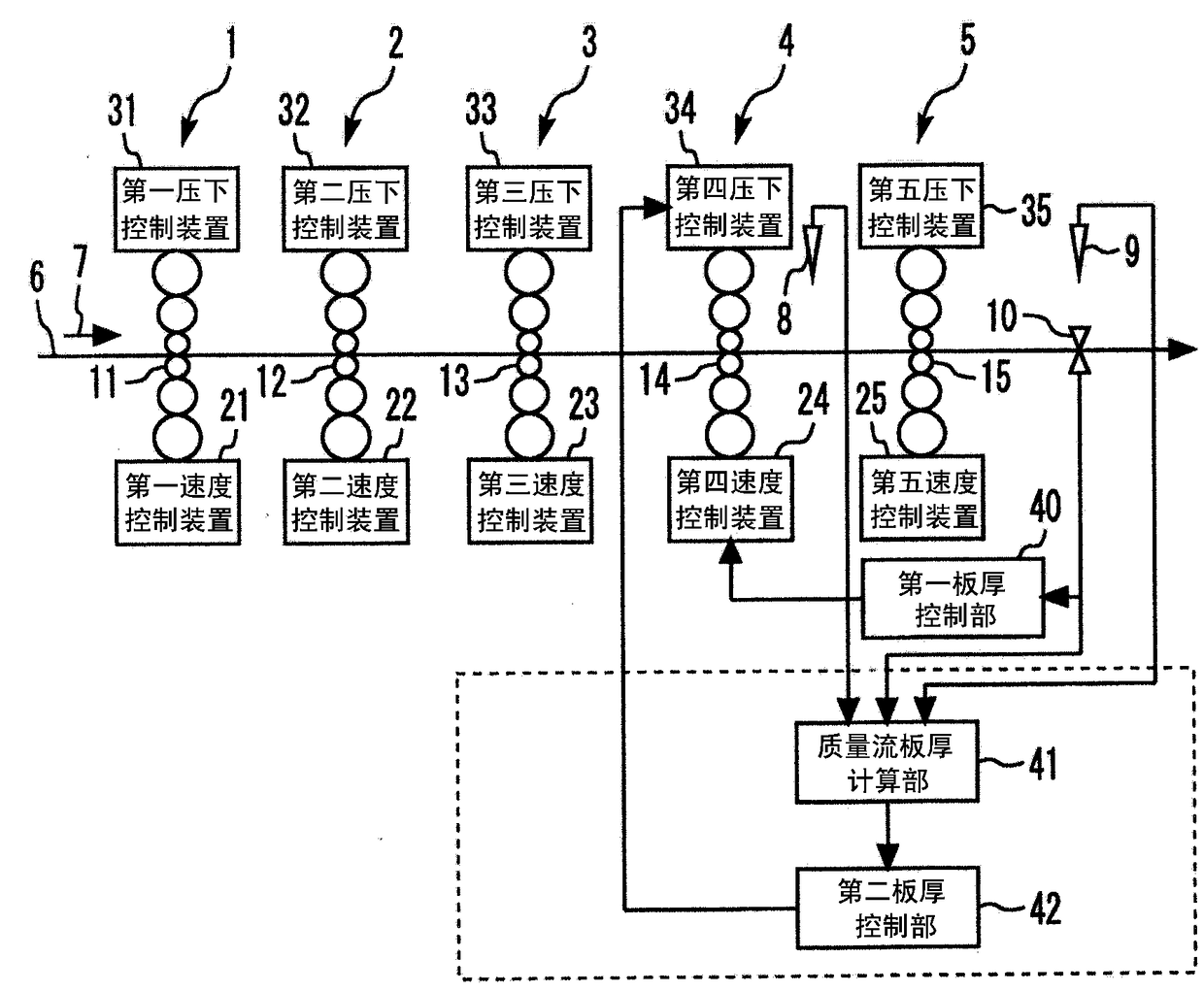

[0043] figure 1 It is a figure for demonstrating the structure of the tandem cold rolling strip thickness control system concerning Embodiment 1 of this invention. The tandem cold rolling mill according to Embodiment 1 includes a plurality of rolling stands. figure 1 A tandem cold rolling mill with 5 rolling stands is described in .

[0044] The 5 rolling stands are the first stand 1, the second stand 2, the third stand 3, the fourth stand 4 and the fifth stand 5 from the upstream side. The five rolling stands are opposite to each other. piece 6 to direction 7 ( figure 1 rolling from left to right).

[0045] Each stand has work rolls, speed control and reduction control. Specifically, the i-th stand (i is a natural number, and i≦n, n=5) has: a pair of i-th work rolls (11-15) for rolling the rolling stock 6; an i-th speed control device (21-25) for controlling the peripheral speed; and an i-th reduction control device (31-35) for controlling the roll gap of the ...

Embodiment approach 2

[0073]

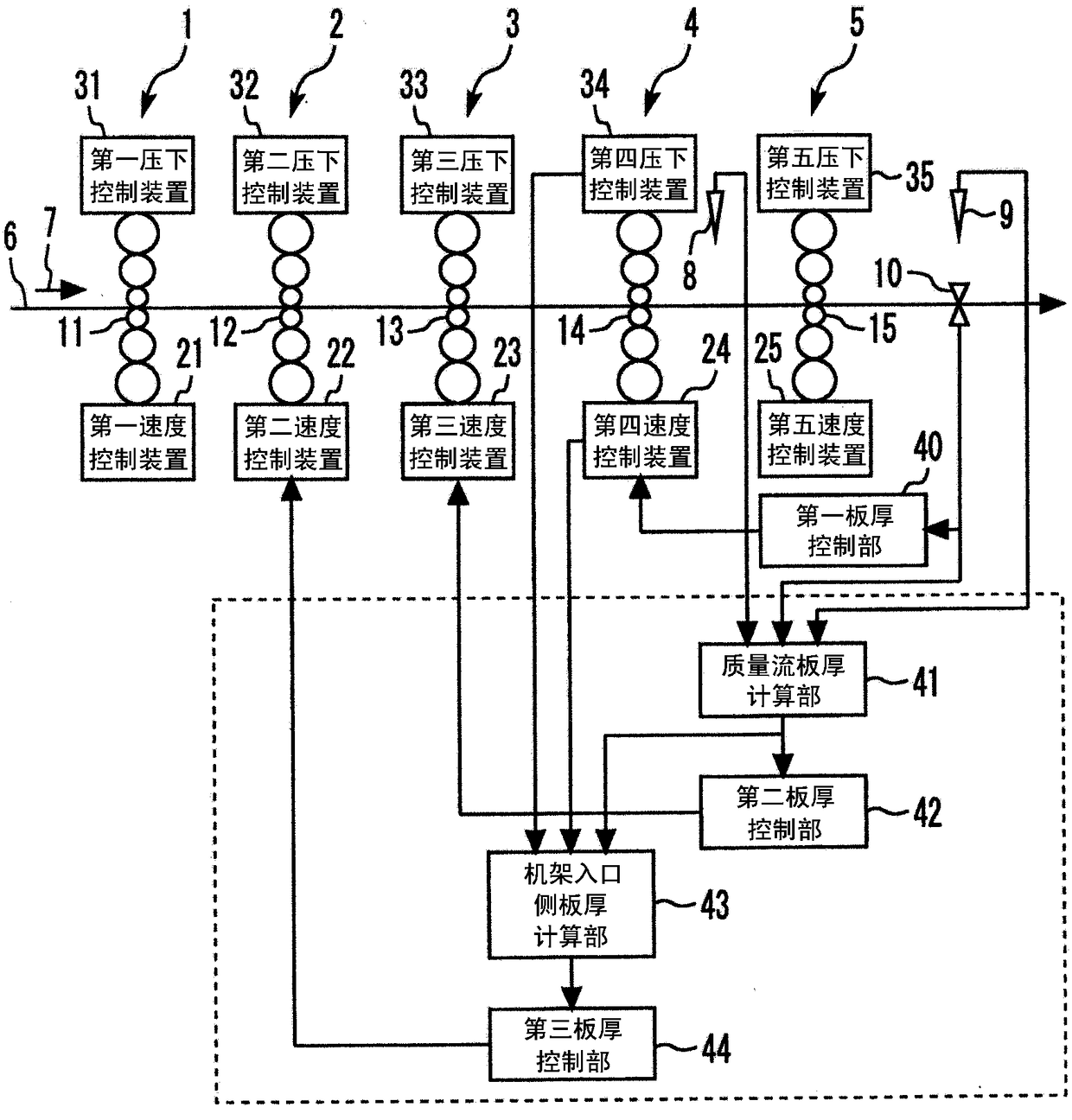

[0074] Below, refer to image 3 , Embodiment 2 of the present invention will be described. image 3 It is a figure for demonstrating the structure of the continuous cold rolling strip thickness control system concerning Embodiment 2 of this invention. image 3 The system configuration shown is the same as that of figure 1 same.

[0075] The system according to Embodiment 2 is the same as that of Embodiment 1, but differs in that it calculates the thickness of the exit side of the third stand 3 and controls it to a target thickness. Hereinafter, only operations different from Embodiment 1 will be described.

[0076]

[0077] The thickness calculation unit 43 at the entrance side of the stand receives the actual rolling load measurement value measured by the fourth reduction control device 34 (n-1th reduction control device), and is controlled by the fourth speed control device 24 (n-1th speed control device). device) measured the work roll peripheral speed of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com