Method for producing cmanufacturing steel sheet

A manufacturing method and steel plate technology, applied in the direction of manufacturing tools, furnace types, furnaces, etc., can solve problems such as poor ductility and lack of processability, and achieve the effects of reducing manufacturing costs and suppressing changes in plate thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

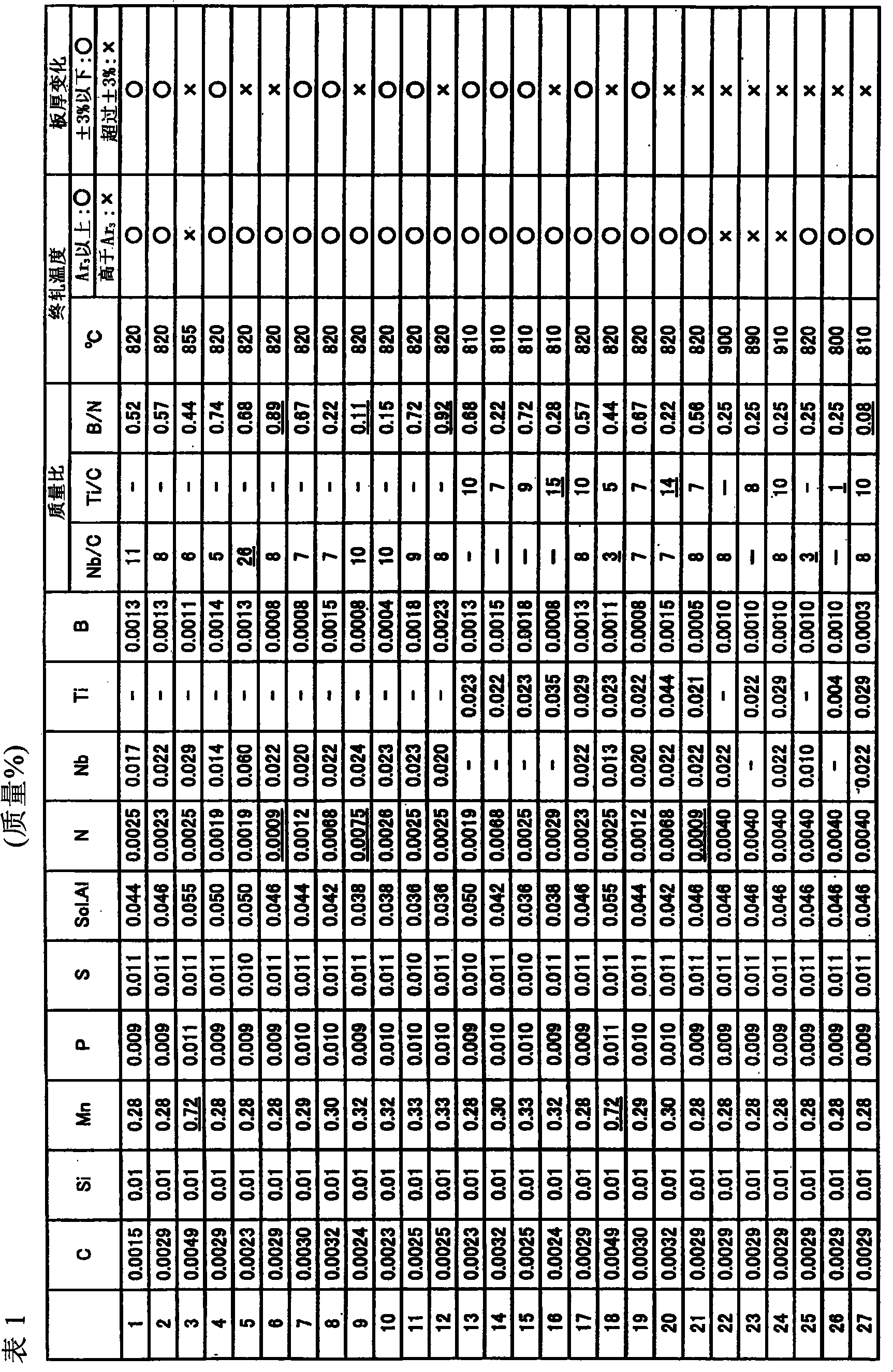

[0062] Examples are described below.

[0063] The various steels shown in Table 1 are smelted to form billets, heated at a heating temperature of 1100-1250°C, hot-rolled at the finishing temperature shown in Table 1, and coiled at a coiling temperature of 680°C. Pick. Next, after pickling, cold rolling was performed at a rolling ratio of 90%.

[0064] The thickness change of the steel sheet obtained as above was evaluated. The change in sheet thickness was evaluated by measuring the sheet thickness after cold rolling for the entire length of the steel sheet coil length with an X-ray sheet thickness meter installed in the cold rolling facility, and evaluating it as a rate of change relative to the average sheet thickness. A steel plate whose rate of change was less than or equal to ±3% acceptable as a product was regarded as acceptable and indicated by ◯, and a steel sheet whose change rate exceeded ±3% was regarded as unacceptable and indicated by ×.

[0065] In addition, i...

Embodiment 2

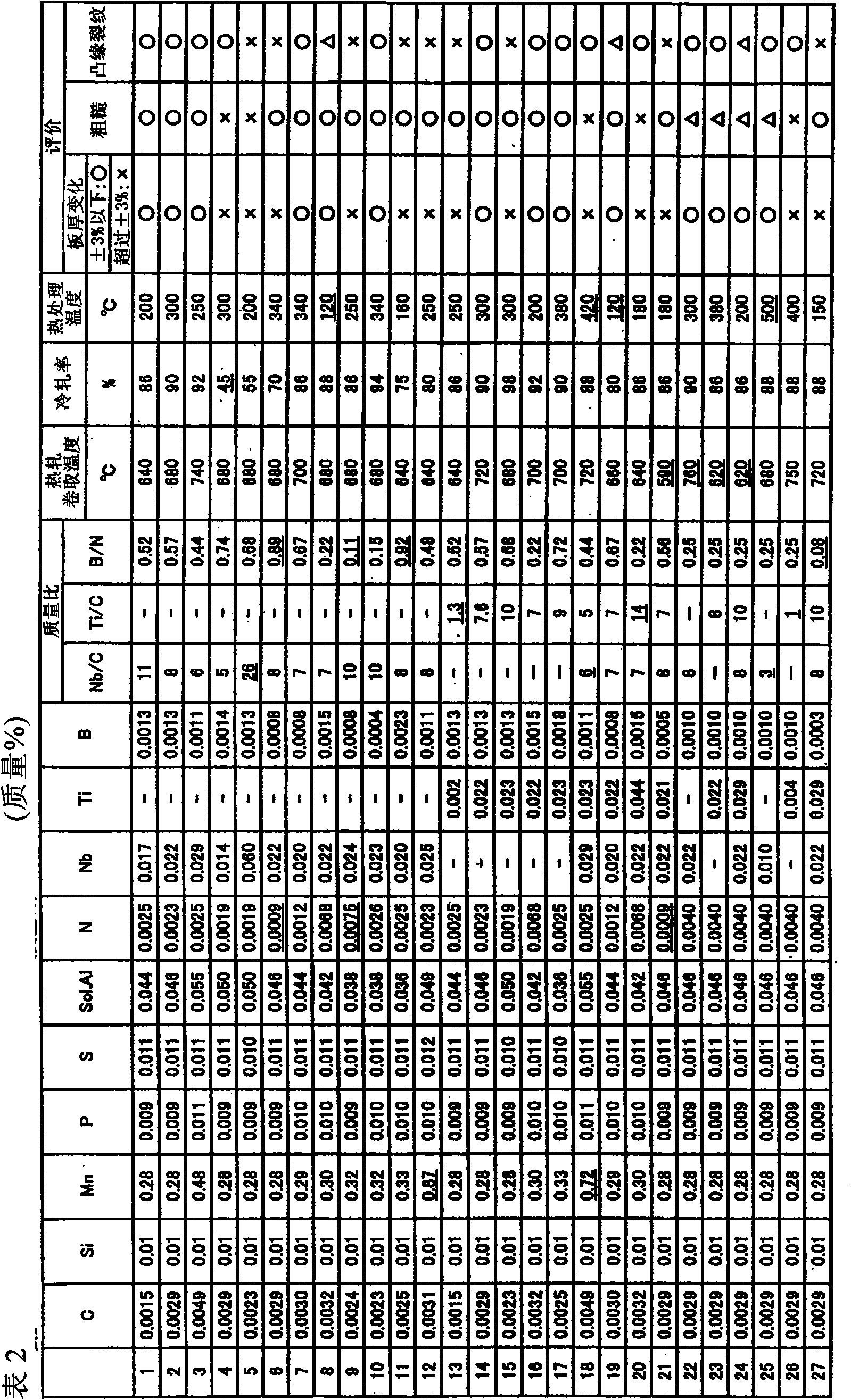

[0069] The various steels shown in Table 2 are smelted and made into steel slabs, and after heating at a heating temperature of 1100-1250°C, the Ar 3 Hot rolling was performed at a finish rolling temperature of 820°C or below the transformation point, and coiling was performed at the coiling temperature shown in Table 2. Next, pickling was performed, and cold rolling was performed at the rolling ratio shown in Table 2.

[0070]The thickness change of the steel sheet obtained as above was evaluated. The change in sheet thickness was evaluated by measuring the sheet thickness after cold rolling for the entire length of the steel sheet coil length with an X-ray sheet thickness meter installed in the cold rolling facility, and evaluating it as a rate of change relative to the average sheet thickness. The evaluation results are shown in Table 2. A steel plate whose rate of change was less than or equal to ±3% acceptable as a product was regarded as acceptable and indicated by ◯, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com