Lifting/lowering type substrate proless device and substrate process system having same

A substrate processing device and lift-type technology, which is applied in the directions of optics, instruments, electrical components, etc., can solve the problems of processing liquid, container enlargement, surface dry spots, etc., and achieve the effect of high-precision control and easy speed control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

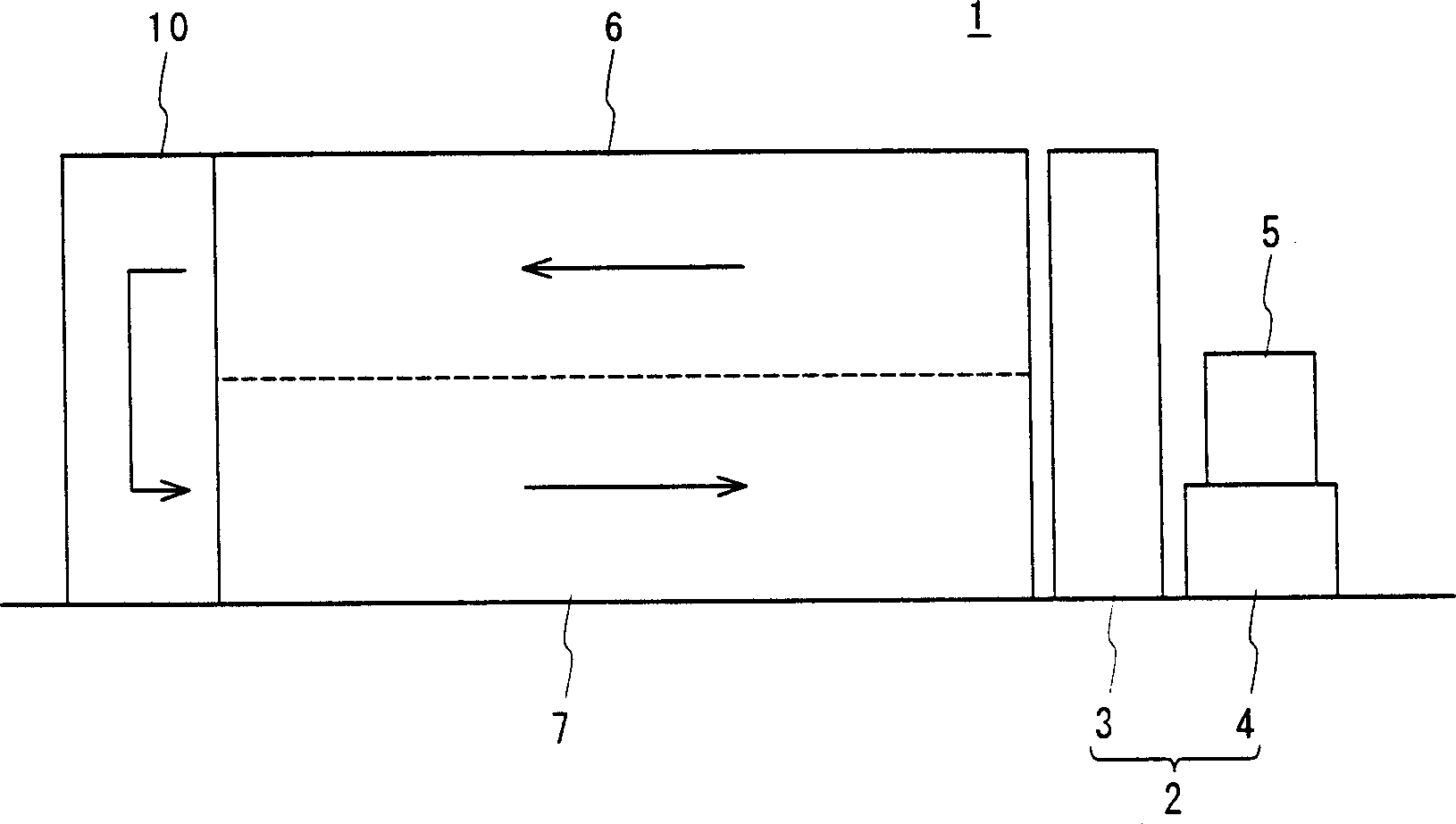

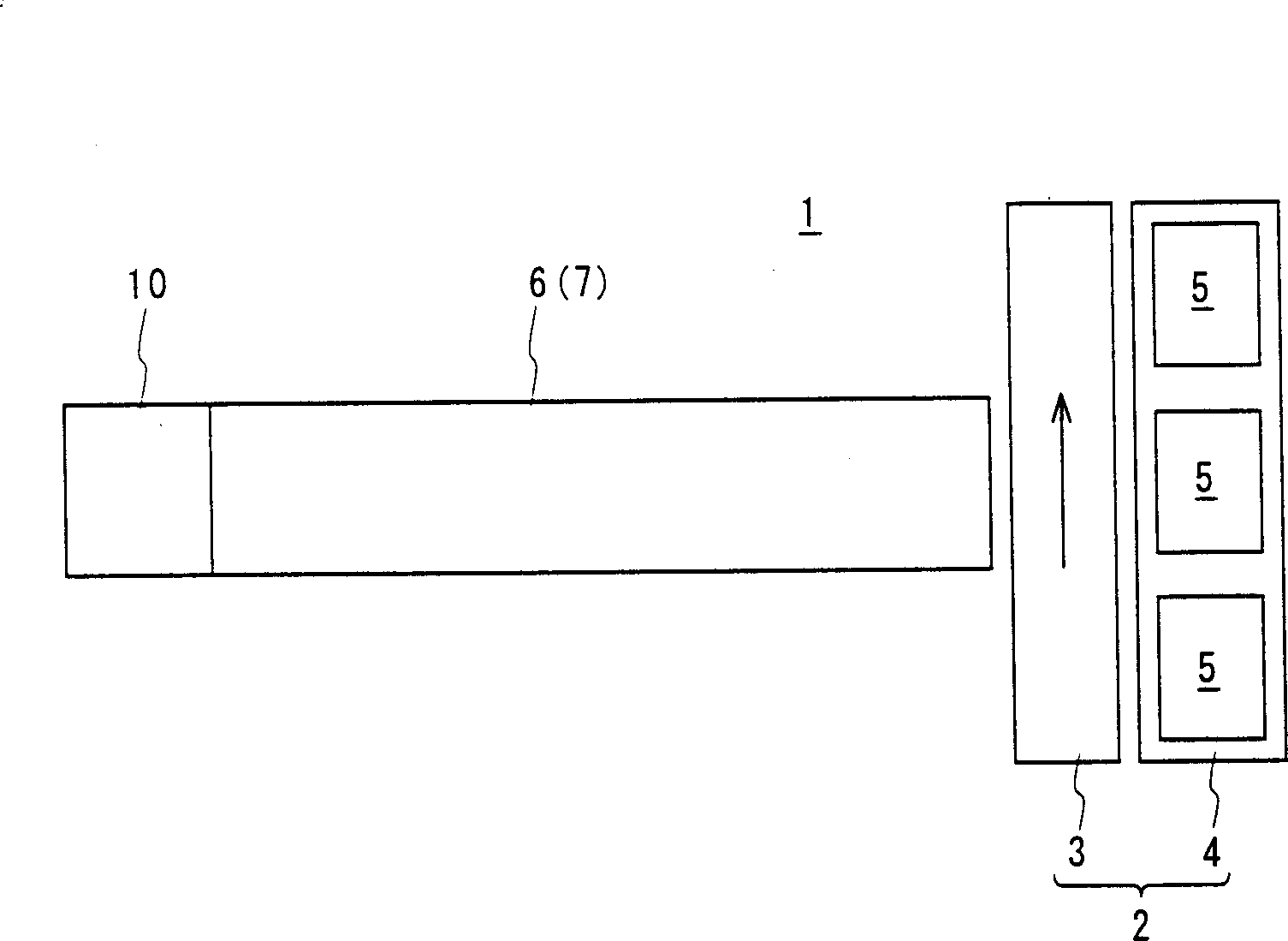

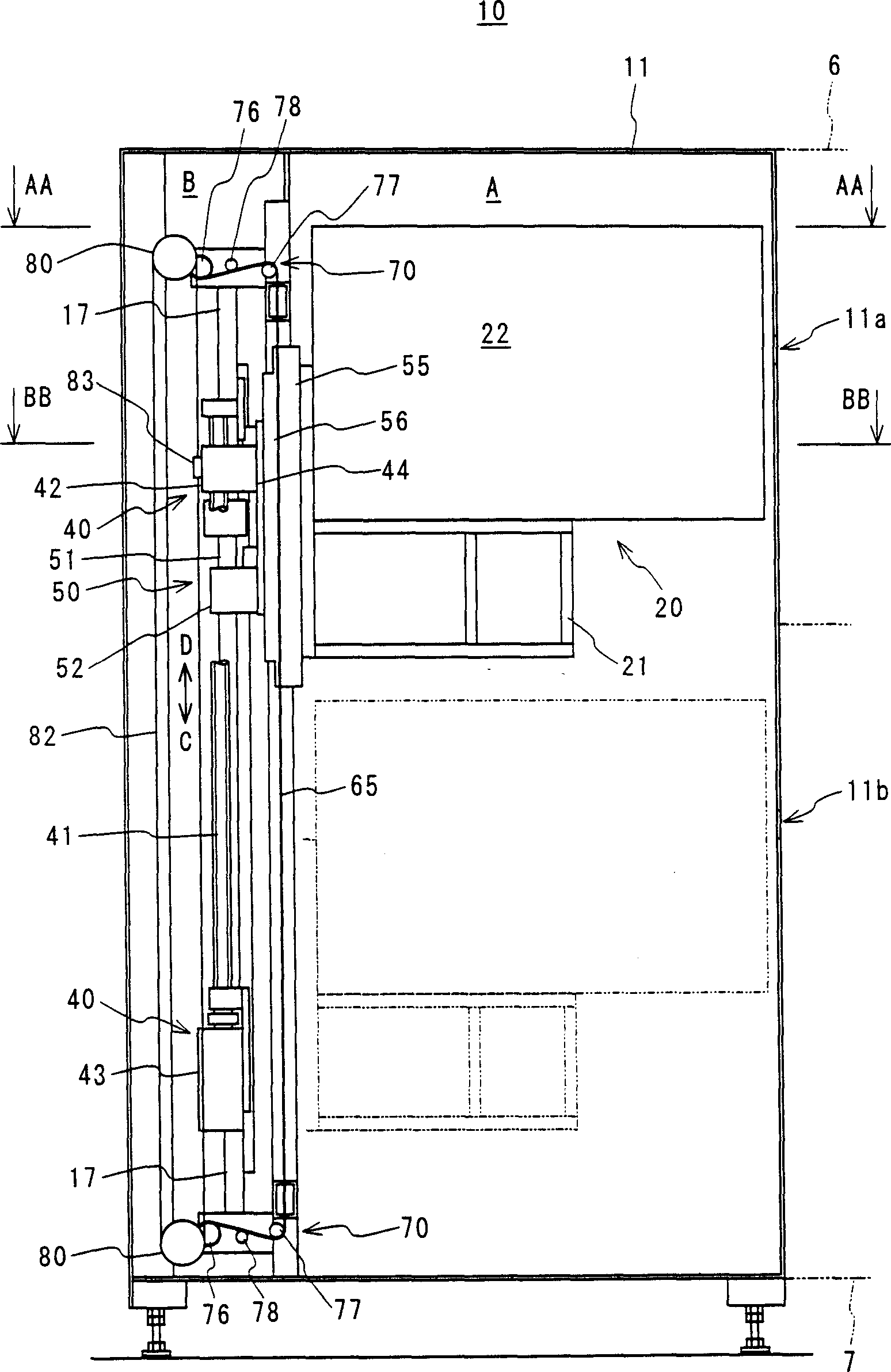

[0069] The following describes specific embodiments of the present invention according to the accompanying drawings. figure 1 is a front view showing a basic configuration of a substrate processing system according to an embodiment of the present invention, figure 2 is its floor plan. in addition, image 3 is a front cross-sectional view showing the basic configuration of the lift-type substrate processing apparatus according to this embodiment, Figure 4 is a front cross-sectional view showing the basic configuration of the cleaning device of this embodiment, Figure 5 is its side sectional view. in addition, Figure 6 is along Figure 5 Plane sectional view of the CC-CC direction in, Figure 7 is along image 3 Plane sectional view of AA-AA direction in, Figure 8 is along image 3 Plane sectional view of BB-BB direction in . also, image 3 also along Figure 7 The sectional view of the DD-DD direction in .

[0070] First, the configuration of the substrate pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com