Method for charging and discharging air as well as maintaining and controlling air pressure

A technology of maintaining control, filling and deflating, applied in the field of servo control system, can solve the problems of inability to expand inflation, inability to accurately control the time of inflation and deflation, etc., to improve test accuracy and work efficiency, improve product operation quality, and stable performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

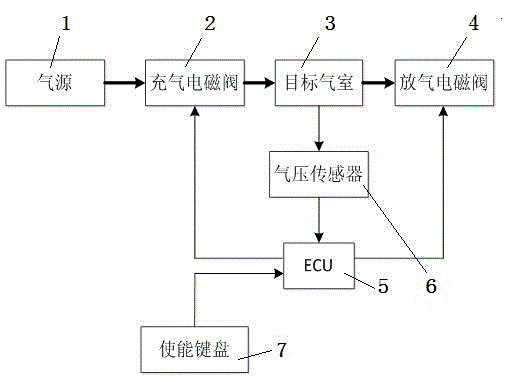

[0017] Such as figure 1 As shown, the inflation and deflation and air pressure maintenance control system of the present invention is composed of an air source 1, an inflation solenoid valve 2, a deflation solenoid valve 4, an ECU control system 5, an air pressure sensor 6 and an enabling keyboard 7. Air source 1, inflation solenoid valve 2, target air chamber 3, and deflation solenoid valve 4 are connected sequentially. Air source 2 provides stable air pressure to target air chamber 3 when needed. Target air chamber 3 is a closed air chamber with any air pressure. The ECU control system 5 is respectively connected to the inflation solenoid valve 2 and the deflation solenoid valve 4 through the control line, the inflation solenoid valve 2 and the deflation solenoid valve 4 are air pressure control valves, and the PWM (pulse width modulation) control signal generated by the ECU control system 5 Switching to the opening and closing of the spool allows the air flow to pass throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com