Adjustable solid material continuous feeding and discharging grinding method and device

A technology of solid material and grinding device, applied in grinding or pulverizing equipment, crushing field, can solve the problems of coal quality influence, large volume, excessive pulverization, etc., and achieve the effect of high sample preparation efficiency, small device volume, and collision avoidance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings.

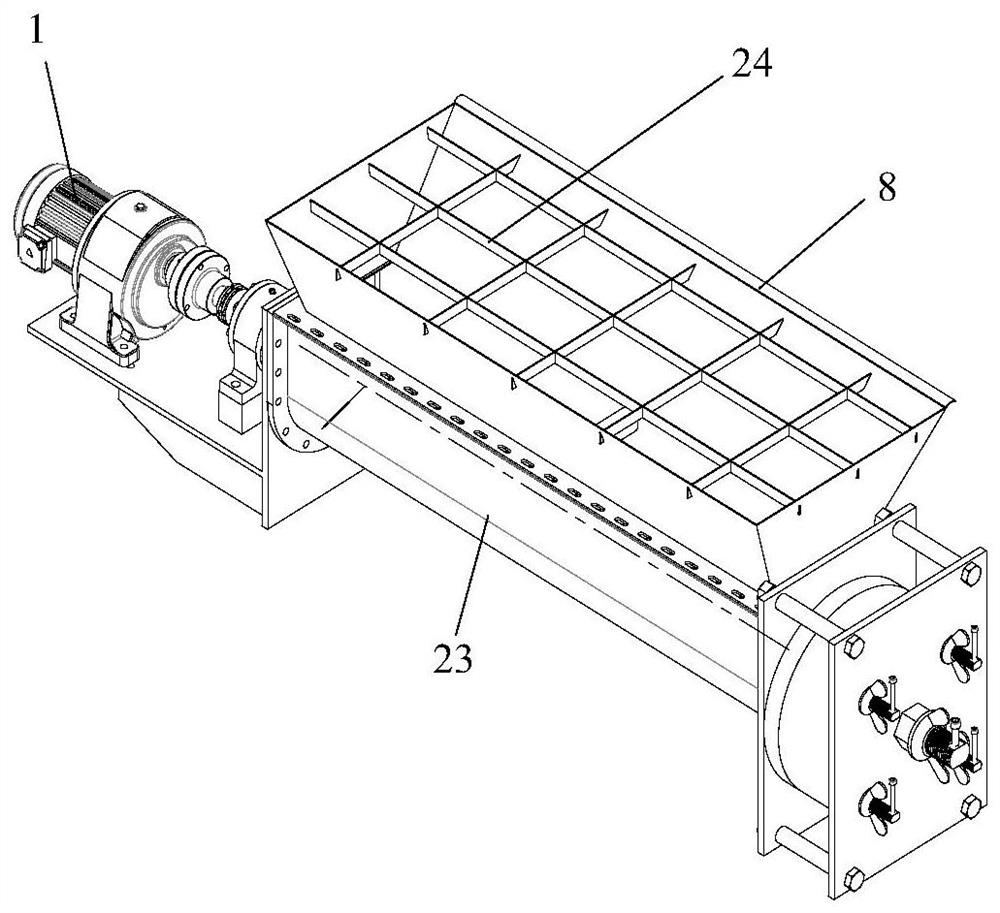

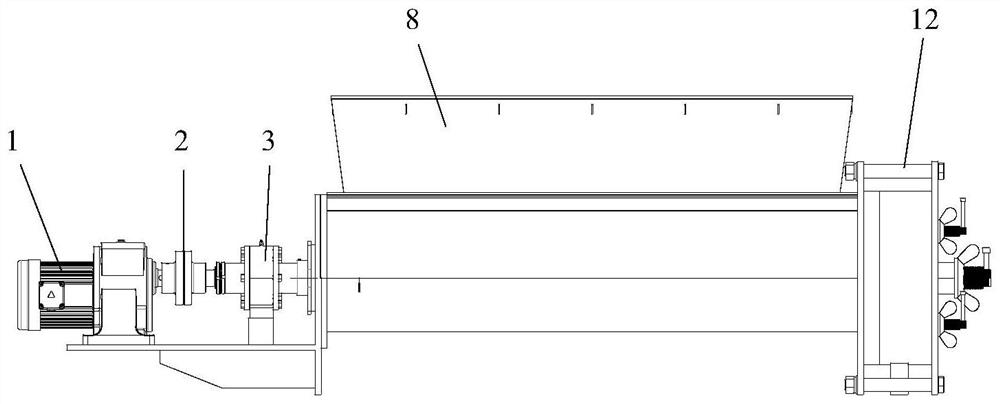

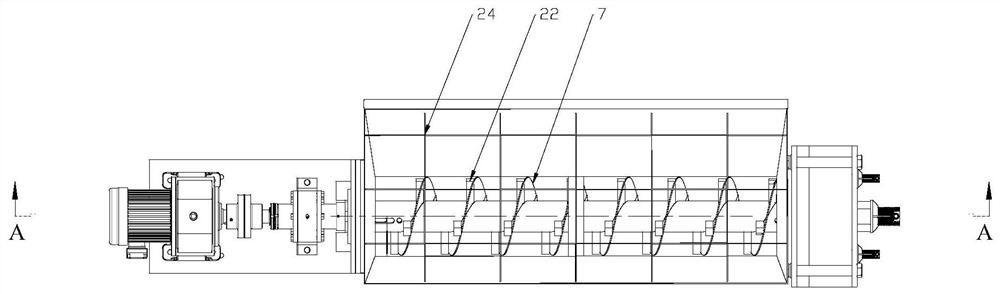

[0035] see Figure 1 to Figure 5 Shown, a kind of grinding device of adjustable solid material continuous feeding and discharging, it comprises:

[0036] Housing, its upper end is covered with the feed inlet of safety net 24;

[0037] Grinding chamber housing 19, which communicates with the housing through the feeding hole 9 and the lower end is provided with a discharge port 20;

[0038] The grinding disc 10 and the adjustable grinding disc 11 are placed in the grinding chamber casing 19 in a coaxial and grinding-face-facing configuration;

[0039] The feeding shaft 6 is driven to rotate by the drive mechanism and extends into the housing from the feeding hole 9 and is inserted into the grinding chamber shell 19 to be coaxially connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com