Nano-structure three-dimensional distributed super-amphiphobic metal surface and preparation method thereof

A nano-structured, three-dimensional distribution technology, applied in metal processing equipment, metal material coating technology, manufacturing tools, etc., to achieve good durability, excellent super-amphiphobic performance, and increase the growth area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] Concrete preparation method of the present invention comprises the steps:

[0032] 1) Pretreatment of the metal substrate: After the metal substrate is machined and polished, it is cleaned in ethanol and acetone in sequence, and then dried with nitrogen gas flow;

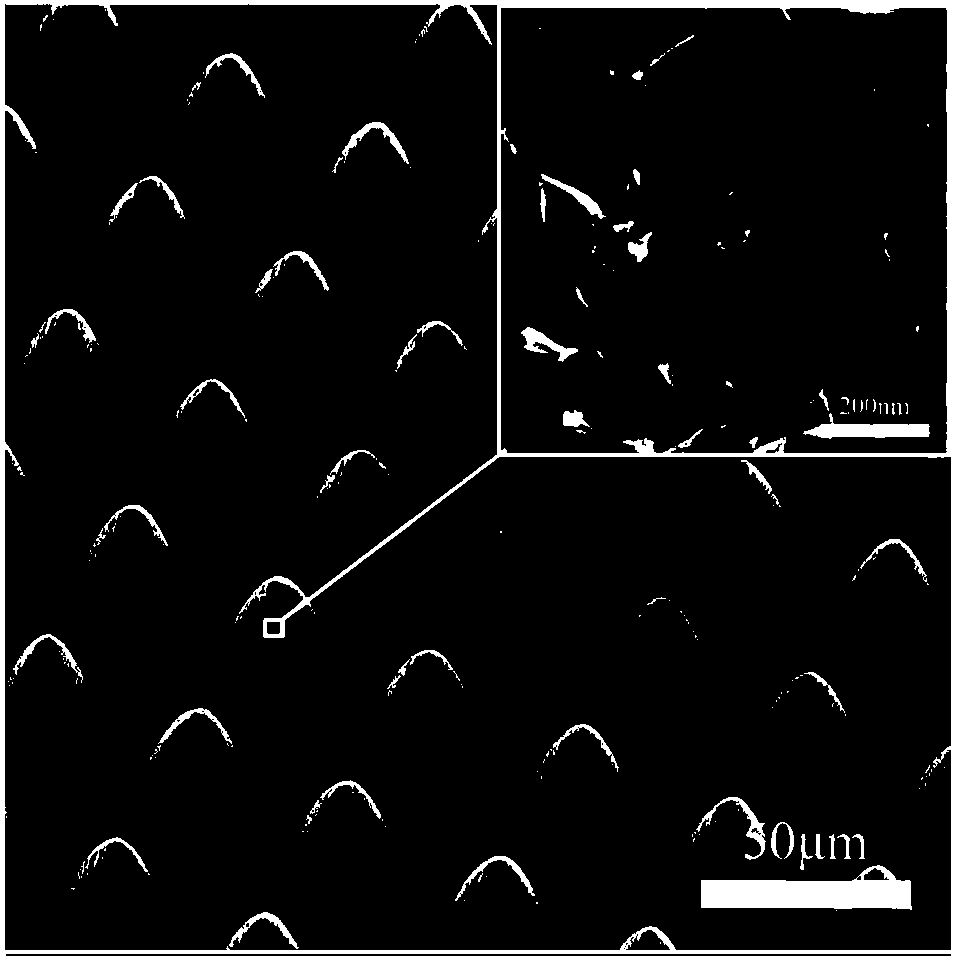

[0033] 2) Construction of a regular microcone array structure on the surface of the metal substrate: use a high-power ultrafast laser to perform selective pattern ablation on the surface of the metal substrate, such as using a femtosecond laser to scan according to the pattern of vertical intersections; The distance between adjacent scanning paths is 30-100 μm, and the total area of the pattern is 0.01-10000 mm 2 , to form a highly ordered micro-cone array structure, and then the sample was ultrasonically cleaned in ethanol and acetone in turn, and then dried with nitrogen gas flow;

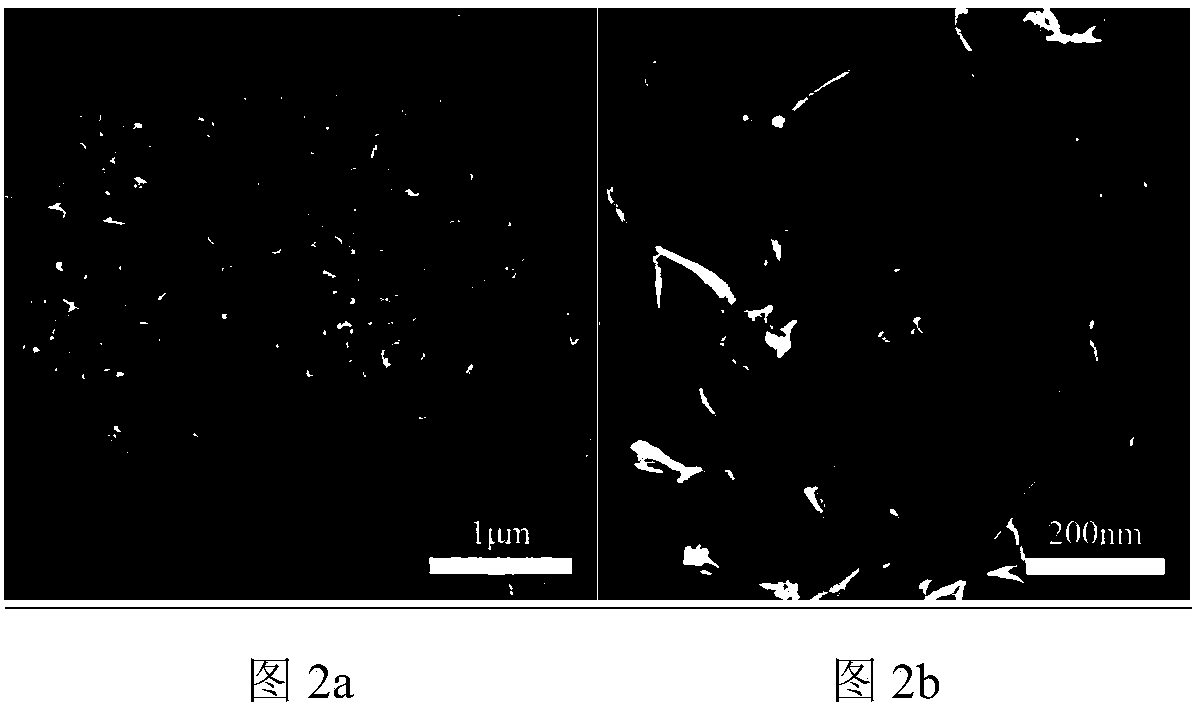

[0034] 3) Constructing the nano-grass structure on the surface of the micro-array structure: the metal substrate with the m...

Embodiment 1

[0037] Example 1: A durable copper-based superamphiphobic hierarchical structure surface with three-dimensional distribution of nanostructures prepared by femtosecond laser ablation and chemical bath oxidation composite method:

[0038] 1) Cut the copper substrate into a copper block with a size of 10mm×10mm×3mm, and use No. 200, No. 400, No. 800, No. 1000, and No. 1500 metallographic sandpaper to polish the surface of the copper substrate in turn, and then polish it deal with. The copper blocks were then ultrasonically cleaned in ethanol, acetone, and then dried using a gentle stream of nitrogen gas.

[0039] 2) A high-power femtosecond laser is used to perform selective pattern ablation on the surface of the copper substrate. The laser wavelength is 1030nm, the pulse width is 800fs, the pulse repetition frequency is 200kHz, and the laser power is 6W. The scanning pattern is a vertical intersection, the distance between adjacent scanning paths is 40 μm, the scanning speed is...

Embodiment 2

[0044] Example 2 Preparation of durable aluminum-based superamphiphobic hierarchical structure surface with three-dimensional nanostructure distribution by femtosecond laser ablation and chemical bath oxidation composite method

[0045] 1) Cut the aluminum substrate into an aluminum block with a size of 10mm×10mm×3mm, and use No. 200, No. 400, No. 800, No. 1000, and No. 1500 metallographic sandpaper to polish the surface of the aluminum substrate in turn, and then polish it deal with. Then the aluminum block was ultrasonically cleaned in ethanol and acetone in turn, and then dried with a gentle nitrogen stream after taking it out.

[0046] 2) A high-power femtosecond laser is used to selectively pattern and ablate the surface of the aluminum substrate. The laser wavelength is 1030nm, the pulse width is 800fs, the pulse repetition frequency is 200kHz, and the laser power is 4W. The scanning pattern is a vertical intersection, the distance between adjacent scanning paths is 40 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com