Patents

Literature

30 results about "Femtosecond laser ablation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

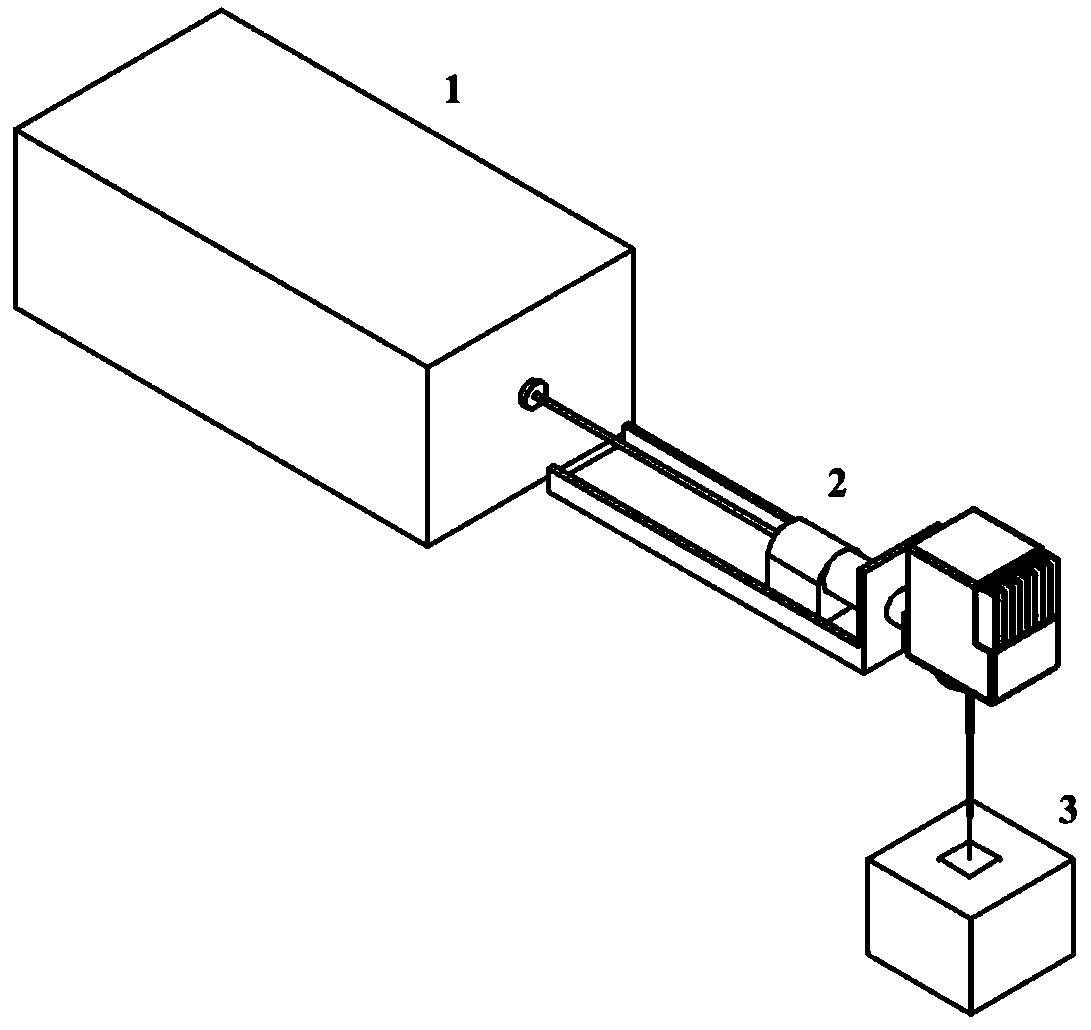

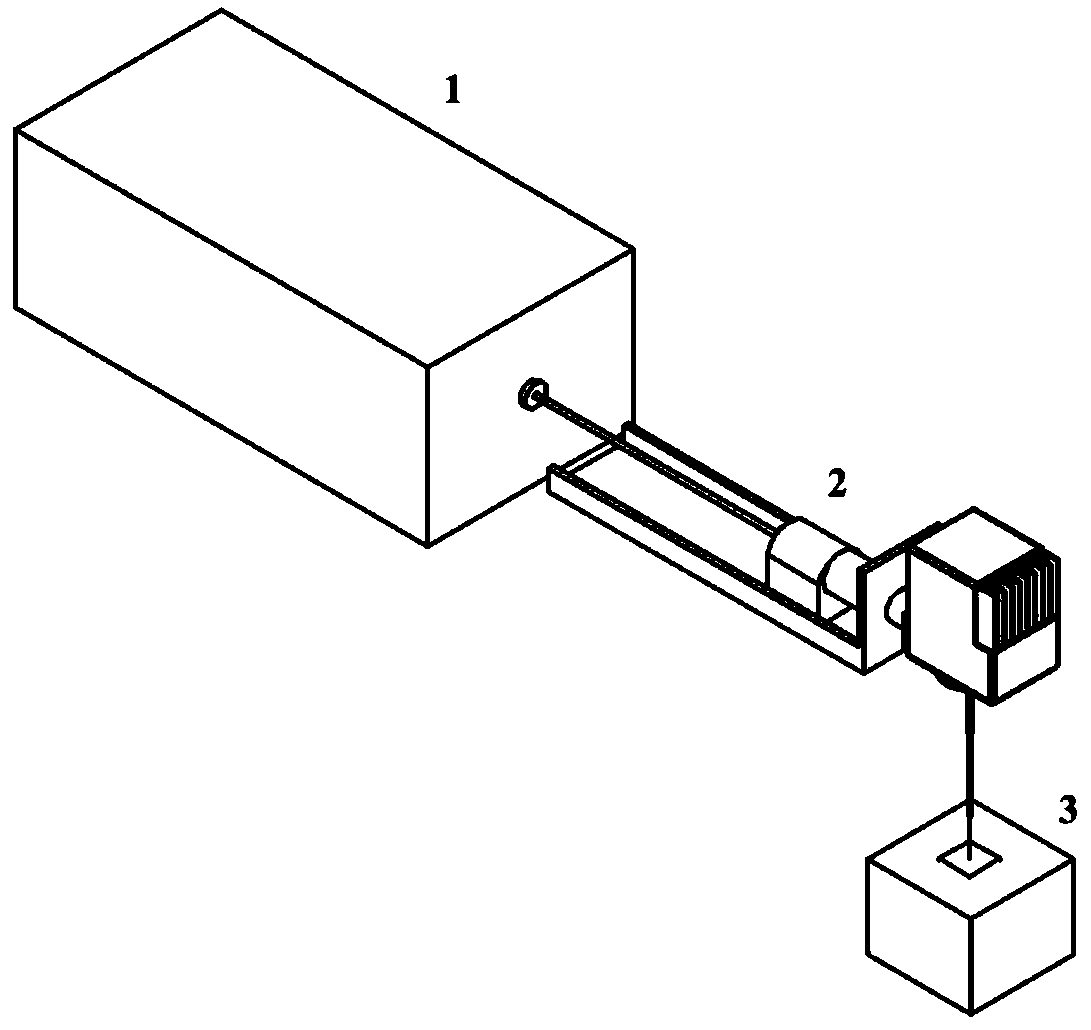

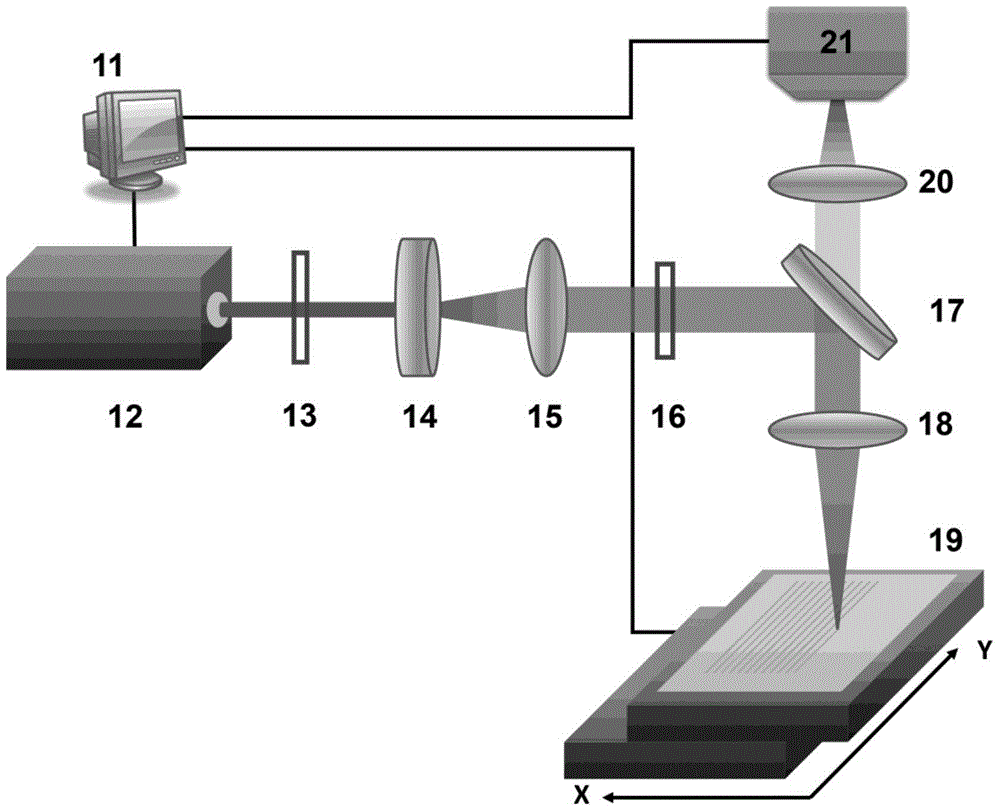

Method and device for preparing bionic super-hydrophobic micro-nano surface through femtosecond laser

ActiveCN104625415AEasy to handleMany processing advantagesLaser beam welding apparatusMicro nanoAutomatic control

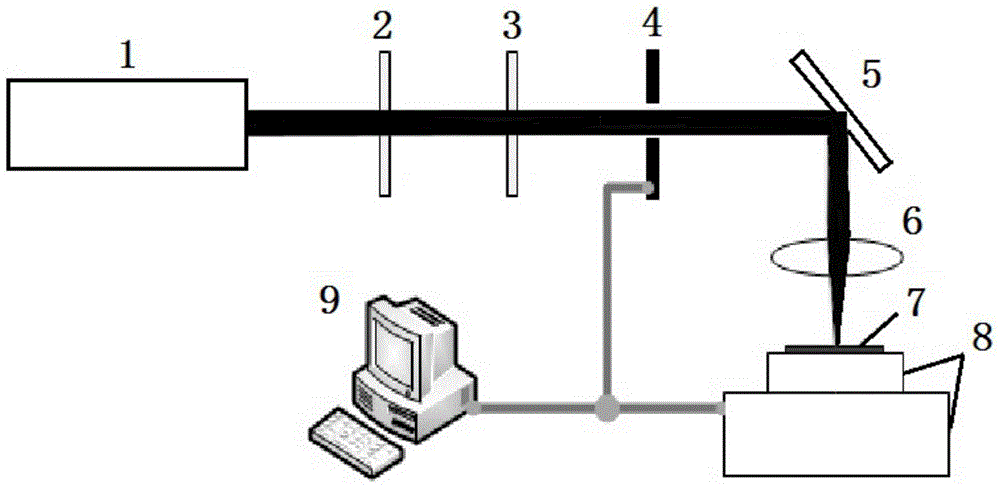

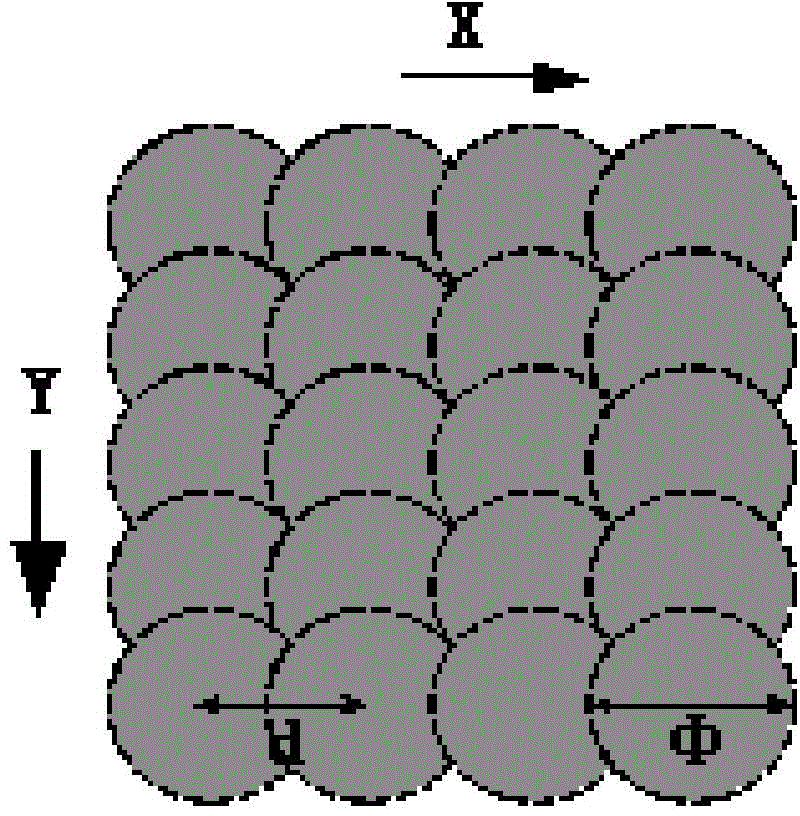

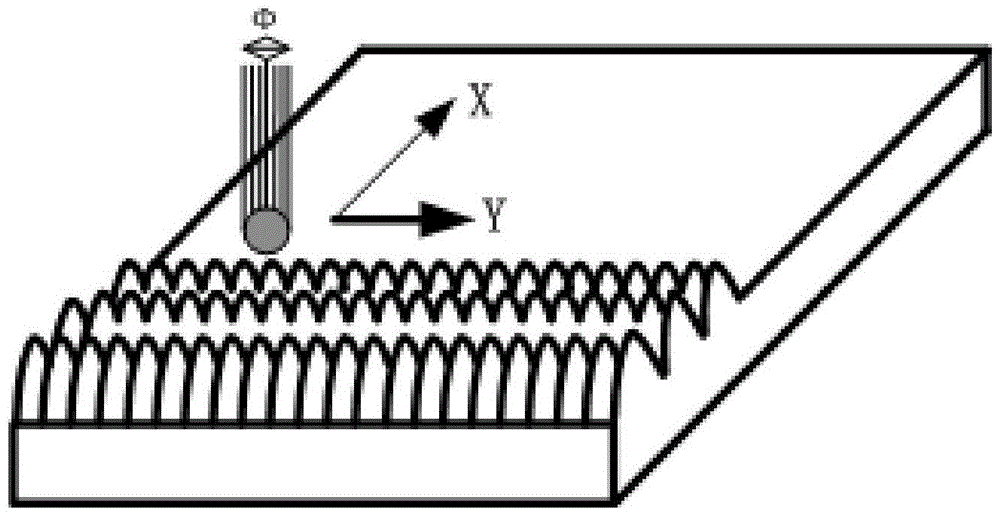

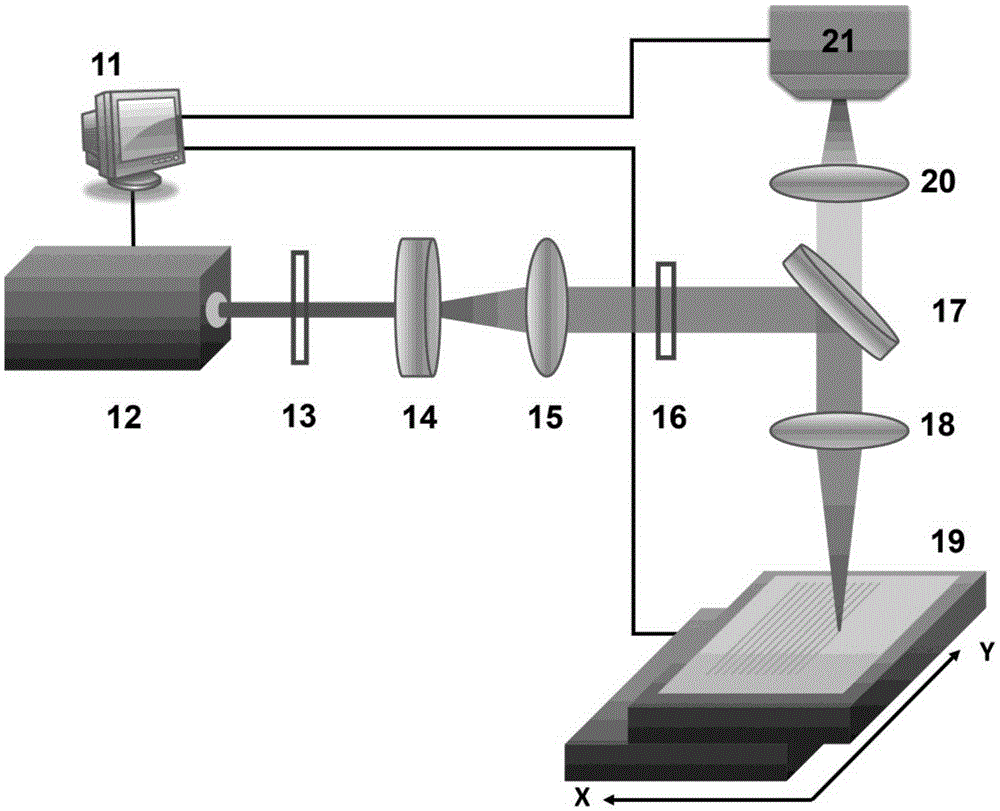

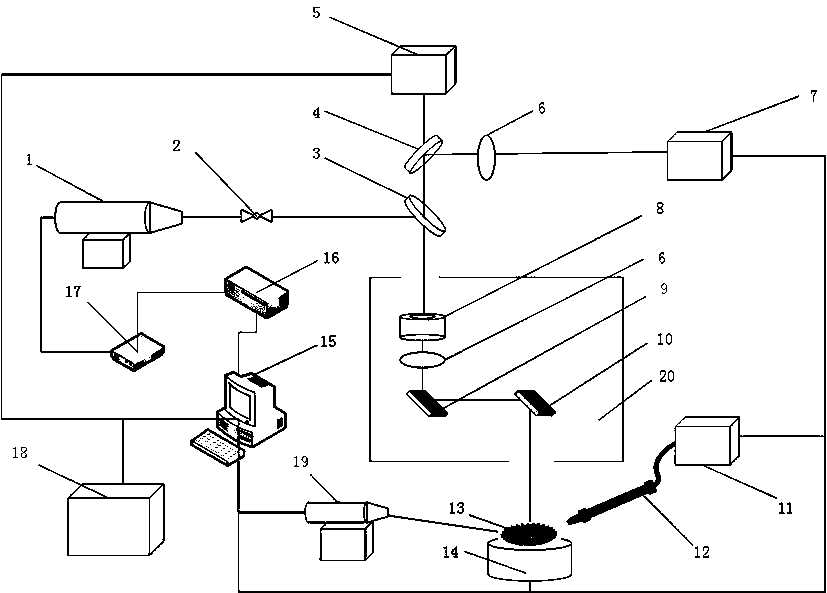

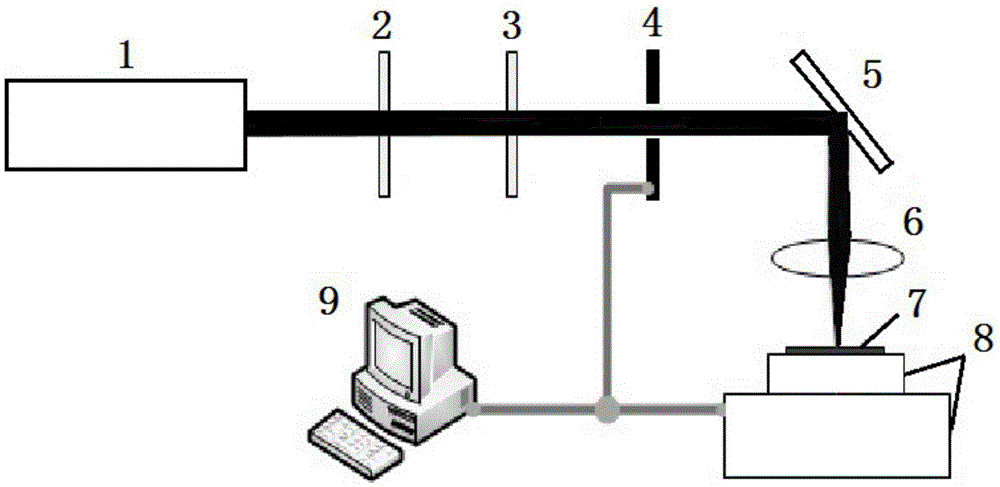

The invention provides a device for preparing the bionic super-hydrophobic micro-nano surface through femtosecond laser. The device comprises a femtosecond laser unit, a light beam control unit, a motion platform unit and an automatic control unit. The femtosecond laser unit is used for transmitting the femtosecond laser. The light beam control unit is used for controlling power, light beam quality and exposure time of the femtosecond laser. The motion unit is used for controlling the movement amount in the three-dimensional direction of the photo-etched surface. The femtosecond laser unit is arranged behind the light beam control unit. The light beam control unit is arranged above the motion platform unit. The light beam control unit and the motion platform unit are electrically connected with the automatic control unit. The invention further provides a method for preparing the bionic super-hydrophobic micro-nano surface through the femtosecond laser, and the device is adopted in the method. The ablation effect of the femtosecond laser is utilized for forming a micro-nano composite structure similar to the surface of a lotus leaf at a time, secondary modeling is not needed, the process is simple, and the micro-nano structure is stable, good in uniformity and high in hydrophobic function.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

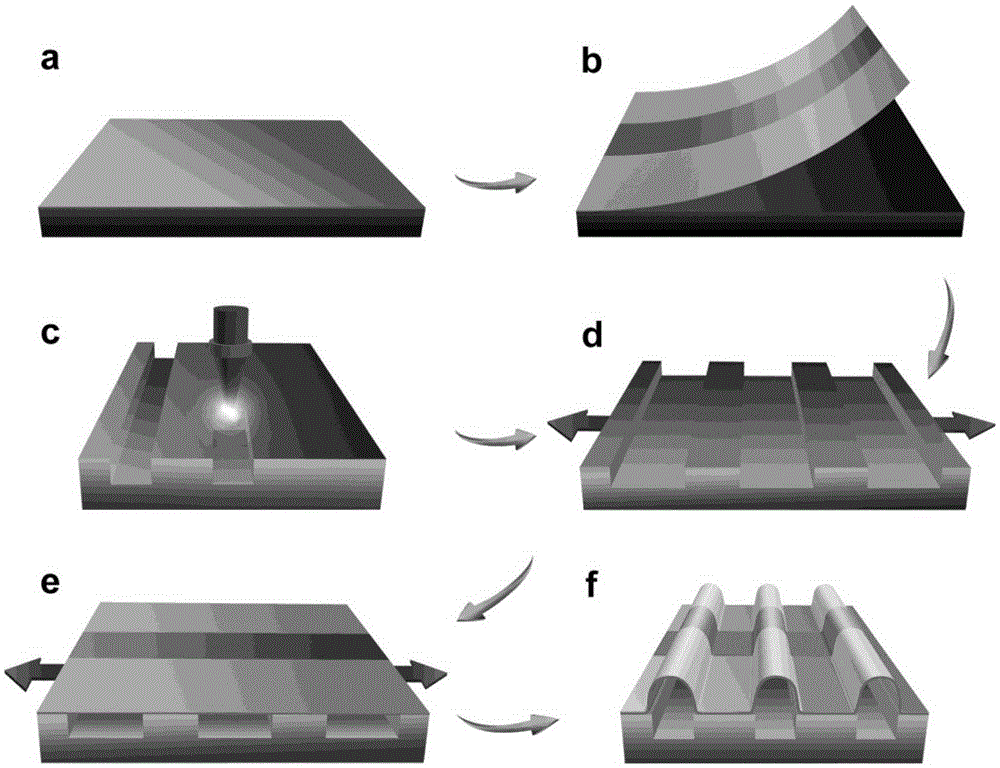

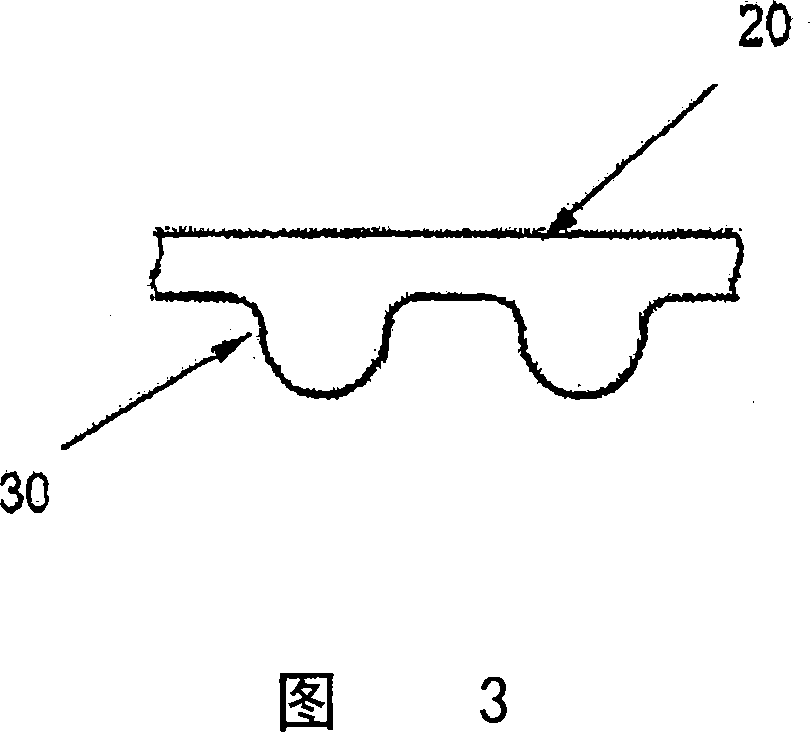

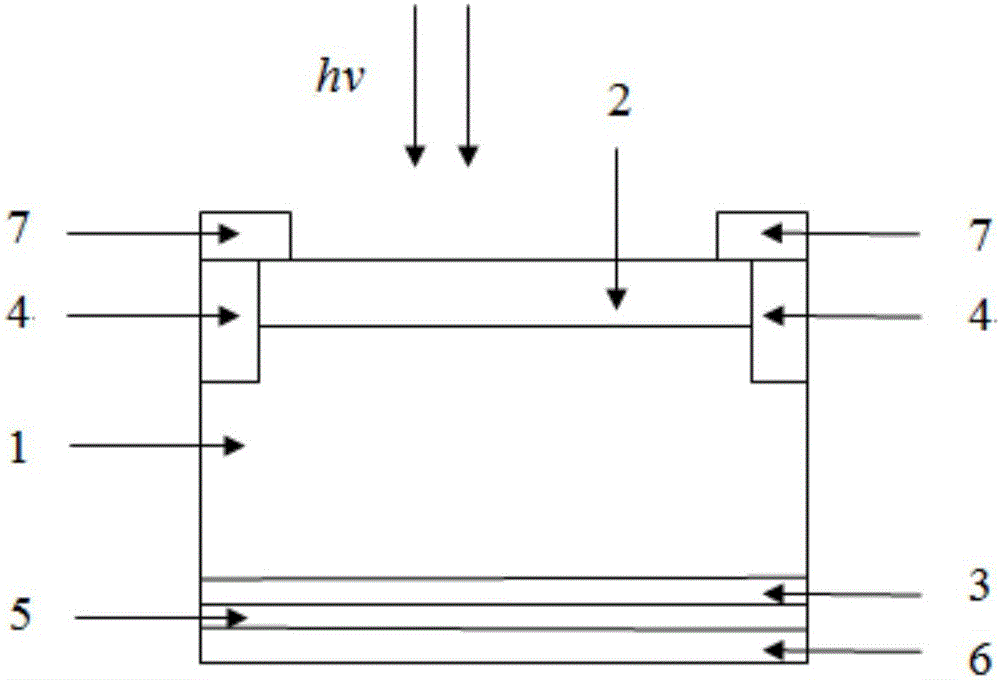

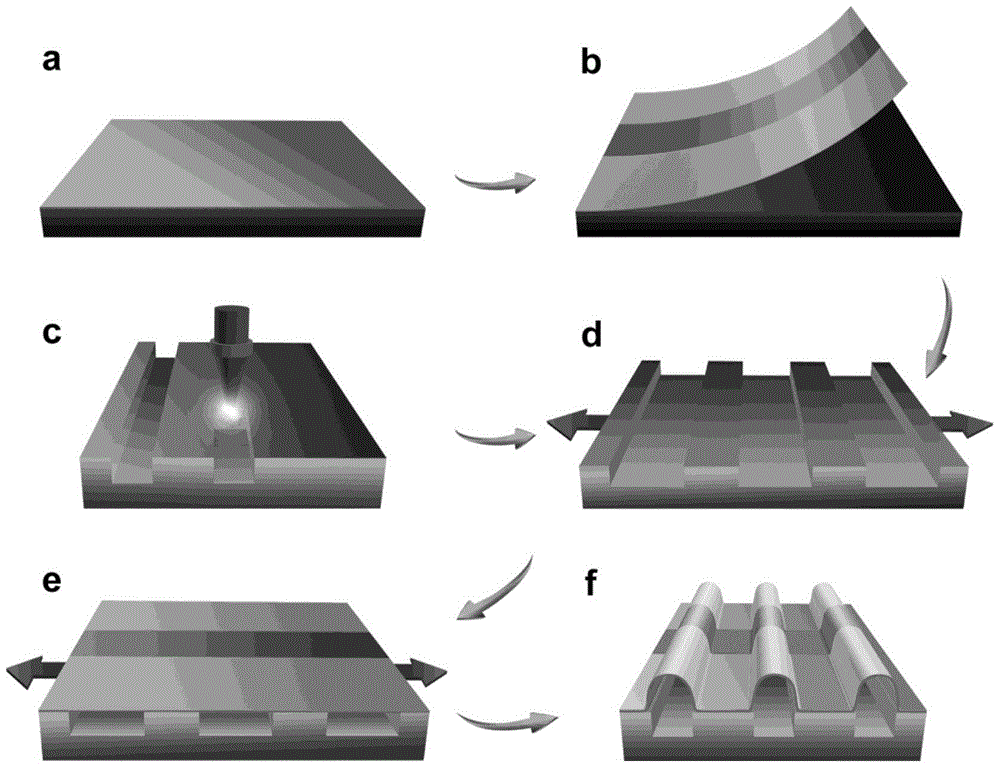

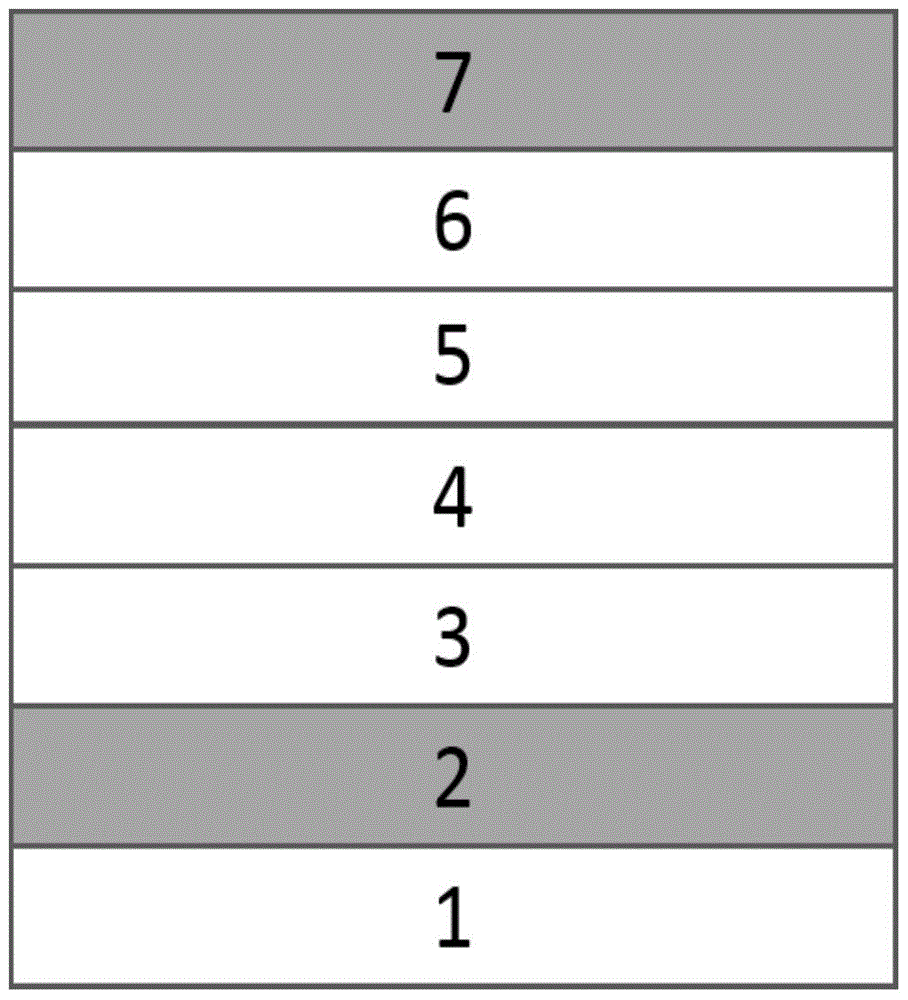

Stretching organic electroluminescence device with periodically regular crease structure

ActiveCN105405983AImprove flexibilityFlat surfaceSolid-state devicesSemiconductor/solid-state device manufacturingGratingElastic substrate

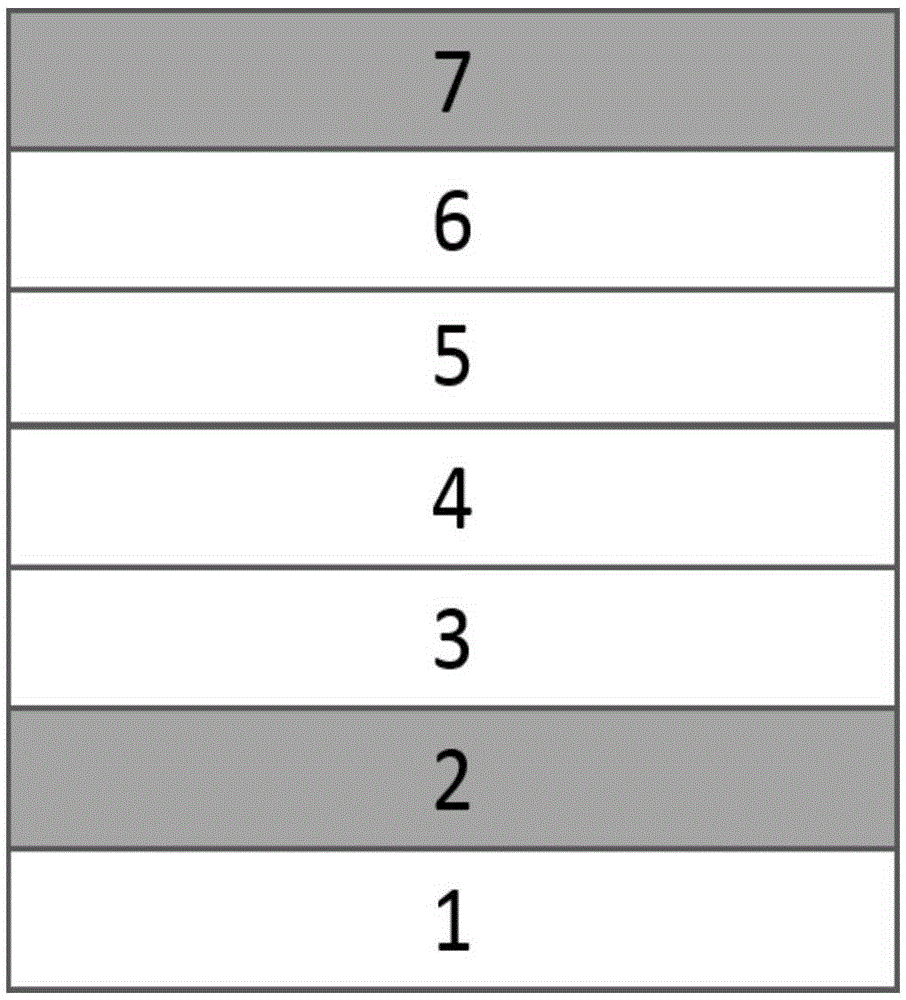

The invention discloses a stretching organic electroluminescence device with a periodically regular crease structure, belongs to the technical field of photoelectrons, and particularly relates to the stretching organic electroluminescence device with a periodically regular crease, which is high in efficiency, high in stability and high in tensile strength. The stretching organic electroluminescence device is prepared by the following steps: processing a long-period grating structure on the surface of an elastic substrate by a femtosecond laser ablation process; obtaining an organic electroluminescence device by combining a vacuum evaporation technology and a demolding technology; and finally combining the elastic substrate with the long-period grating structure and the organic electroluminescence device. The stretching organic electroluminescence device has very high stretching stability; the photoelectric property of the device only slightly fluctuates along with the change of the tensile strength; and more importantly, the properties of the device only lightly attenuate in multiple repeated tensile tests, so that the stretching organic electroluminescence device has very high practical value.

Owner:JILIN UNIV

Method of producing a micro- or nano-mechanical part, comprising a femto-laser-assisted ablation step

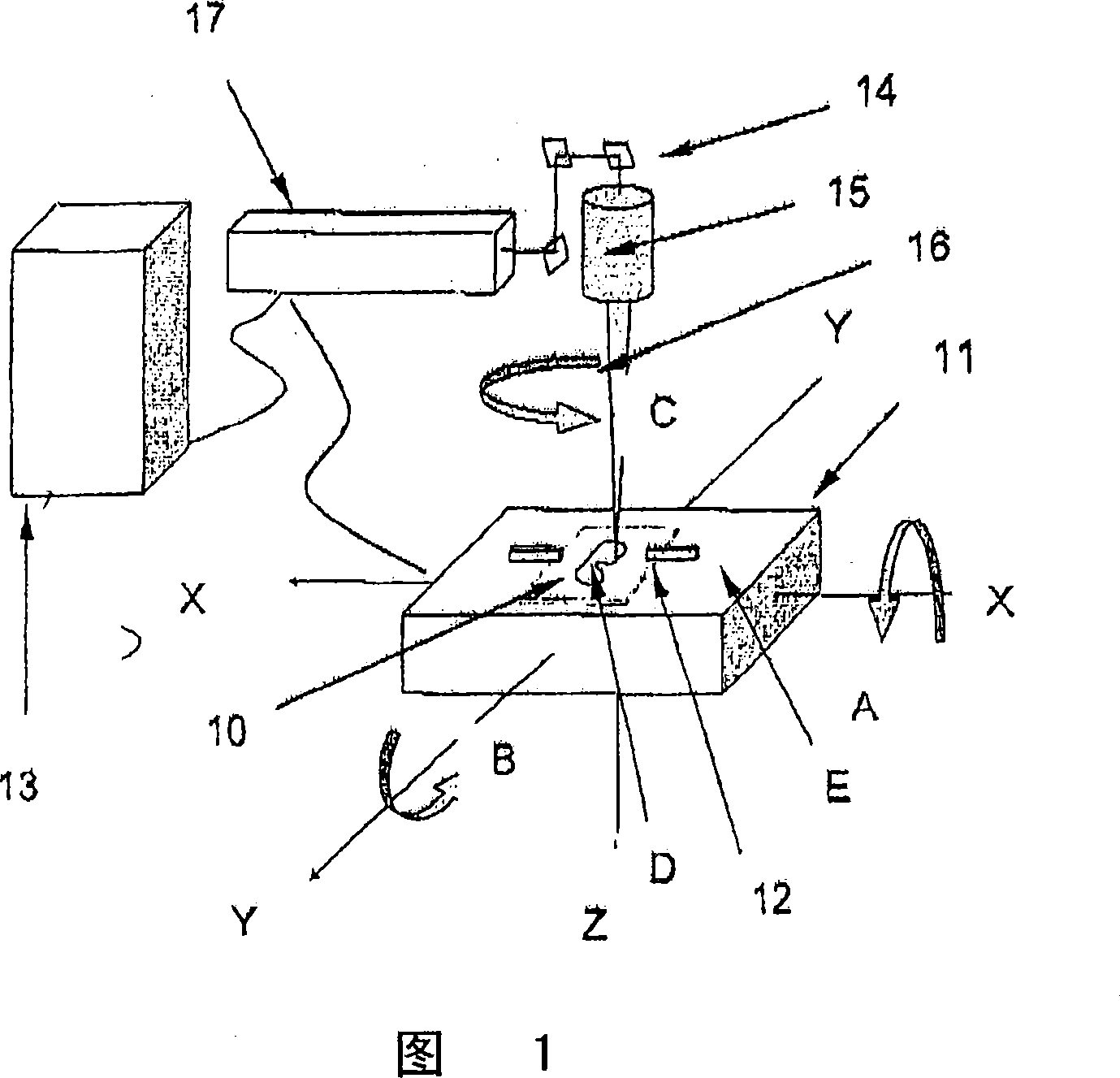

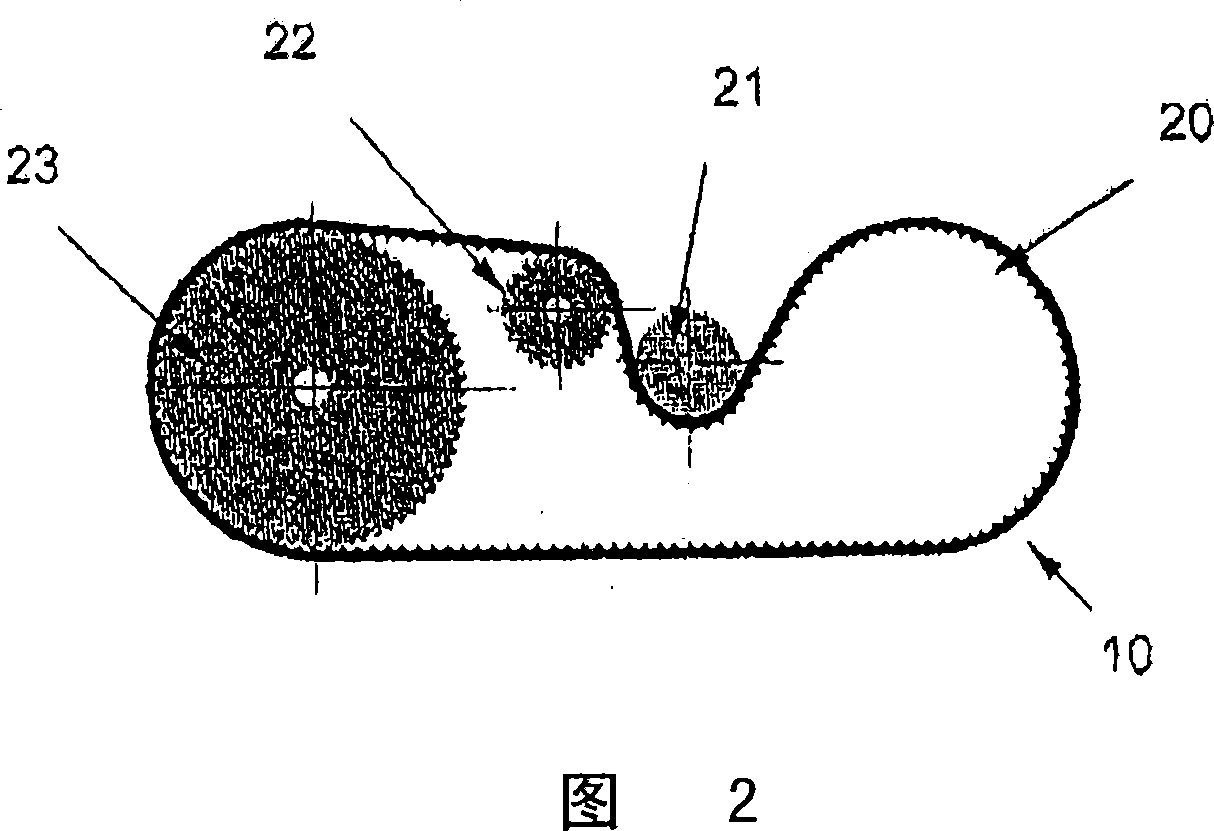

InactiveCN101048256AShort durationIncrease powerRepair toolsWelding/soldering/cutting articlesLight beamLaser assisted

The invention relates to a method of producing a micro- or nano-mechanical part, such as a pulley or belt for clock making, comprising a laser ablation step which is performed with the aid of a femto-laser, i.e. a laser having a pulse with a duration of less than 5x10<-13> seconds and a power of more than 10<12 >watts on the beam / material interaction surface. According to the invention, the part to be machined is pre-modelled in three dimensions and said three-dimensional model is used to generate the machining programme.

Owner:TAG HEUER SA

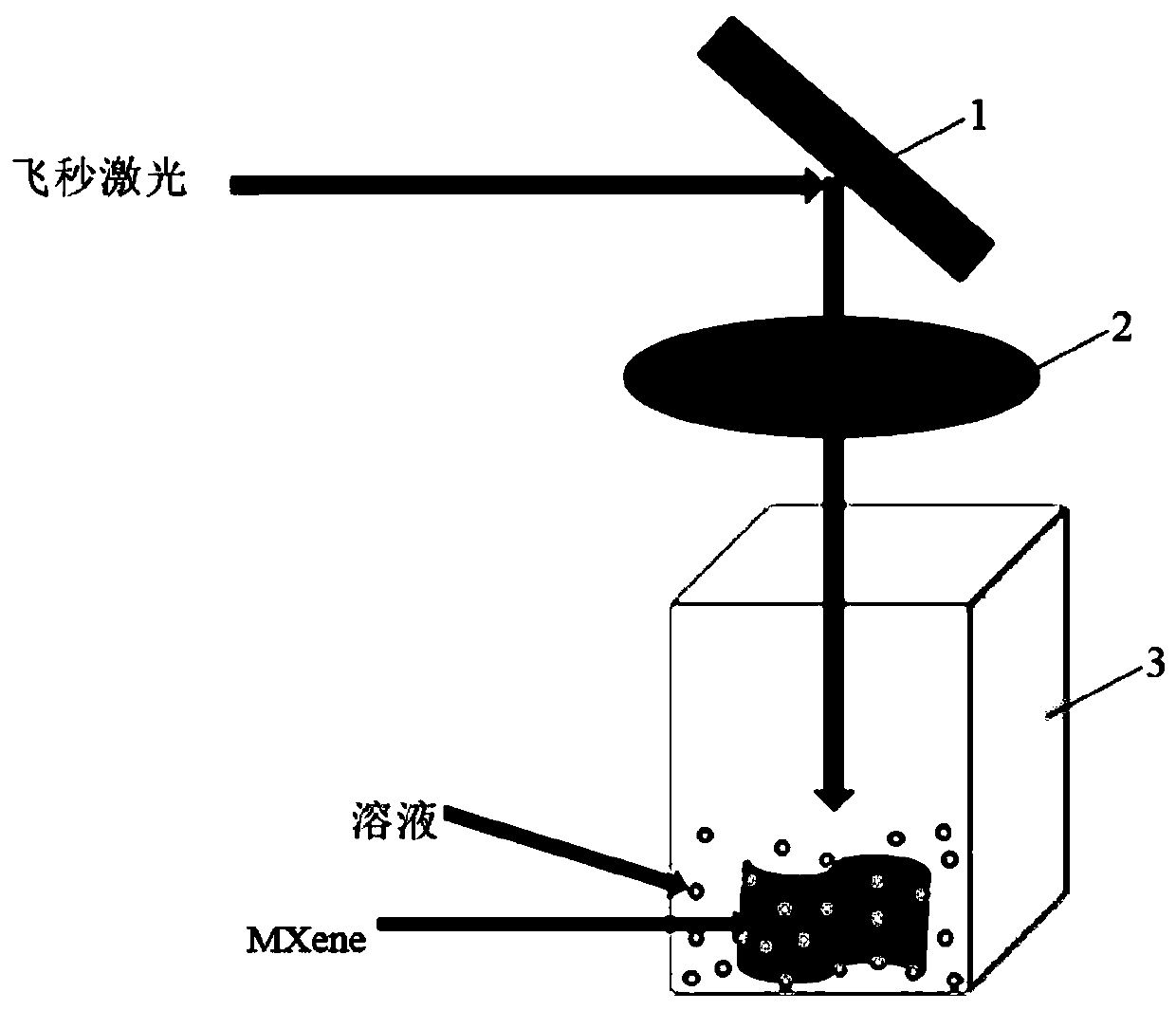

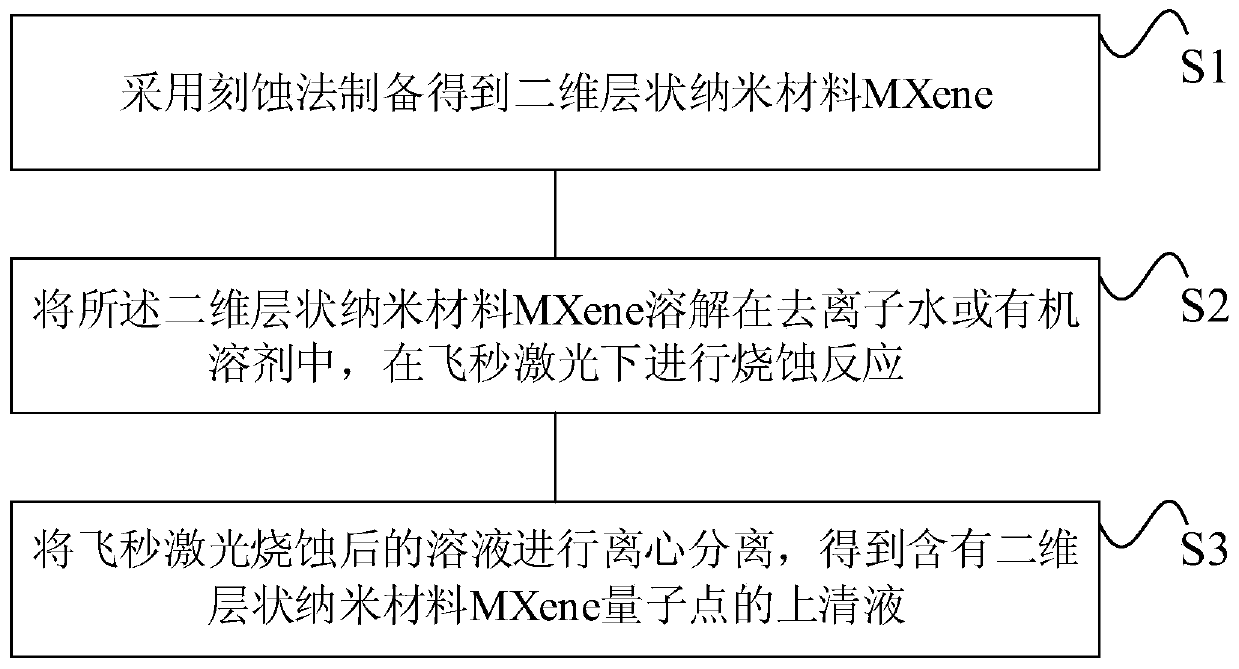

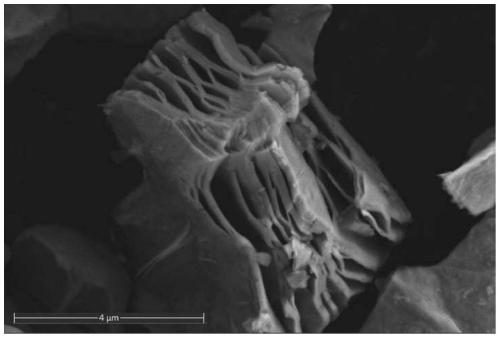

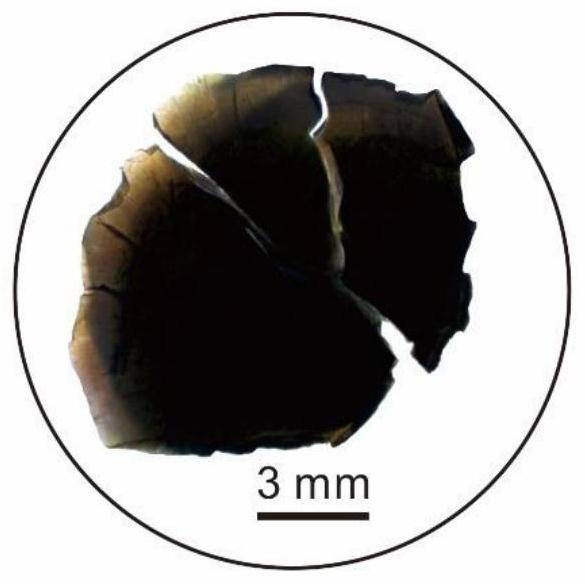

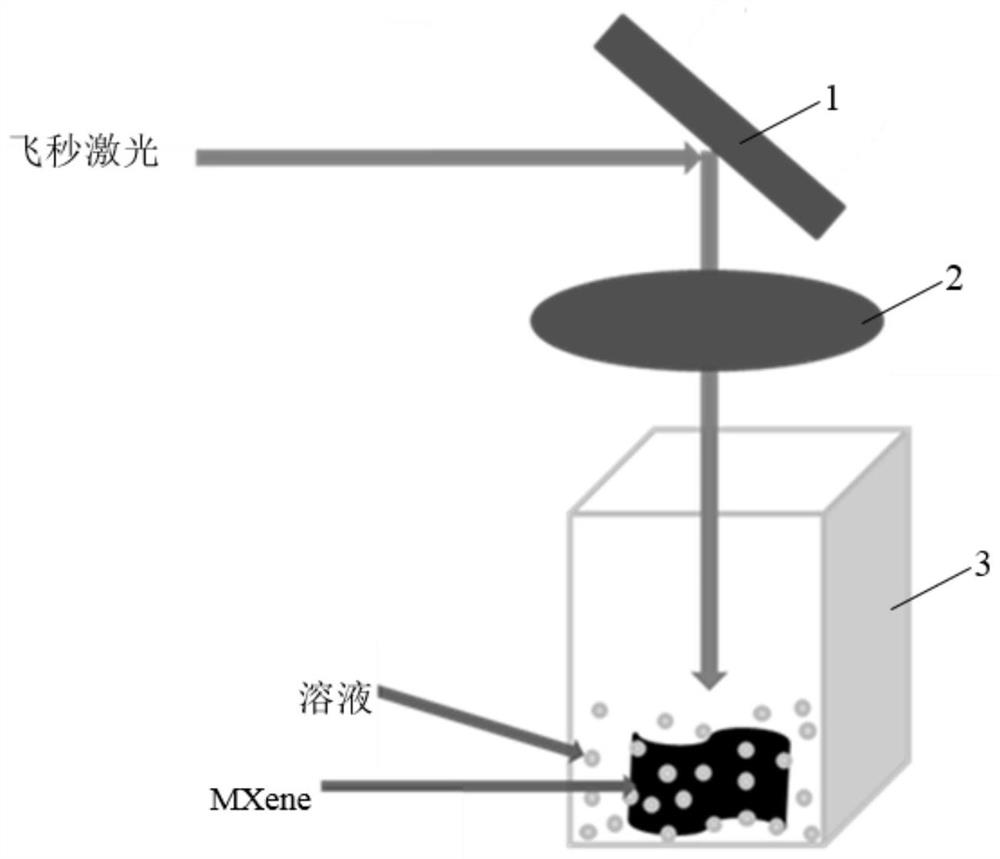

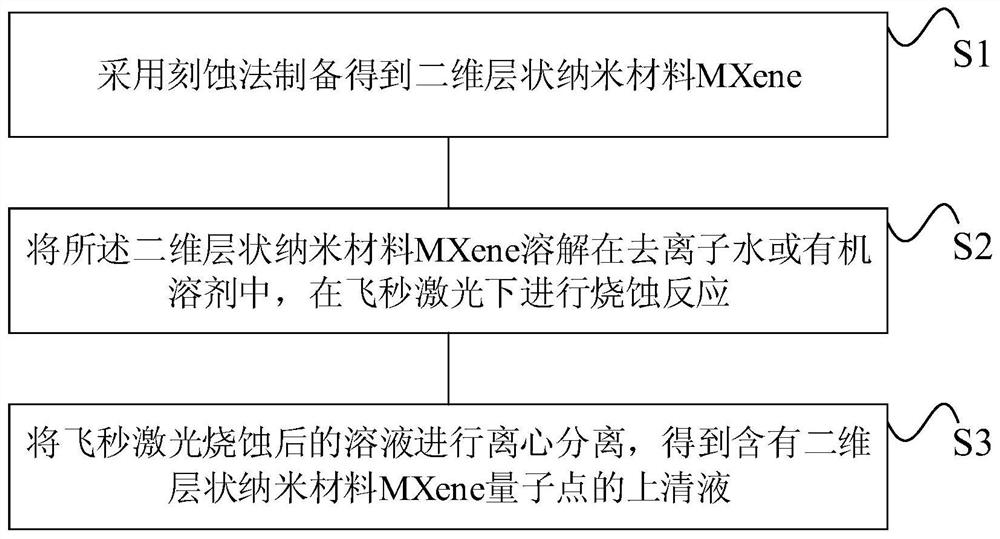

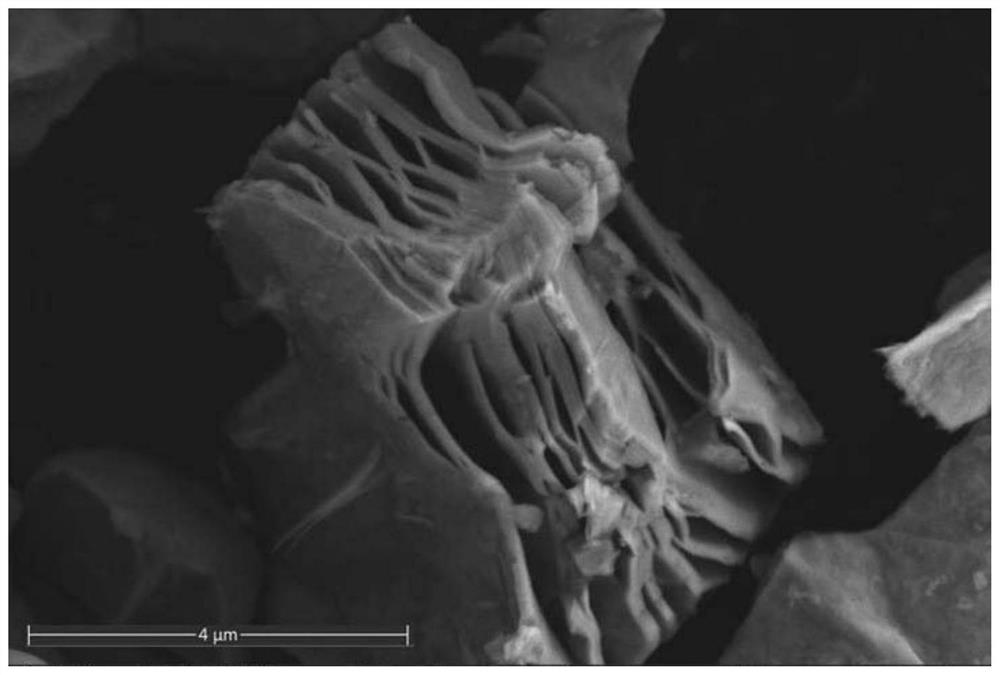

Preparation method of two-dimensional layered nano material MXene quantum dots

ActiveCN110272048AImprove photoelectric performanceReduce pollutionMaterial nanotechnologyCarbon compoundsSolventComputational chemistry

The invention relates to a preparation method of two-dimensional layered nano material MXene quantum dots. The method comprises the following steps: step 1, preparing a two-dimensional layered nano material MXene by adopting an etching process; step 2, dissolving the two-dimensional layered nano material MXene into deionized water or an organic solvent, and performing an ablation reaction under a femtosecond laser; and step 3, performing centrifugal separation on a solution obtained by ablation of the femtosecond laser to obtain a supernatant containing the two-dimensional layered nano material MXene quantum dots. The method provided by the invention utilizes the liquid phase femtosecond laser ablation process to prepare the two-dimensional layered nano material MXene quantum dots, is simple and safe to operate, has lower costs, uses a green solvent such as the deionized water to reduce pollution to the environment, has high reproducibility, is easy to operate, can be used for large-scale production, and can control particle sizes and particle size distribution of the two-dimensional layered nano material MXene quantum dots by controlling power of the femtosecond laser, thereby obtaining the MXene quantum dots with better photoelectric properties.

Owner:XIDIAN UNIV

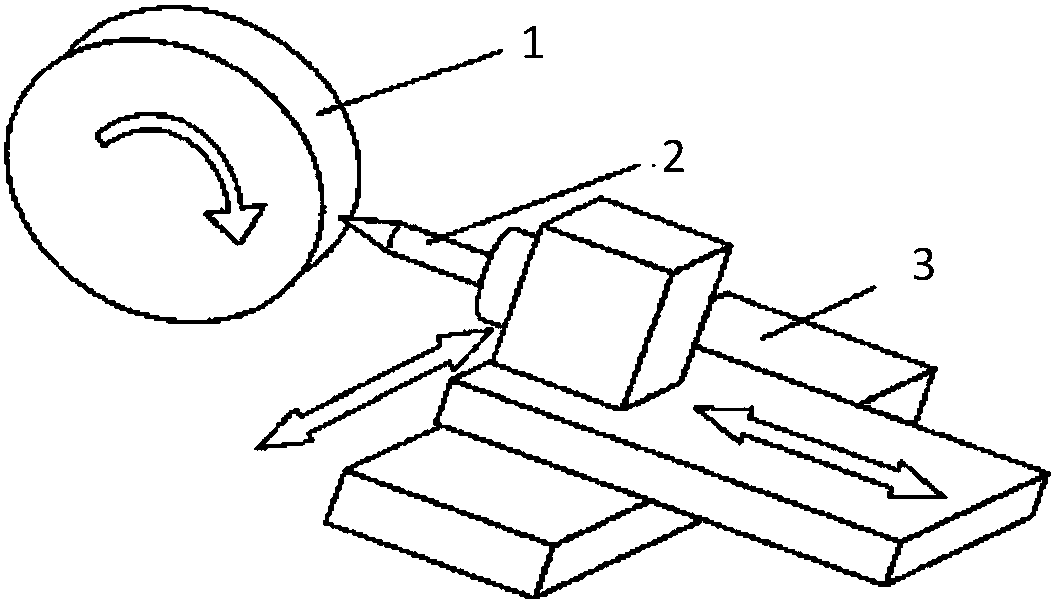

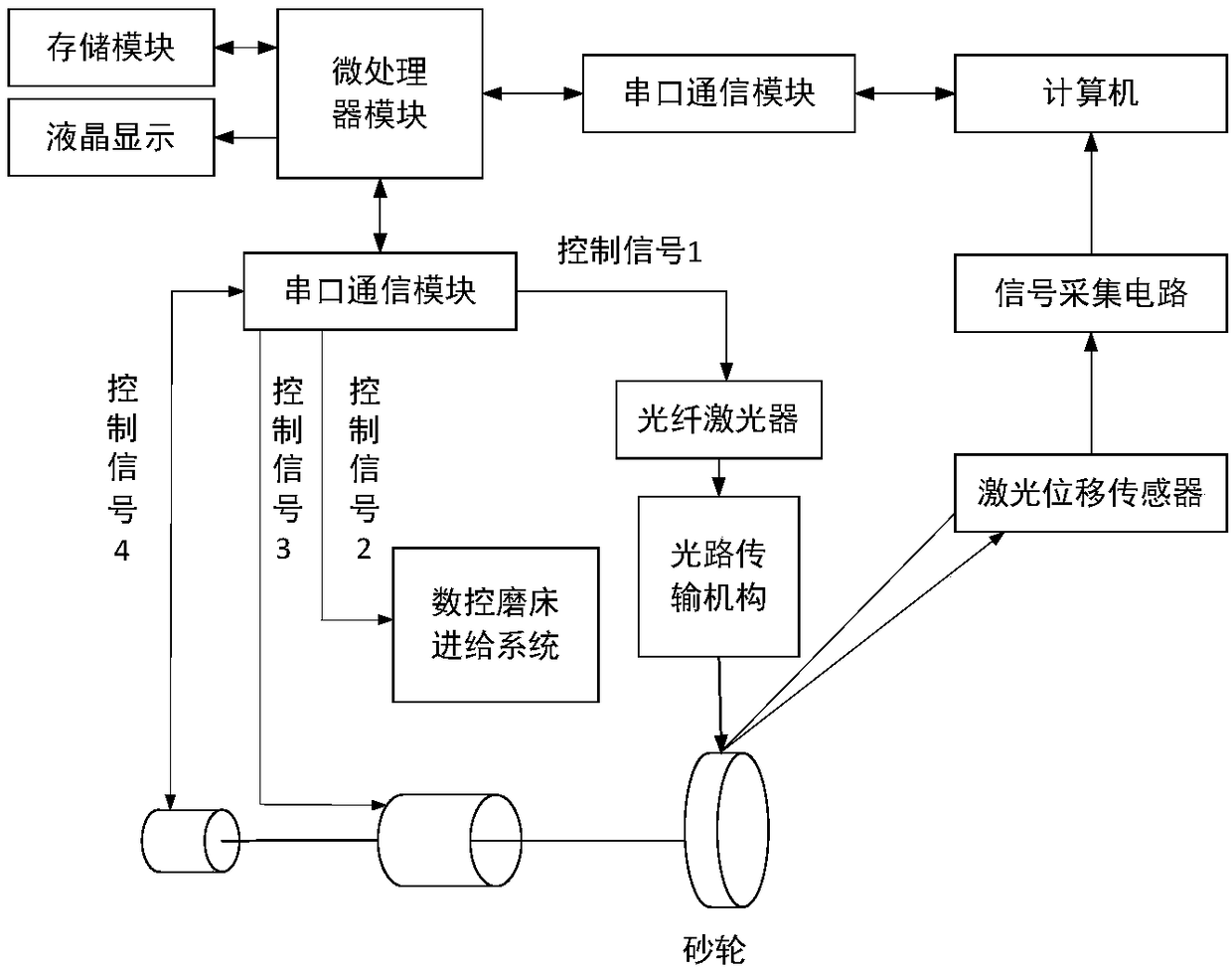

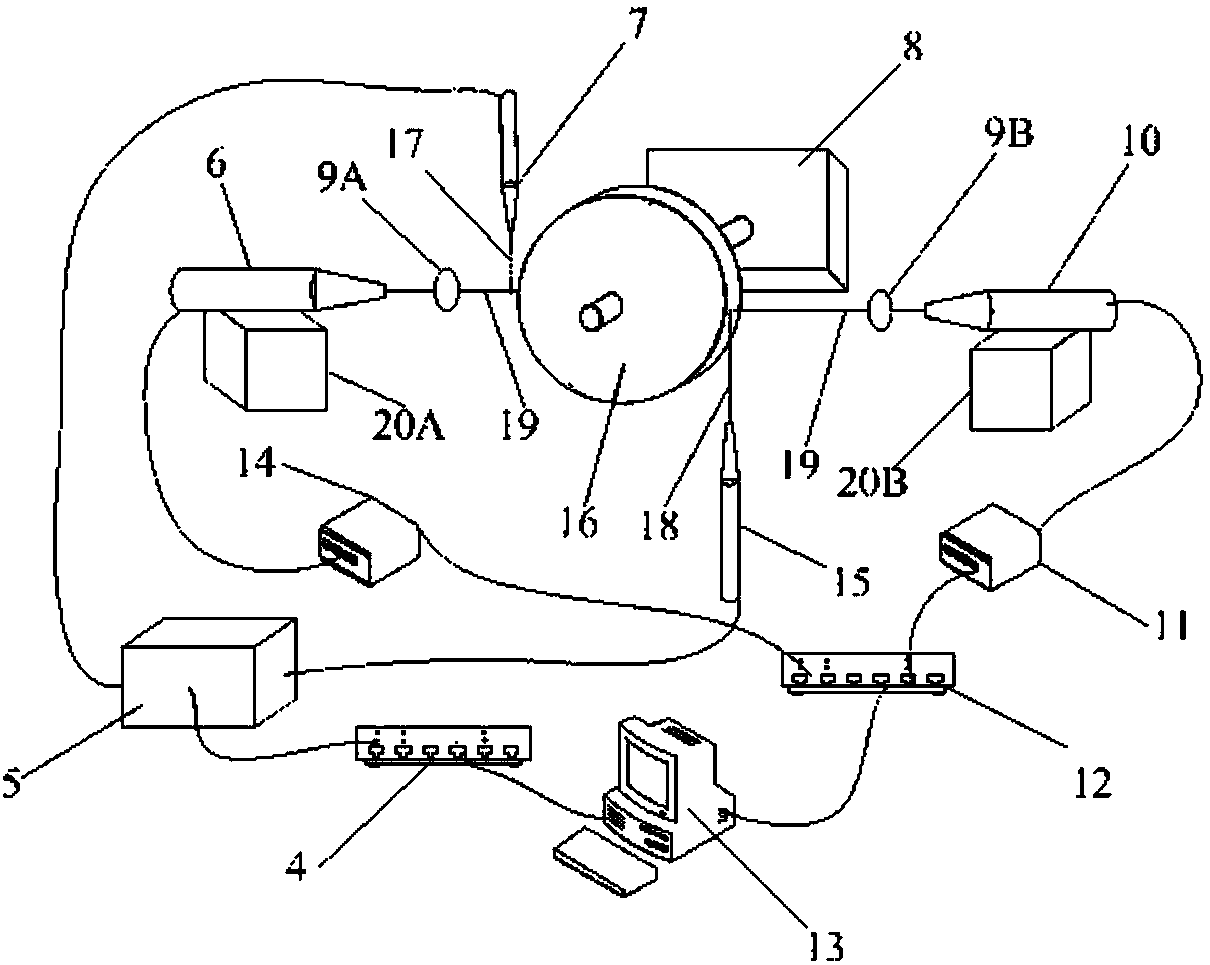

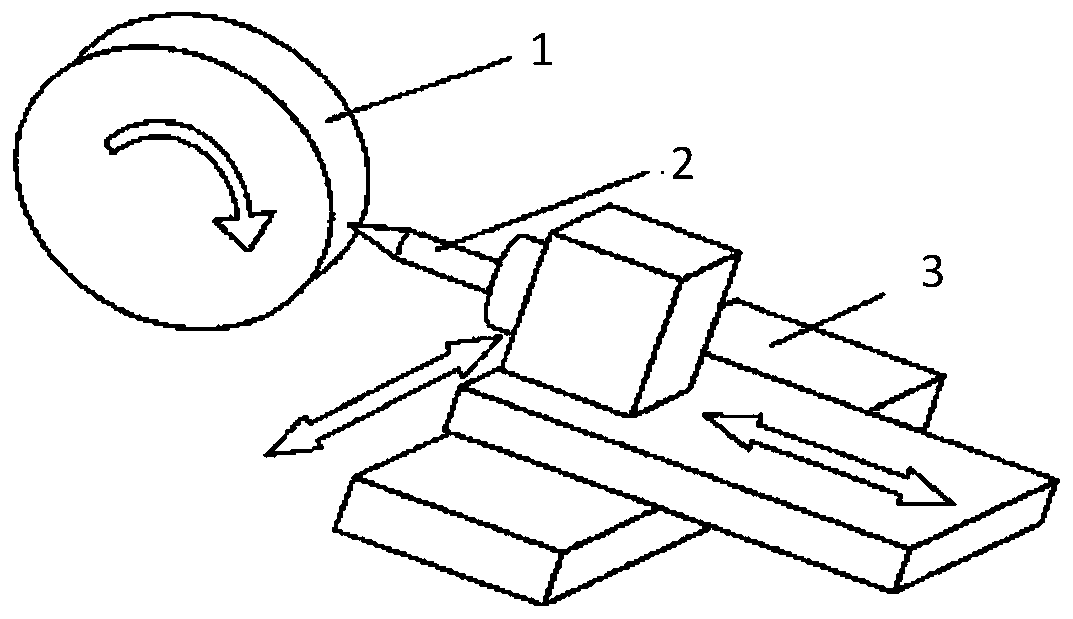

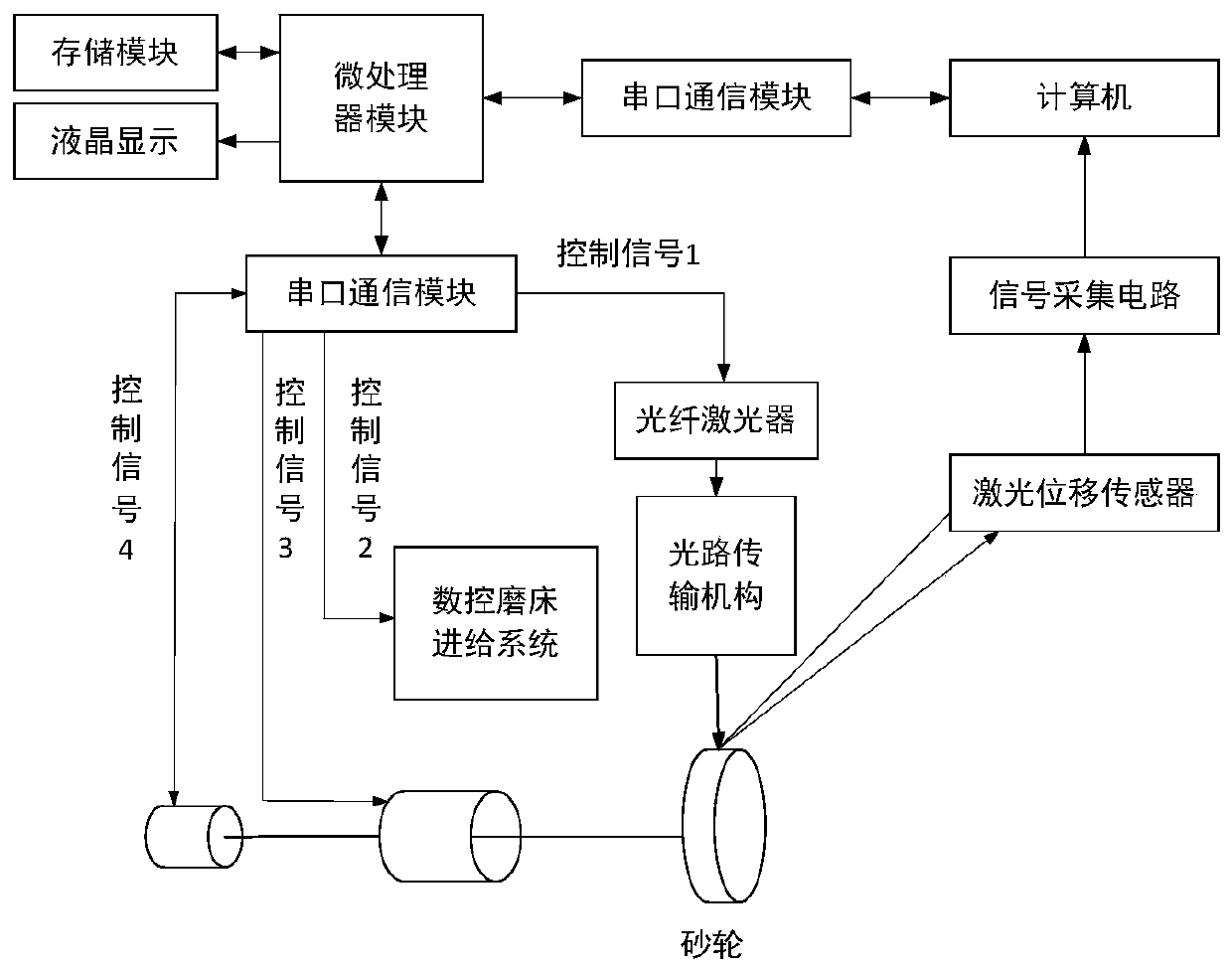

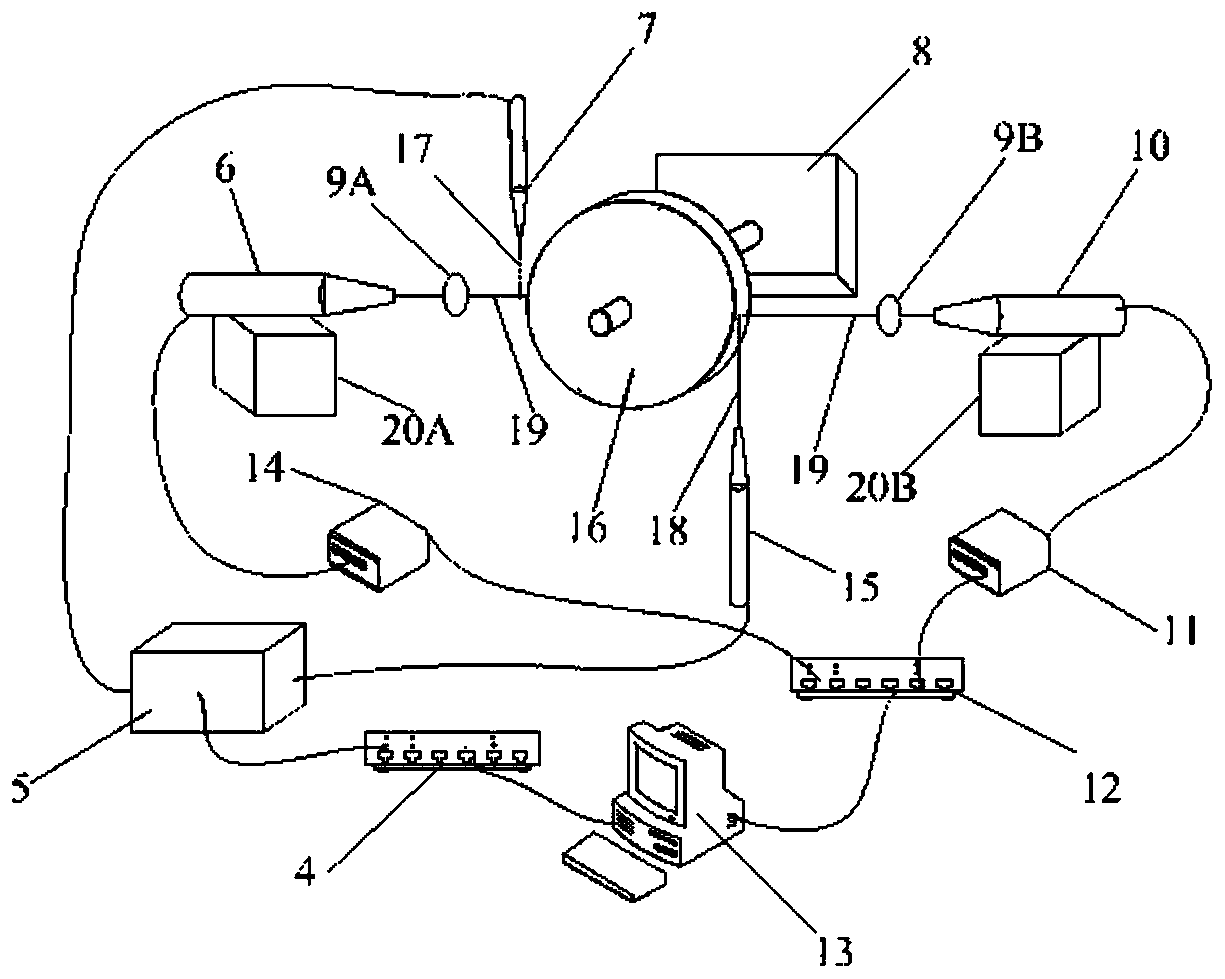

Gas-liquid parallel tube type grinding wheel double laser trimming device and method

ActiveCN108081137AReduced chip spaceAvoid Coulomb ExplosionsAbrasive surface conditioning devicesAutomatic grinding controlPicosecond laserFemto second laser

The invention discloses a gas-liquid parallel tube type grinding wheel double laser trimming device. The gas-liquid parallel tube type grinding wheel double laser trimming device comprises gas-liquidcontrol equipment, a gas-liquid control operating platform, a picosecond laser ablation head, a gas-guide flexible pipe, a grinding machine, focusing lenses, a femtosecond laser ablation head, a femtosecond laser device, a laser device control operating platform, control equipment, a picosecond laser device, a fine water-guide pipe, a superhard grinding-material grinding wheel, a gas column flow,a liquid column flow, laser beams and three-dimensional moving platforms. By means of the gas-liquid parallel tube type grinding wheel double laser trimming device and method, the auxiliary gas-liquidparallel tube type grinding wheel double laser trimming device is provided, the situations that diamond grinding particle chip tolerance space of the grinding wheel is reduced and the height of highlighted binder is not enough caused by plasma particles and phase explosion effect are avoided, and the defects of microcracks, graphite metamorphic layers and the like generated by peripheral heat accumulation during diamond grinding are overcome; and by means of the gas-liquid parallel tube type grinding wheel double laser trimming device and the method, the generation of coulomb explosion can beavoided, the surface grating and micro-cone structure of the grinding wheel are reduced, the utilization efficiency of laser energy is improved, and the grinding wheel trimming efficiency and the trimming surface quality are improved.

Owner:HUAZHONG UNIV OF SCI & TECH

Method for preparing micro-fluidic chip

InactiveCN102218595AGood optical processing performanceGood chemical stabilityLaser beam welding apparatusMachine partsGlass chip

The invention relates to a method for preparing a micro-fluidic chip. A glass substrate sheet is ablated by a femto-second laser; during the machining process, a cleaning solution always carries out effective cleaning on a machining part inside the sheet; heat treatment is carried out on the glass substrate sheet that is machined by the femto-second laser; after the heat treatment, the diameter of a micro-fluidic passage and the dimension of a liquid bath in the sheet are reduced; the internal surfaces of the micro-fluidic passage and the liquid bath are smooth; a PDMS (Polydimethylsiloxane) sheet is selected as a connecting body; the position on the PDMS sheet corresponding to the longitudinal passage opening position of a micro-fluidic glass chip is bored; and subsequently the PDMS sheet is bonded with the micro-fluidic glass chip, thereby obtaining the micro-fluidic chip. The method has simple machining process and ensures that the laser can carry out continuously stable ablation on substration material; and the integrated micro-fluidic chip with complex and multi-layer structures can be prepared in the glass substrate. The prepared micro-fluidic chip has the characteristics of miniaturization and integration, has the functions of separation, reaction and detection, and can be widely applied to the analysis fields.

Owner:HARBIN INST OF TECH AT WEIHAI

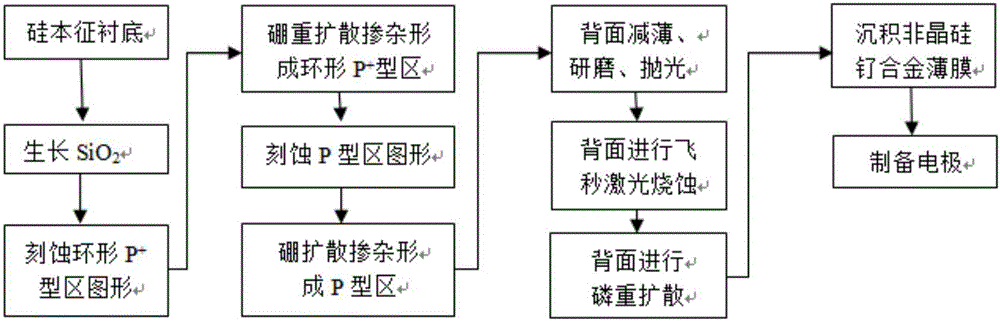

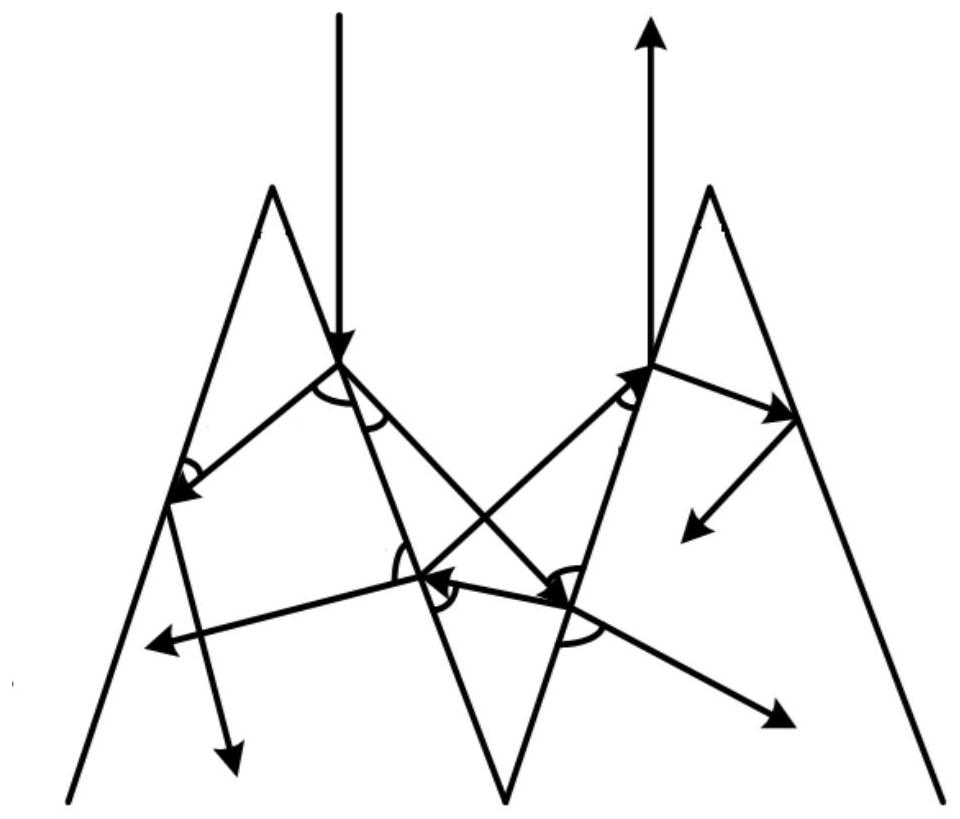

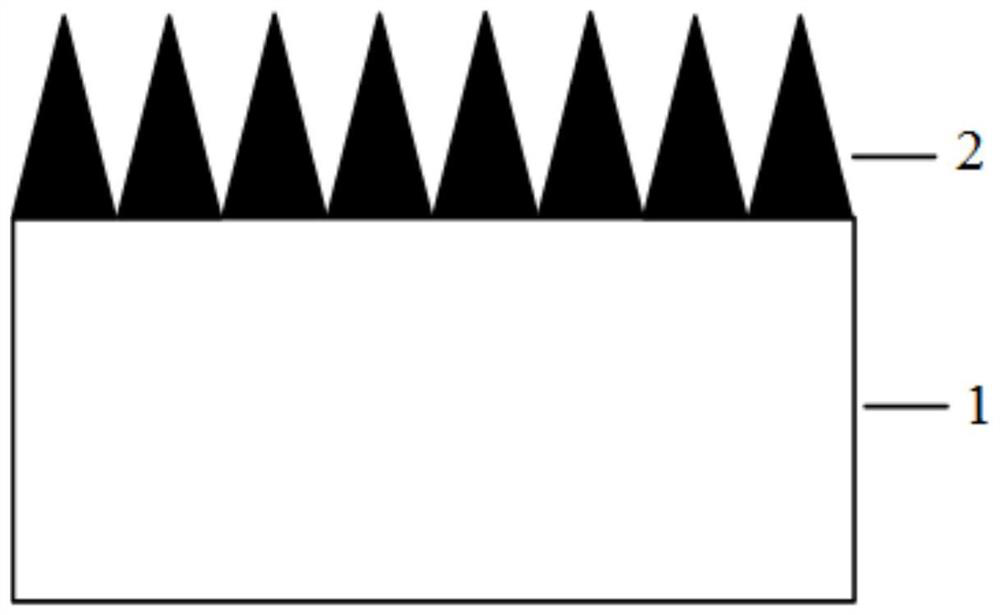

Femtosecond laser ablation-based infrared-enhanced Si-PIN detector and preparation method thereof

InactiveCN106206831AImprove light absorptionBand gap adjustableFinal product manufactureSemiconductor devicesPath lengthAlloy

The invention provides a femtosecond laser ablation-based infrared-enhanced Si-PIN detector and a preparation method thereof. The detector comprises an intrinsic silicon substrate, a femtosecond laser ablation microstructure layer, an infrared-enhanced amorphous silicon-ruthenium alloy film, a lower electrode, a P-type region, an annular P+ type region and an upper electrode, wherein the femtosecond laser ablation microstructure layer is a micron sharp cone array. The unabsorbed light which transmits through a space charge region is reflected for multiple times; a light propagation path and the photo capture ratio are increased; absorption and utilization of the light are improved; more photo-induced carriers are excited; the responsivity of the detector is improved; a relatively narrow optical band gap is obtained through controlling the ruthenium content; and the band gap of a silicon material is narrowed, so that near-infrared light with lower energy and a larger wavelength is captured; absorption of the near-infrared light can be additionally increased; and the detection spectrum range of a photoelectric detector is expanded.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

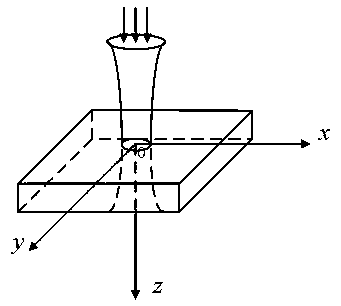

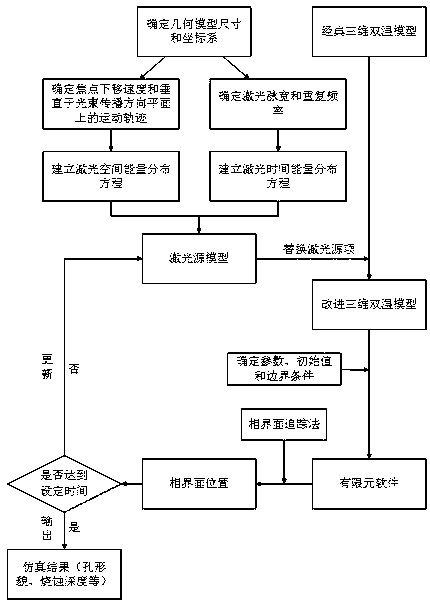

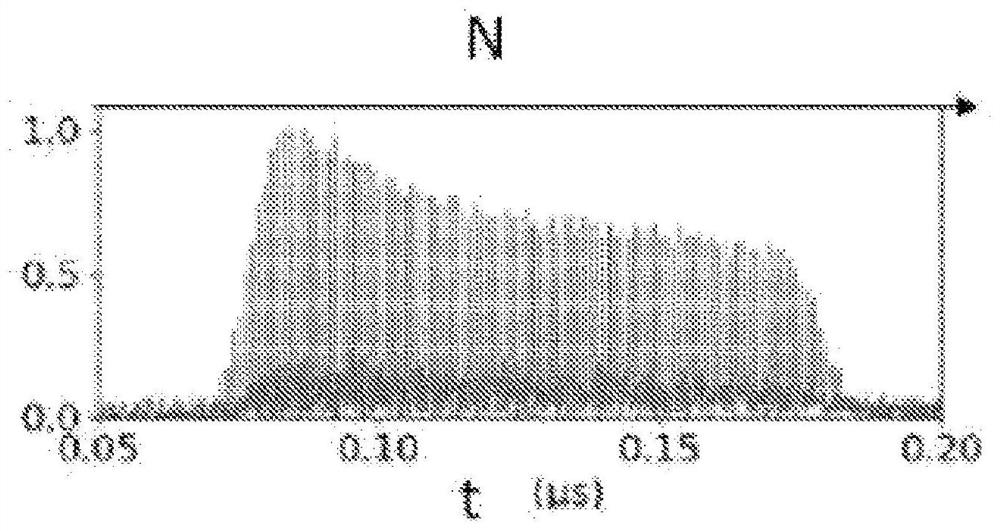

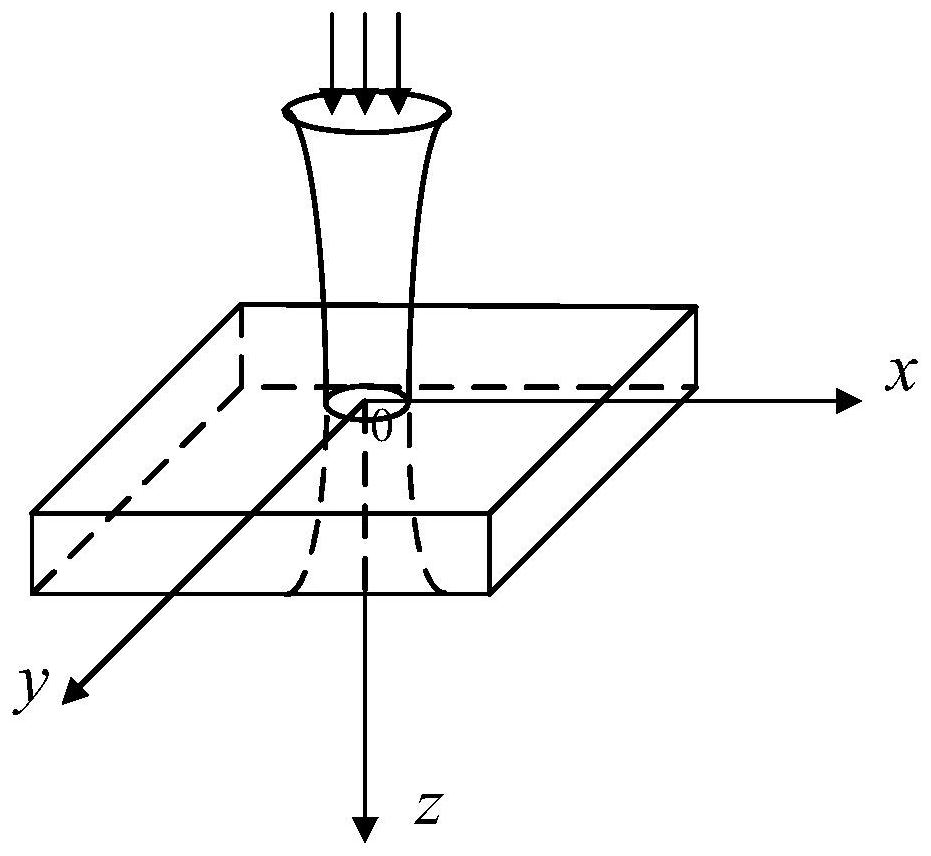

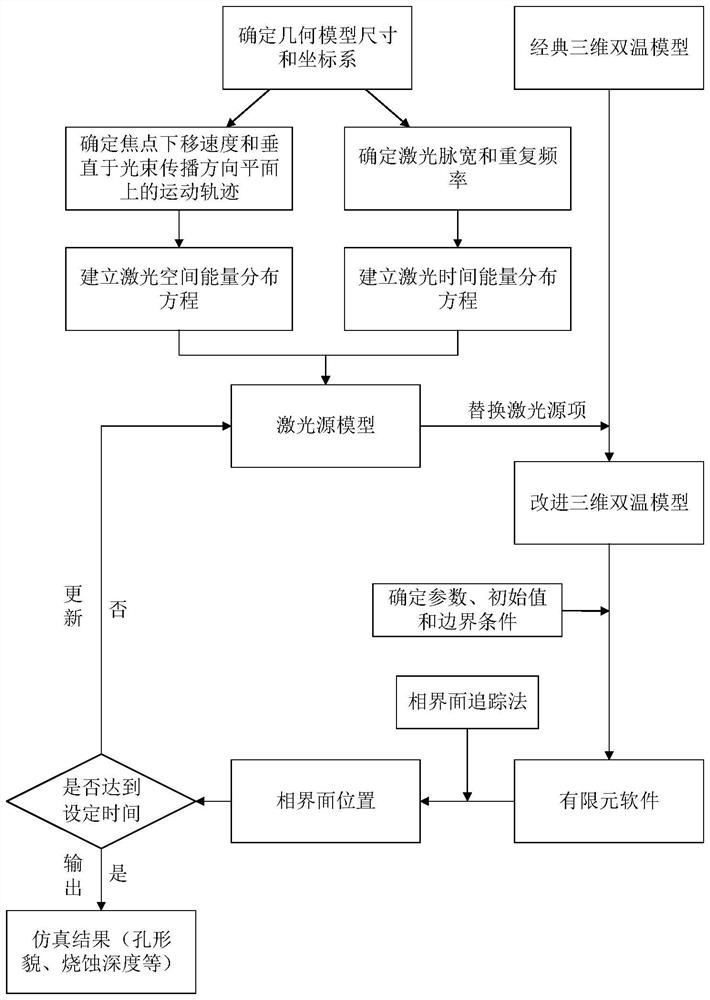

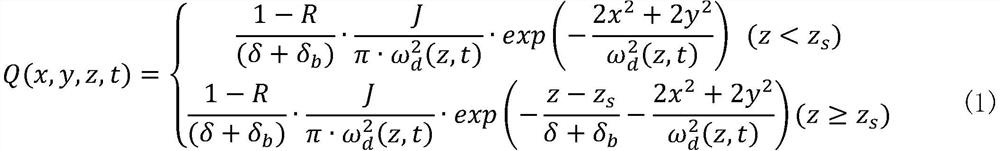

Method for establishing laser source model for femtosecond laser ablation simulation

ActiveCN108875264AReasonable attenuation of energy densityDesign optimisation/simulationSpecial data processing applicationsMaterial removalOpen source

The invention provides a method for establishing a laser source model for femtosecond laser ablation simulation, which provides a laser source model with a focus moving down according to a spatial andtemporal distribution of the laser,. According to the method for establishing laser source model for femtosecond laser ablation simulation, the proposed laser source three-dimensional model can describe the situation in which the laser focus moves down with the material removal during the actual machining process, , it is ensured that the laser energy density above the material surface is realistic by dividing the expression into two segments at the machining plane position as shown in the description, and the energy density below the material surface (i.e., inside of the material) is reasonably attenuated. The proposed laser source three-dimensional model can also describe the spiral motion of the laser focus on the material plane during actual machining.

Owner:XIAMEN UNIV +1

Spiral bevel gear femtosecond laser processing system and fine correction method thereof

PendingCN110385529ASolve the technical problems of dynamic and precise focusingGood linkageLaser beam welding apparatusHeat-affected zoneEngineering

A spiral bevel gear femtosecond laser processing system and a fine correction method thereof. The system comprises a femtosecond laser system, a light guide assembly, a three-dimensional galvanometersystem, an illumination system, a precise moving system and a CCD monitoring system, wherein the femtosecond laser system comprises a femtosecond laser, a femtosecond laser ablation head and a laser control operation platform; the light guide assembly and the three-dimensional galvanometer system jointly form a light path; the laser emitted by the femtosecond laser system and the illumination light emitted by the illumination system are transmitted along the light path; the precise moving system comprises a precise three-dimensional moving shaft and a control platform and, is arranged at the outlet of the light path, and a spiral bevel gear is fixed to the upper part of the precise moving platform; and the CCD monitoring system is arranged on an illumination light reflection light path. According to the system, the femtosecond laser with extremely short pulse width and extremely high peak power is adopted, so that a heat affected zone of a processing area is small, and the processing is extremely accurate. Therefore, the femtosecond laser processing system and the fine correction method are high in processing efficiency, high in processing accuracy and high in linkage performance and are suitable for fine correction of tooth surfaces of different spiral bevel gears.

Owner:HUNAN UNIV OF TECH

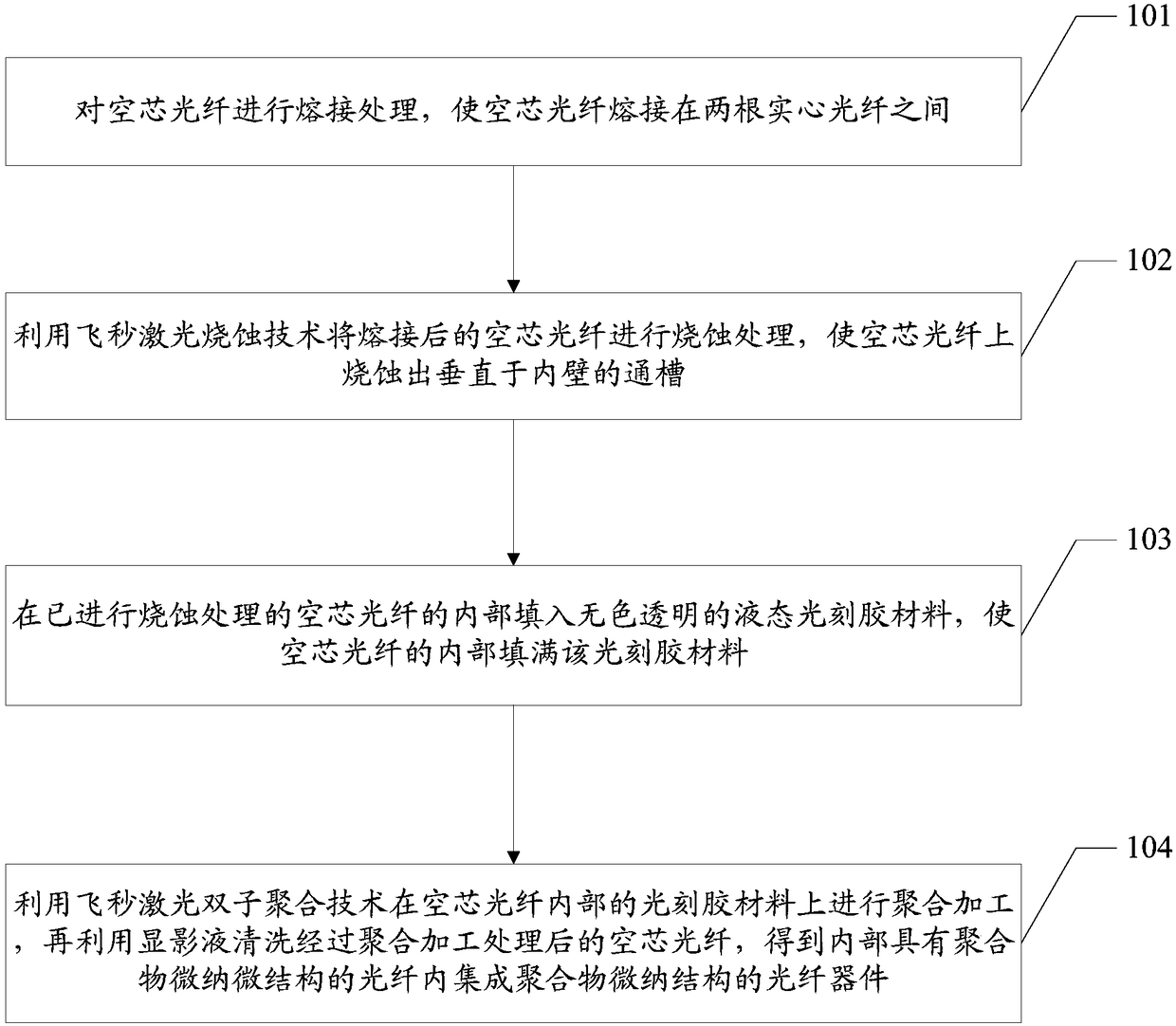

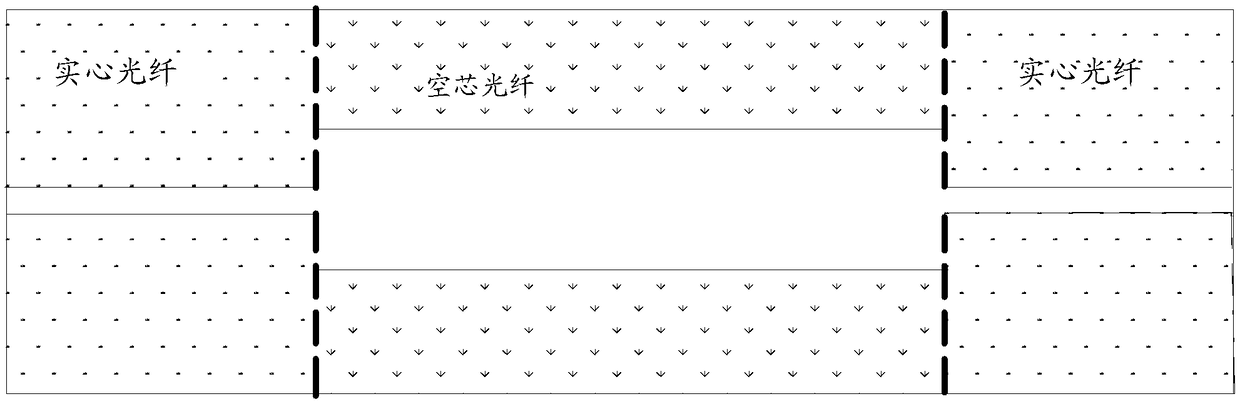

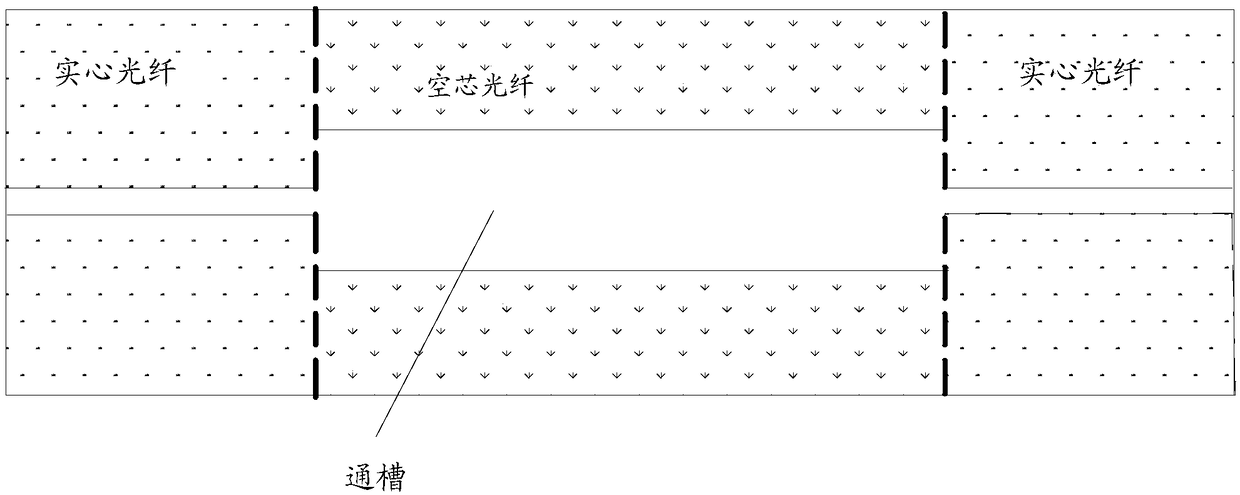

Optical fiber device integrated with polymer micro-nano structure in optical fiber and preparation method thereof

ActiveCN108490535AEasy to weldAchieve integrationCladded optical fibreOptical waveguide light guideMicro nanoPlastic optical fiber

The invention discloses a preparation method of an optical fiber device integrated with a polymer micro-nano structure in an optical fiber. The preparation method comprises the following steps: carrying out fusion welding treatment on a hollow optical fiber, so that the hollow optical fiber is fused and welded between two solid optical fibers; carrying out ablation treatment on the hollow opticalfiber subjected to fusing and welding by utilizing a femtosecond laser ablation technology, so that a through slot vertical to the inner wall is ablated on the hollow optical fiber; then filling the interior of the hollow optical fiber with a colorless and transparent photoresist material, so that the interior of the hollow optical fiber is filled with the photoresist material; then carrying out polymerization processing on the photoresist material inside the hollow optical fiber by utilizing a femtosecond laser gemini polymerization technology, and finally cleaning the hollow optical fiber subjected to the polymerization processing with developing solution, so that a device with a polymer micro-nano structure inside is obtained. The device has the polymer micro-nano structure inside, thereby having functional characteristics of a polymer; and the device well combines material characteristics of the polymer with transmission characteristics of the optical fiber together, and the integration of a complex polymer functional microstructure and the optical fiber is realized.

Owner:SHENZHEN UNIV

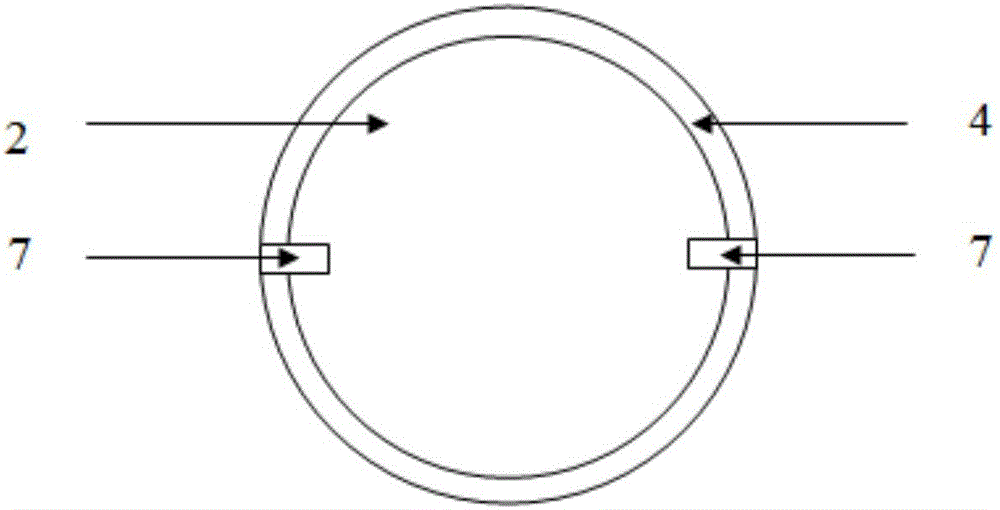

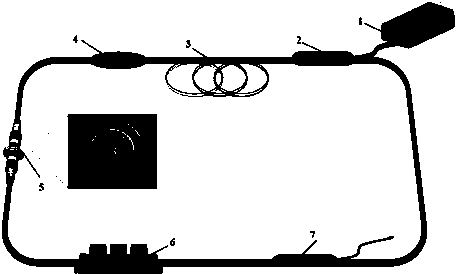

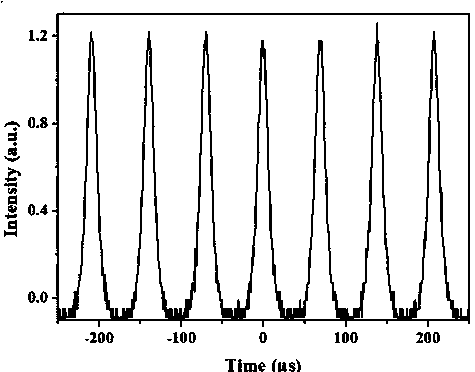

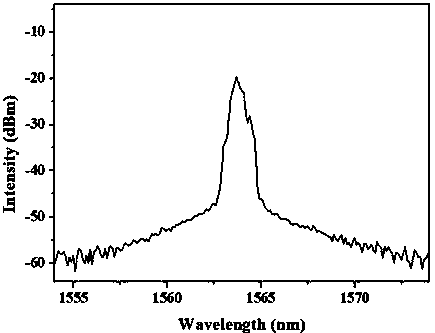

Preparation of chromium-doped zinc selenide nanoparticle saturable absorber and all-fiber Q-switched laser formed by same

InactiveCN110061408ASmall sizeEasy to operateActive medium shape and constructionChromium dopingZinc selenide

The invention relates to a preparation of a chromium-doped zinc selenide nanoparticle saturable absorber and an all-fiber Q-switched laser formed by the same, belonging to the technical field of fiberlaser. The chromium-doped zinc selenide has a wide absorption band and a large absorption cross section in a 1.5-2.1 [mu]m wave band, has a high damage threshold and can be used as an excellent saturable absorber. The chromium-doped zinc selenide nano-particles prepared by a femtosecond laser ablation method are doped into polyvinyl alcohol or polymethyl methacrylate to prepare the film saturableabsorber. The invention also provides an annular cavity Q-switched laser adopting the saturable absorber. The annular cavity Q-switched laser comprises a wavelength division multiplexer, a gain optical fiber, an optical isolator, a polarization controller, a saturable absorber and an optical fiber coupler. The saturable absorber based on the nano particle film has the advantages of simple preparation process, low cost, easiness in integration and the like, and meanwhile, the constructed all-fiber structure laser has the advantages of compact structure, stable performance and the like, and issuitable for practical application.

Owner:SICHUAN UNIV

Method for preparing mark stamp based on femtosecond laser ablation composite induction

ActiveCN109702354AImprove reliabilityIncreased durabilityLaser beam welding apparatusTime markGalvanometer

The invention discloses a method for preparing a mark stamp based on femtosecond laser ablation composite induction. A titanium alloy TC4 or nickel-based alloy GH4169 metal sheet is adopted as a machining object, a light path is established, a femtosecond laser device outputs light to be focused to a shear type lifting table through a two-axis scanning galvanometer system, and the femtosecond laser device and the two-axis scanning galvanometer system are connected with a computer; the computer is utilized for adjusting the femtosecond laser device to output lasers, the wavelength of the lasersis 1,030 nm, the pulse width is 240 fs, the repetition frequency is 1-200 kHz and can be adjusted, and the maximum single pulse energy is 200 mu J; and the titanium alloy TC4 or nickel-based alloy GH4169 metal sheet is fixed to a machining station of the shear type lifting table, and through adjustment of the repetition frequency, the single pulse energy, the scanning speed and the groove distance, optimal laser ablation primary mark stamp basic parameters and laser induction second-time mark stamp basic parameters are obtained. By means of the method, the quality, efficiency and recognitionrate of the femtosecond laser mark stamp are improved, and adaptability is achieved for a titanium alloy and a nickel-based alloy.

Owner:无锡超通智能制造技术研究院有限公司

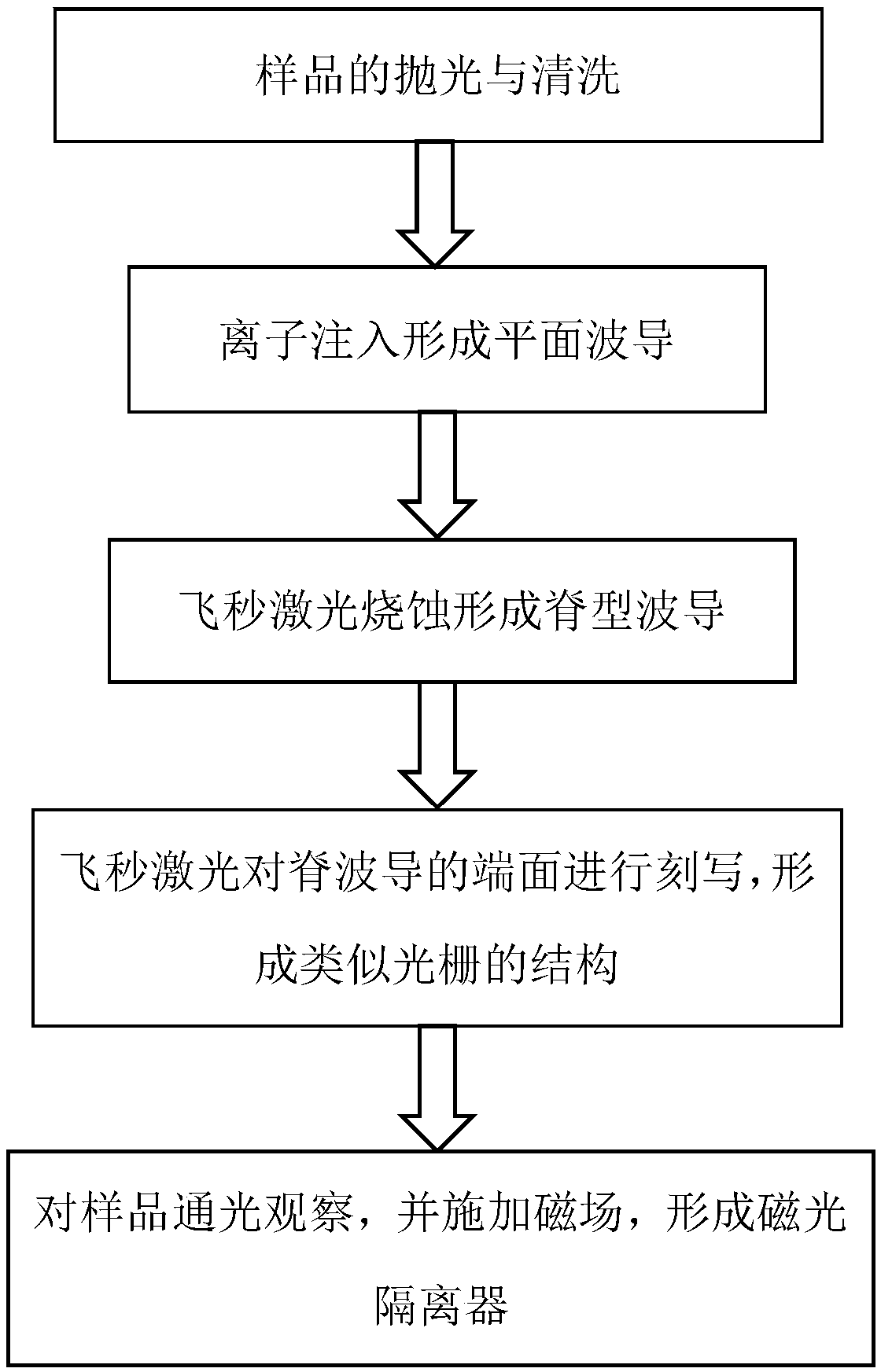

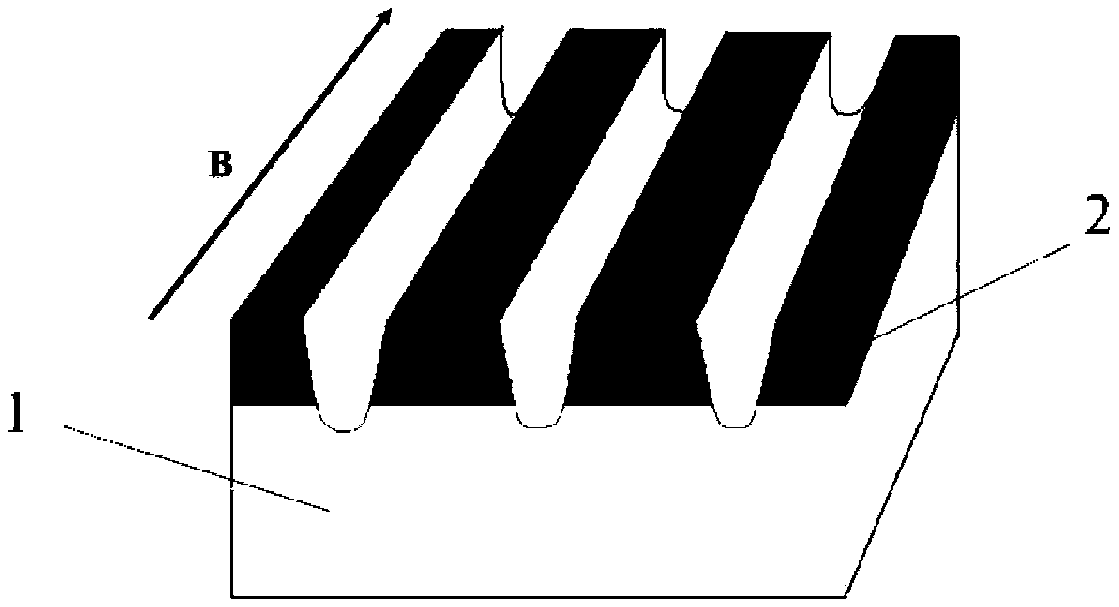

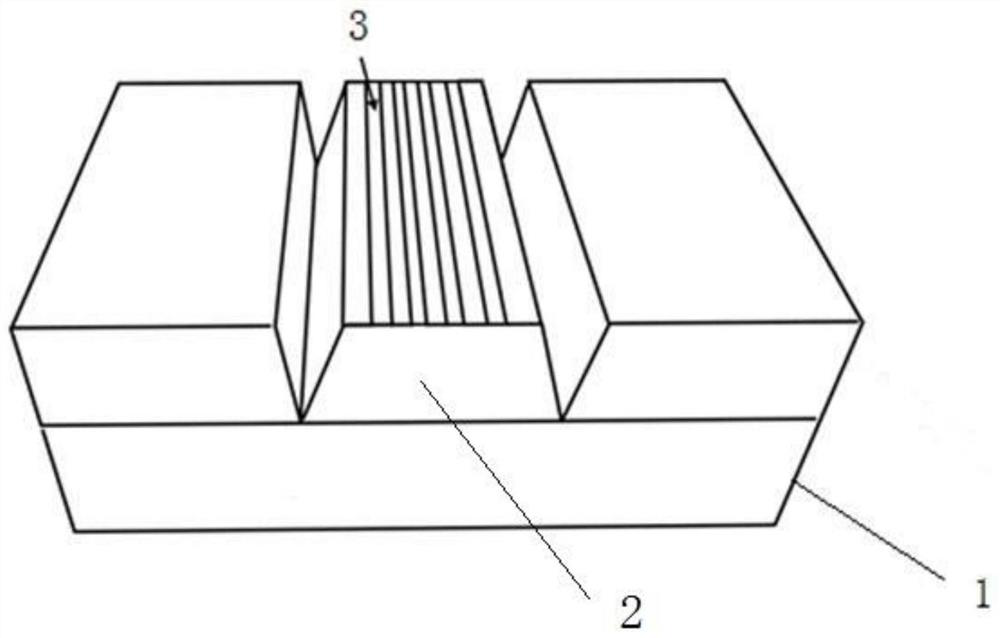

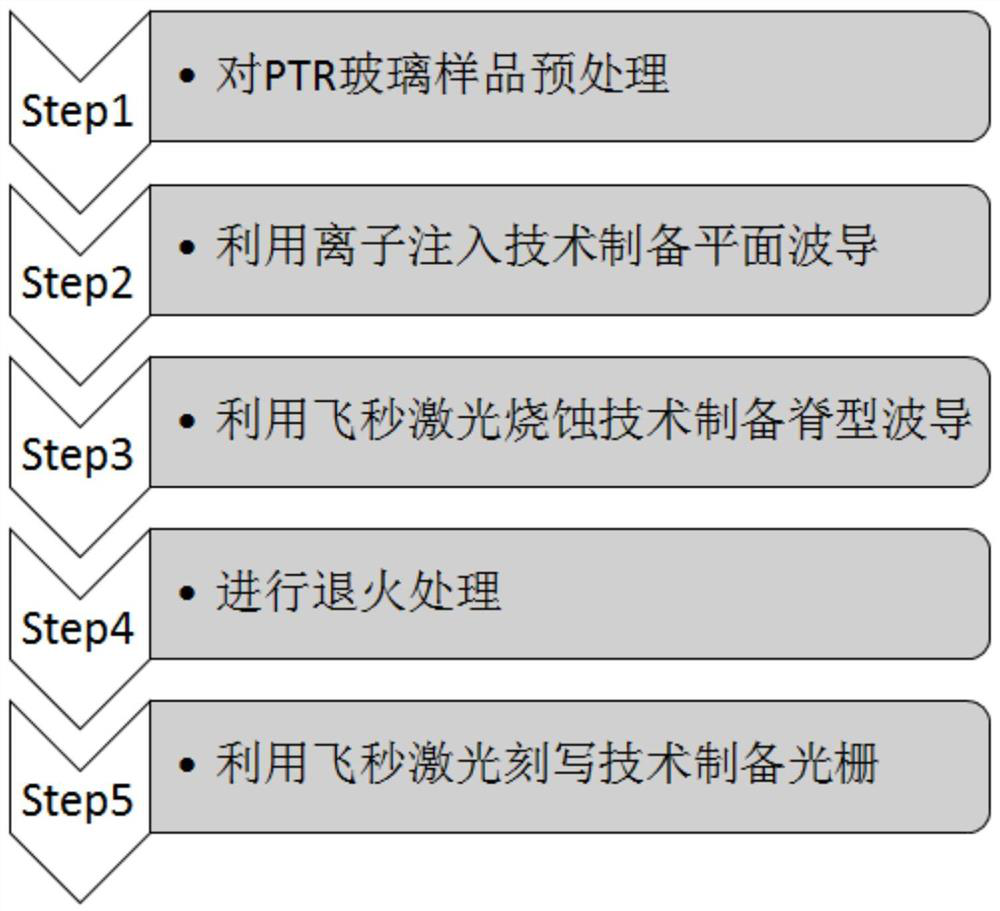

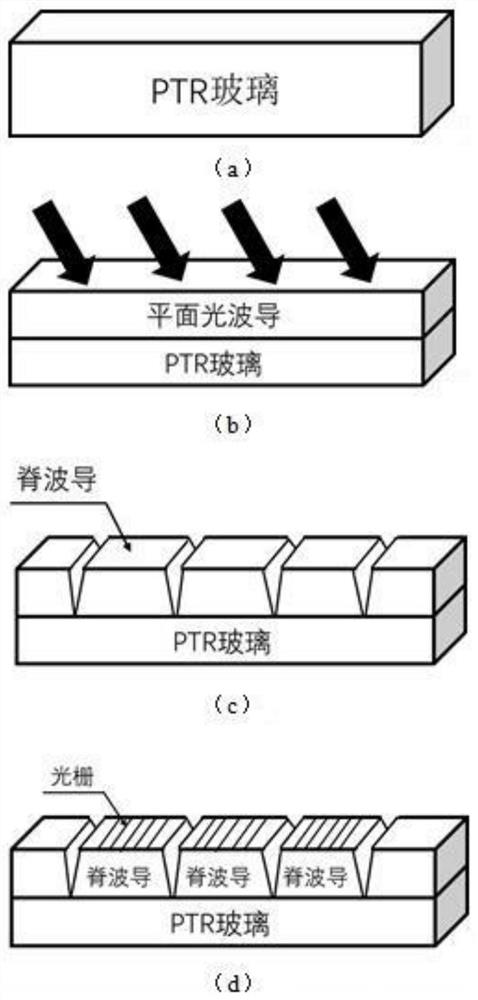

Isolator based on magneto-optic waveguide and preparation method thereof

InactiveCN109459871ASmall sizeMiniaturizationOptical light guidesNon-linear opticsIsolation effectSlot-waveguide

The invention relates to an isolator based on magneto-optic waveguide and a preparation method thereof, and belongs to the field of integrated optics. The isolator is used for overcoming the defects that the size of an existing magneto-optic isolator is large, and the requirements of miniaturization and integration cannot be met. A ridge waveguide structure is prepared in a magneto-optic materialby using a method combining an ion implantation technology and a femtosecond laser ablation technology, optical gratings are etched on two optical transmission end surfaces of the ridge waveguide structure by using the femtosecond laser, and therefore the integrated magneto-optic isolator is prepared. The isolation effect is achieved through an applied magnetic field. Miniaturized and integrated preparation of the optoisolator is finally achieved by designing the structure of devices.

Owner:NANJING UNIV OF POSTS & TELECOMM

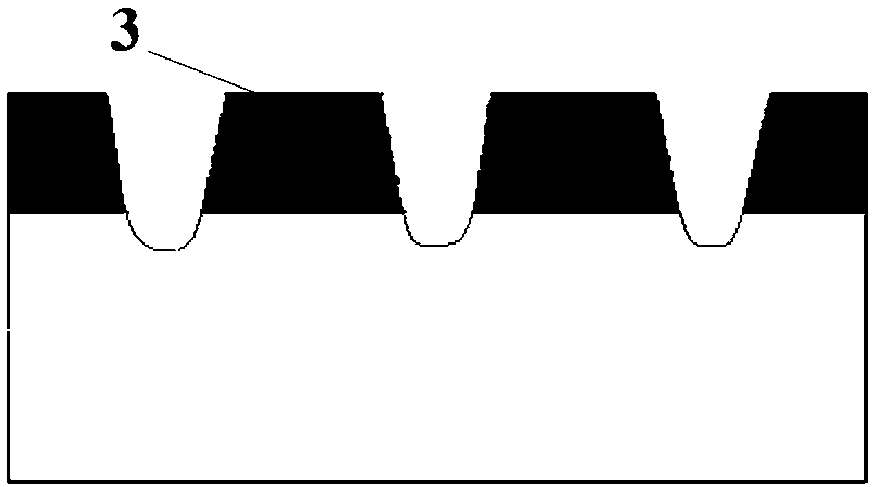

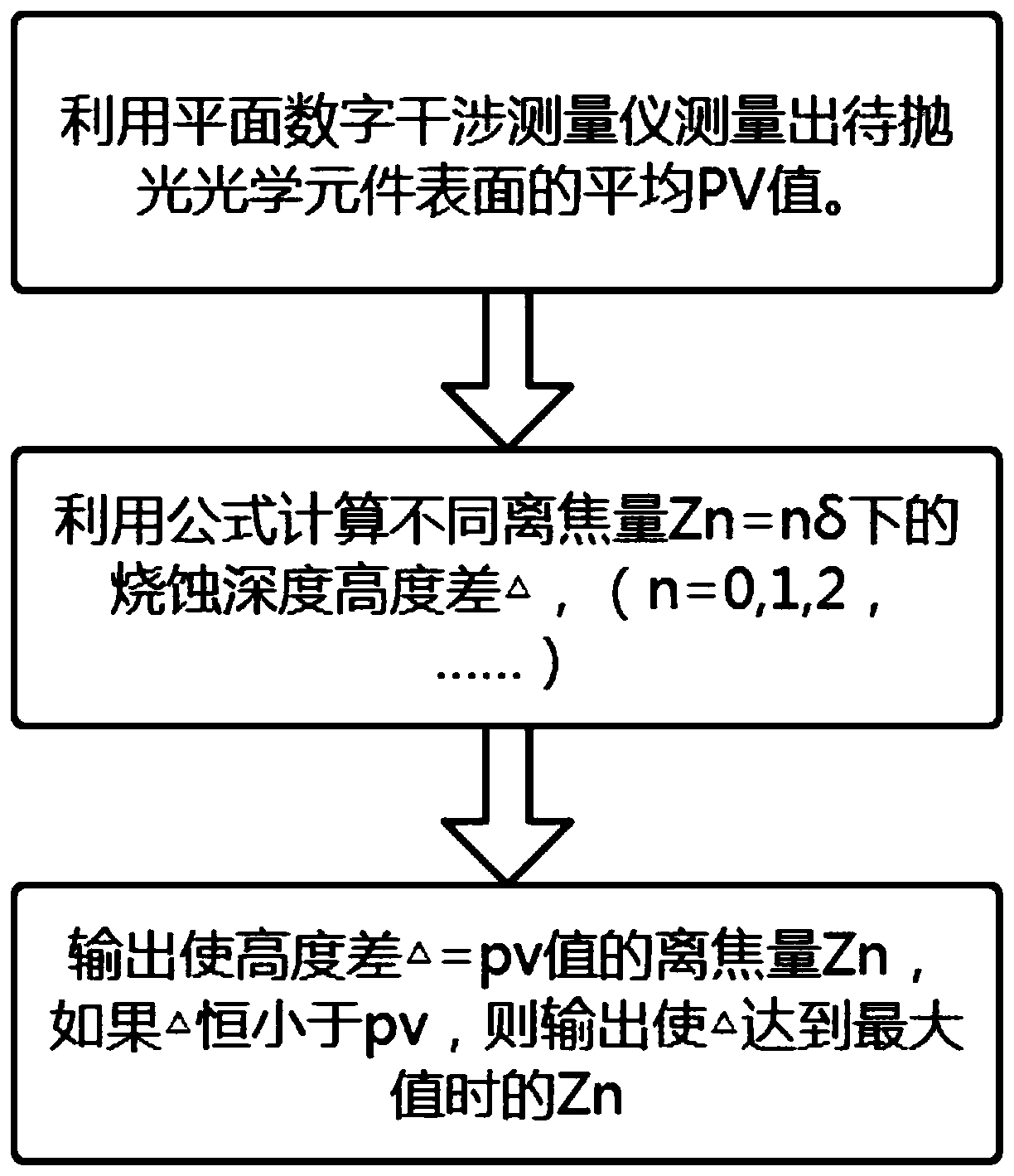

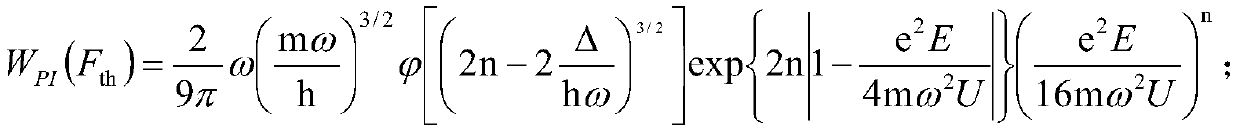

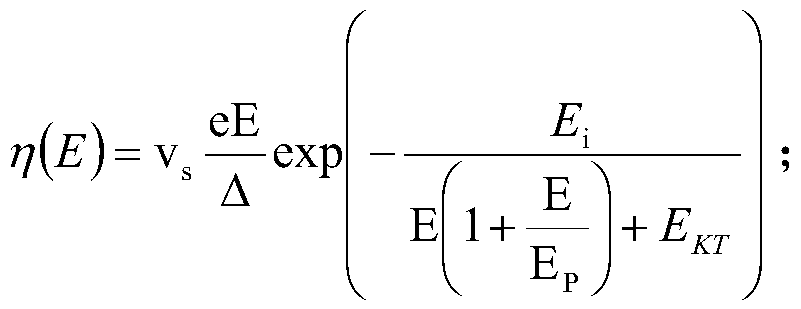

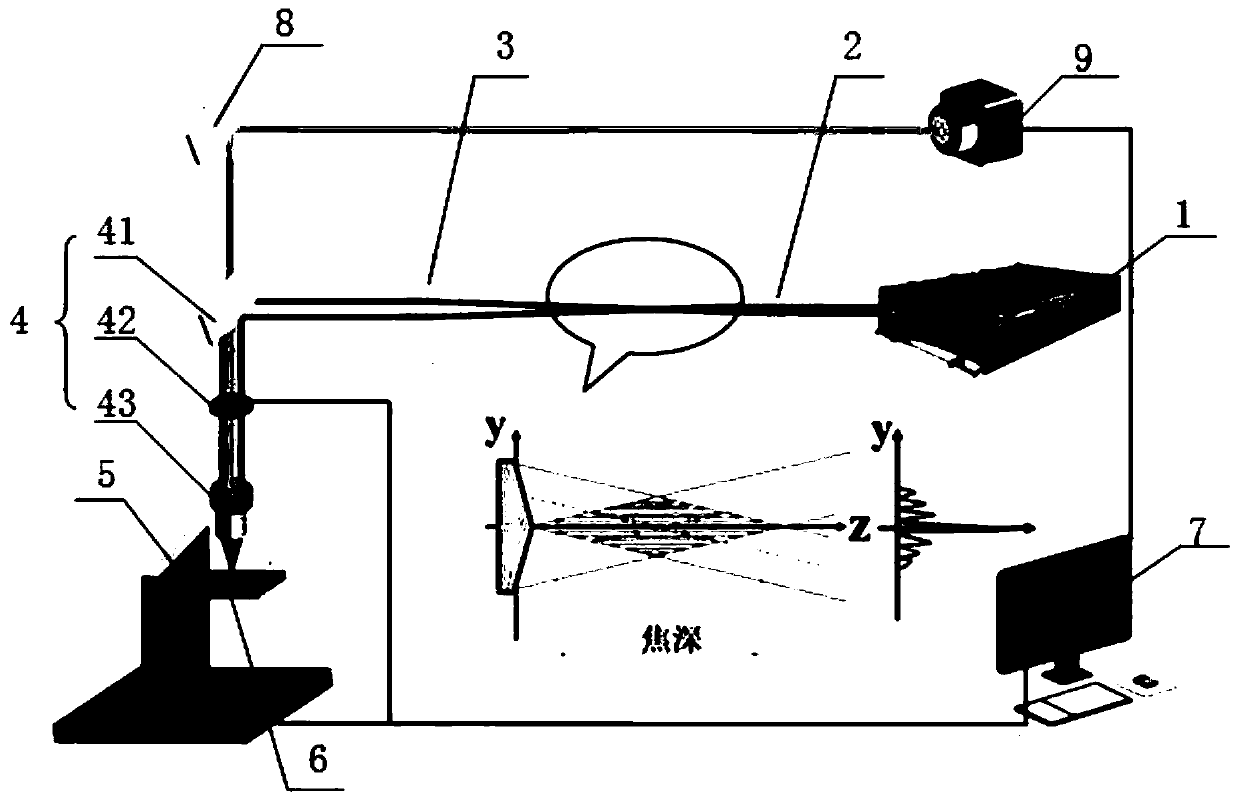

Method for determining laser defocusing amount in femtosecond laser polishing process of optical element

PendingCN111368243AImprove efficiencyImprove accuracyLaser beam welding apparatusComplex mathematical operationsFemto second laserMathematical model

The invention discloses a method for determining the laser defocusing amount in the femtosecond laser polishing process of an optical element, which belongs to the technical field of mechanical precision manufacturing engineering, and comprises the following steps of: outputting laser wavelength and focusing spot radius by using a femtosecond laser, and calculating Rayleigh length of a light beam;calculating the energy density when the laser reaches the surface of the material by utilizing the output pulse energy of the laser to focus the spot radius and the defocusing amount; calculating theablation depth of the surface of the energy material by using a femtosecond laser ablation rate mathematical model; solving the ablation depth of the femtosecond laser to the material under differentdefocusing amounts according to the laser ablation rate mathematical model; measuring the average value of the surface of the to-be-polished optical element, and determining the optimal polishing defocusing amount by substituting the height difference of the wave crest and the wave trough into calculation. The defocusing amount of femtosecond laser polishing can be rapidly, efficiently and accurately determined, the cost is low, the efficiency is high, and the accuracy is high.

Owner:TIANJIN UNIV

Method for preparing micro-fluidic chip

InactiveCN102218595BGood optical processing performanceGood chemical stabilityLaser beam welding apparatusMaterial analysisGlass chipFemto second laser

The invention relates to a method for preparing a micro-fluidic chip. A glass substrate sheet is ablated by a femto-second laser; during the machining process, a cleaning solution always carries out effective cleaning on a machining part inside the sheet; heat treatment is carried out on the glass substrate sheet that is machined by the femto-second laser; after the heat treatment, the diameter of a micro-fluidic passage and the dimension of a liquid bath in the sheet are reduced; the internal surfaces of the micro-fluidic passage and the liquid bath are smooth; a PDMS (Polydimethylsiloxane) sheet is selected as a connecting body; the position on the PDMS sheet corresponding to the longitudinal passage opening position of a micro-fluidic glass chip is bored; and subsequently the PDMS sheet is bonded with the micro-fluidic glass chip, thereby obtaining the micro-fluidic chip. The method has simple machining process and ensures that the laser can carry out continuously stable ablation on substration material; and the integrated micro-fluidic chip with complex and multi-layer structures can be prepared in the glass substrate. The prepared micro-fluidic chip has the characteristics of miniaturization and integration, has the functions of separation, reaction and detection, and can be widely applied to the analysis fields.

Owner:HARBIN INST OF TECH AT WEIHAI

PEEK bone repair material and surface modification method and application thereof

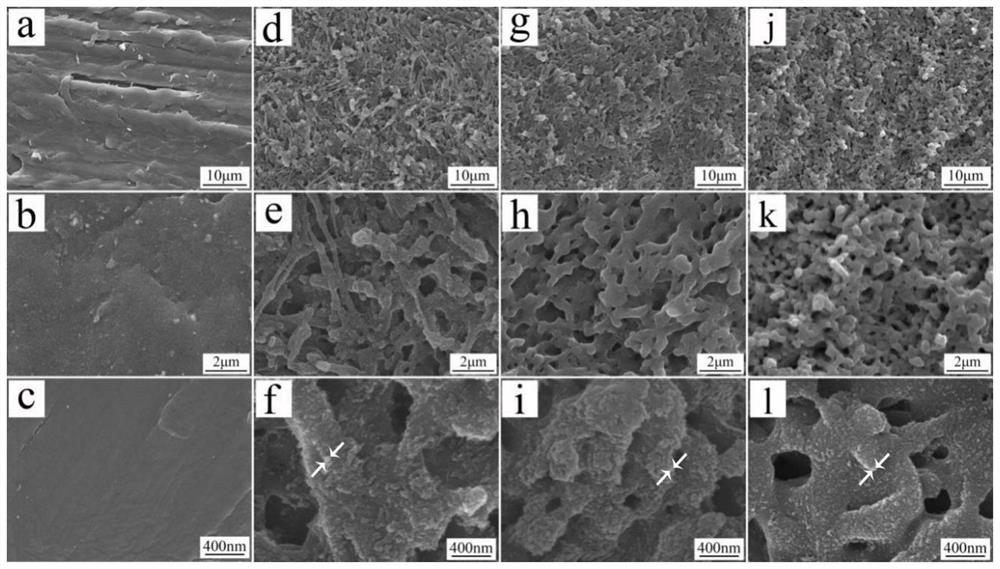

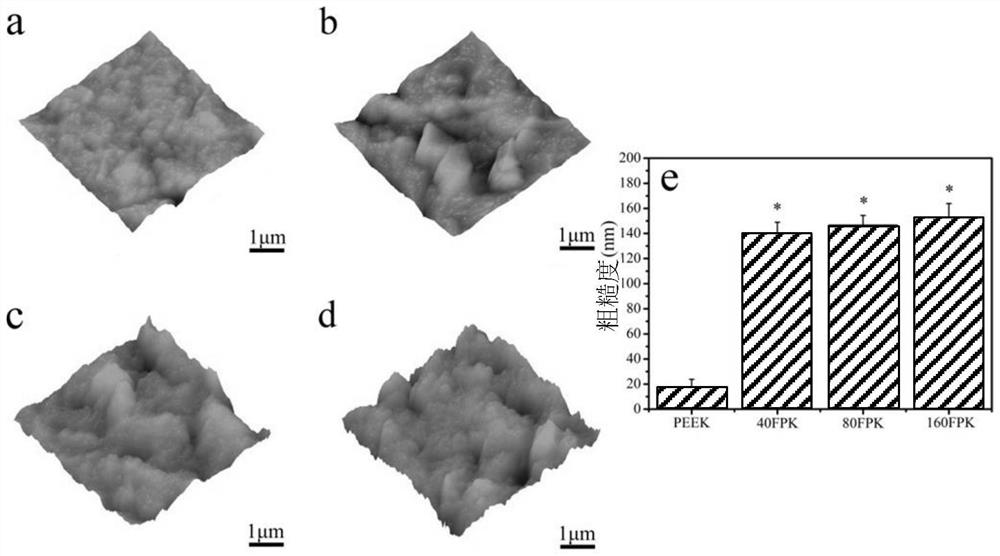

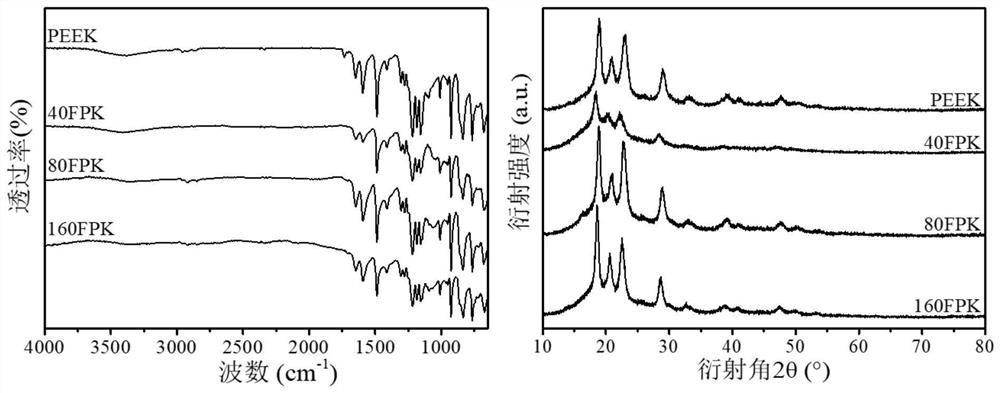

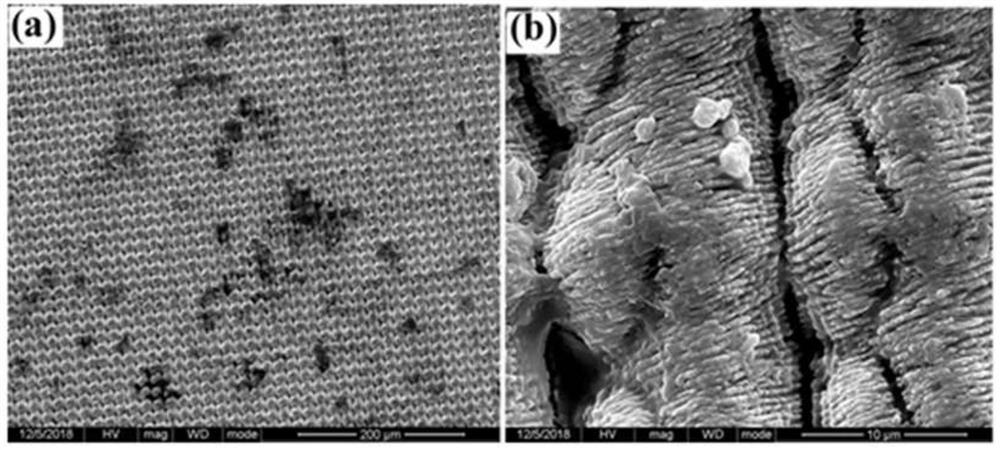

InactiveCN112535765AImprove hydrophilicityImprove adsorption capacityPharmaceutical delivery mechanismTissue regenerationPolymer scienceCell adhesion

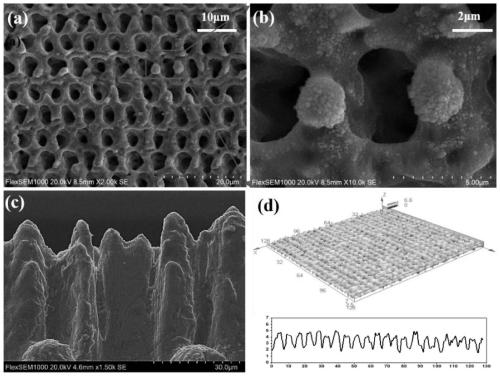

The invention discloses a PEEK bone repair material and a surface modification method and application thereof. The surface modification method of the PEEK bone repair material comprises the followingsteps that femtosecond laser ablation is conducted on the surface of PEEK to be modified, and the surface-modified PEEK bone repair material is obtained; in the femtosecond laser ablation process, thelaser power is 40-160mW; and femtosecond laser ablation is plane scanning ablation conducted on the surface of PEEK to be modified. The PEEK bone repair material is in a micro-nano morphology, has excellent hydrophilicity and surface roughness and can promote cell adhesion, proliferation and cell differentiation.

Owner:EAST CHINA UNIV OF SCI & TECH

Method and device for preparing biomimetic superhydrophobic micro-nano surface by femtosecond laser

ActiveCN104625415BEasy to handleMany processing advantagesLaser beam welding apparatusMicro nanoAutomatic control

The invention provides a device for preparing the bionic super-hydrophobic micro-nano surface through femtosecond laser. The device comprises a femtosecond laser unit, a light beam control unit, a motion platform unit and an automatic control unit. The femtosecond laser unit is used for transmitting the femtosecond laser. The light beam control unit is used for controlling power, light beam quality and exposure time of the femtosecond laser. The motion unit is used for controlling the movement amount in the three-dimensional direction of the photo-etched surface. The femtosecond laser unit is arranged behind the light beam control unit. The light beam control unit is arranged above the motion platform unit. The light beam control unit and the motion platform unit are electrically connected with the automatic control unit. The invention further provides a method for preparing the bionic super-hydrophobic micro-nano surface through the femtosecond laser, and the device is adopted in the method. The ablation effect of the femtosecond laser is utilized for forming a micro-nano composite structure similar to the surface of a lotus leaf at a time, secondary modeling is not needed, the process is simple, and the micro-nano structure is stable, good in uniformity and high in hydrophobic function.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

Femtosecond laser ablation-surface coating combined processing method for super-hydrophobic surface

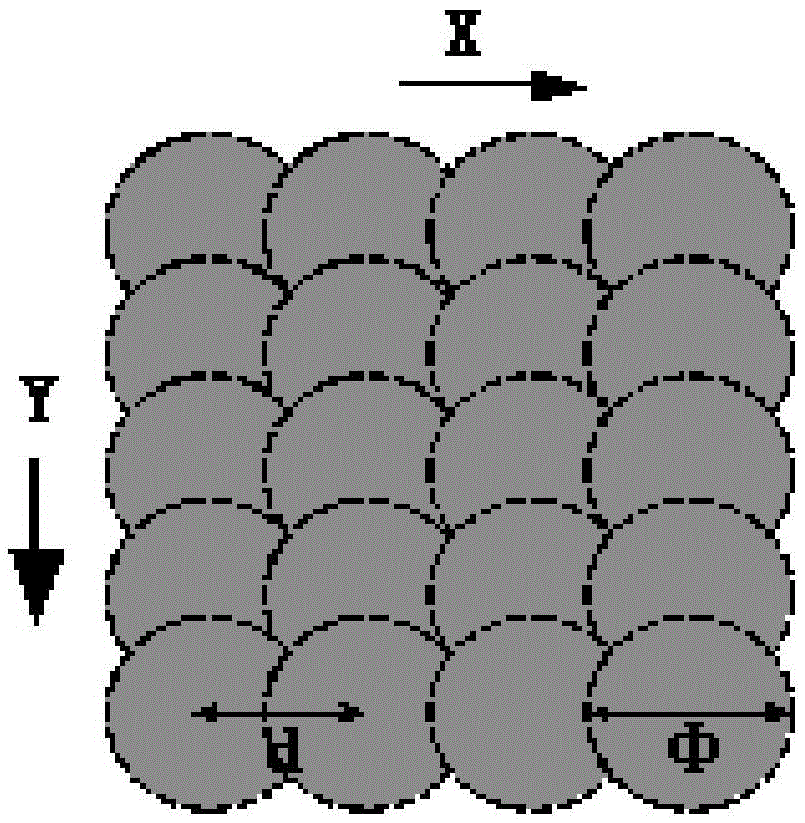

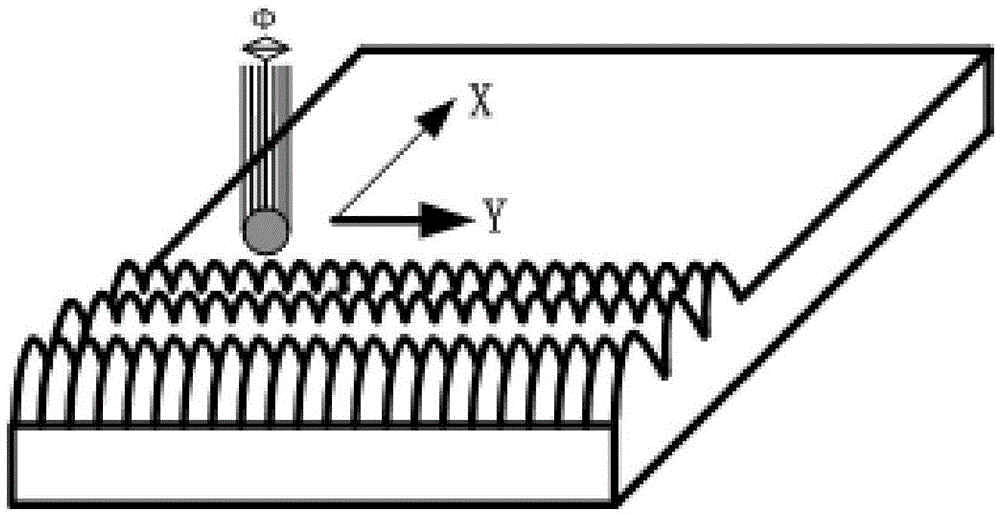

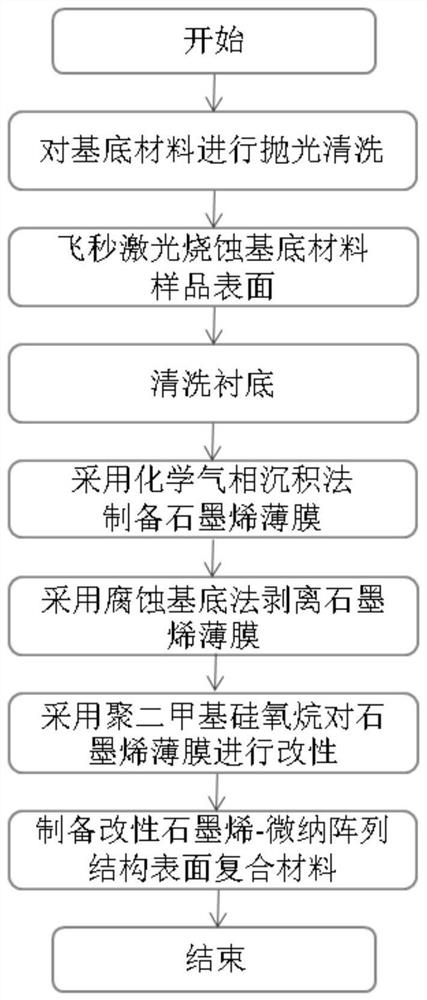

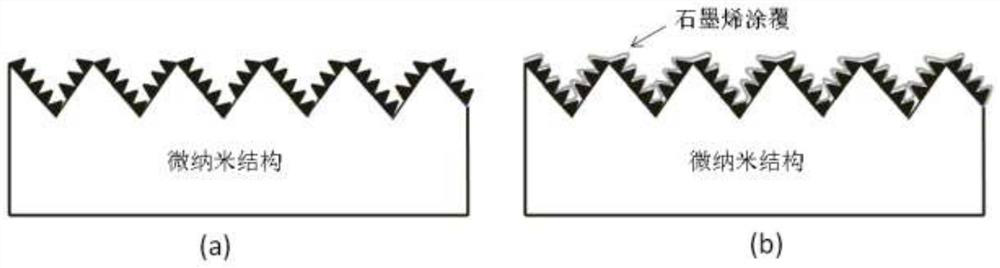

PendingCN114211121AImprove machining accuracyImprove stabilityChemical vapor deposition coatingLaser beam welding apparatusThin membraneFemtosecond laser ablation

The invention discloses a femtosecond laser ablation-surface coating combined machining method for a super-hydrophobic surface, and belongs to the technical field of photoelectricity. The method comprises the following steps: firstly, etching the surface of a substrate material sample by femtosecond pulse laser to obtain a material sample with a micro-nano array surface; and then coating a layer of low-energy-state hydrophobic film on the material sample with the micro-nano array surface to obtain the low-energy-state hydrophobic film-micro-nano array structure surface composite material, thereby realizing the comprehensive hydrophobic performance of physical hydrophobic and chemical hydrophobic. According to the method, the femtosecond laser etching technology and the low-energy-state hydrophobic film coating technology are combined, and the method has the advantages of being high in machining precision and stability, rapid and efficient in preparation and the like and can be widely applied to machining of micro-nano arrays on the surfaces of various compounds.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

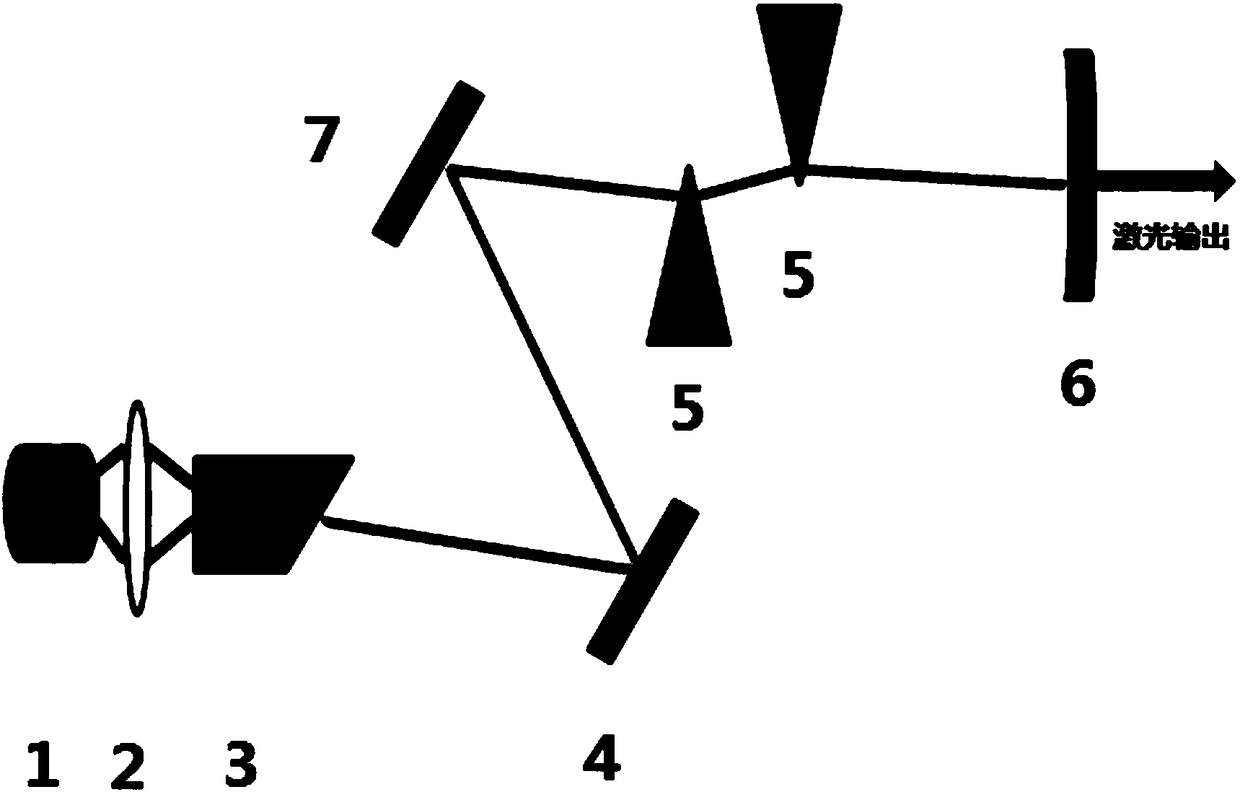

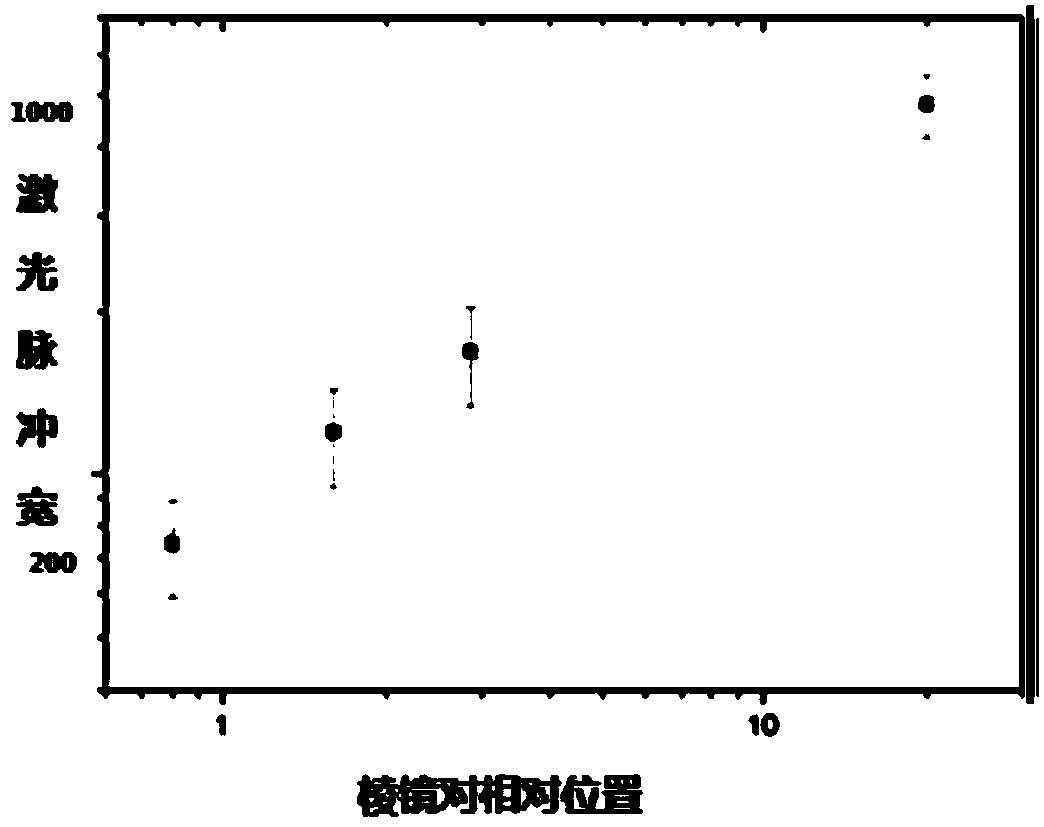

Femto-second laser device convenient for laser pulse width adjustment

InactiveCN108075347AHigh beam qualityLaser ablation effect is goodLaser detailsAnalysis by thermal excitationFemto second laserChirped mirror

The invention relates to a femto-second laser device convenient for laser pulse width adjustment. The laser device comprises a pump laser diode, a condenser lens, a laser crystal, a chirped mirror, asemiconductor saturable absorber mirror, prisms and an end mirror which are sequentially disposed on the laser output path, wherein the prisms are a prism pair arranged on a motorized translation stage and can realize adjustment of the relative position, and a laser chamber of the femto-second laser device further comprises one chirped mirror for dispersion compensation and the prism pair. The invention further relates to the femto-second laser device for purposes of steel sample component detection or the laser eye surgery. The femto-second laser device is advantaged in that a light source with 200-1000 femto-second continuous change laser pulse width for the femto-second laser eye surgery can be realized, the laser pulse width changes along with the laser position in a cornea during femto-second laser ablation of the cornea, and the best laser ablation effect can be realized.

Owner:ACAD OF OPTO ELECTRONICS CHINESE ACAD OF SCI

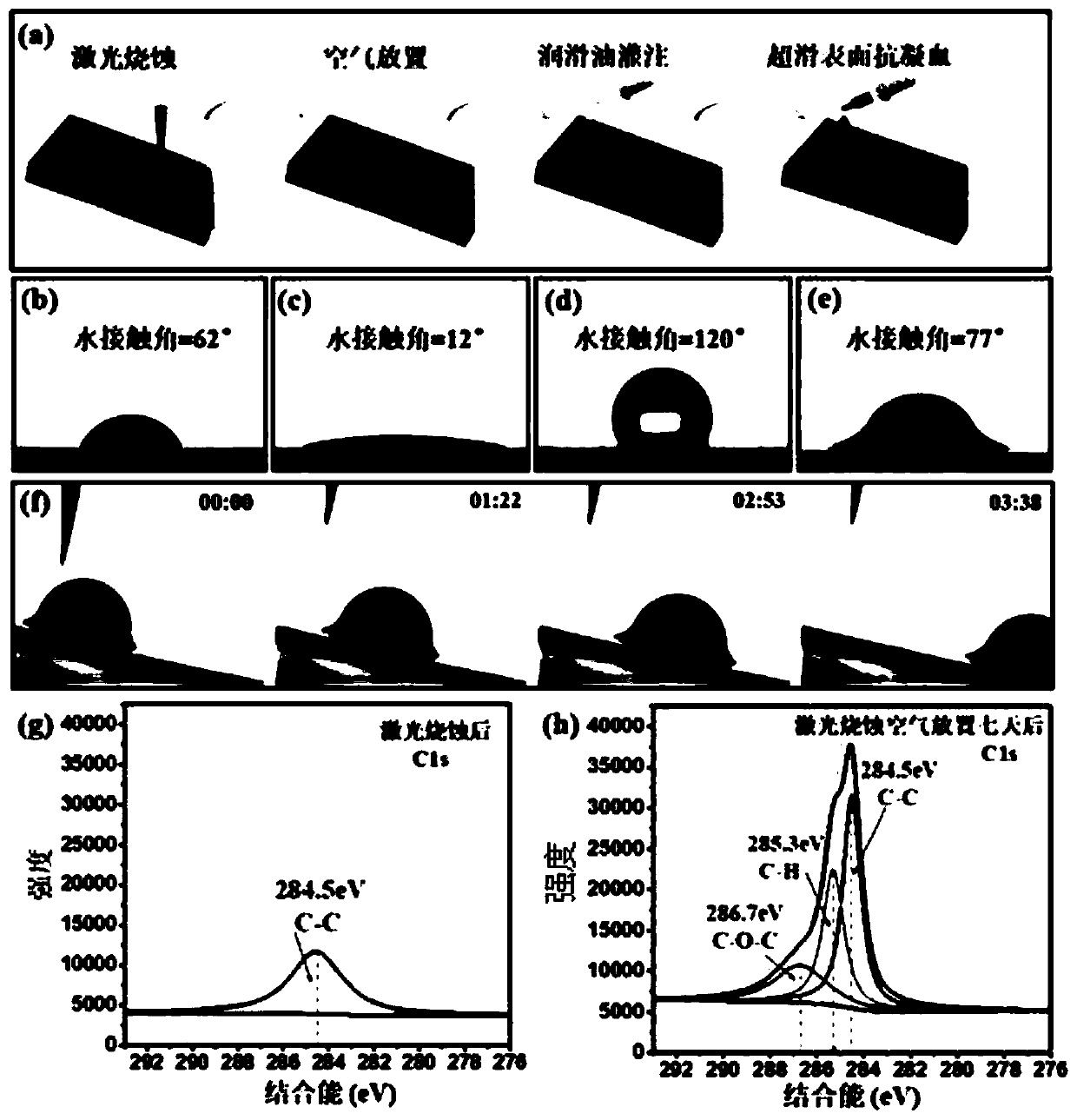

Titanium-nickel alloy material with high blood compatibility and preparation method thereof

PendingCN111168231ADoes not involve reduced activityStable structureLaser beam welding apparatusPharmaceutical drugNickel alloy

The invention relates to a titanium-nickel alloy material and a preparation method thereof, in particular to a titanium-nickel alloy material with high blood compatibility and a preparation method thereof. The material and the method solve the technical problems that at present, by applying a coating method, a coating is prone to fall off and local corrosion at a point with the coating falling offis generated, by applying an anticoagulant drug fixation method, the activity of heparin is reduced, and by applying a chemical method, pollution is generated. The titanium-nickel alloy material withthe high blood compatibility is characterized by comprising a titanium-nickel alloy substrate, wherein uniform porous structures are distributed in the surface of the titanium-nickel alloy substrate,the porous structures are formed by adopting femtosecond laser ablation, and lubricating oil fills the porous structures. The invention also provides the preparation method of the titanium-nickel alloy material with the high blood compatibility. The titanium-nickel alloy material with the high blood compatibility can be applied to medical implantation and blood contact equipment.

Owner:XI AN JIAOTONG UNIV

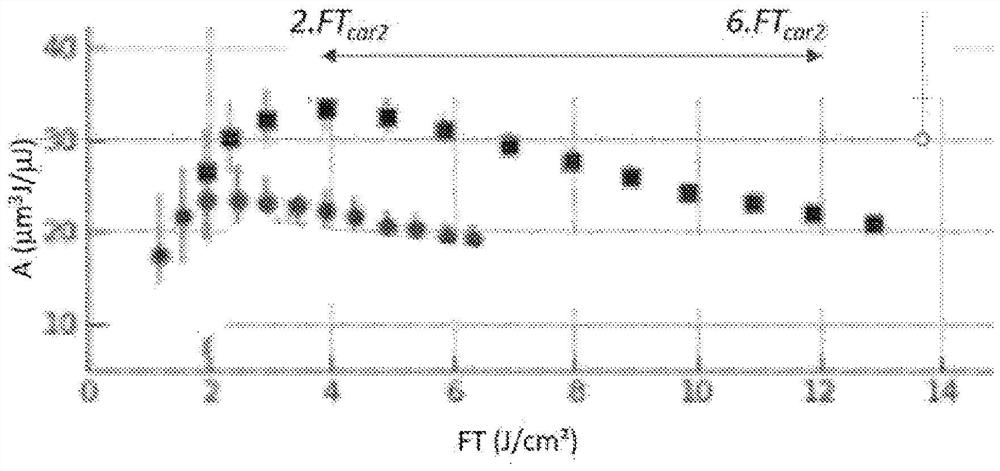

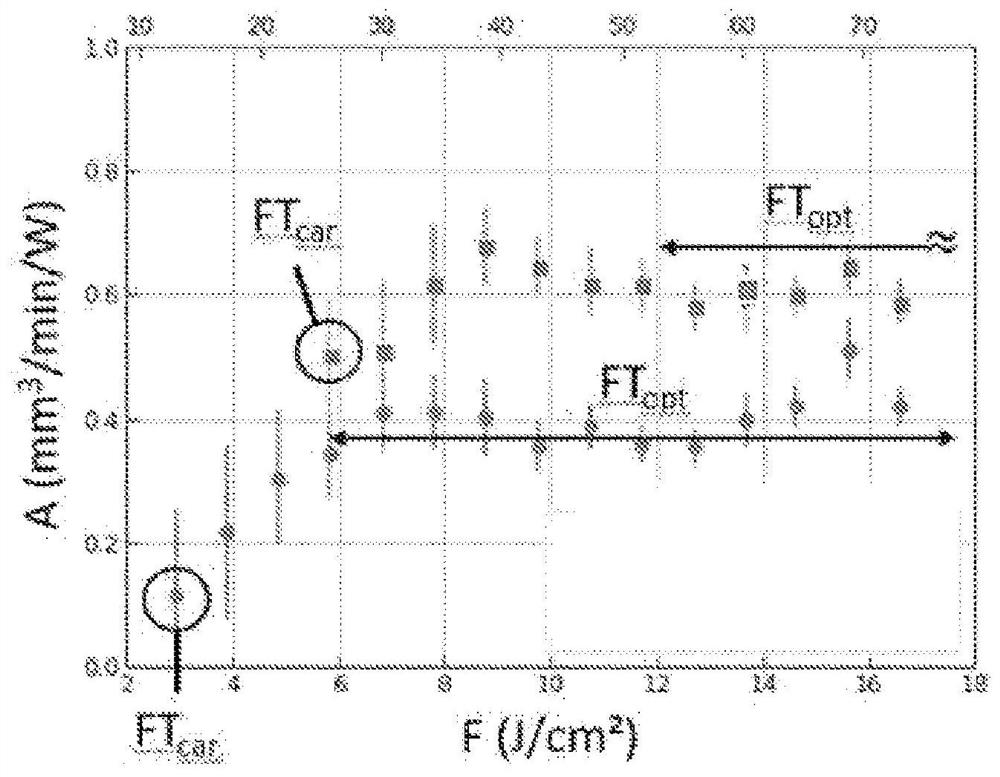

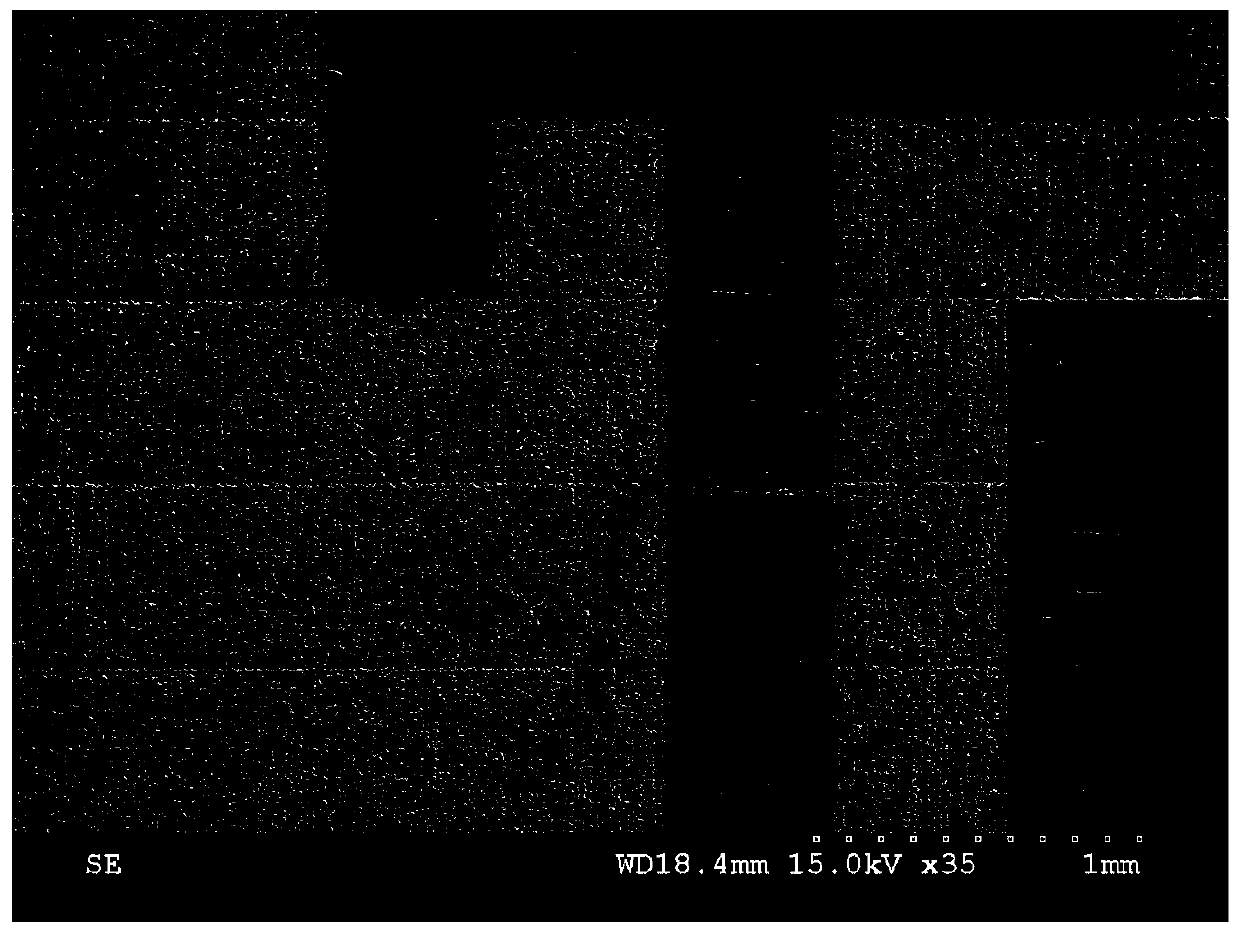

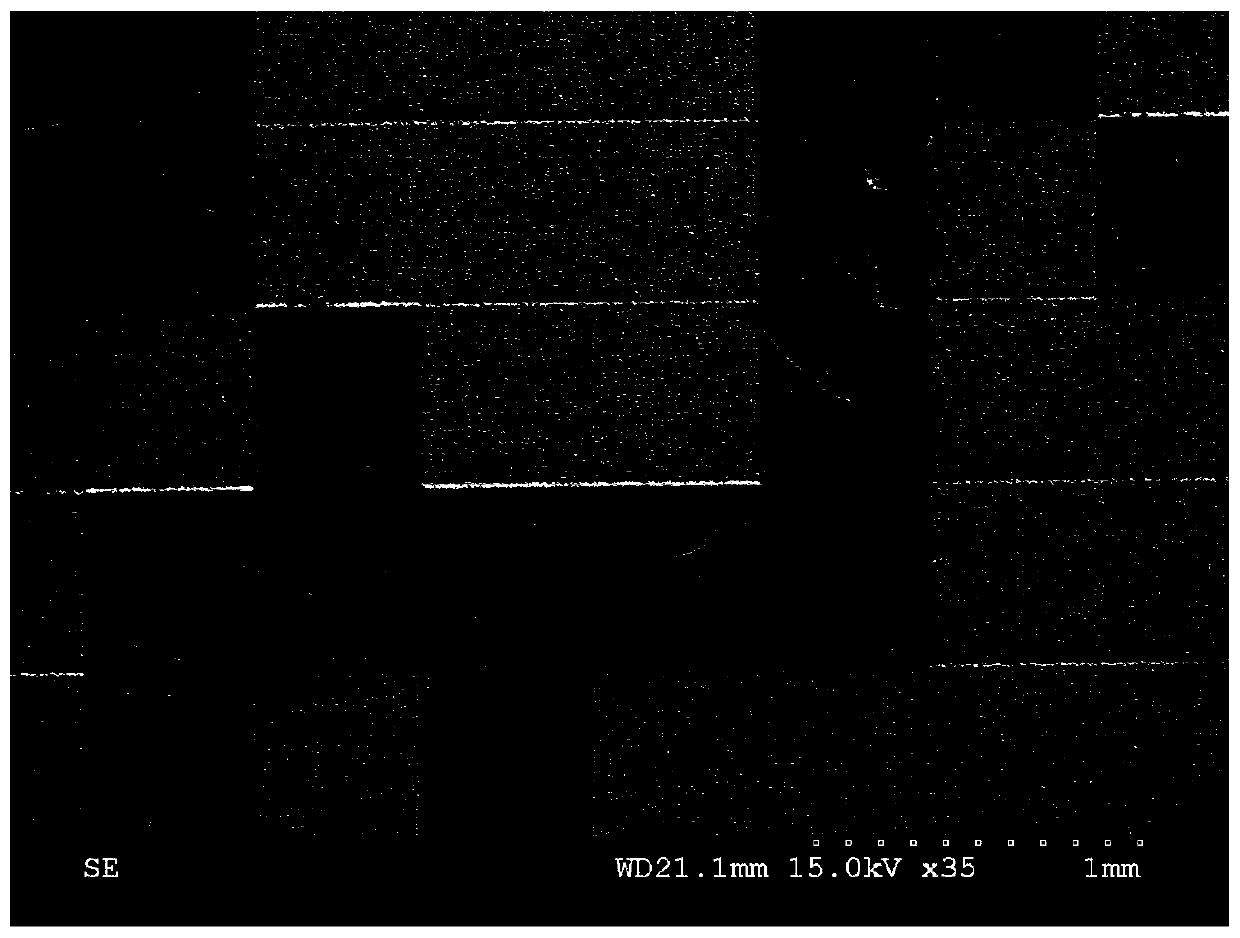

Method for determining the operational conditions of a method for high-repetition rate femtosecond laser ablation for a given material and method for laser welding between parts of a determined material

PendingCN113710403AMaterial thermal analysisLaser beam welding apparatusThermal diffusion coefficientFemtosecond laser ablation

The invention proposes a method for determining the operational conditions of a method for high-repetition rate femtosecond laser ablation for a given material comprising a first step of determining a set of parameters of a burst of laser pulses adapted to generate an ablation crater in the material, the set of parameters comprising an intra-burst repetition frequency f between several hundred MHz and 100 GHz, a number N of pulses of the burst of laser pulses equal to a number Ne of heating and ablation pulses, with Ne being defined by the equation Nc = (L2.f) / D, where L represents a test depth and D represents a thermal diffusion coefficient of the material to be ablated, with Nc being greater than or equal to 10, a characteristic total fluence FTchar of the burst of pulses and a characteristic fluence per pulse Fchar=FTchar / Nc per pulse below an ablation threshold fluence Fs1 of the material by a single laser pulse.

Owner:振幅公司 +2

A Method for Preparing Marks Based on Femtosecond Laser Ablation Composite Induction

ActiveCN109702354BImprove reliabilityIncreased durabilityLaser beam welding apparatusFemto second laserGalvanometer

The invention discloses a method for preparing a mark stamp based on femtosecond laser ablation composite induction. A titanium alloy TC4 or nickel-based alloy GH4169 metal sheet is adopted as a machining object, a light path is established, a femtosecond laser device outputs light to be focused to a shear type lifting table through a two-axis scanning galvanometer system, and the femtosecond laser device and the two-axis scanning galvanometer system are connected with a computer; the computer is utilized for adjusting the femtosecond laser device to output lasers, the wavelength of the lasersis 1,030 nm, the pulse width is 240 fs, the repetition frequency is 1-200 kHz and can be adjusted, and the maximum single pulse energy is 200 mu J; and the titanium alloy TC4 or nickel-based alloy GH4169 metal sheet is fixed to a machining station of the shear type lifting table, and through adjustment of the repetition frequency, the single pulse energy, the scanning speed and the groove distance, optimal laser ablation primary mark stamp basic parameters and laser induction second-time mark stamp basic parameters are obtained. By means of the method, the quality, efficiency and recognitionrate of the femtosecond laser mark stamp are improved, and adaptability is achieved for a titanium alloy and a nickel-based alloy.

Owner:无锡超通智能制造技术研究院有限公司

Biomimetic cell culture substrates

ActiveUS10941380B2High expressionLow variabilityCell culture supports/coatingGeneral culture methodsPolymer scienceCell culture media

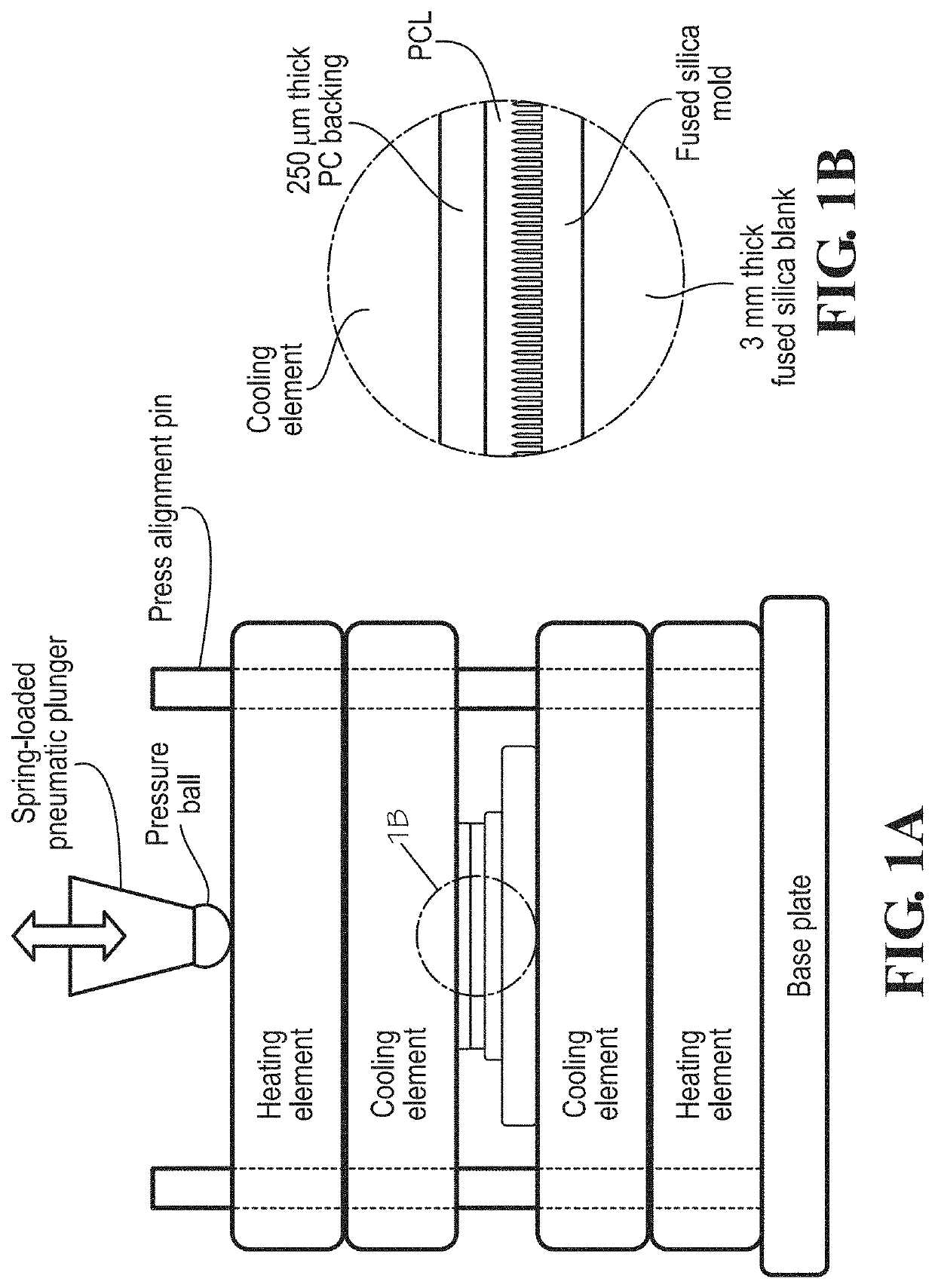

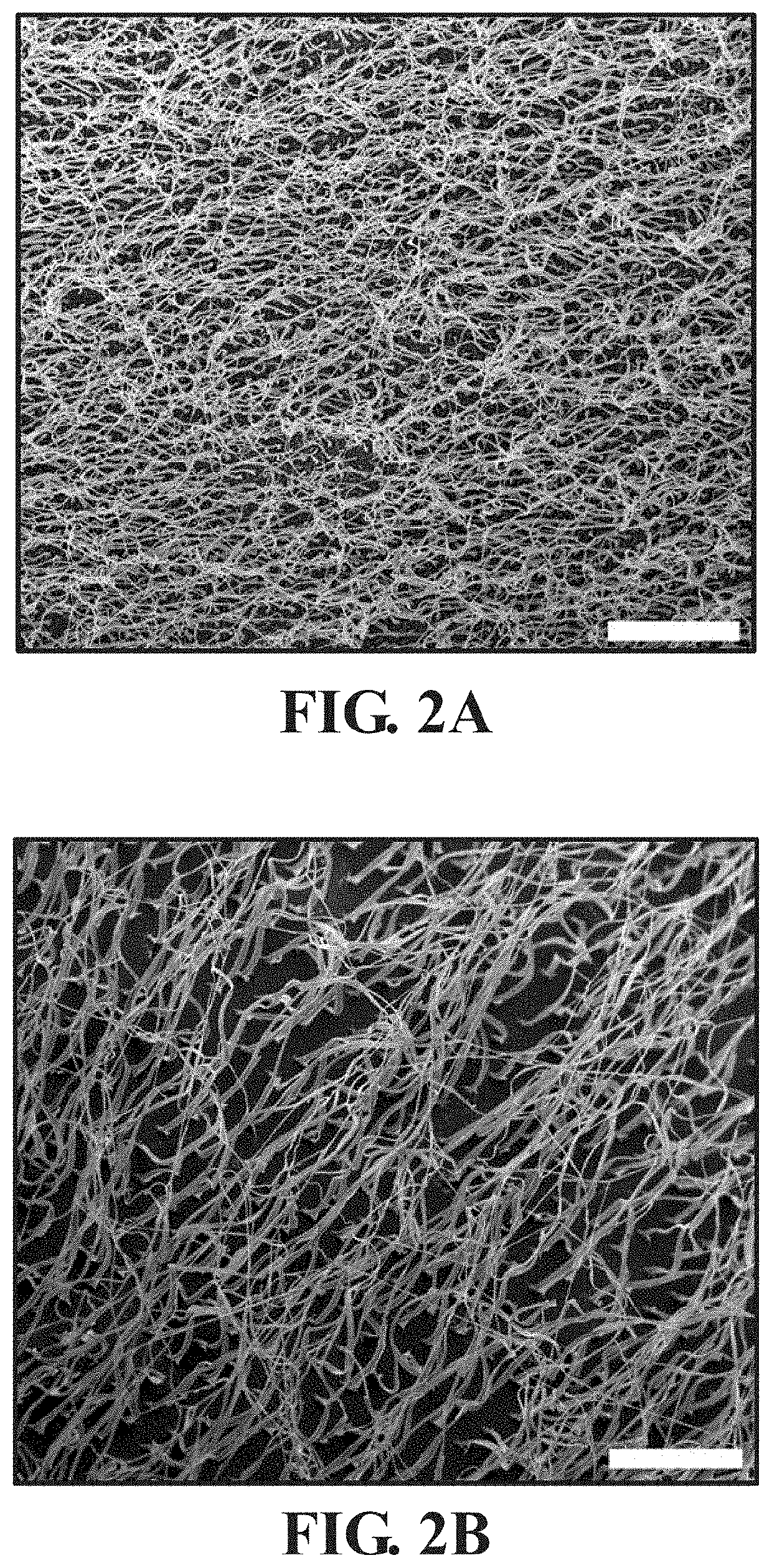

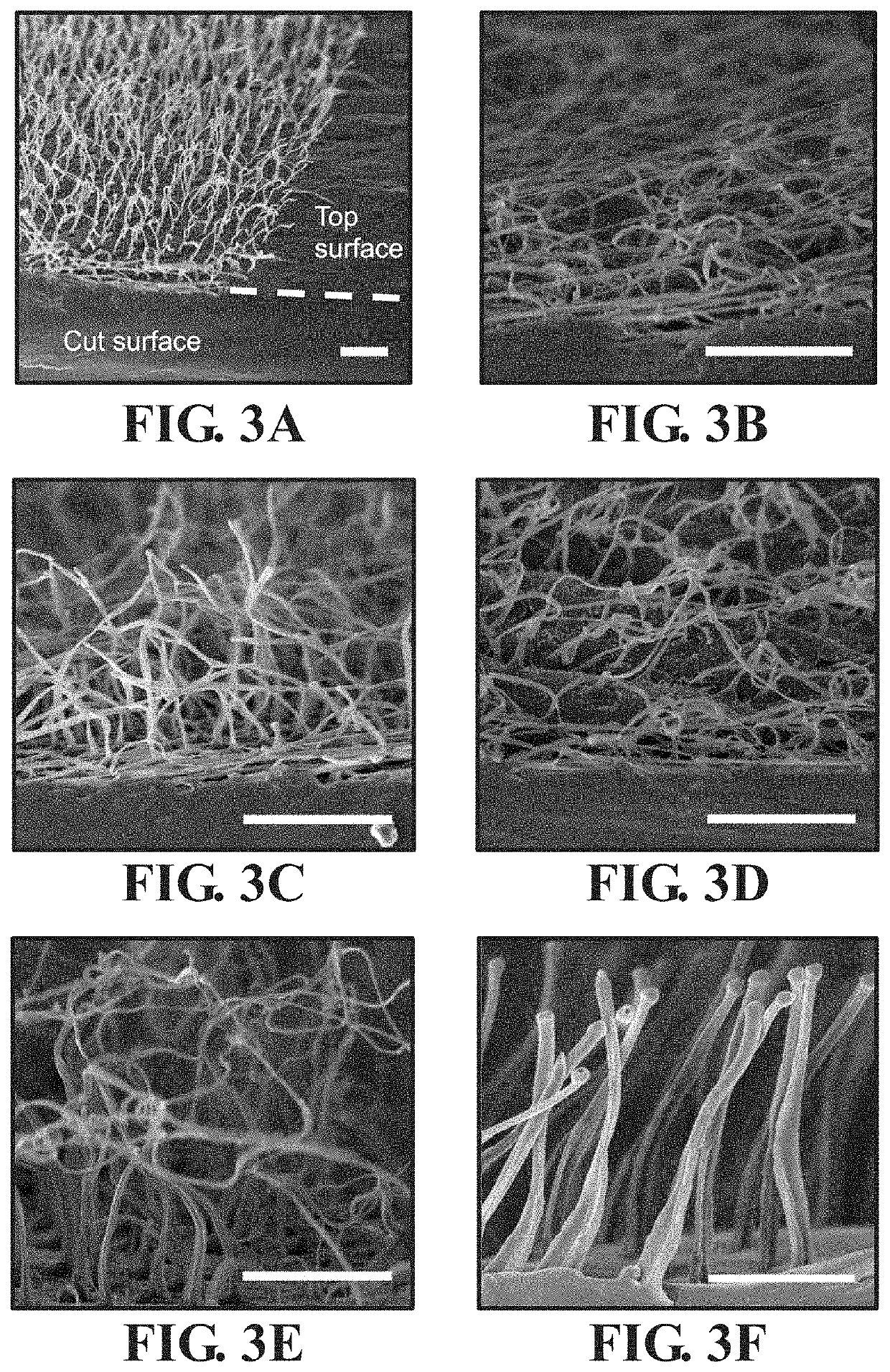

Embodiments of the presently disclosed subject matter provide biomimetic cell culture substrates comprising highly tunable patterned polymer nanofiber matrices capable of modulating expression of critical self-renewal factors and markers of cell-cell interaction to maintain stemness of human mesenchymal stem cells in vitro. Embodiments of the presently-disclosed subject matter also provide scalable, highly repeatable methods of making biomimetic cell culture substrates by hot pressing thermoplastic polymer films into femtosecond laser-ablated nanopore molds to form patterned polymer nanofiber matrices on flat thermoplastic substrates.

Owner:ULTRA SMALL FIBERS

A dual laser dressing device and method for grinding wheel with gas-liquid parallel tube type

ActiveCN108081137BReduced chip spaceAvoid Coulomb ExplosionsAbrasive surface conditioning devicesAutomatic grinding controlPicosecond laserFemto second laser

The invention discloses a gas-liquid parallel tube type grinding wheel double laser trimming device. The gas-liquid parallel tube type grinding wheel double laser trimming device comprises gas-liquidcontrol equipment, a gas-liquid control operating platform, a picosecond laser ablation head, a gas-guide flexible pipe, a grinding machine, focusing lenses, a femtosecond laser ablation head, a femtosecond laser device, a laser device control operating platform, control equipment, a picosecond laser device, a fine water-guide pipe, a superhard grinding-material grinding wheel, a gas column flow,a liquid column flow, laser beams and three-dimensional moving platforms. By means of the gas-liquid parallel tube type grinding wheel double laser trimming device and method, the auxiliary gas-liquidparallel tube type grinding wheel double laser trimming device is provided, the situations that diamond grinding particle chip tolerance space of the grinding wheel is reduced and the height of highlighted binder is not enough caused by plasma particles and phase explosion effect are avoided, and the defects of microcracks, graphite metamorphic layers and the like generated by peripheral heat accumulation during diamond grinding are overcome; and by means of the gas-liquid parallel tube type grinding wheel double laser trimming device and the method, the generation of coulomb explosion can beavoided, the surface grating and micro-cone structure of the grinding wheel are reduced, the utilization efficiency of laser energy is improved, and the grinding wheel trimming efficiency and the trimming surface quality are improved.

Owner:HUAZHONG UNIV OF SCI & TECH

A method for establishing a laser source model for femtosecond laser ablation simulation

ActiveCN108875264BDesign optimisation/simulationSpecial data processing applicationsMaterial removalFemtosecond laser ablation

The invention provides a method for establishing a laser source model for femtosecond laser ablation simulation. According to the distribution of laser light in space and time, a laser source model with a downward focus is obtained. The proposed three-dimensional model of the laser source can be Describe the situation that the laser focus moves down with material removal in the actual processing process. By dividing the expression into two sections at the position of the processing plane ( ), it is ensured that the laser energy density above the material surface is in line with reality, and in the material The energy density below the surface (i.e. inside the material) is reasonably attenuated, and the proposed 3D model of the laser source can also describe the helical movement of the laser focus on the material plane during actual processing.

Owner:XIAMEN UNIV +1

Stretchable organic electroluminescent devices with periodic regularly wrinkled structures

ActiveCN105405983BImprove flexibilityFlat surfaceSolid-state devicesSemiconductor/solid-state device manufacturingGratingElastic substrate

The invention discloses a stretchable organic electroluminescent device with periodic regular wrinkle structure, which belongs to the field of optoelectronic technology. The invention specifically relates to processing a long-period grating structure on the surface of an elastic substrate by using a femtosecond laser ablation process, and combining a vacuum evaporation technology with a stripping process to obtain an organic electroluminescent device. The substrate is combined with the organic electroluminescent device to prepare a stretchable organic electroluminescent device with periodic regular wrinkles, high efficiency, high stability and large stretching degree. This kind of stretchable organic electroluminescent device has very high tensile stability. With the change of stretching degree, the photoelectric performance of the device has only slight fluctuations. More importantly, in repeated stretching tests, the device performance Only a small attenuation occurs and has very high practical value.

Owner:JILIN UNIV

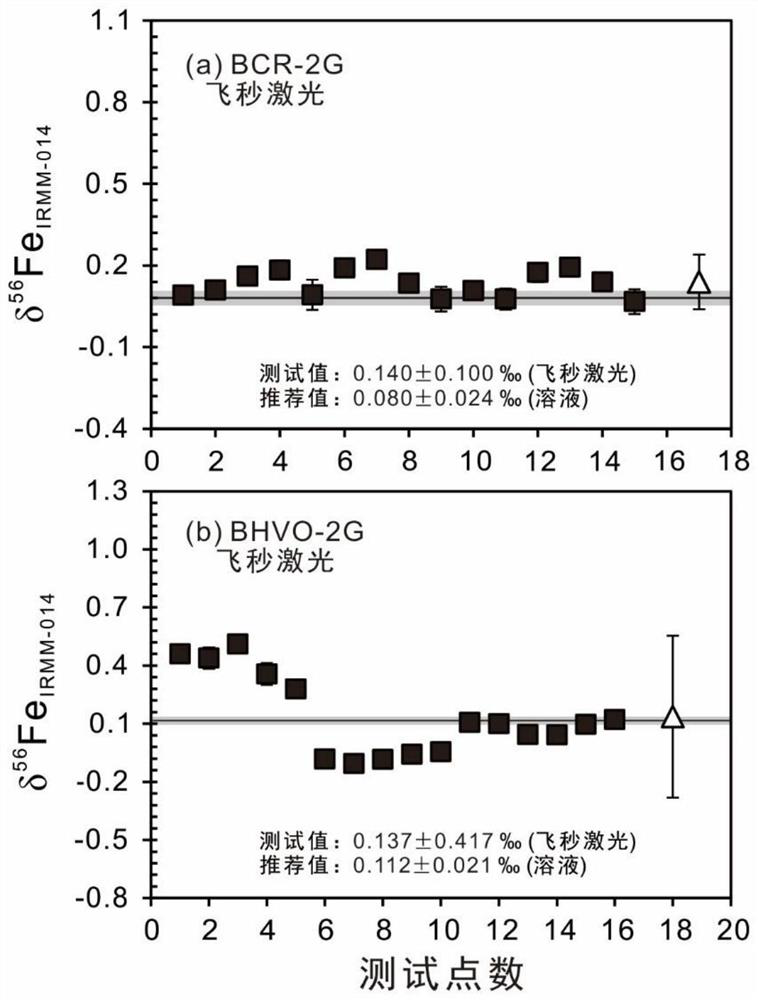

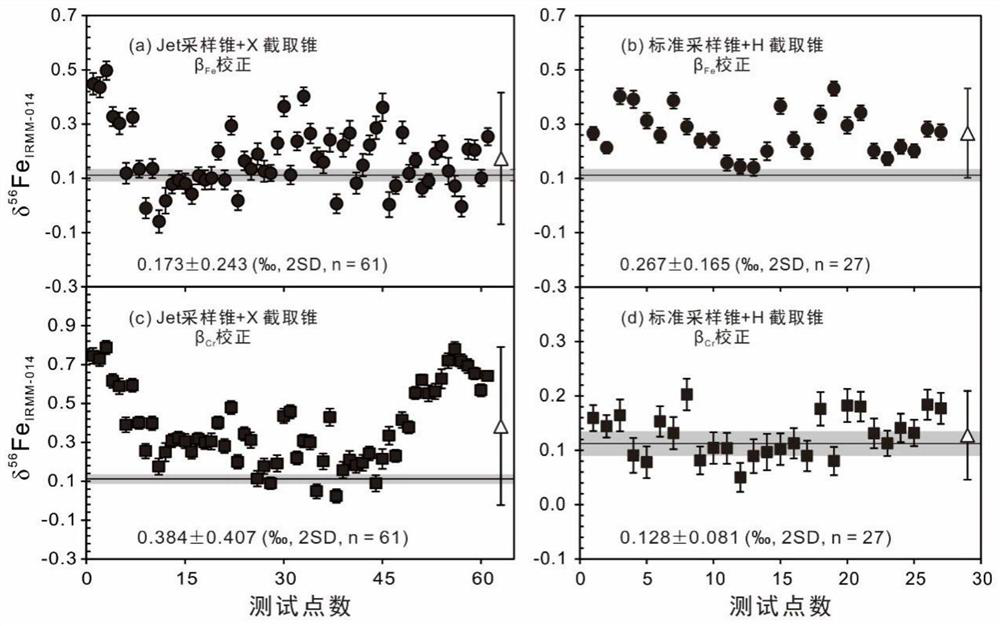

A laser method for measuring the Fe isotope composition of Cr-rich geological samples

ActiveCN112986372BUniform compositionEfficiently subtract mass spectral interferencesPreparing sample for investigationMaterial analysis by electric/magnetic meansFemto second laserIsotopic composition

Owner:INST OF GEOLOGY & GEOPHYSICS CHINESE ACAD OF SCI +1

A preparation method of two-dimensional layered nanomaterial mxene quantum dots

ActiveCN110272048BImprove photoelectric performanceReduce pollutionMaterial nanotechnologyCarbon compoundsOrganic solventFluid phase

The invention relates to a method for preparing a two-dimensional layered nanomaterial MXene quantum dot, comprising: S1: preparing the two-dimensional layered nanomaterial MXene by an etching method; S2: dissolving the two-dimensional layered nanomaterial MXene in In deionized water or an organic solvent, the ablation reaction is carried out under the femtosecond laser; S3: The solution after the femtosecond laser ablation is centrifuged to obtain the supernatant containing the two-dimensional layered nanomaterial MXene quantum dots. The invention utilizes the liquid-phase femtosecond laser ablation method to prepare the two-dimensional layered nanomaterial MXene quantum dots, which is simple and safe to operate, and the cost is low. Green solvents such as deionized water are used to reduce pollution to the environment and have high repeatability. , easy to operate, and can be mass-produced. At the same time, by controlling the power of the femtosecond laser, the particle size and particle size distribution of the two-dimensional layered nanomaterial MXene quantum dots can be controlled, so as to obtain MXene quantum dots with better photoelectric properties.

Owner:XIDIAN UNIV

A waveguide grating coupler based on photothermosensitive refractive glass and its preparation method

ActiveCN110824615BThe production process is simple and convenientExcellent optical propertiesOptical waveguide light guideLaser processingRidge waveguides

The invention discloses a waveguide grating coupler based on photothermo-sensitive refraction glass and a preparation method thereof. The waveguide grating coupler includes a substrate material, a ridge optical waveguide structure and a grating, and the substrate material is photothermal Refractive glass, the ridge-shaped optical waveguide structure is prepared on the surface of the substrate material by ion implantation and femtosecond laser ablation technology, and the grating is integrated and prepared on the surface of the ridge-shaped optical waveguide structure by femtosecond laser writing technology. The invention only needs to use ion implantation and femtosecond laser processing technology to realize the preparation of the ridge waveguide grating coupler. Femtosecond laser processing technology can not only complete the preparation of ridge waveguides but also write gratings, killing two birds with one stone, and the preparation process is simpler and more convenient.

Owner:NANJING UNIV OF POSTS & TELECOMM

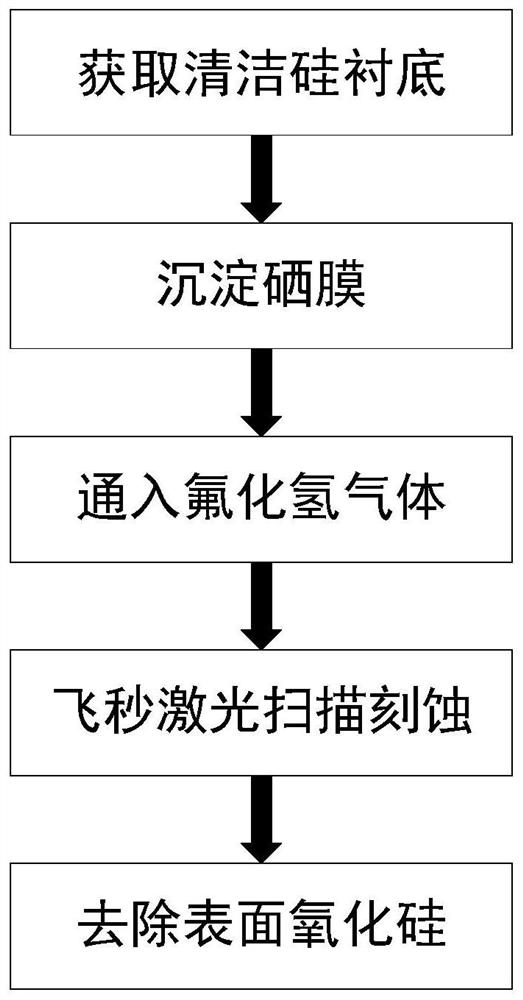

A kind of black silicon material and preparation method thereof

ActiveCN109950336BUniform thickness distributionGuaranteed volatilityFinal product manufactureSemiconductor devicesChemical reactionSurface oxidation

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com