Patents

Literature

32 results about "Rayleigh length" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

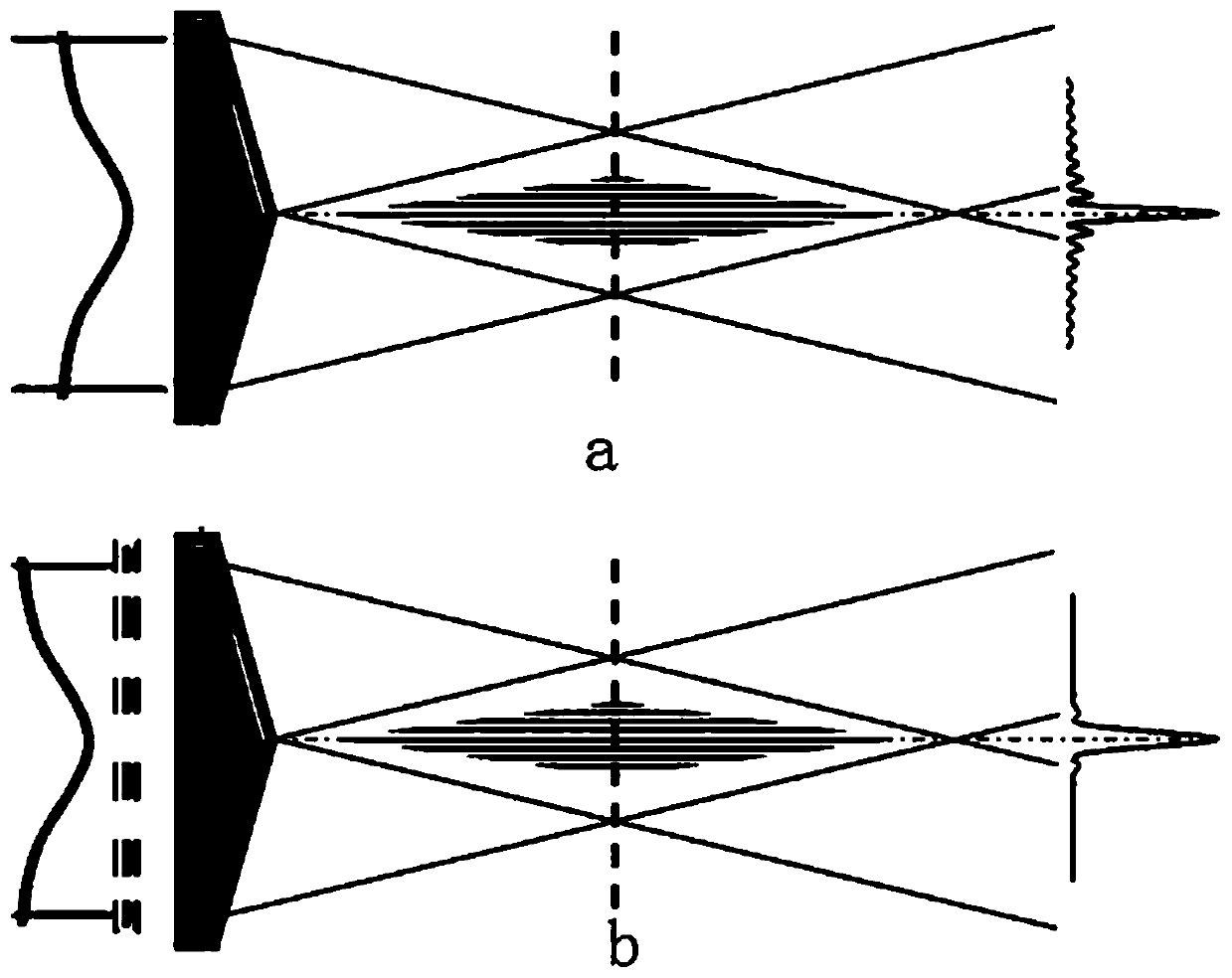

In optics and especially laser science, the Rayleigh length or Rayleigh range, zR, is the distance along the propagation direction of a beam from the waist to the place where the area of the cross section is doubled. A related parameter is the confocal parameter, b, which is twice the Rayleigh length. The Rayleigh length is particularly important when beams are modeled as Gaussian beams.

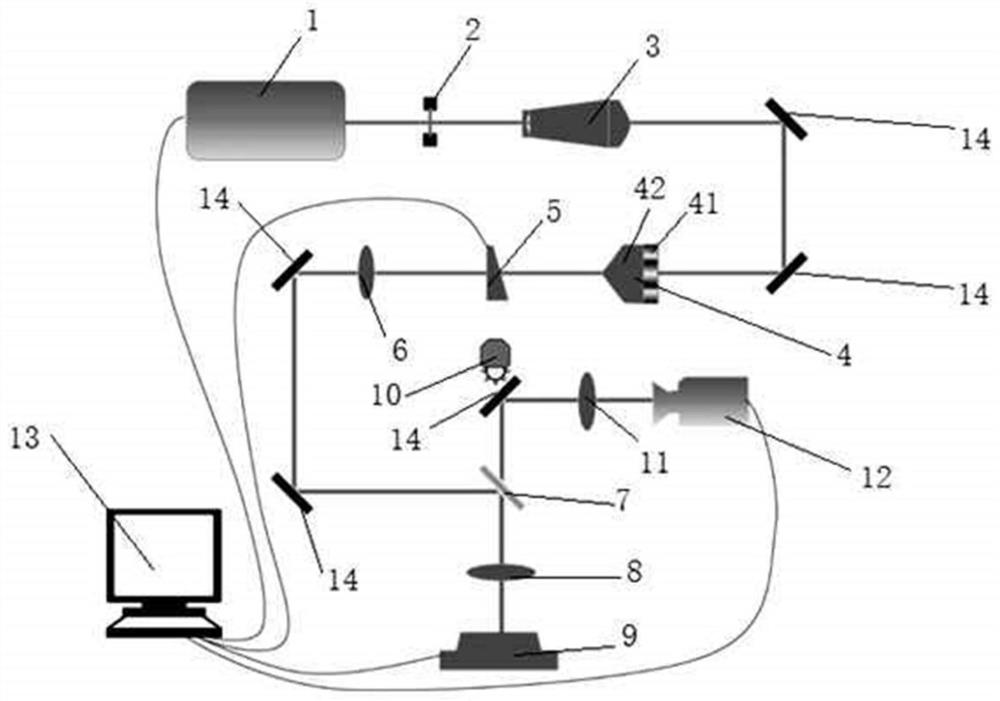

Optical nonlinearity measuring device and measuring method for nonlinearity thick photonics materials

InactiveCN105092477AEliminates the effects of optically nonlinear measurementsEliminate the effects ofPhase-affecting property measurementsPhotonicsTransmittance

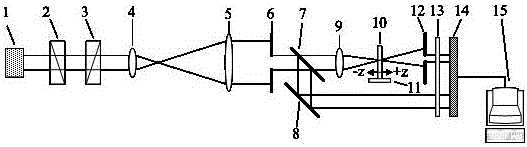

The invention discloses an optical nonlinearity measuring device and a measuring method for nonlinearity thick photonics materials, and belongs to the technical field of nonlinearity photonics materials and nonlinearity photonics measurement. Tophat type laser pulses serve as probe light, a reference standard sample with the suitable thickness is selected according to the thickness of a sample to be measured, the reference standard sample and the sample to be measured are subjected to Z scanning measurement respectively, energy of incident light is adjusted to obtain the same normalization transmittance peak-to-valley values, and a nonlinearity refraction coefficient of the sample to be measured is obtained by data processing. The optical nonlinearity measuring device and the measuring method for nonlinearity thick photonics materials are suitable for nonlinearity photonics materials of which the thicknesses exceed a Rayleigh length.

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS

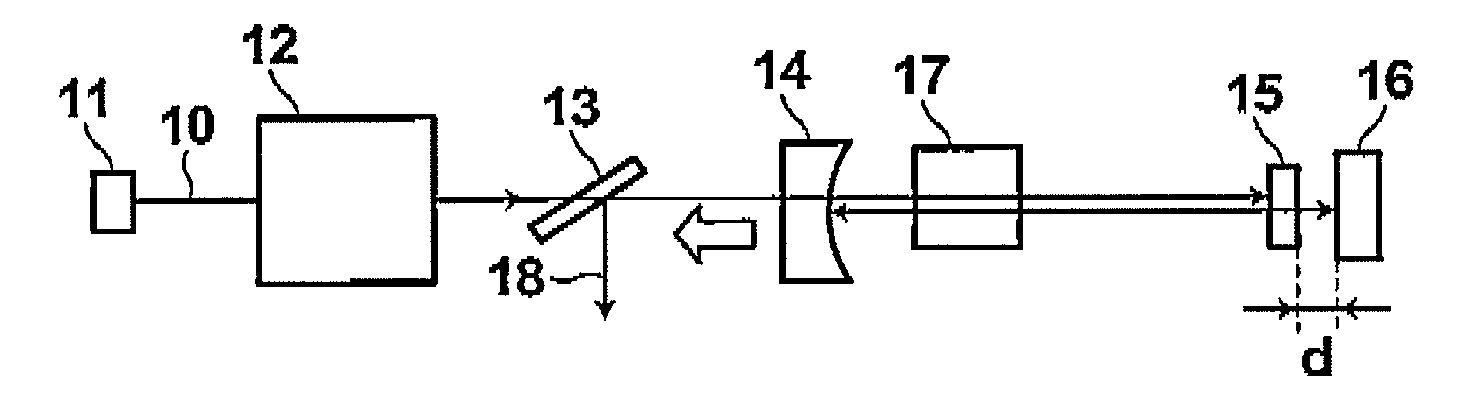

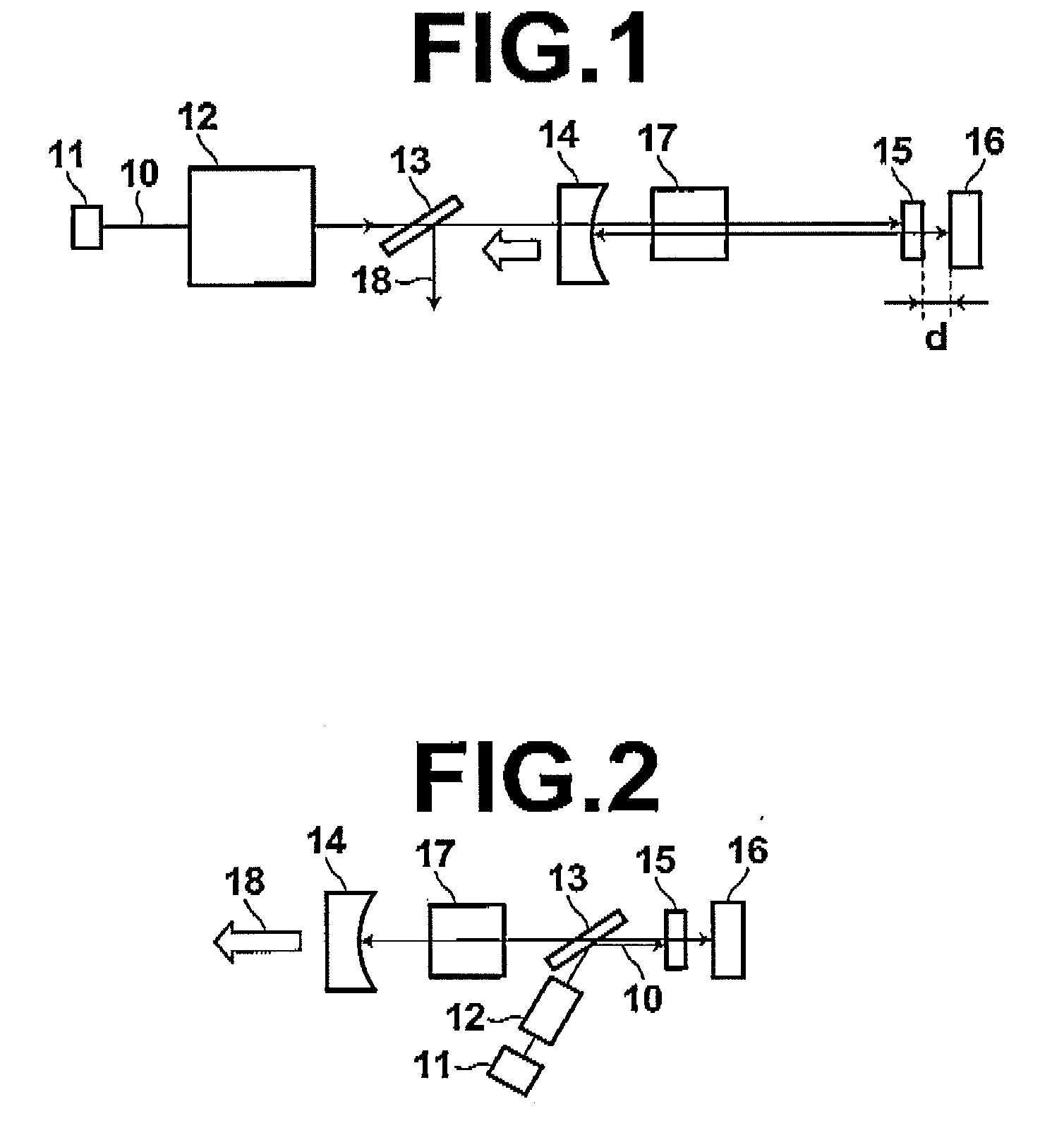

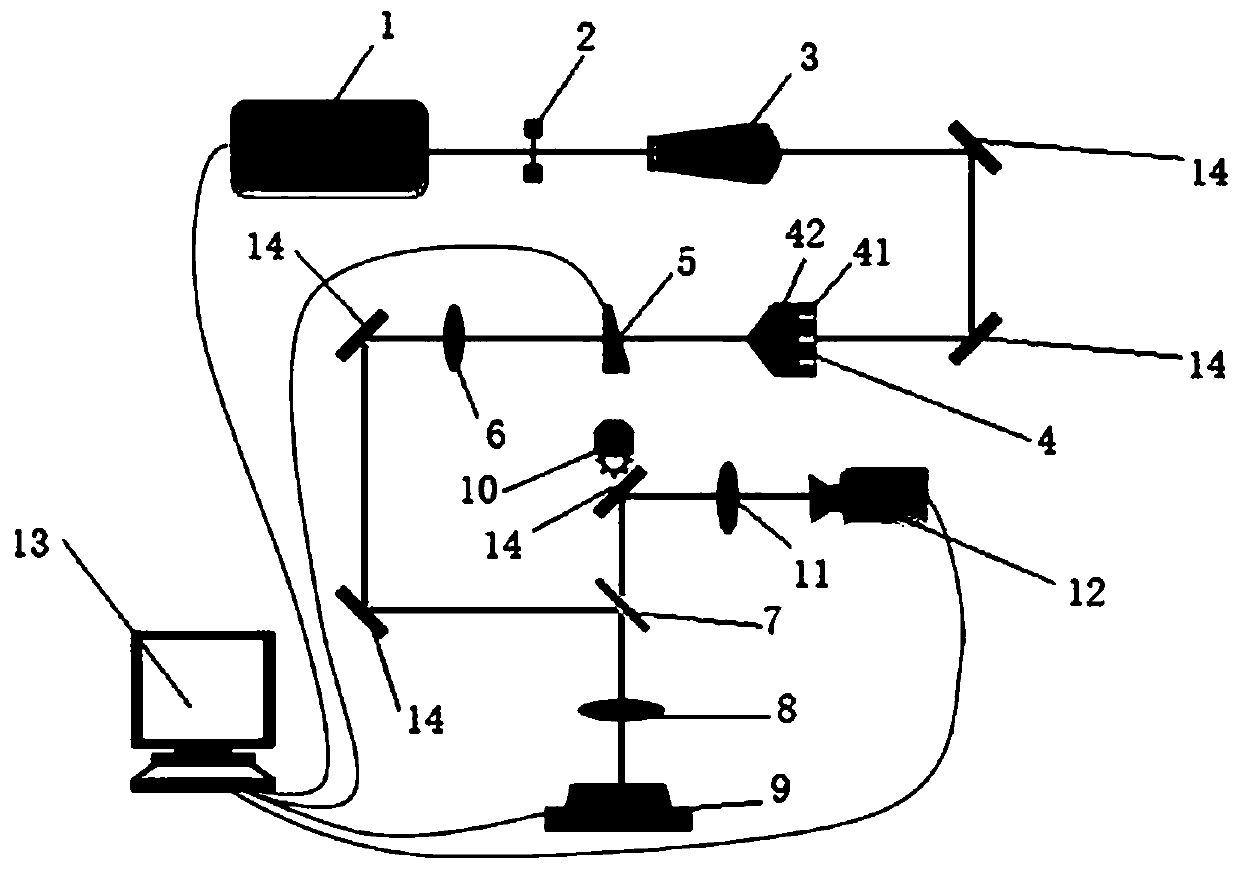

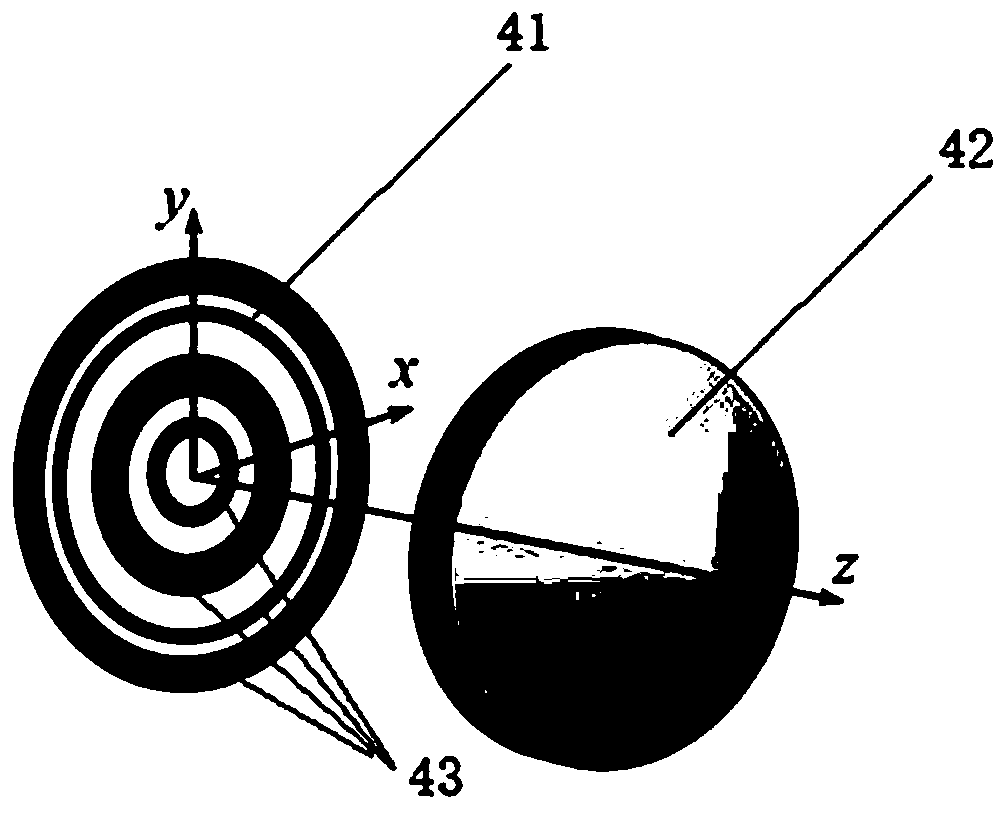

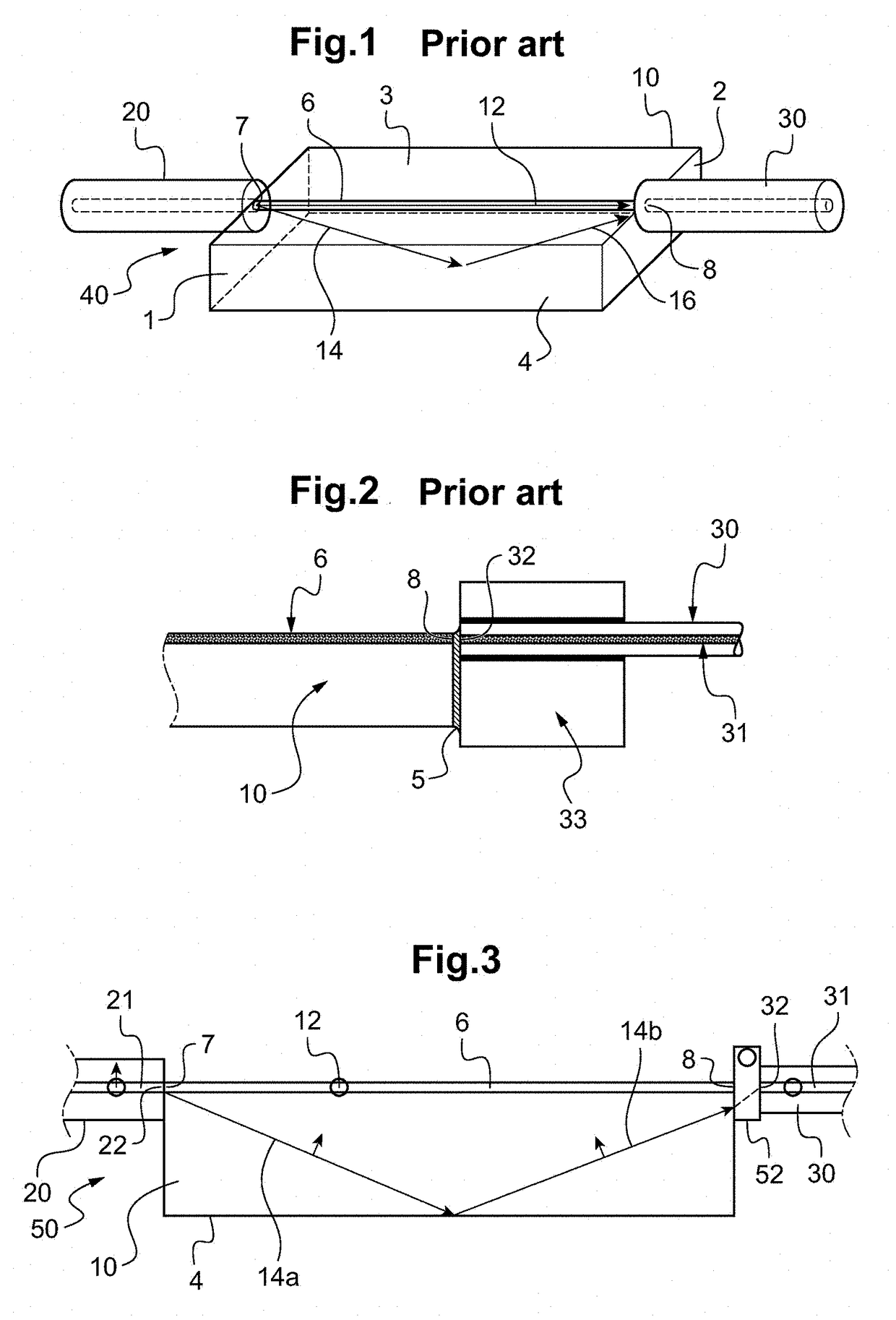

Spatially distributed laser resonator

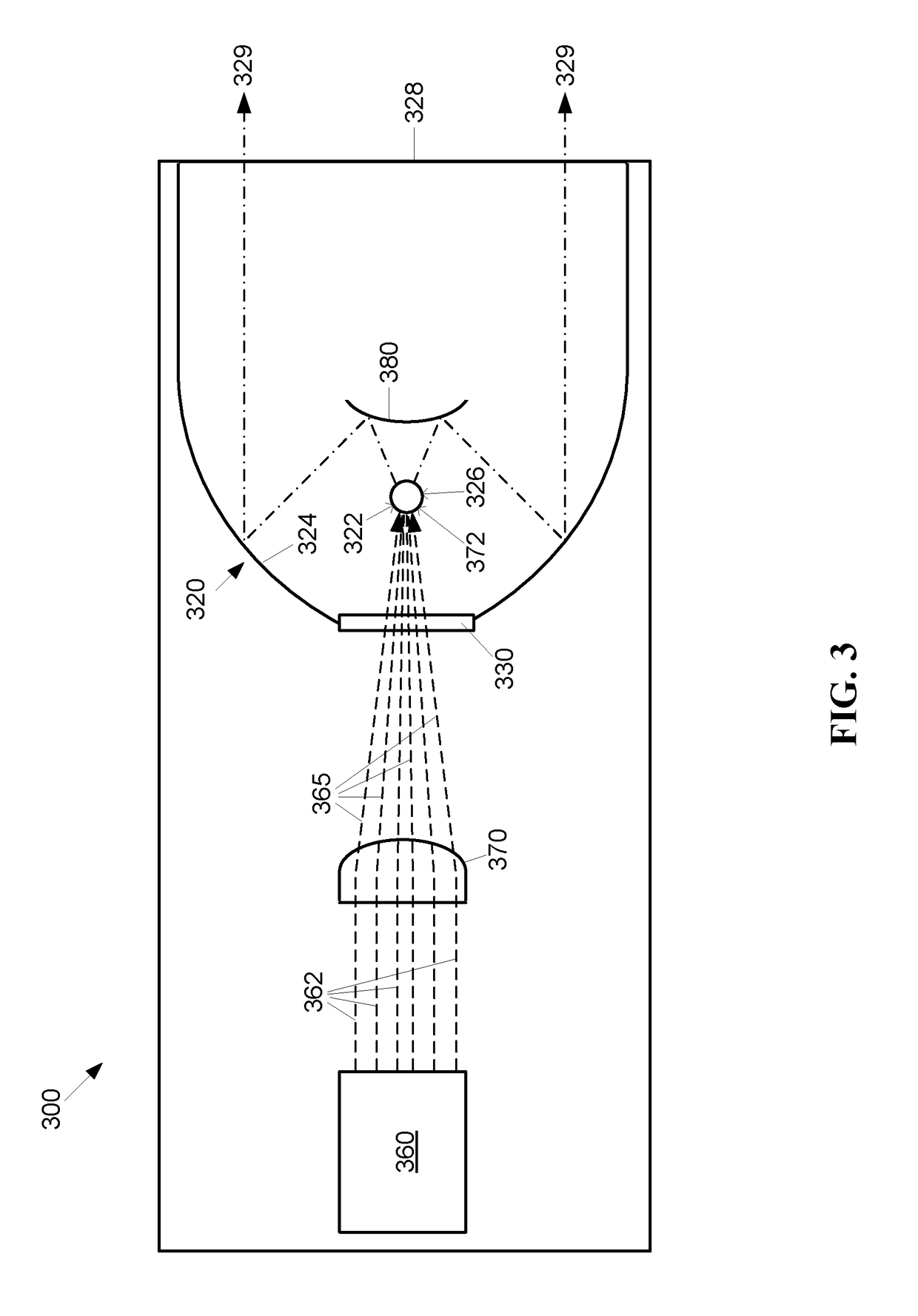

ActiveUS20140126603A1Optical resonator shape and constructionActive medium shape and constructionElectric power transmissionPupil

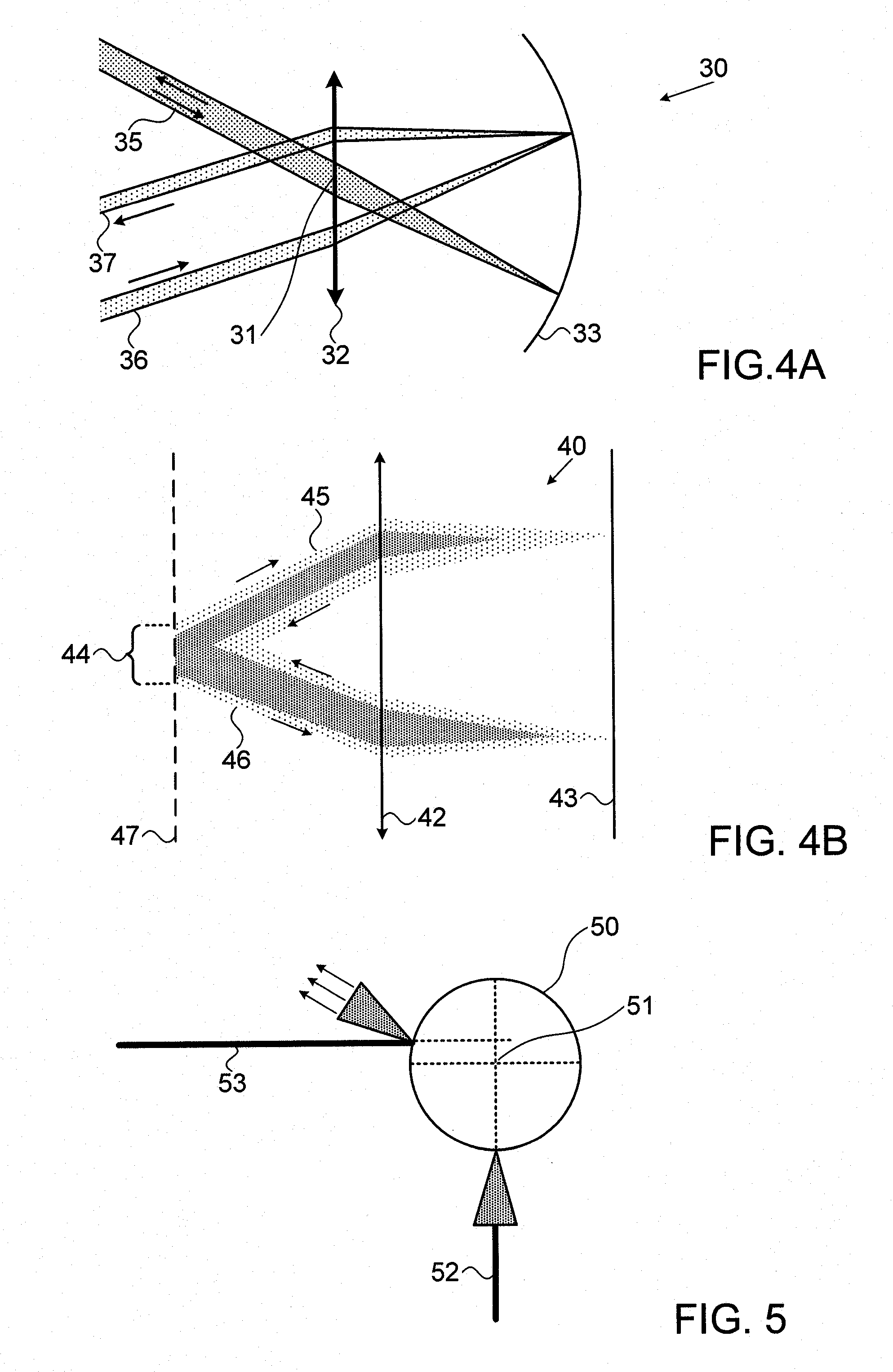

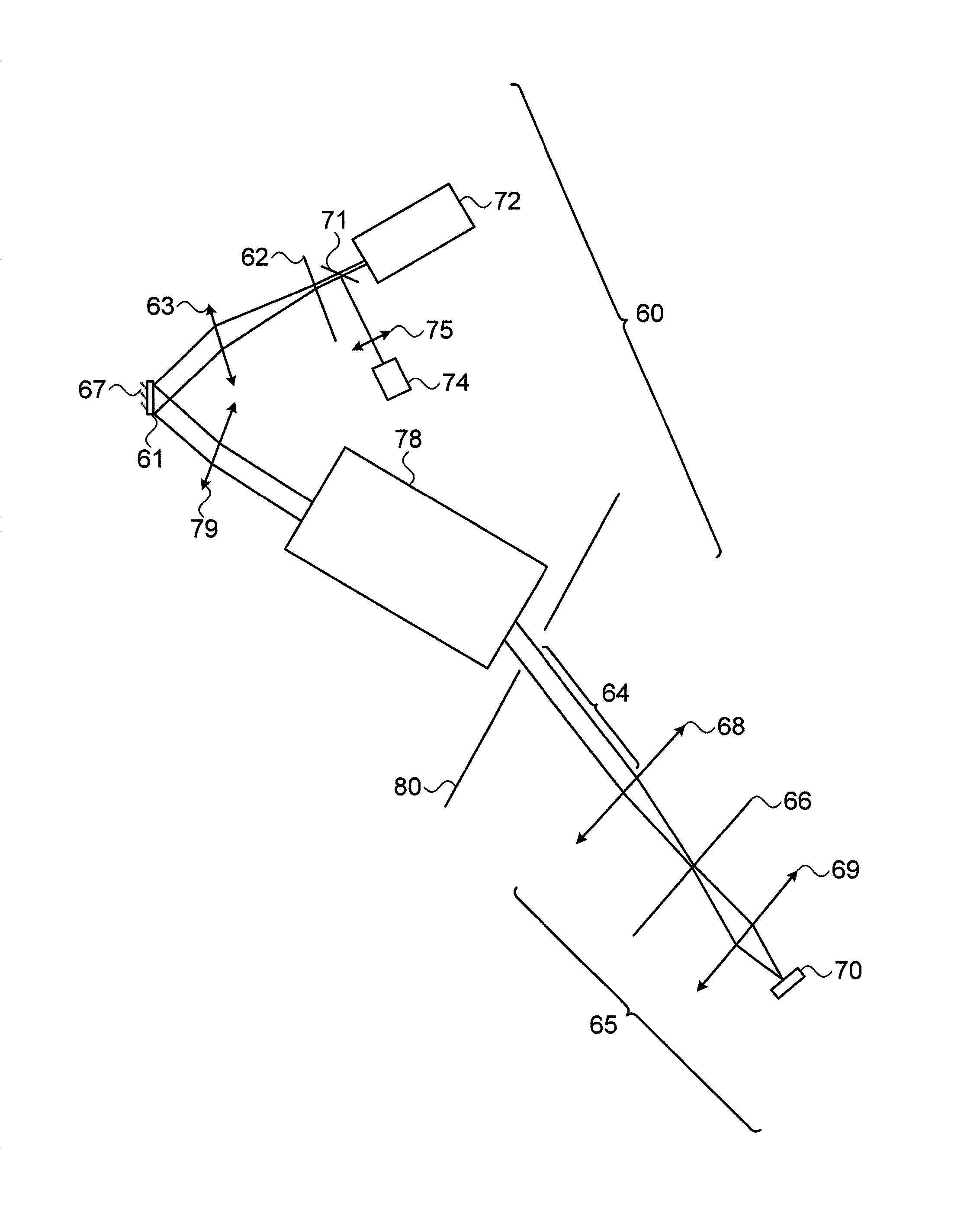

A distributed resonator laser system using retro-reflecting elements, in which spatially separated retroreflecting elements define respectively a power transmitting and a power receiving unit. The retroreflectors have no point of inversion, so that an incident beam is reflected back along a path essentially coincident with that of the incident beam. This enables the distributed laser to operate with the beams in a co-linear mode, instead of the ring mode described in the prior art. This feature allows the simple inclusion of elements having optical power within the distributed cavity, enabling such functions as focusing / defocusing, increasing the field of view of the system, and changing the Rayleigh length of the beam. The optical system can advantageously be constructed as a pupil imaging system, with the advantage that optical components, such as the gain medium or a photo-voltaic converter, can be positioned at such a pupil without physical limitations.

Owner:WI CHARGE

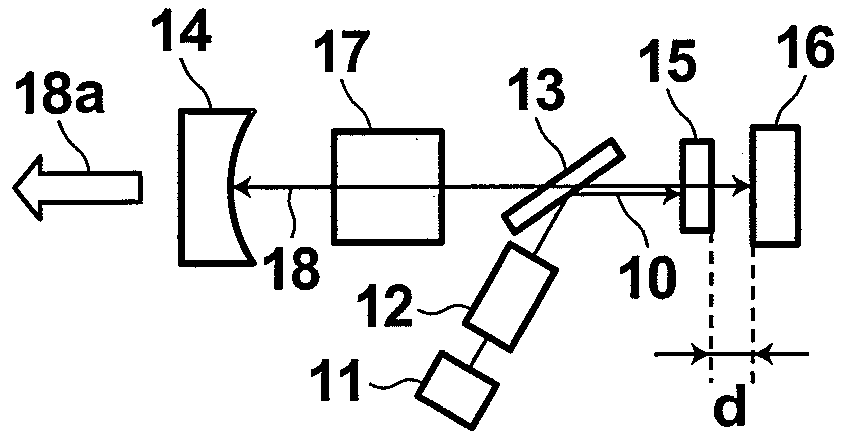

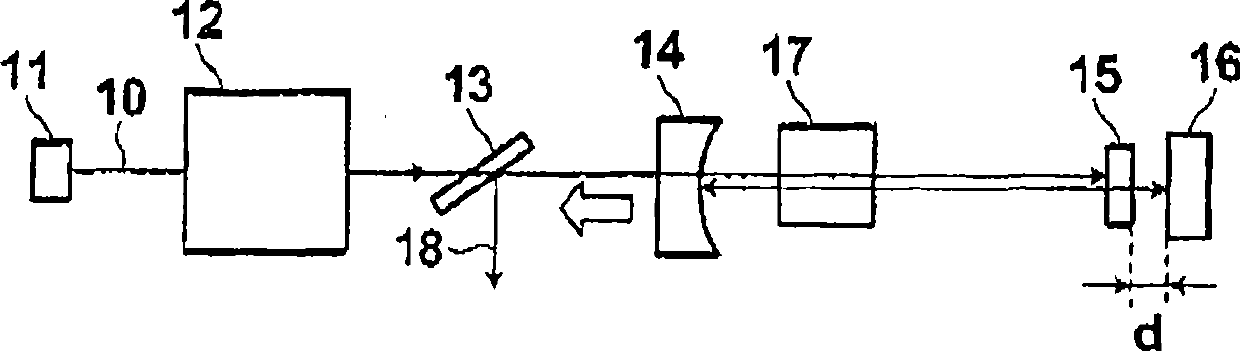

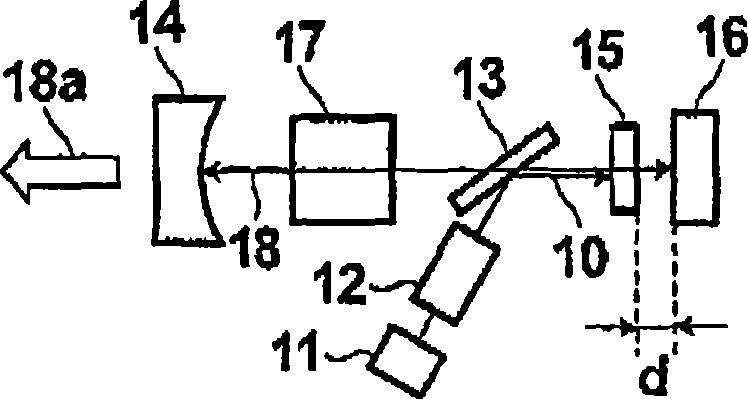

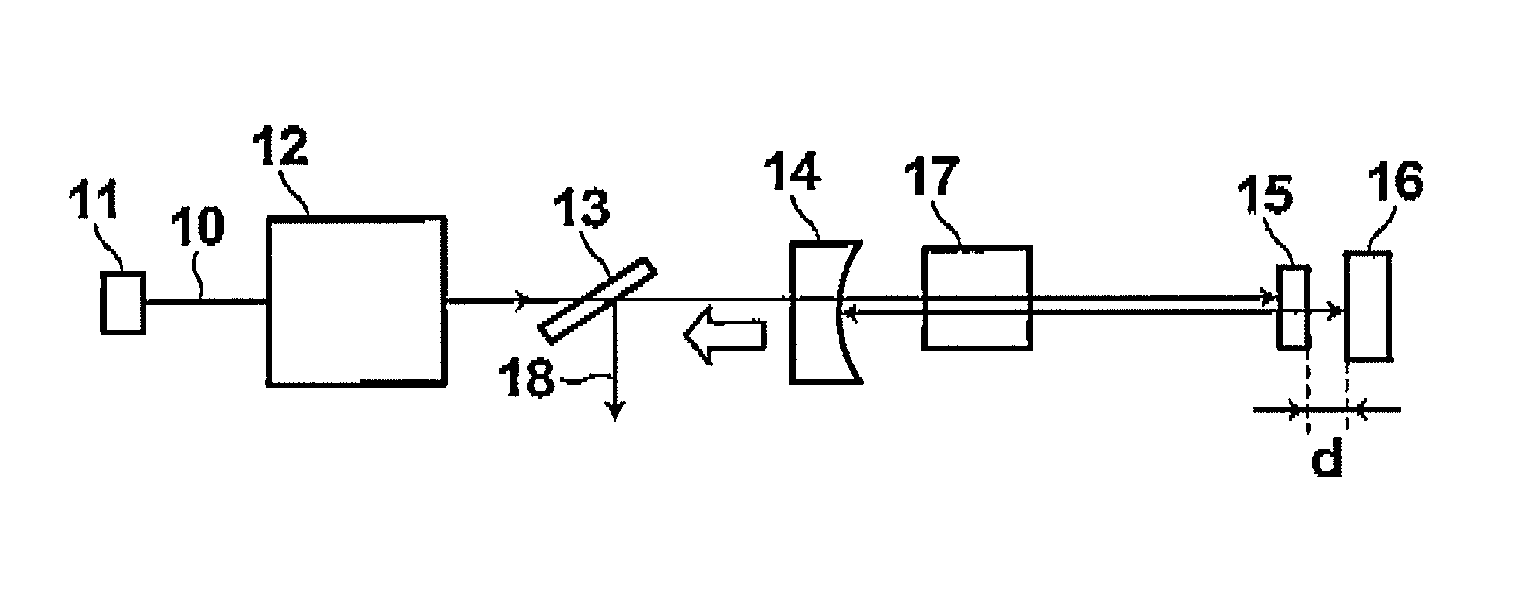

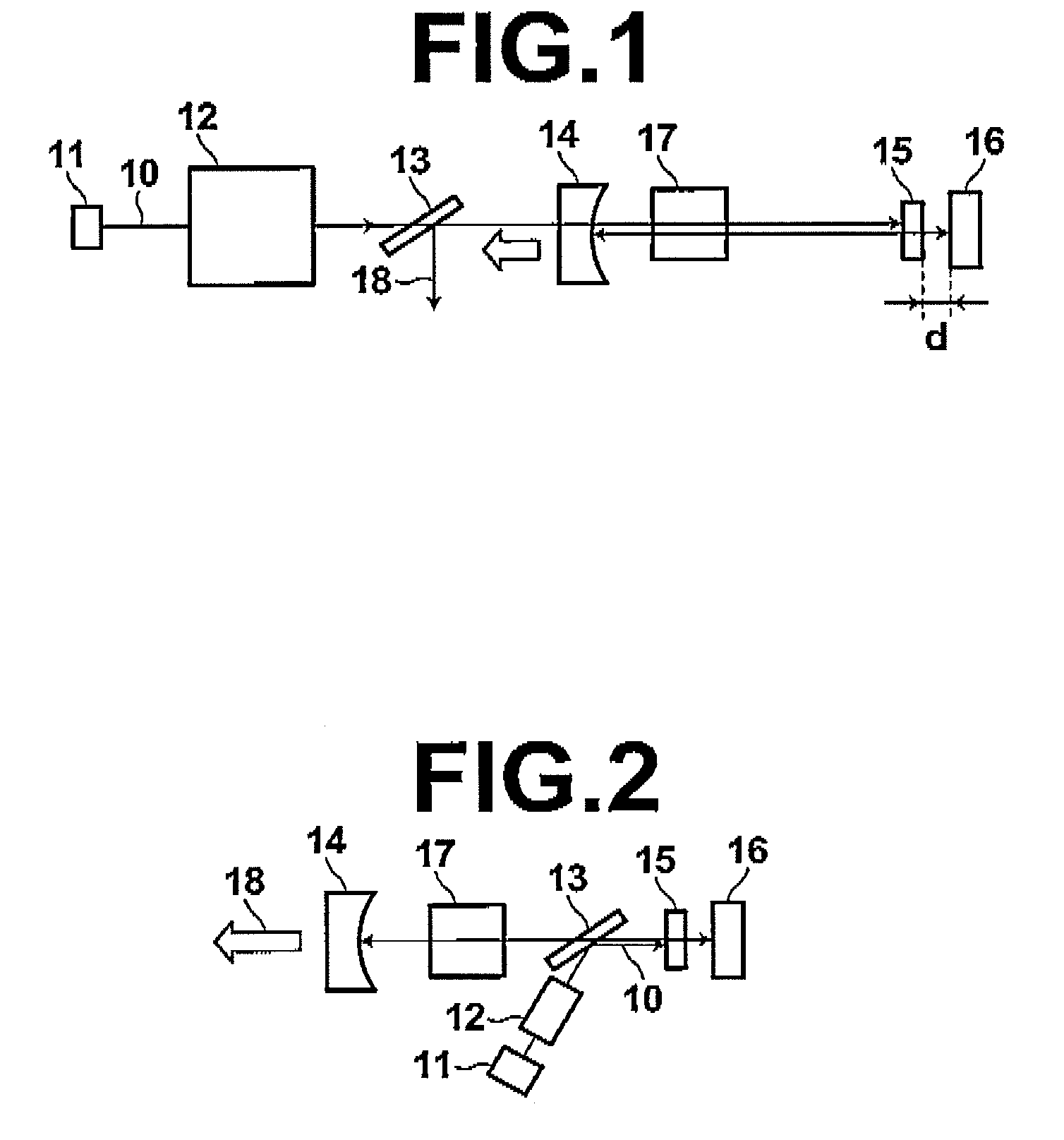

Mode-locked solid-state laser apparatus

InactiveUS20090086772A1Small and stable CW mode-locked laserReduce the numberOptical resonator shape and constructionSolid-state laser deviceGroup velocity dispersion

Owner:FUJIFILM CORP

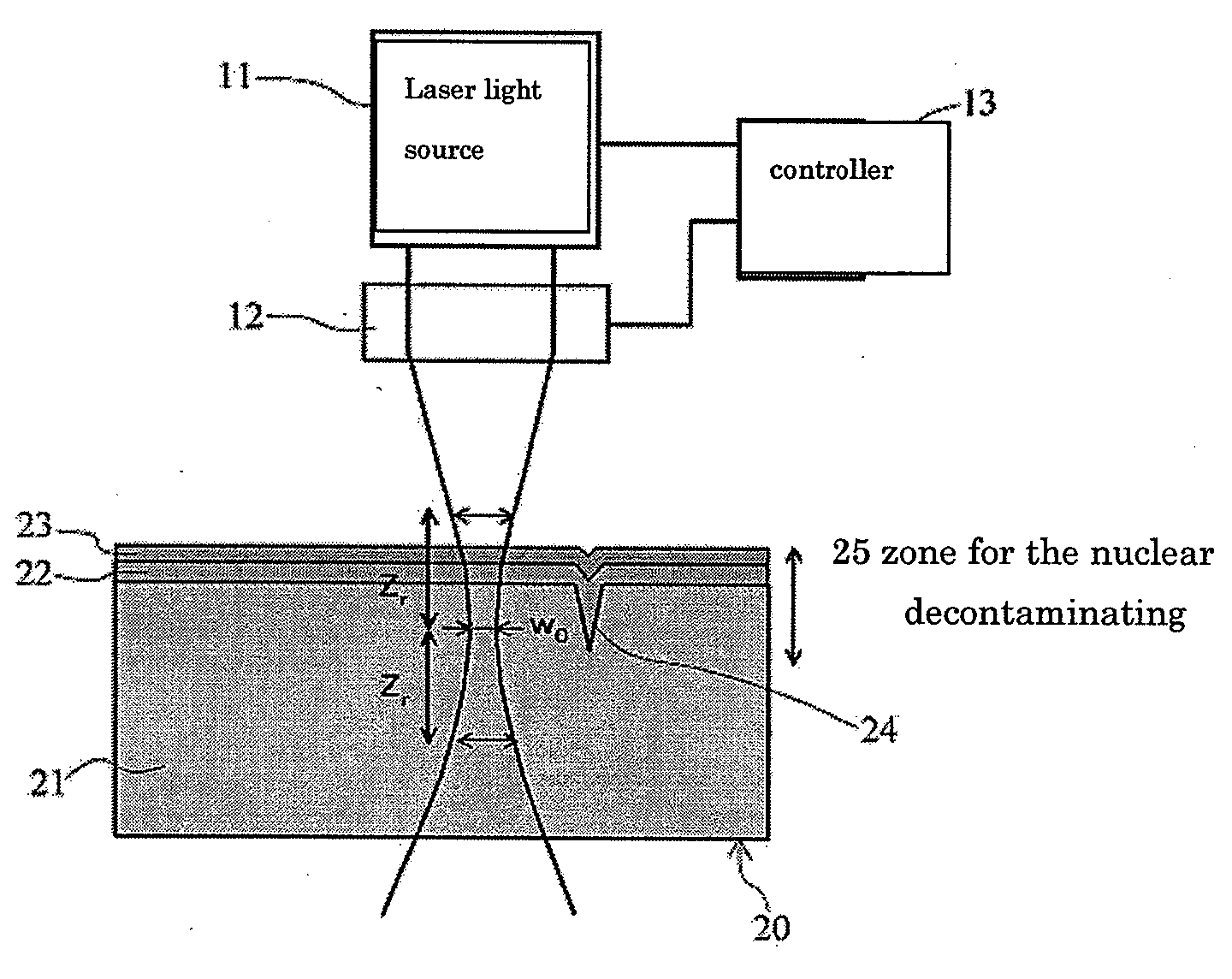

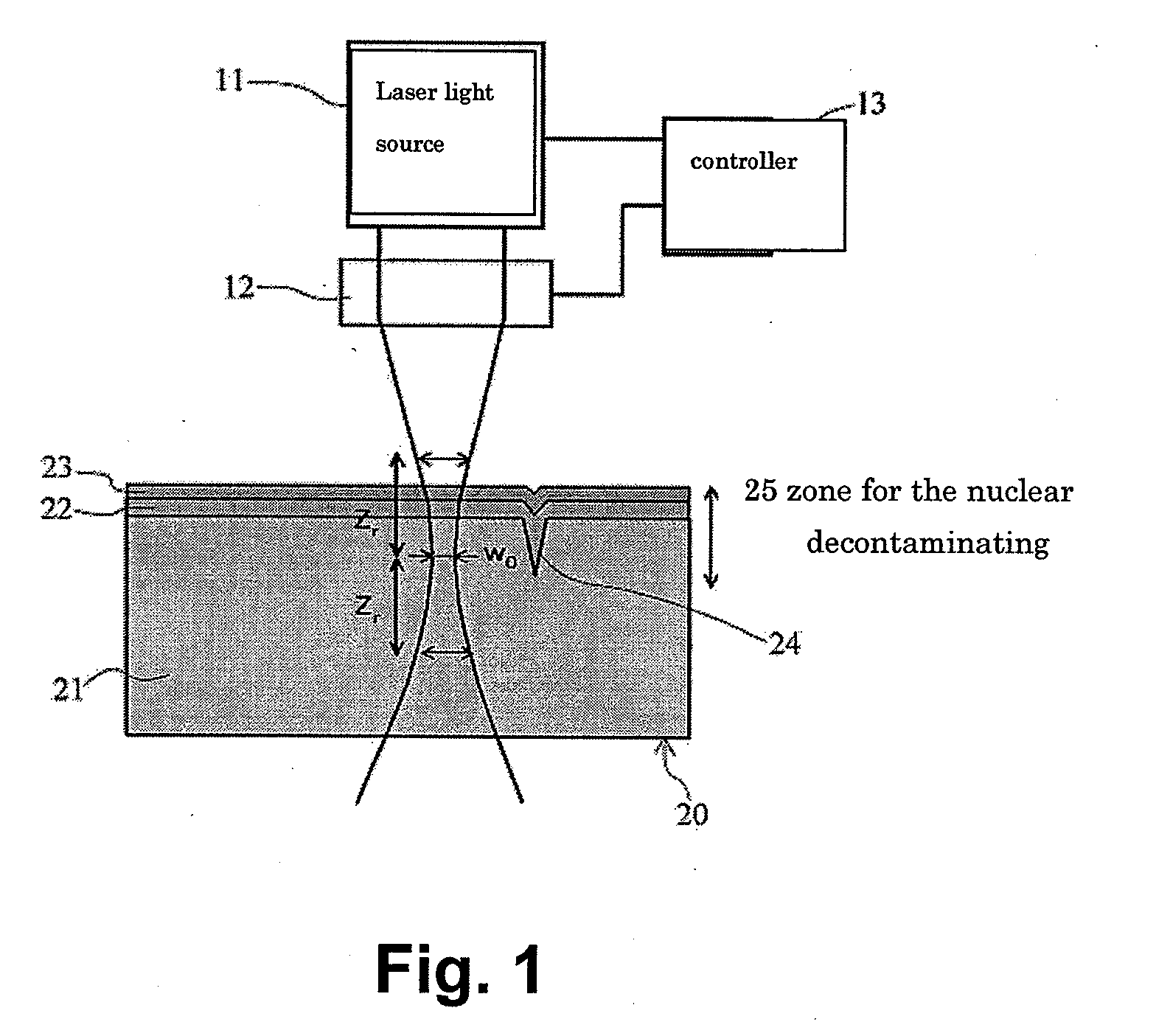

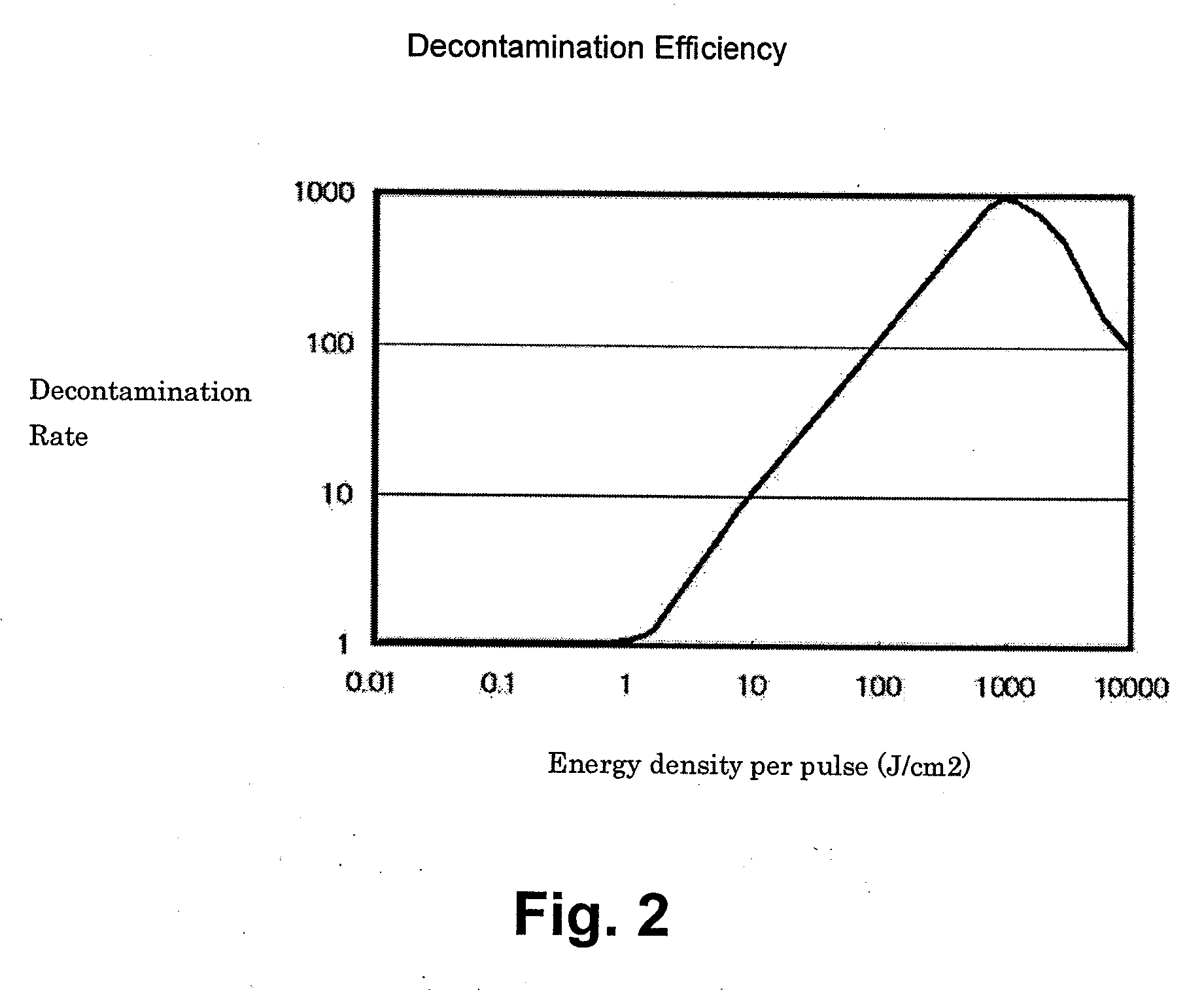

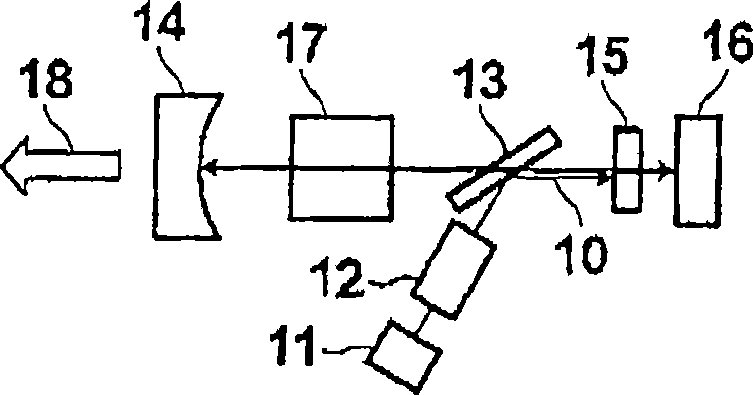

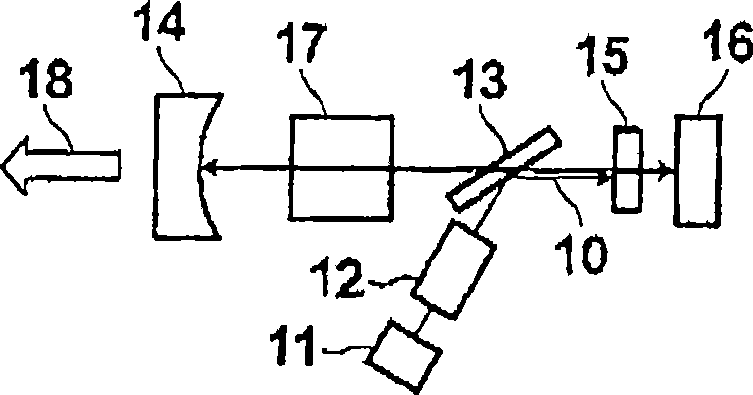

Nuclear decontamination device and a method of decontaminating radioactive materials

InactiveUS20100269851A1Effective decontaminationElectrostatic cleaningRadioactive decontaminationRadioactive agentVolumetric Mass Density

This is an efficient nuclear decontamination device using the laser light to remove the radioactive substance from the polluted parts of the radioactive object sample in the nuclear devices and facilities. In the nuclear decontamination device, the laser source (11) of the oscillator and amplifier system is used to irradiate on the surface (20) of the decontamination object sample through the condensing optics (12). The controller (13) optimizes the laser energy density on the surface by using both of the laser sources (11) and condensing optics (12). In the optimization, the energy density per pulse is controlled by optics system (12) of condensing within the range of 1 J / cm2-1000 J / cm2 in the surface of the decontamination object sample (20). Minimum beam spot size and Rayleigh length are chosen to keep the energy density per pulse in the above-mentioned range of the energy density.

Owner:MINEHARA EISUKE

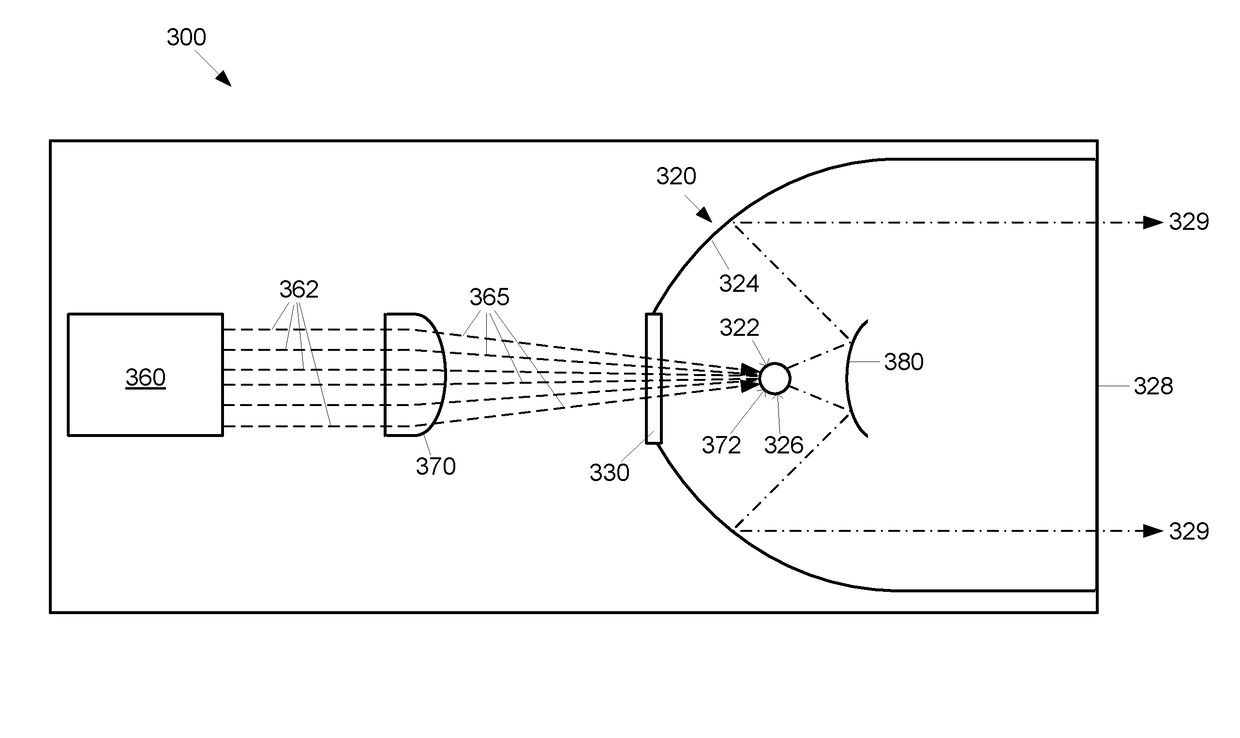

Electrodeless single low power CW laser driven plasma lamp

ActiveUS10057973B2Electric discharge tubesPhotomechanical exposure apparatusFull width at half maximumLaser light

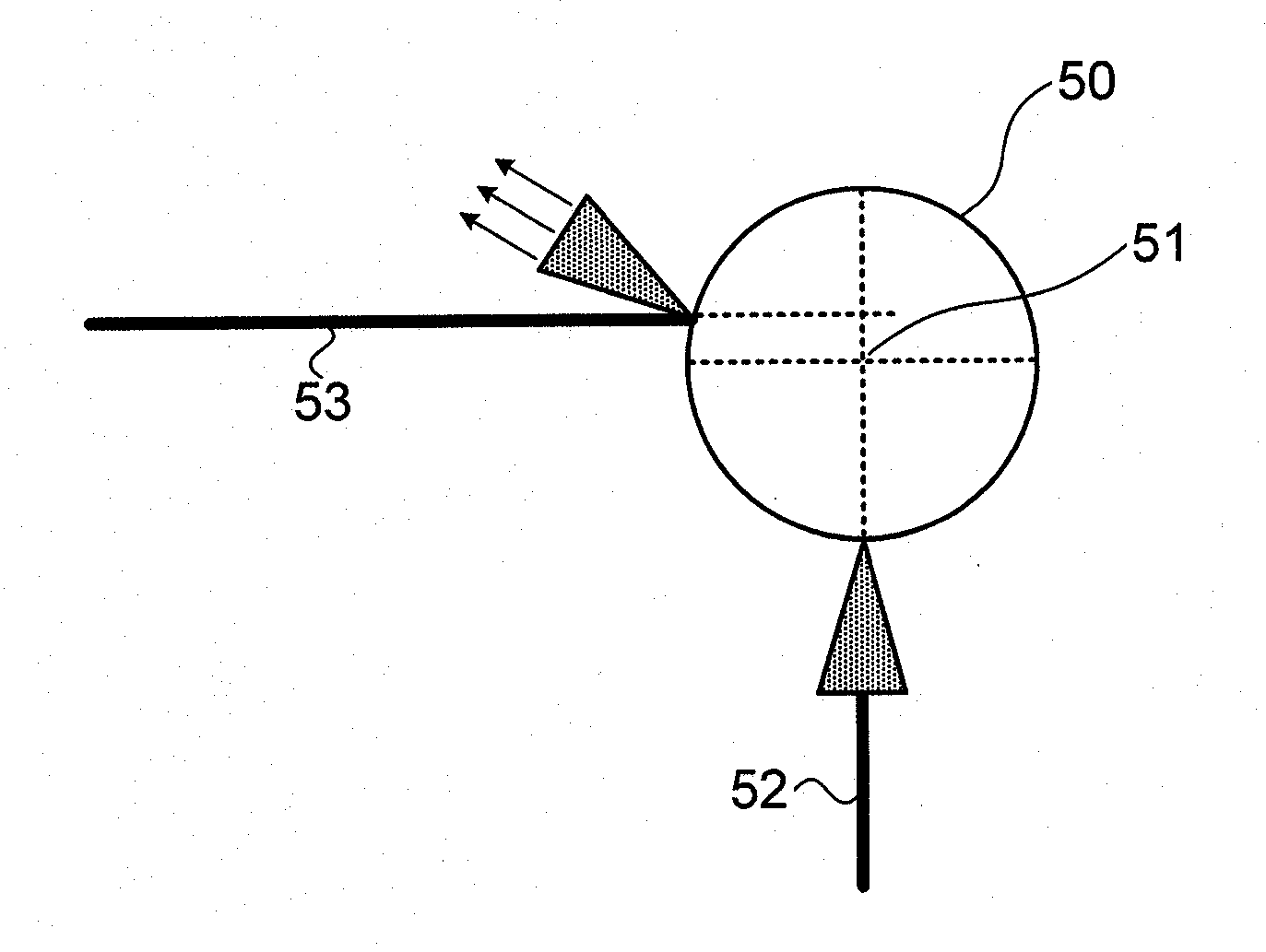

An ignition facilitated electrodeless sealed high intensity illumination device is configured to receive a laser beam from a continuous wave (CW) laser light source. A sealed chamber is configured to contain an ionizable medium. The chamber has an ingress window disposed within a wall of a chamber interior surface configured to admit the laser beam into the chamber, a plasma sustaining region, and a high intensity light egress window configured to emit high intensity light from the chamber. The CW laser beam is producible by a CW laser below 250 Watts configured to produce a wavelength below 1100 nm. The device is configured to focus the laser beam to a full width at half maximum (FWHM) beam waist of 1-15 microns2 and a Rayleigh length of 6 microns or less, and the plasma is configured to be ignited by the CW laser beam.

Owner:EXCELITAS TECH

Mode-locked solid-state laser apparatus

InactiveUS20090116516A1Small sectionLow costOptical resonator shape and constructionSolid-state laser deviceOptical axis

A mode-locked solid-state laser apparatus having a resonator which includes a solid-state laser medium, a saturable absorption mirror, and a negative group dispersion element therein, in which the solid-state laser medium and the saturable absorption mirror are disposed at a distance not greater than twice a Rayleigh length which is determined by the beam radius of oscillation light formed at the saturable absorption mirror. The apparatus further includes a dichroic mirror in the resonator that reflects excitation light inputted from a direction crossing the optical axis of the resonator toward the solid-state laser medium and transmits oscillation light.

Owner:FUJIFILM CORP

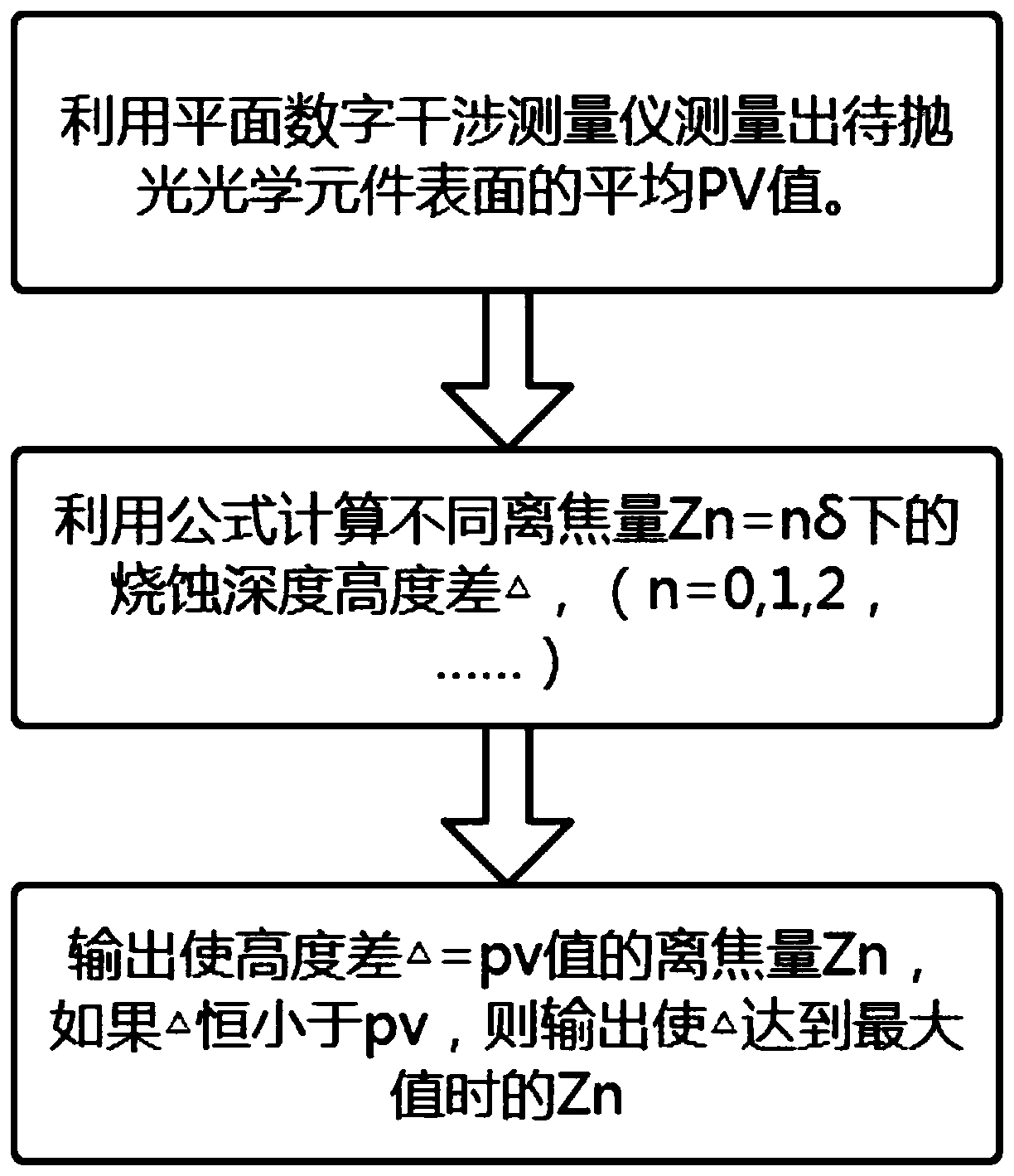

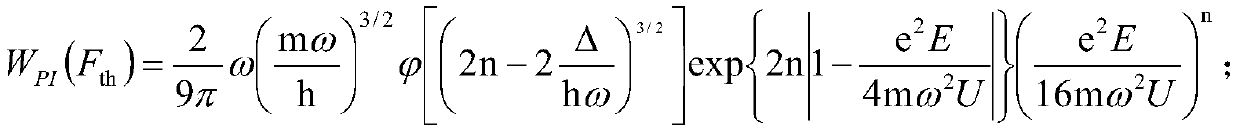

Method for determining laser defocusing amount in femtosecond laser polishing process of optical element

PendingCN111368243AImprove efficiencyImprove accuracyLaser beam welding apparatusComplex mathematical operationsFemto second laserMathematical model

The invention discloses a method for determining the laser defocusing amount in the femtosecond laser polishing process of an optical element, which belongs to the technical field of mechanical precision manufacturing engineering, and comprises the following steps of: outputting laser wavelength and focusing spot radius by using a femtosecond laser, and calculating Rayleigh length of a light beam;calculating the energy density when the laser reaches the surface of the material by utilizing the output pulse energy of the laser to focus the spot radius and the defocusing amount; calculating theablation depth of the surface of the energy material by using a femtosecond laser ablation rate mathematical model; solving the ablation depth of the femtosecond laser to the material under differentdefocusing amounts according to the laser ablation rate mathematical model; measuring the average value of the surface of the to-be-polished optical element, and determining the optimal polishing defocusing amount by substituting the height difference of the wave crest and the wave trough into calculation. The defocusing amount of femtosecond laser polishing can be rapidly, efficiently and accurately determined, the cost is low, the efficiency is high, and the accuracy is high.

Owner:TIANJIN UNIV

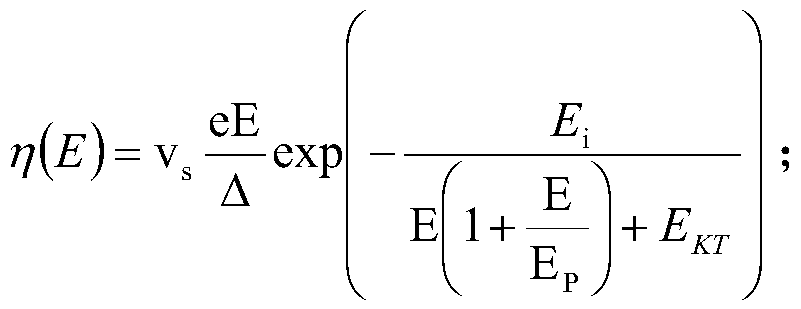

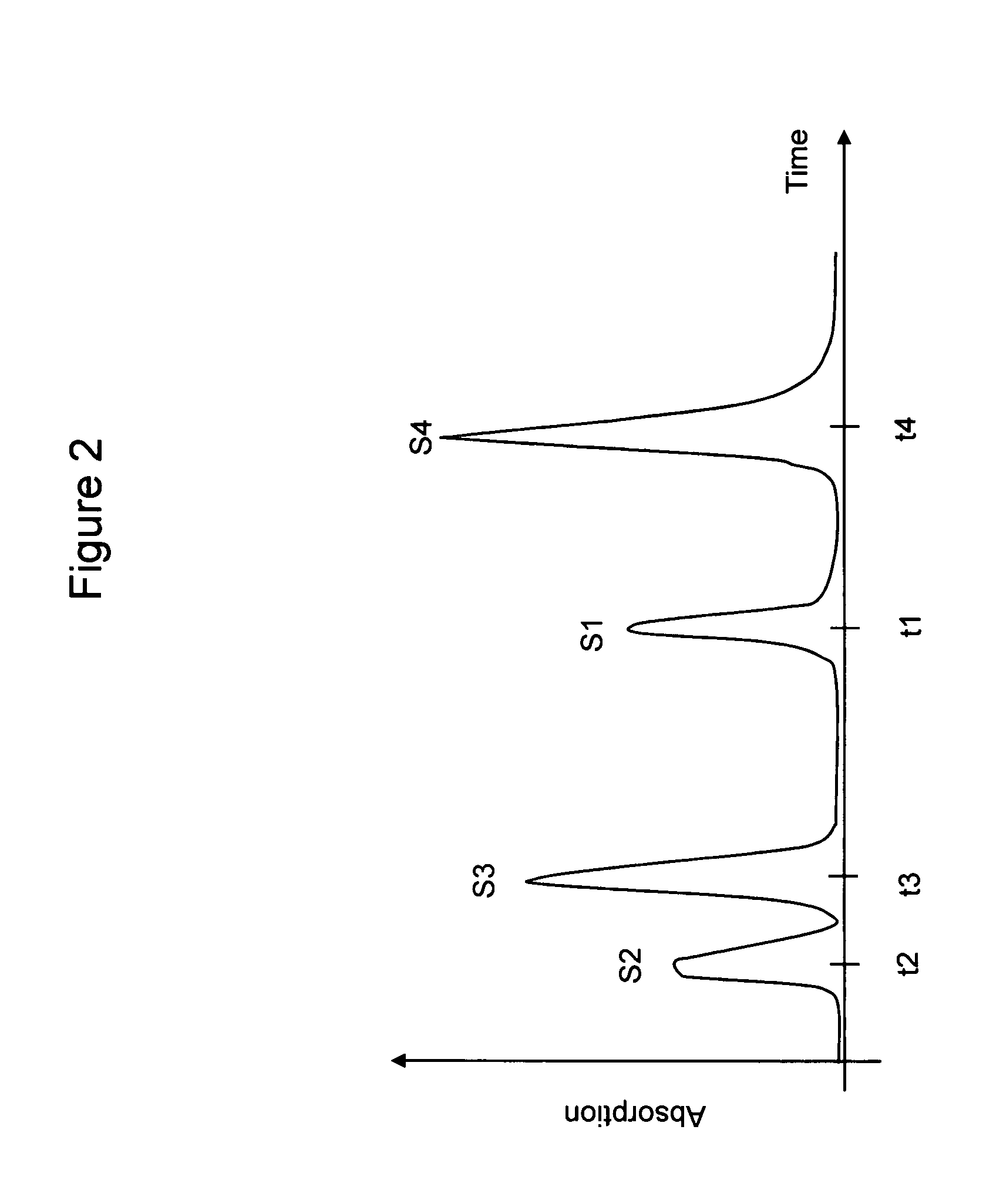

Thermal lens spectroscopy for ultra-sensitive absorption measurement

A thermal lens detection apparatus comprising: i) an optical cell for containing at least one target analyte present in a carrier liquid, ii) a probe beam having a pre-determined wavelength, iii) an excitation beam having a pre-determined wavelength shorter than that of the probe beam and a Rayleigh length approximately equal to the radius of said optical cell, the beam axis of said probe beam and the beam axis of said excitation beam being at an angle to each other but both the probe beam and excitation beam being focusable so that their beams overlap in the interior portion of the optical cell, iv) a signal photo-detector for receiving at least a portion of said probe beam signal after its passage through said optical cell, and iv) an optical cutoff filter which blocks the excitation beam from impinging on said signal photo-detector.

Owner:FINESSE SOLUTIONS

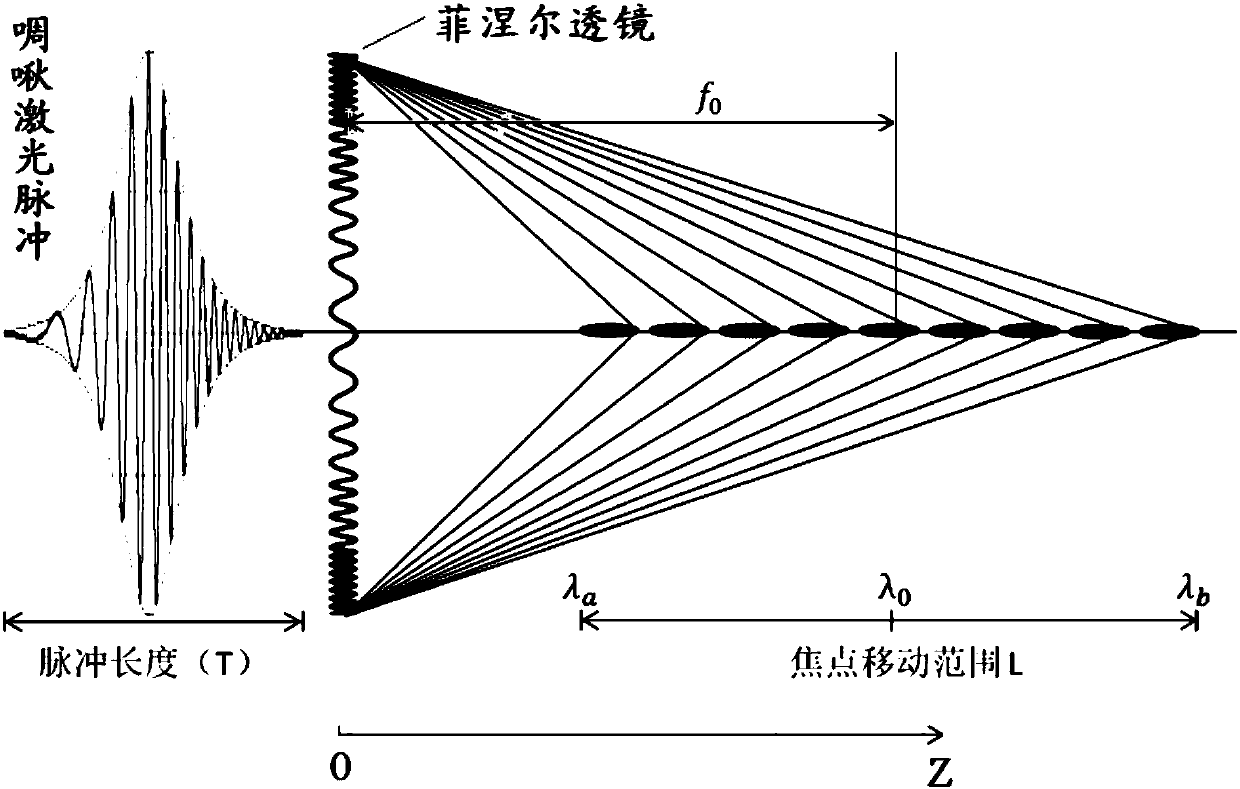

System and method for generating teraHertz wave by using flight focusing

ActiveCN108054623AHigh strengthControl spreadLaser detailsSolid masersComputational physicsHigh intensity

The invention discloses a system and method for generating teraHertz waves by using flight focusing, wherein the system for generating the teraHertz waves by using the flight focusing comprises a chirped signal generating device and a flight focusing device, wherein the chirped signal generating device is used for generating chirped laser pulse; the flight focusing device uses a diffraction element for focusing the chirped laser pulse so as to stimulate and generate air plasma and to further generate the teraHertz waves. The chirped laser pulse and the diffraction element are combined by the system and method for generating teraHertz waves by using flight focusing provided by the invention, so that the moving speed of the peak value intensity of the laser focus point region is controlled;the propagation of the laser light beams in the focusing regions can be controlled; in addition, the propagation length is many times of the Rayleigh length. Compared with the existing method for generating the teraHertz waves by the air, the method provided by the invention has the advantages that the intensity of the teraHertz waves generated by the method is greatly enhanced; the blank in the technical field of the existing high-intensity teraHertz wave generation is filled; high scientific research and practical application values are realized.

Owner:CAPITAL NORMAL UNIVERSITY

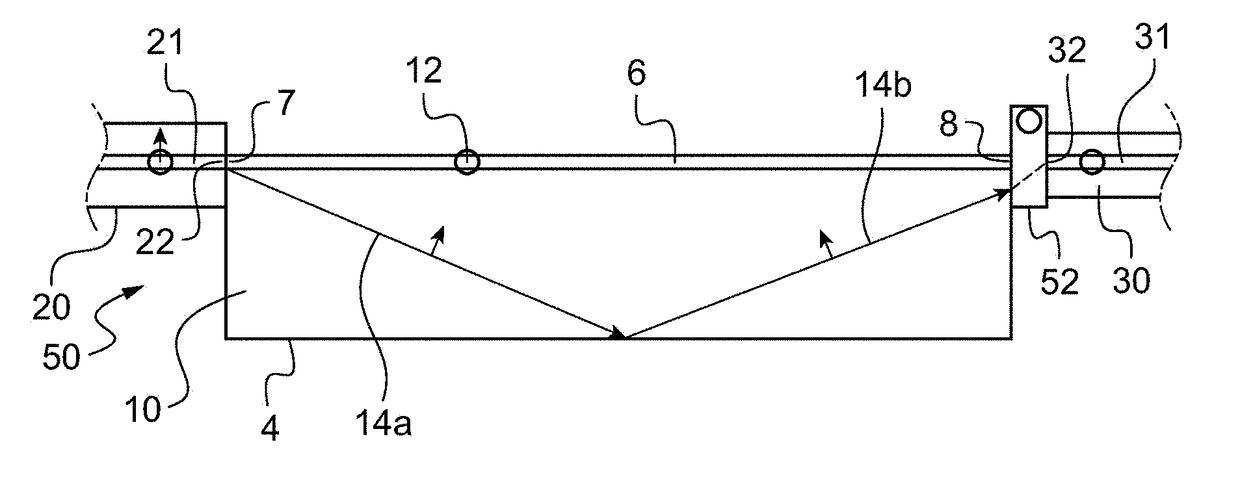

Spatially distributed laser resonator

ActiveUS9225140B2Optical resonator shape and constructionActive medium materialElectric power transmissionPupil

A distributed resonator laser system using retro-reflecting elements, in which spatially separated retroreflecting elements define respectively a power transmitting and a power receiving unit. The retroreflectors have no point of inversion, so that an incident beam is reflected back along a path essentially coincident with that of the incident beam. This enables the distributed laser to operate with the beams in a co-linear mode, instead of the ring mode described in the prior art. This feature allows the simple inclusion of elements having optical power within the distributed cavity, enabling such functions as focusing / defocusing, increasing the field of view of the system, and changing the Rayleigh length of the beam. The optical system can advantageously be constructed as a pupil imaging system, with the advantage that optical components, such as the gain medium or a photo-voltaic converter, can be positioned at such a pupil without physical limitations.

Owner:WI CHARGE

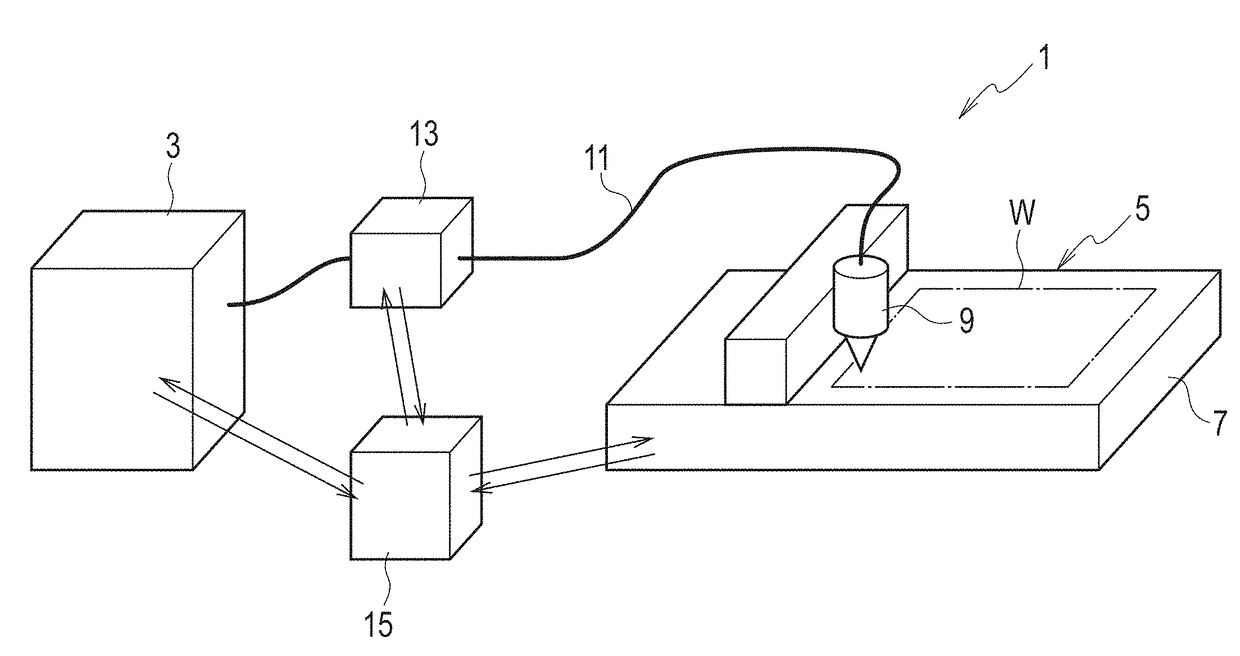

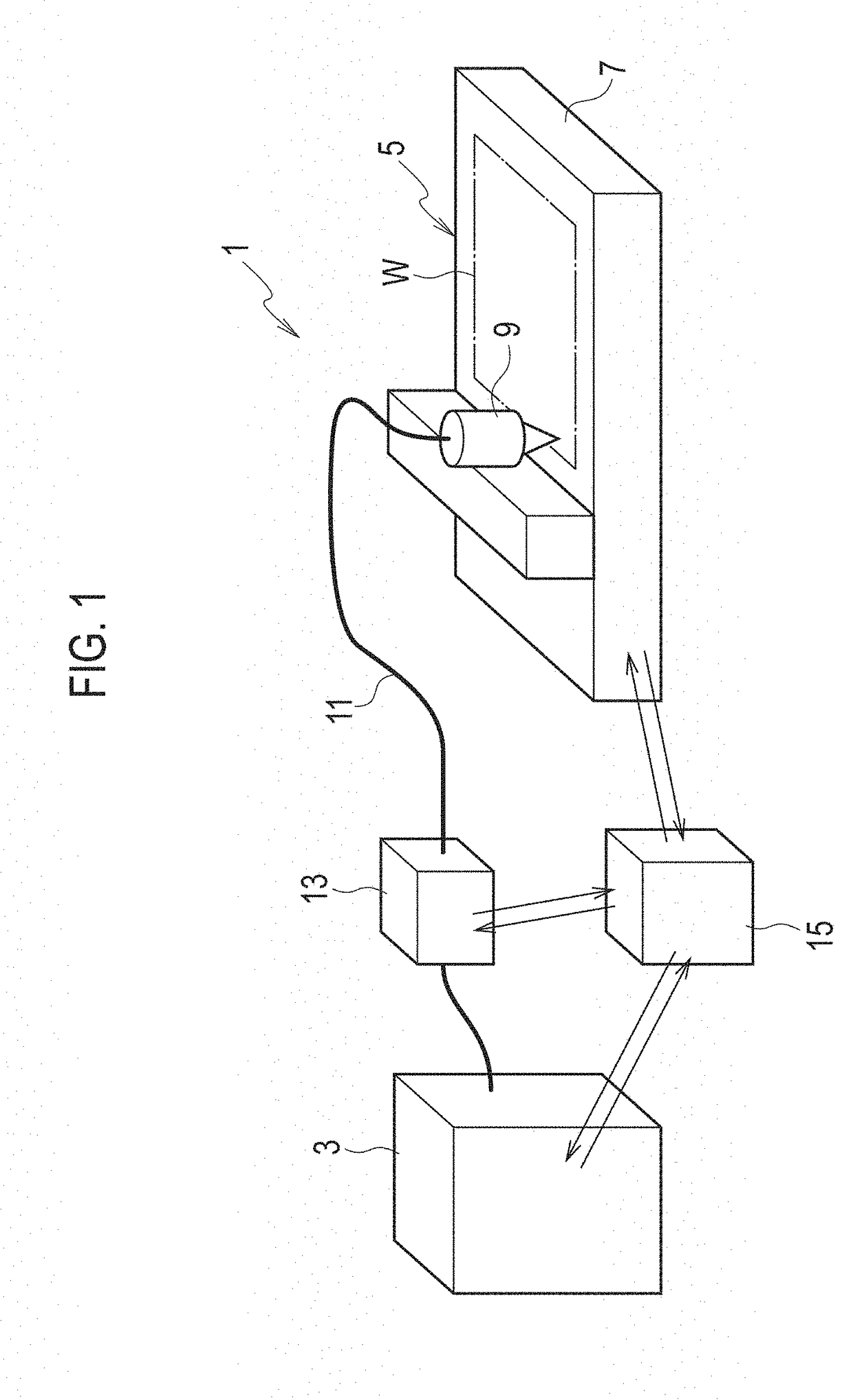

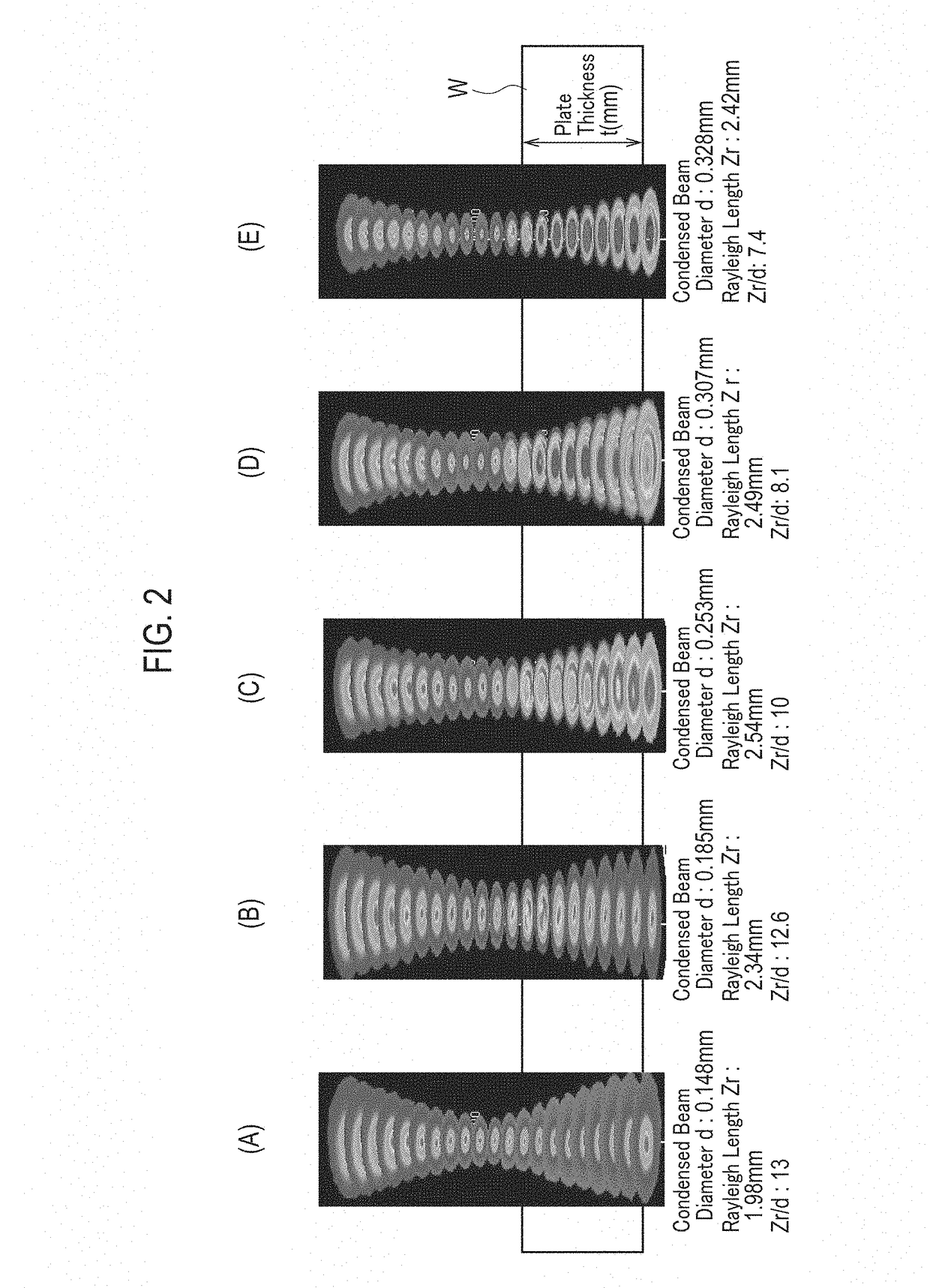

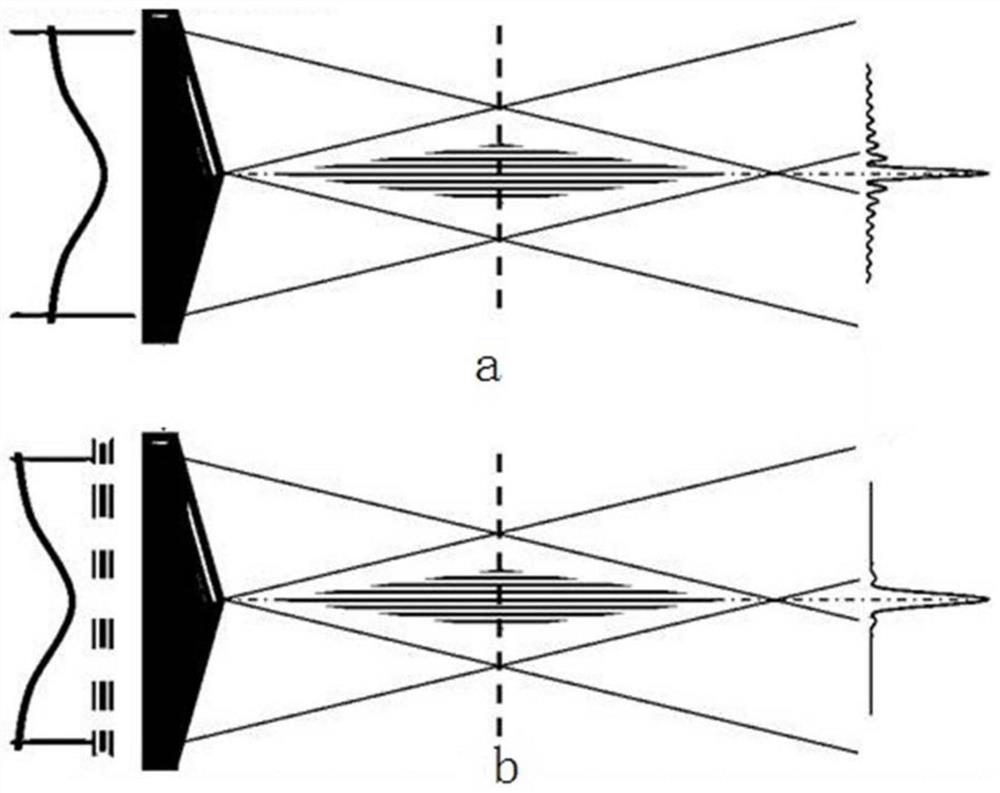

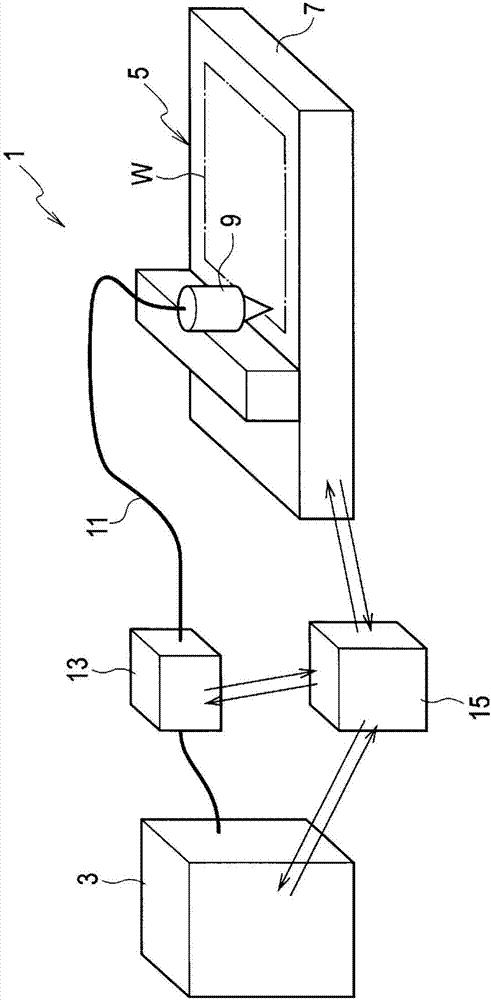

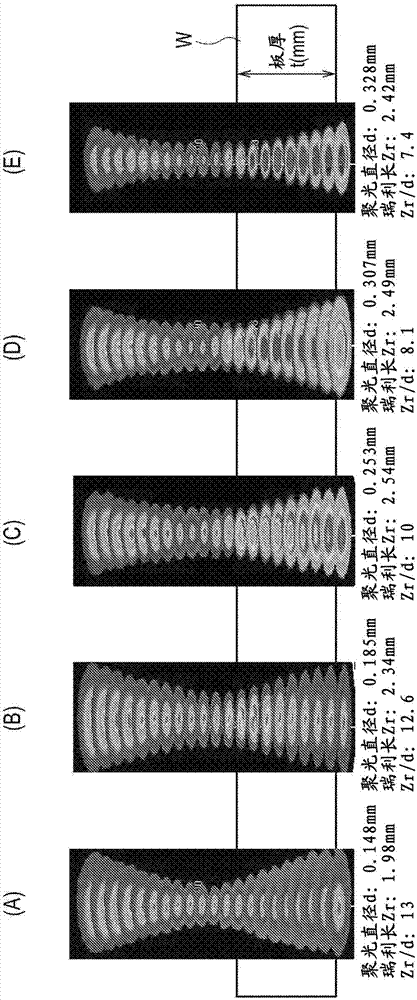

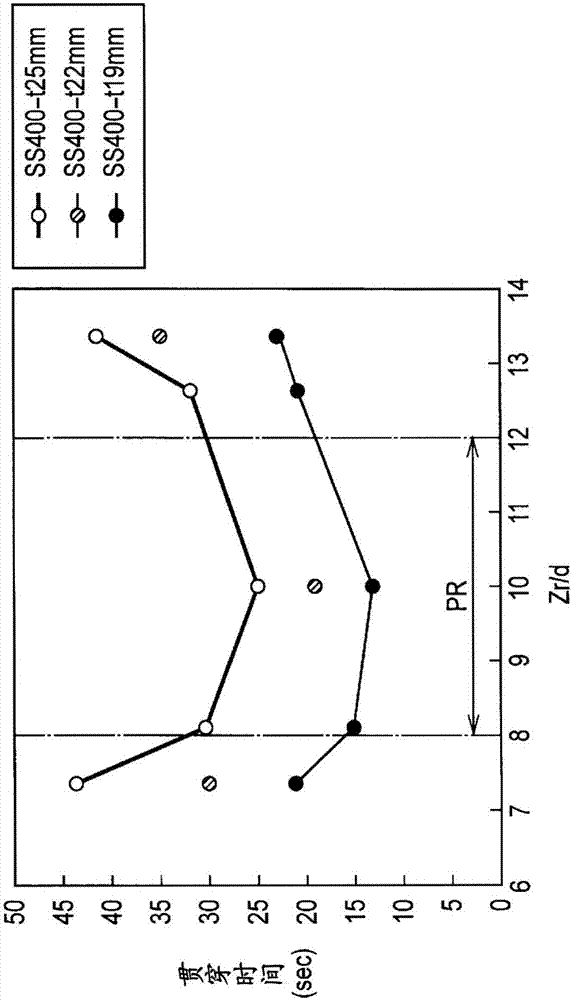

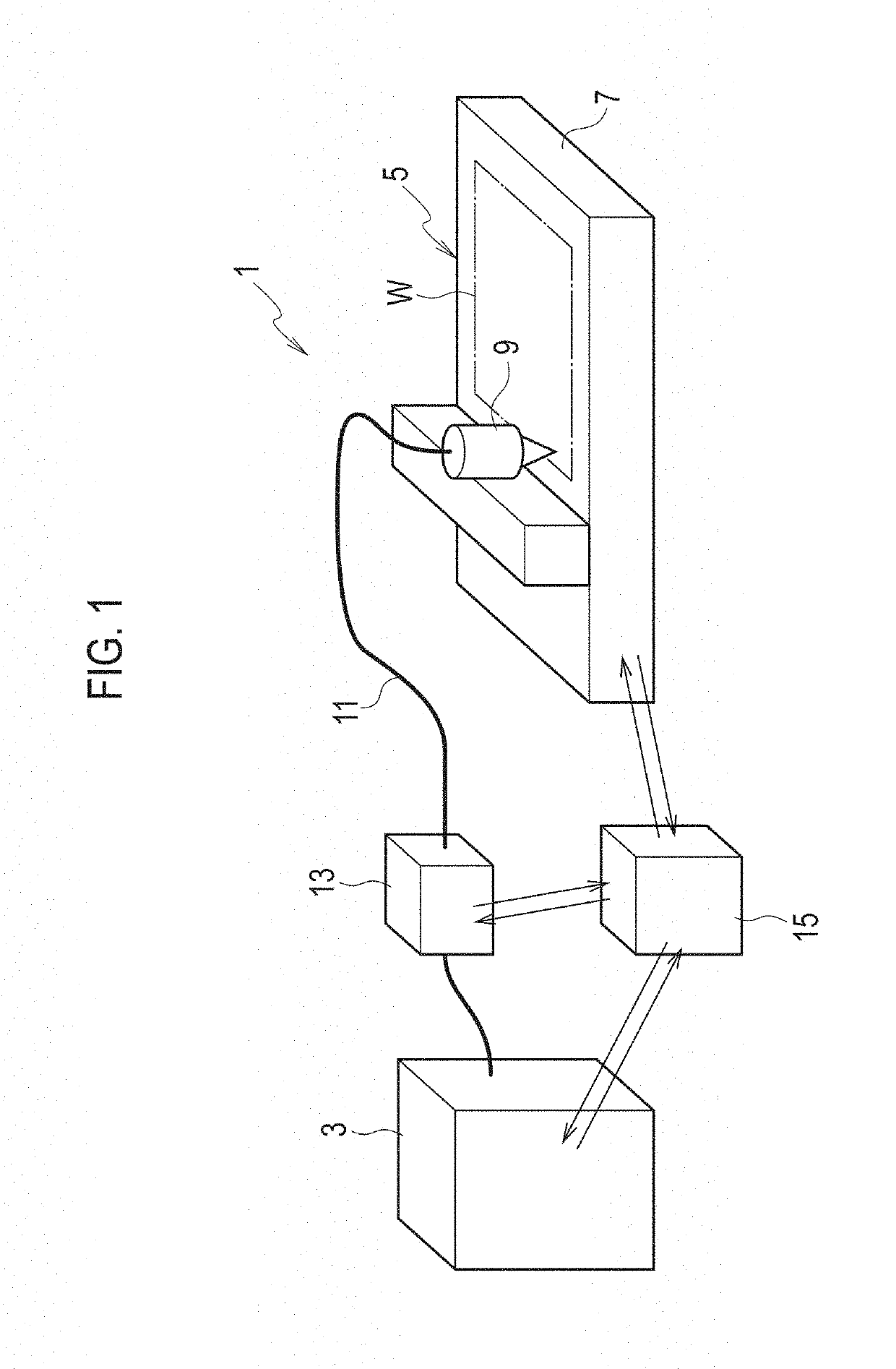

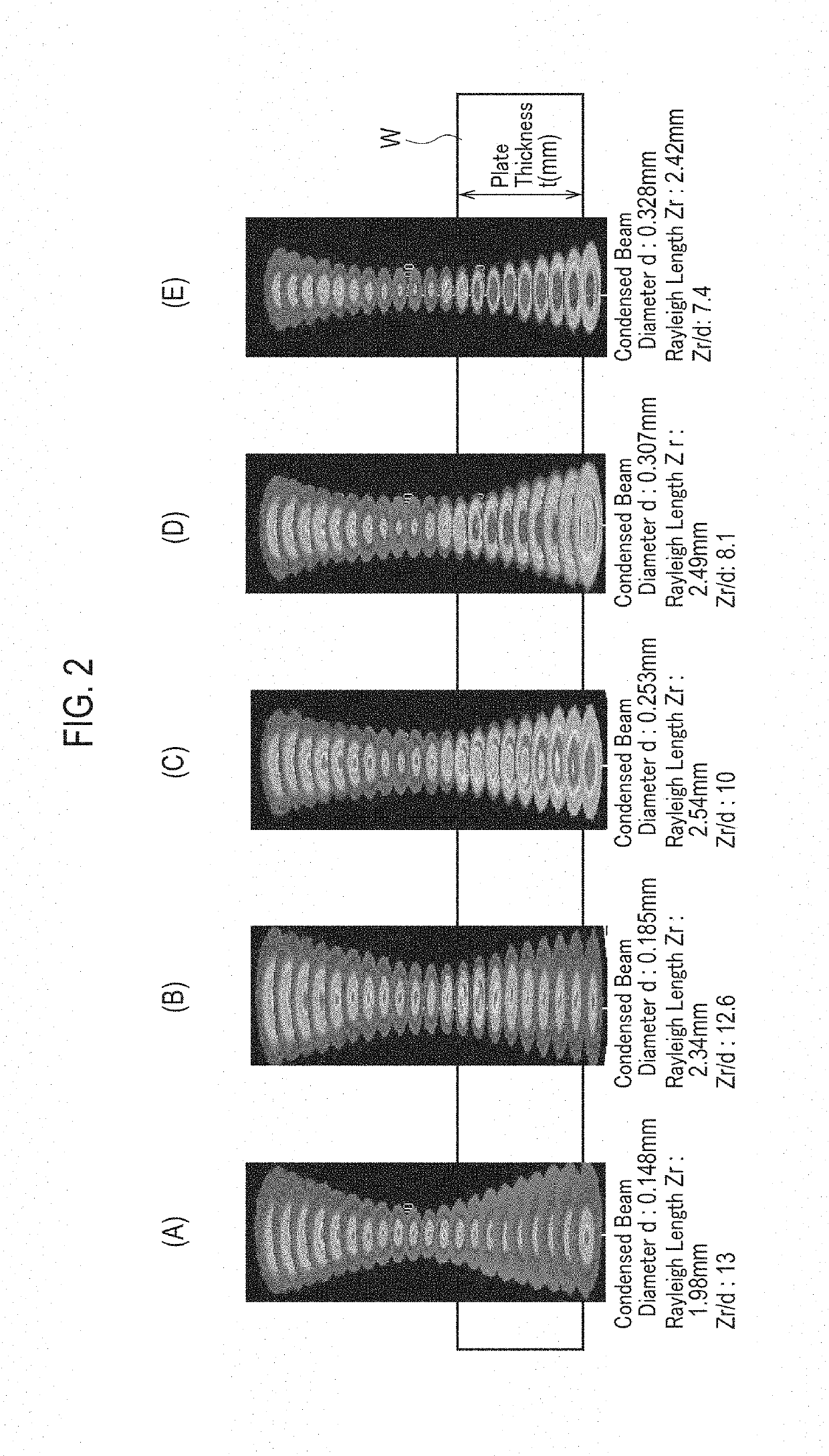

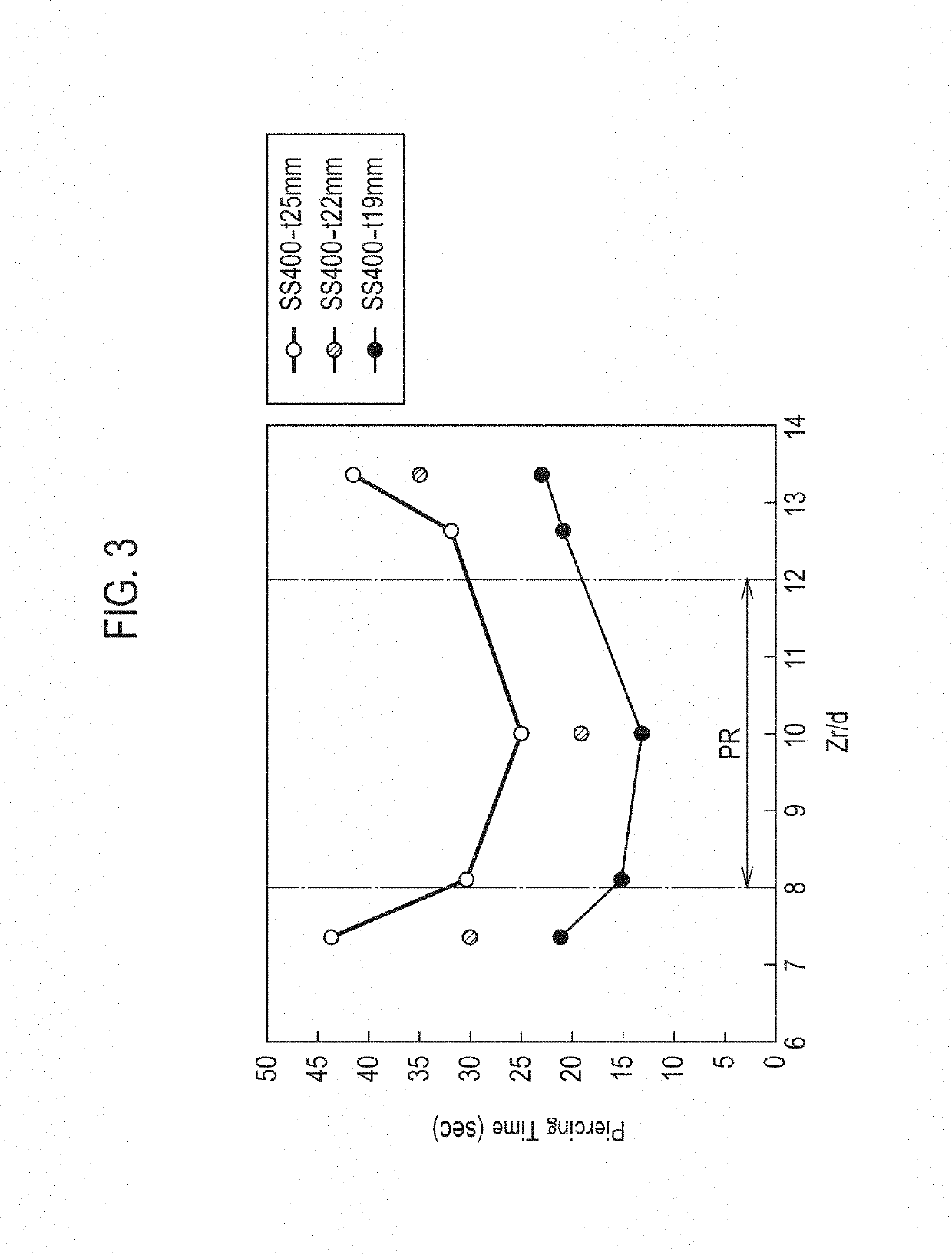

Piercing processing method and laser processing machine

A piercing processing method and a laser processing machine capable of carrying out a piercing processing on a thick plate in short time are provided. It is a processing method for carrying out a piercing processing on a metallic material by laser beams with wavelengths in 1 μm band, where the piercing processing is carried out by maintaining a range of 8≦Zr / d≦12 when a condensed beam diameter of the laser beams is set to be d and a Rayleigh length of the laser beams is set to be Zr. At that time, a focal position of the laser beams is set to be on a surface of a workpiece or an external of the workpiece. Then, a beam profile of the laser beams is such that the laser beams of a single mode are converted into a bowler hat shape by a beam quality tunable device.

Owner:AMADA HLDG CO LTD

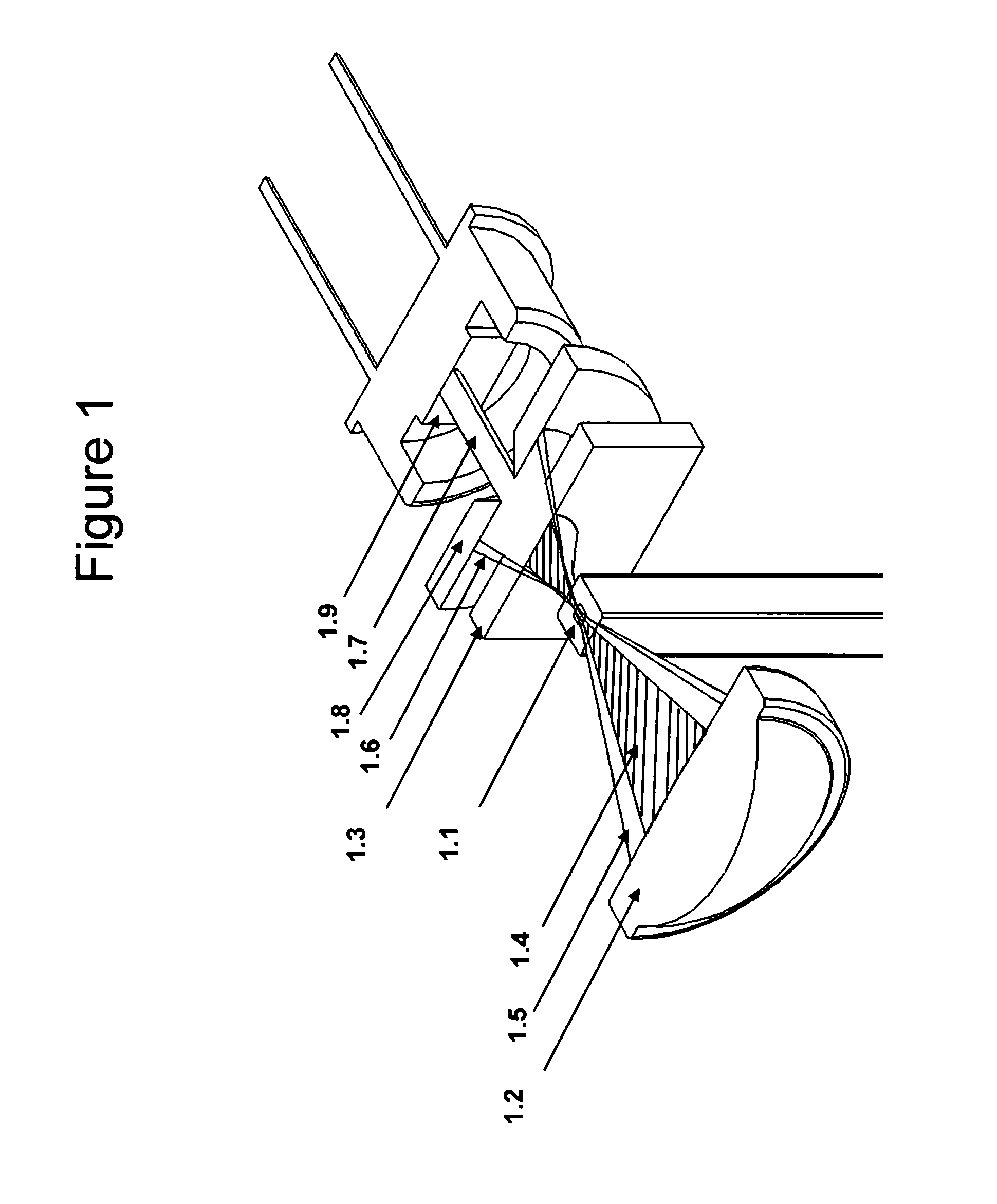

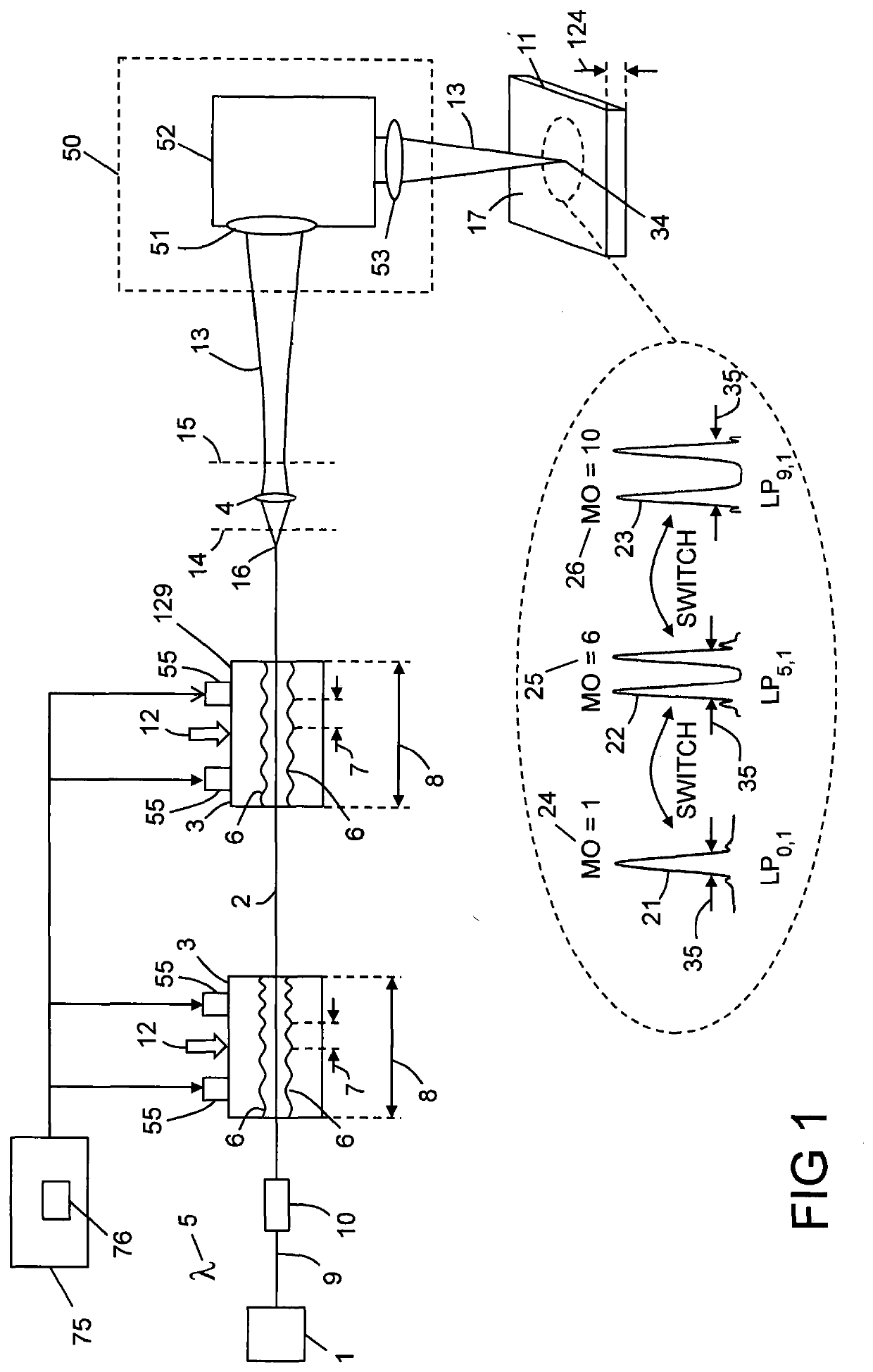

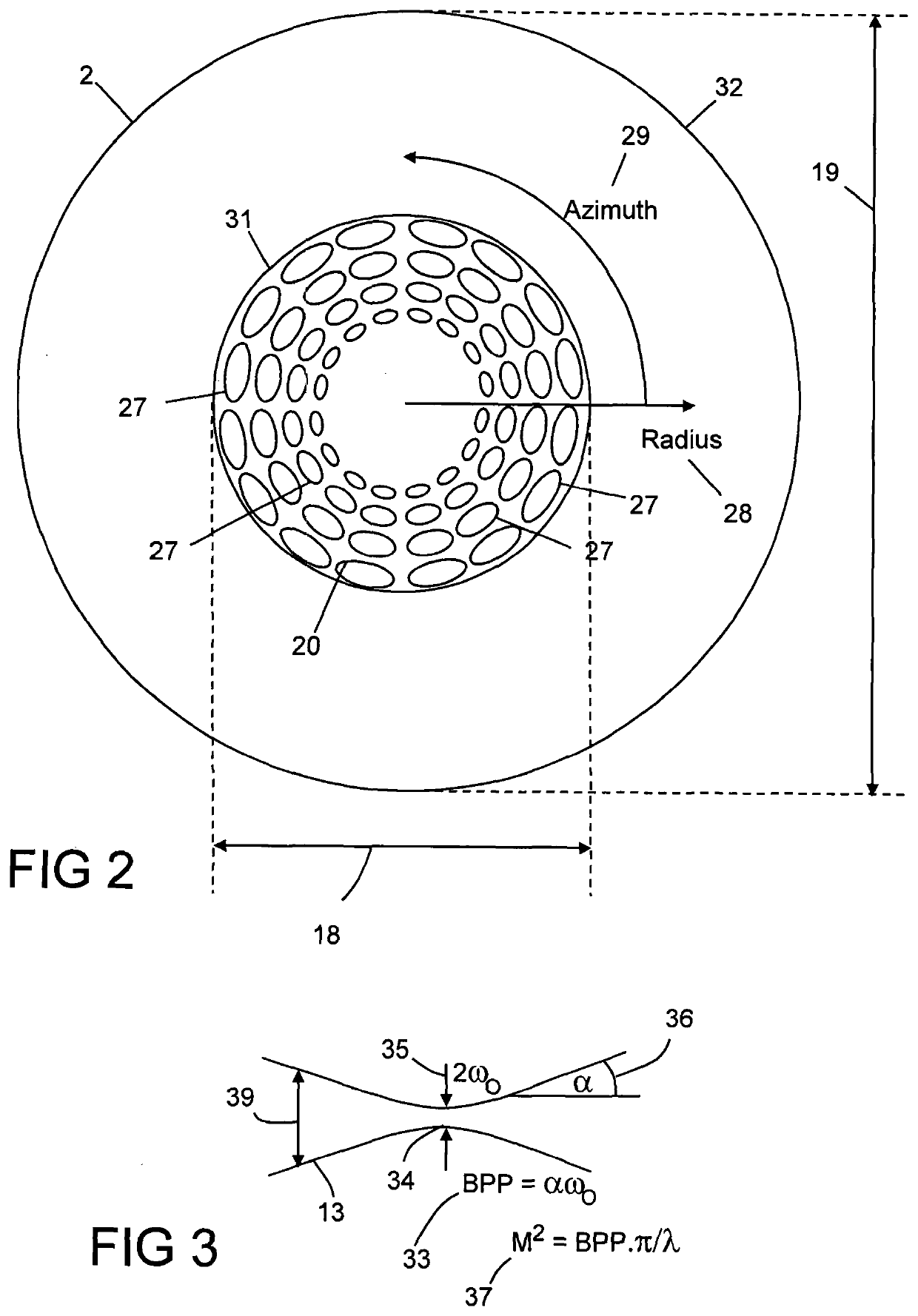

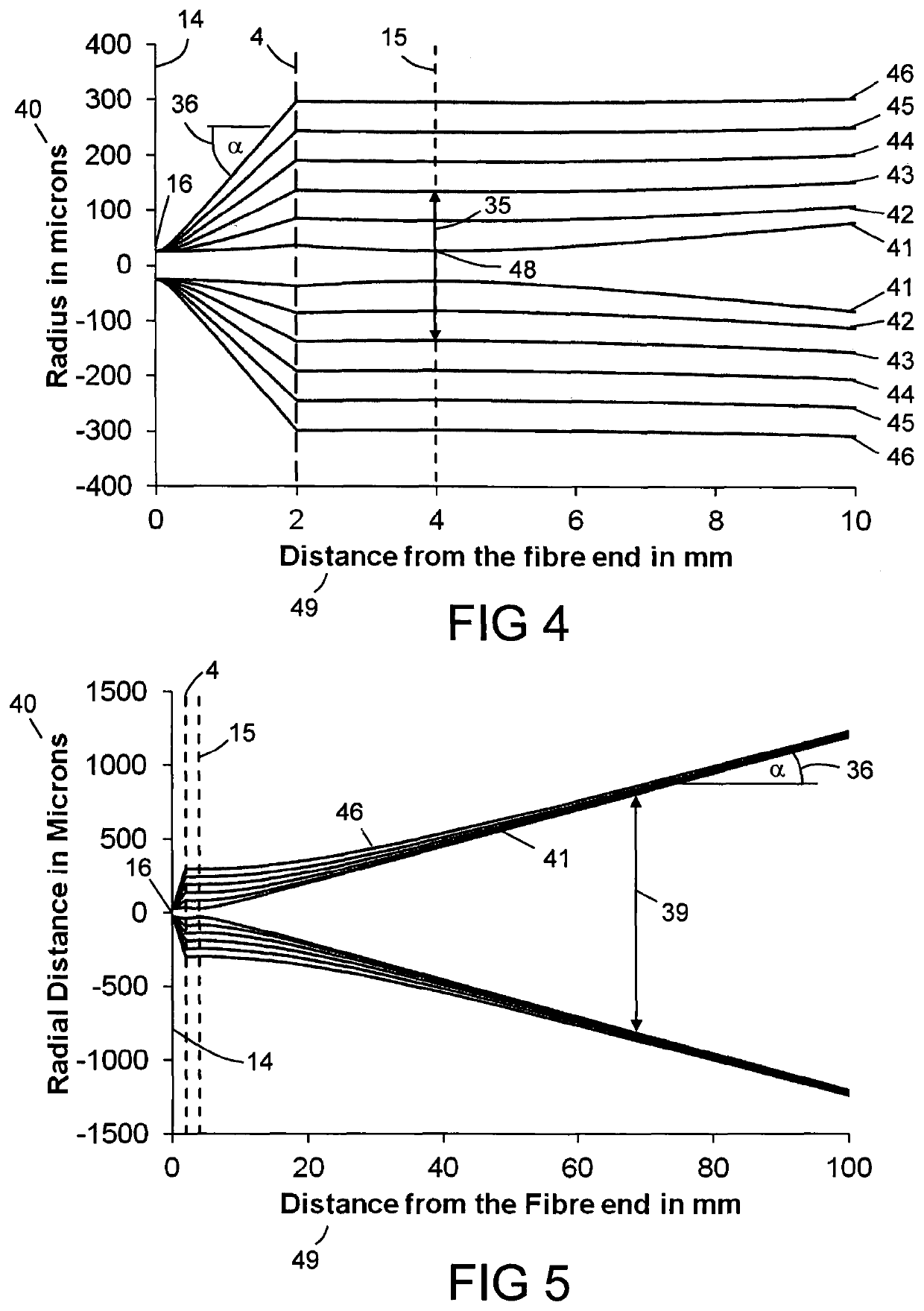

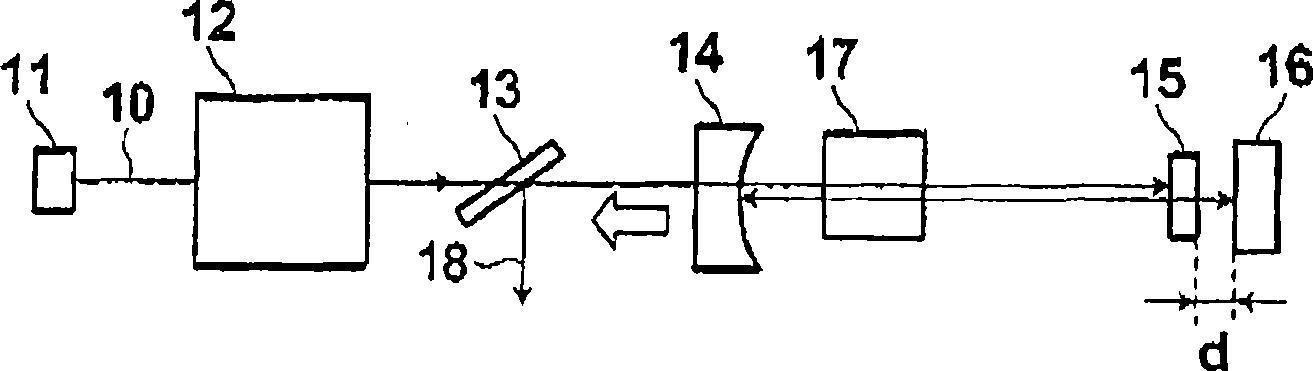

Apparatus And Method For Laser Processing A Material

ActiveUS20210031303A1Avoiding unintentional mode couplingStable optical mode outputAdditive manufacturing apparatusIncreasing energy efficiencyLaser processingRayleigh length

Apparatus for laser processing a material (11), which apparatus comprises an optical fibre (2), at least one squeezing mechanism (3), and a lens (4), wherein: the optical fibre (2) is a multimode optical fibre; the optical fibre (2) is such that laser radiation (13) is able to propagate along the optical fibre (2) in a first optical mode (21) and in a second optical mode (22); the squeezing mechanism (3) comprises at least one periodic surface (6) defined by a pitch (7); and the periodic surface (6) is located adjacent to the optical fibre (2); and the apparatus is characterized in that: the pitch (7) couples the first optical mode (21) and the second optical mode C(22) together; the first optical mode (21) is defined by a first mode order (24), and the second optical mode (22) is defined by a second O mode order (25) which is higher than the first mode order (24); the squeezing mechanism (3) is configured to squeeze the periodic surface (6) and the optical fibre (2) together with a squeezing force (12), thereby coupling the first optical mode (21) to the second optical mode (22); the lens (4) is defined by a front focal plane (14) and a rear focal plane (15); the first optical mode (21) is defined by a Rayleigh length (217); and the lens (4) is located within two of the Rayleigh lengths (217) from the distal end (16) of the optical fibre (2).

Owner:TRUMPF LASER UK LTD

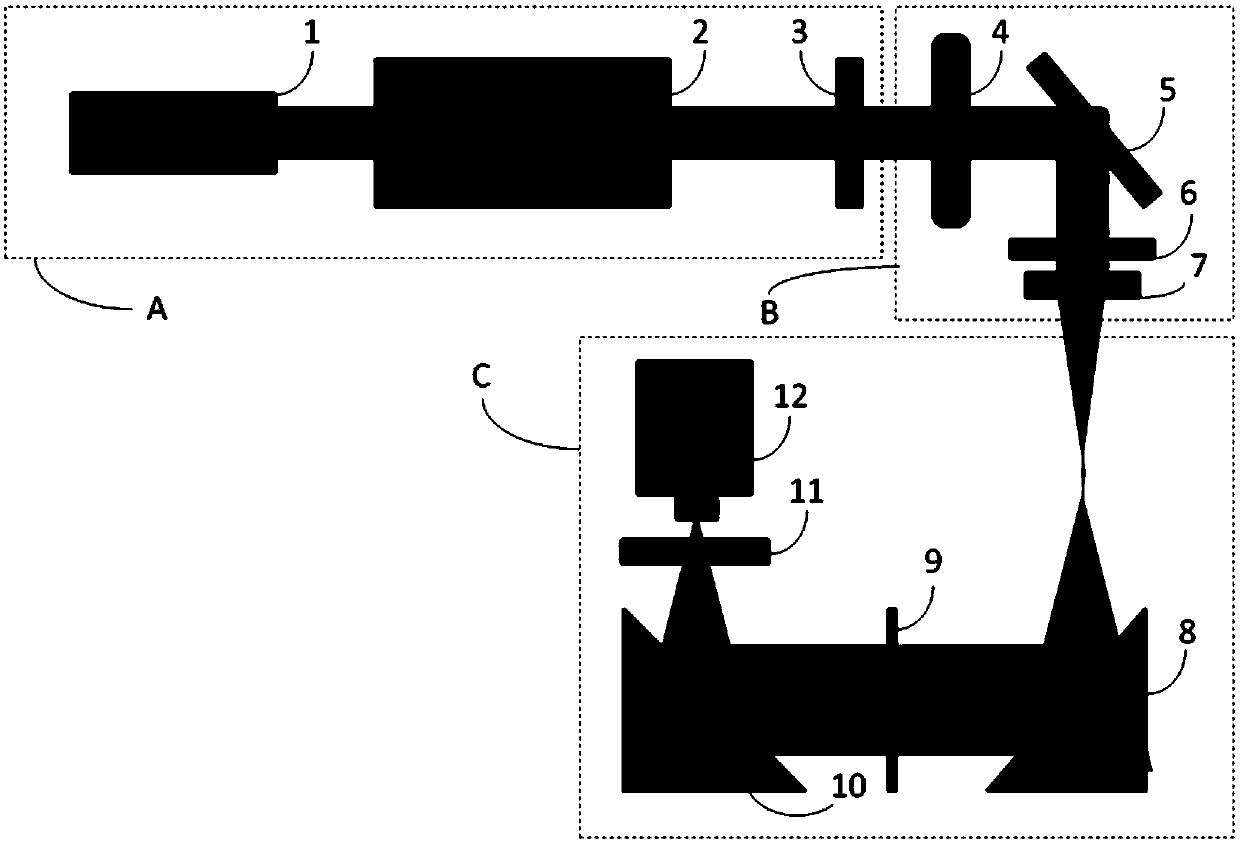

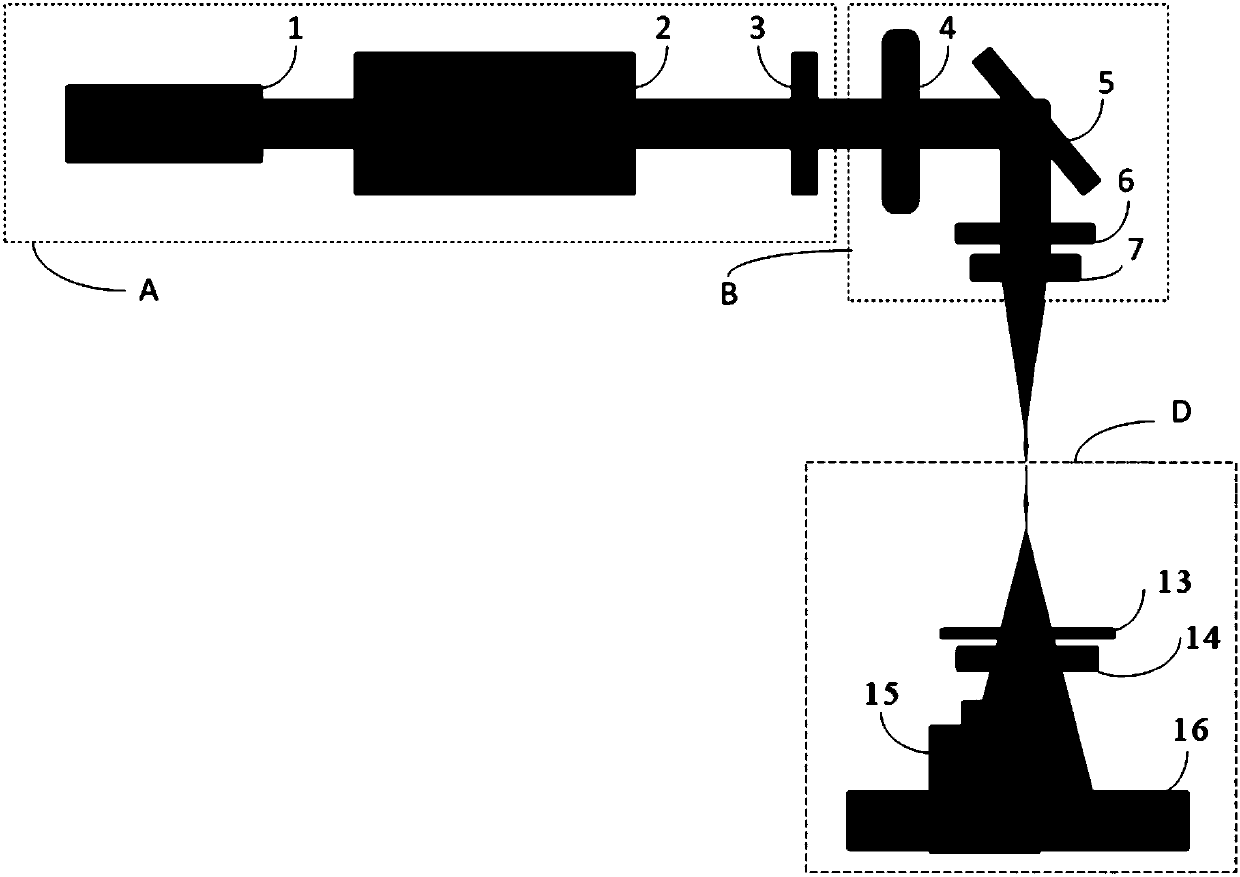

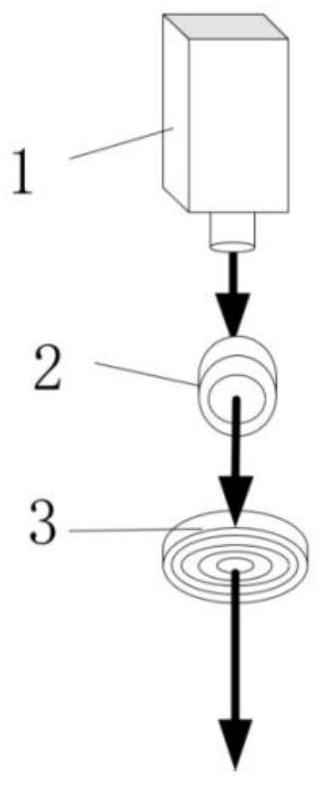

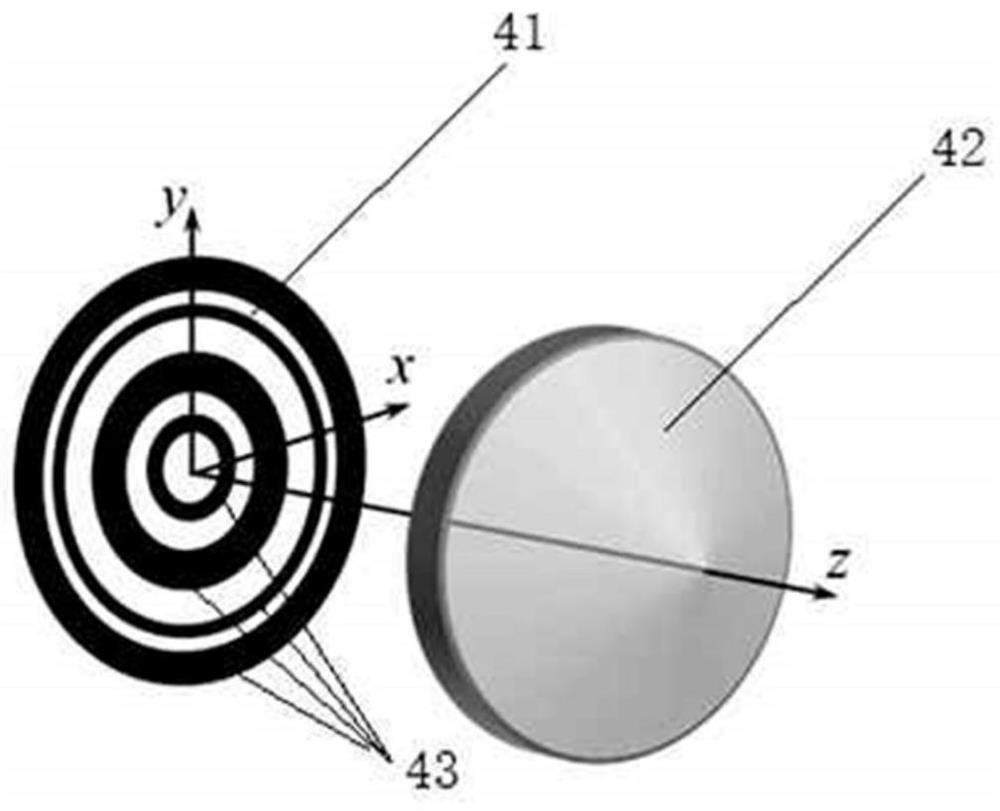

Ultraviolet nanosecond laser direct-writing micro-fluidic chip preparation system and method

ActiveCN110744206AReduce oxidationReduce chippingLaboratory glasswaresLaser beam welding apparatusConvertersUltraviolet

The invention relates to an ultraviolet nanosecond laser direct-writing micro-fluidic chip preparation system and method. The micro-fluidic chip preparation system comprises an ultraviolet nanosecondlaser, an electrically controlled diaphragm, a laser beam expander, a light beam converter, a light beam rotator, a lens, a dichroscope, a laser cutting head, a three-dimensional moving platform and acontrol device. The light beam converter composed of a binary phase plate and an axicon is adopted, a smooth high-quality zero-order and large-Rayleigh-length Bessel laser can be effectively generated, a first-order aperture outside zero-order light in the center of a zero-order Bessel light beam is effectively erased, and therefore the processing quality of the Bessel light beam is effectively improved. Processing of a laser direct-writing micro-fluidic chip with a high vertical depth ratio can be achieved, the laser processing efficiency is improved, and the system is simple in structure, convenient to operate and capable of being used for high-efficiency and high-quality processing of micro-fluidic chips in various schemes.

Owner:广州市凯佳光学科技有限公司

Pin-like light beam generation device and deep hole laser machining device and method

ActiveCN113427123ASelf-bendingEliminate transverse wave vectorsLaser beam welding apparatusGaussian beamLaser processing

The invention relates to a pin-like light beam generation device and a deep hole laser machining device and method, and belongs to the technical field of laser machining. The problems that in the prior art, the Rayleigh length of a light beam generated by focusing a laser through a lens is small, and the precision and efficiency of deep hole laser machining are low are solved. The pin-like light beam generation device comprises a collimation assembly used for collimating a Gaussian light beam generated by a laser device, and a phase mask plate used for carrying out cubic phase front regulation and control on the collimated Gaussian light beam to obtain a pin-like light beam. According to the device, the pin-like light beam with a large Rayleigh length can be obtained, and the precision and efficiency of deep hole laser machining are improved to a great extent.

Owner:齐鲁空天信息研究院

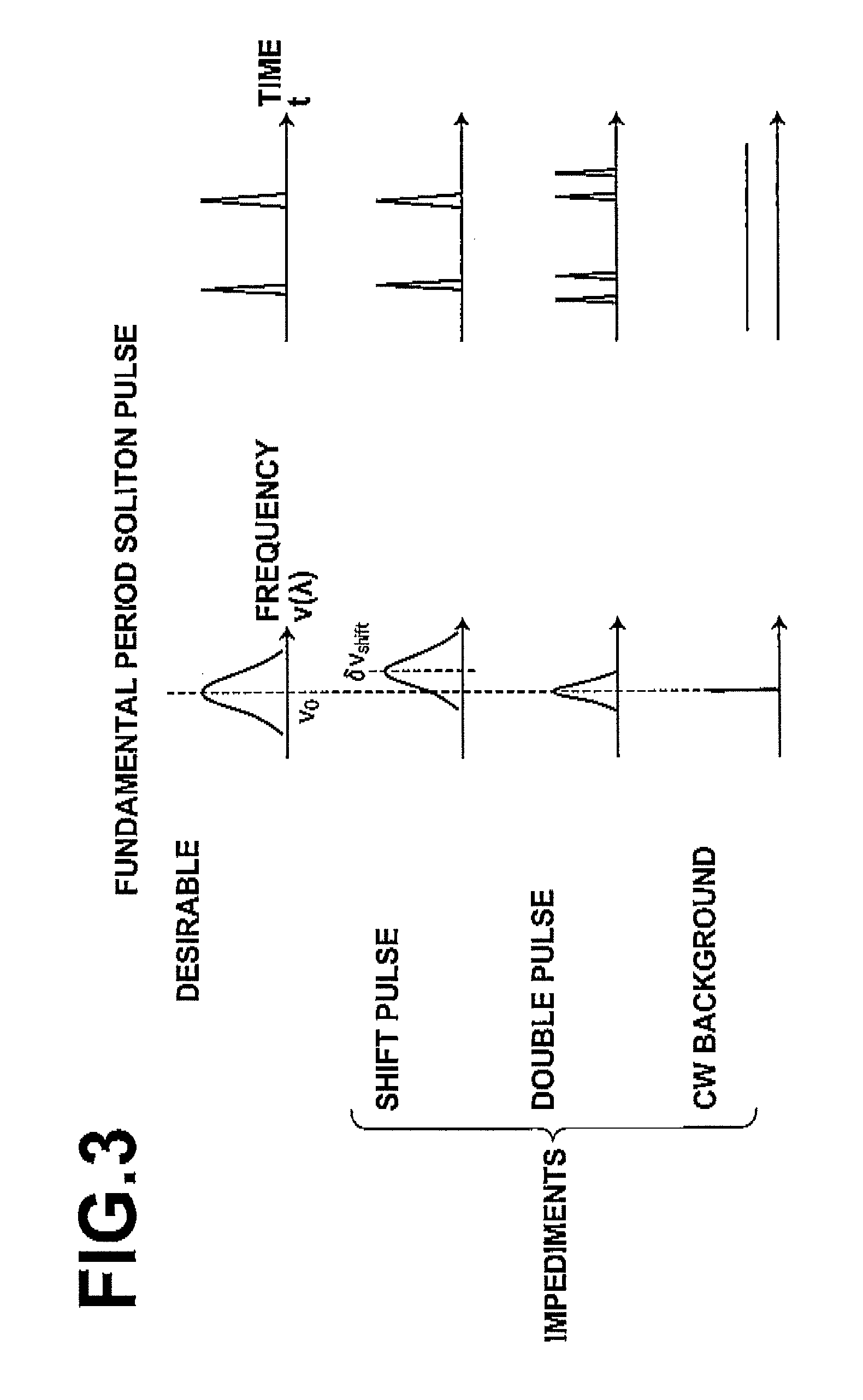

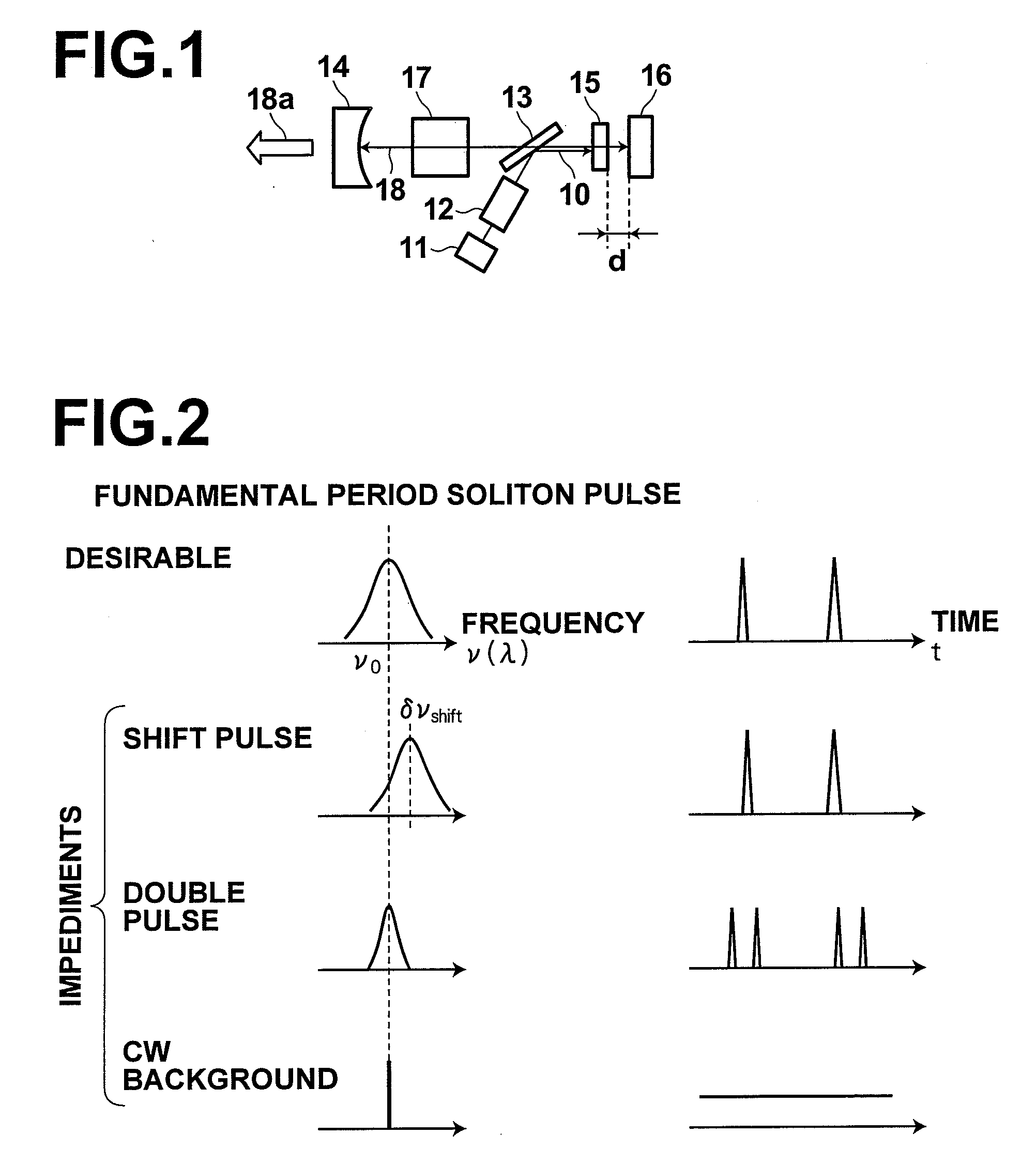

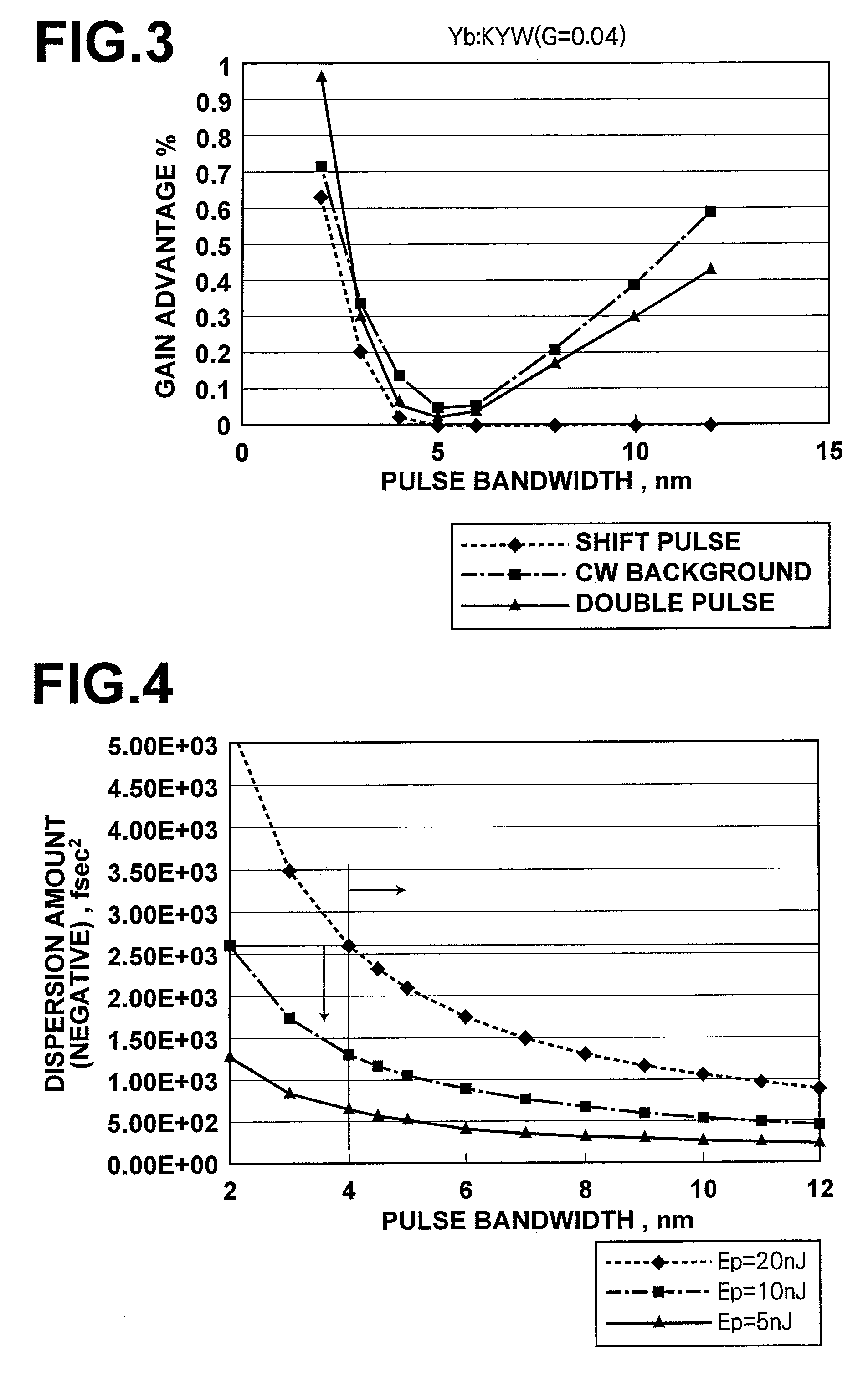

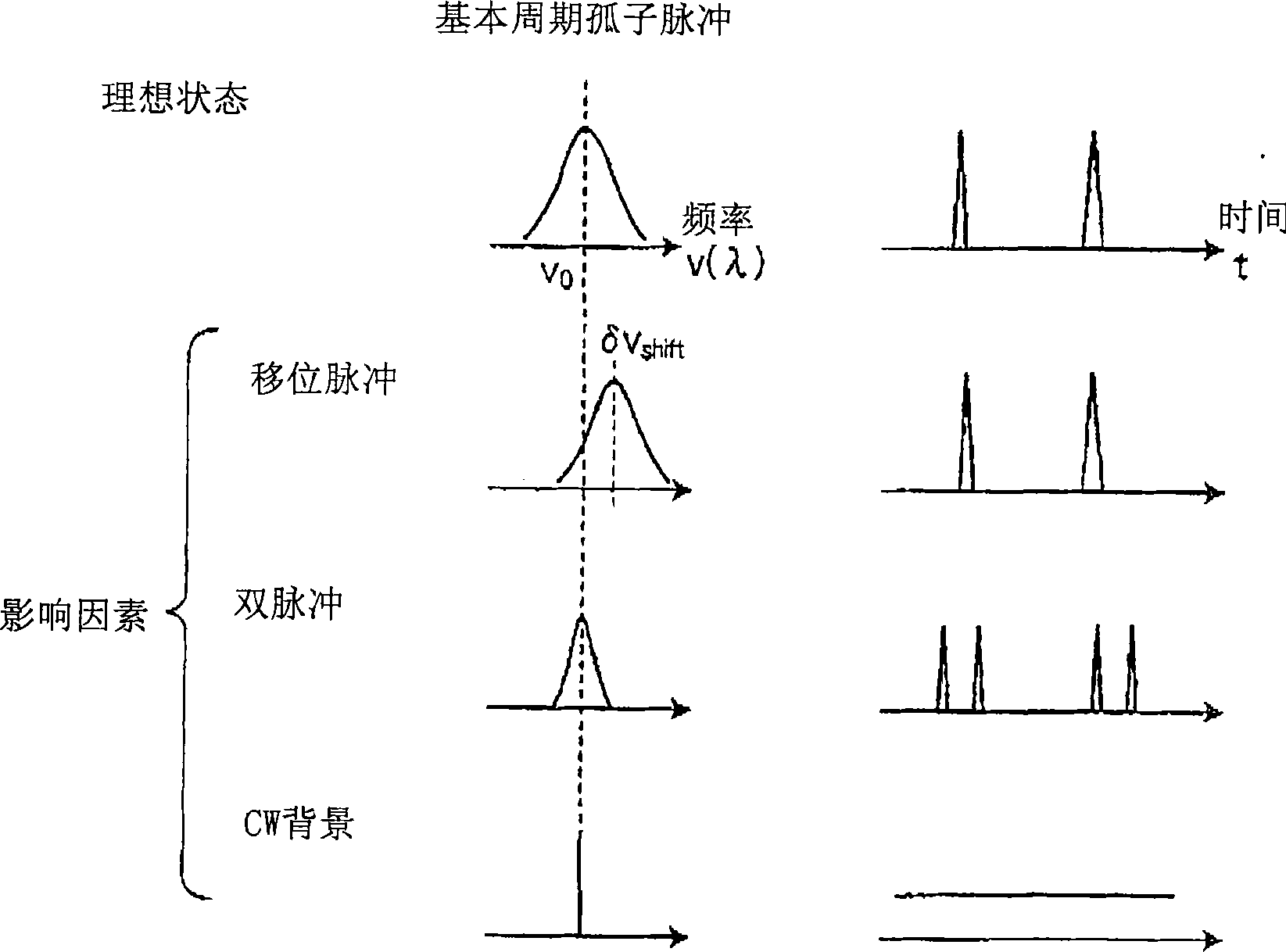

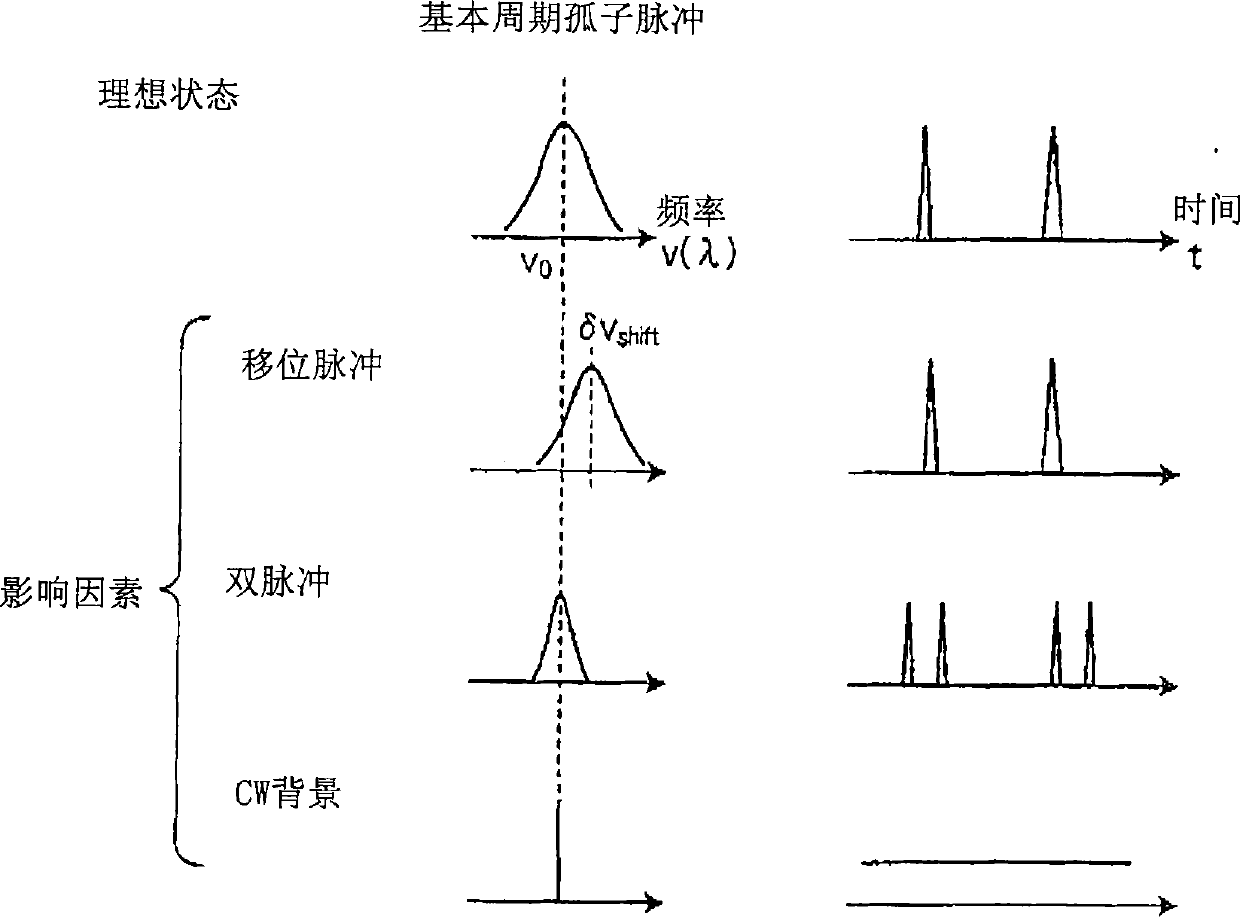

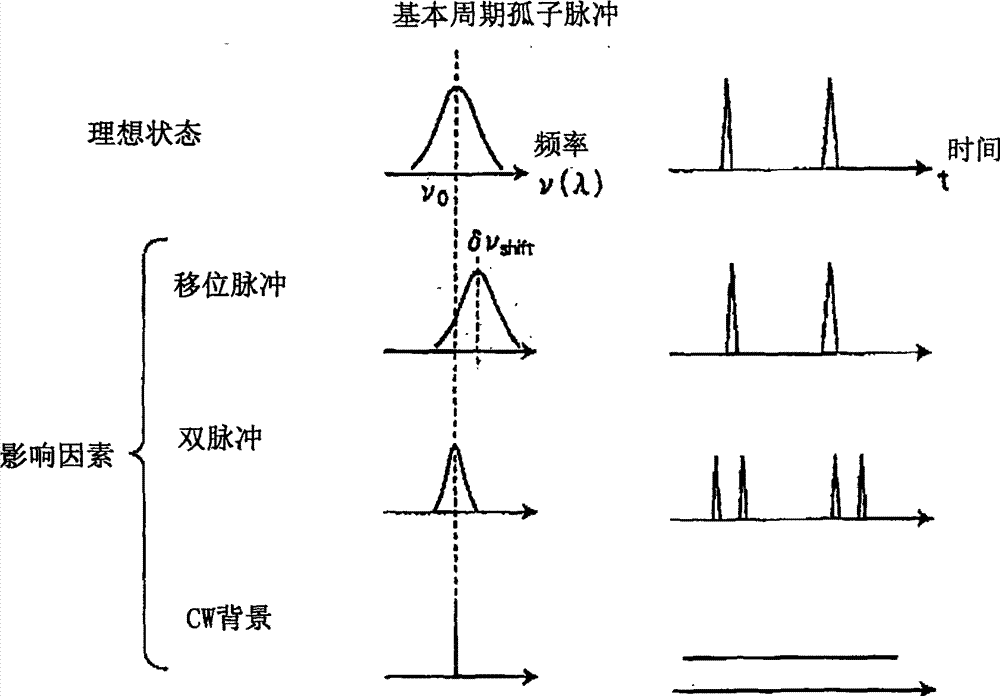

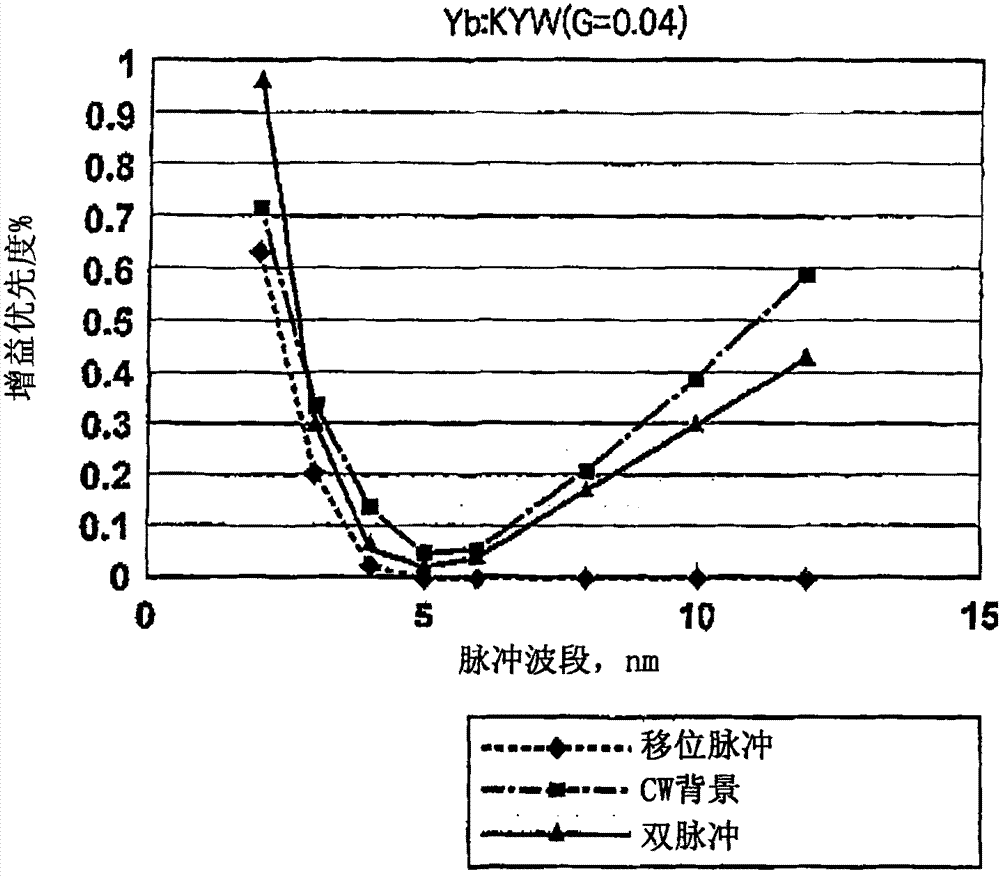

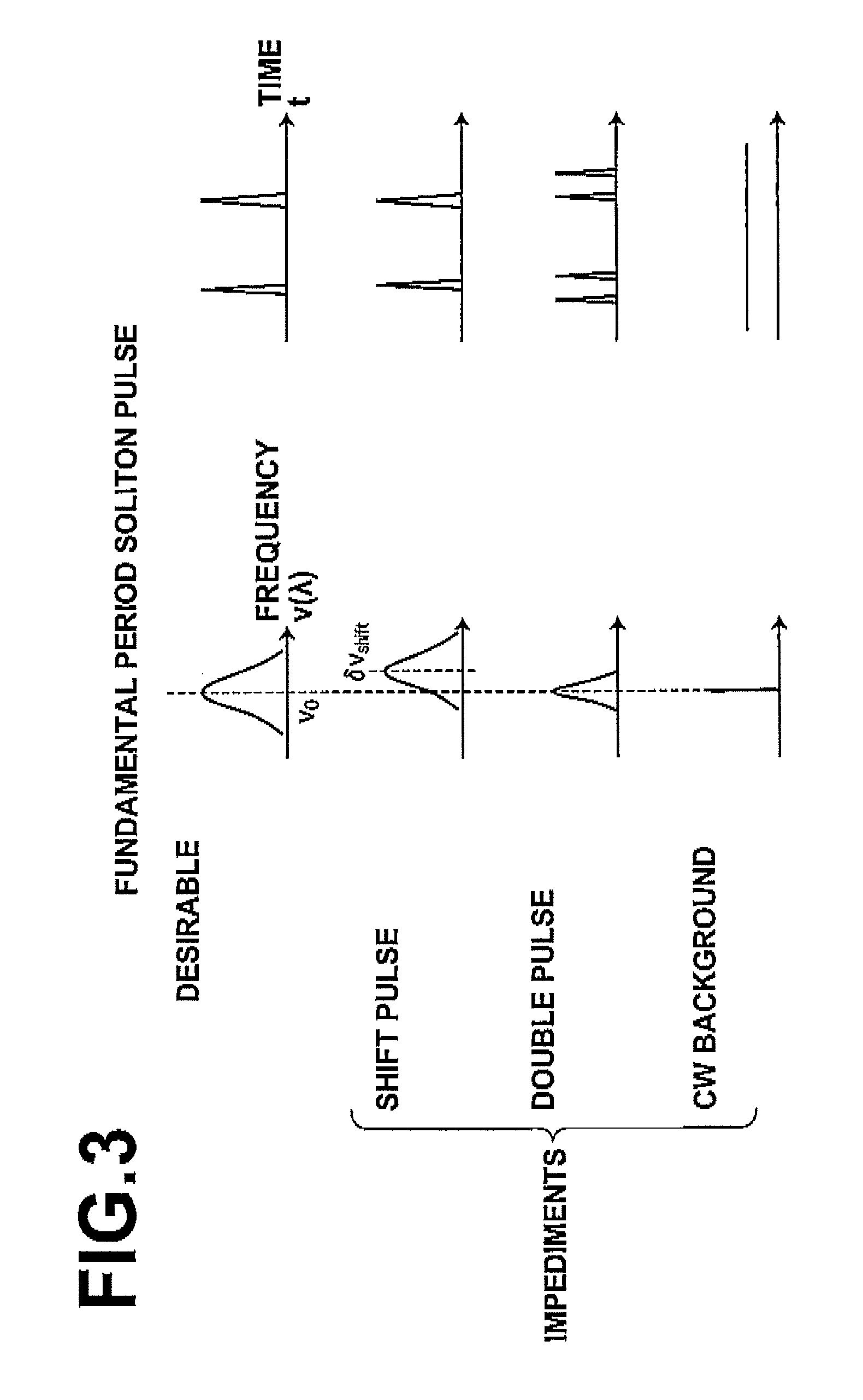

Mode-locked solid-state laser apparatus

A mode-locking solid-state laser apparatus is a soliton-type mode-locking solid-state laser apparatus, having a solid-state laser medium, a saturable absorption mirror and a negative group velocity dispersion element in a resonator, wherein the solid-state laser medium and he absorption mirror are disposed at a distance not greater than twice a Rayleigh length. Then, the absorption modulation depth Delta R of the saturable absorption mirror is set to a value not less than 0.4%, and the absolute value lDl of a total intracavity dispersion amount when light having a predetermined wavelength makes one round trip in the resonator, which is represented by the following mathematic expression (1), is set within a pulse bandwidth in which operation modes other than a fundamental period soliton pulse can be suppressed by the saturable absorption mirror.

Owner:FUJIFILM CORP

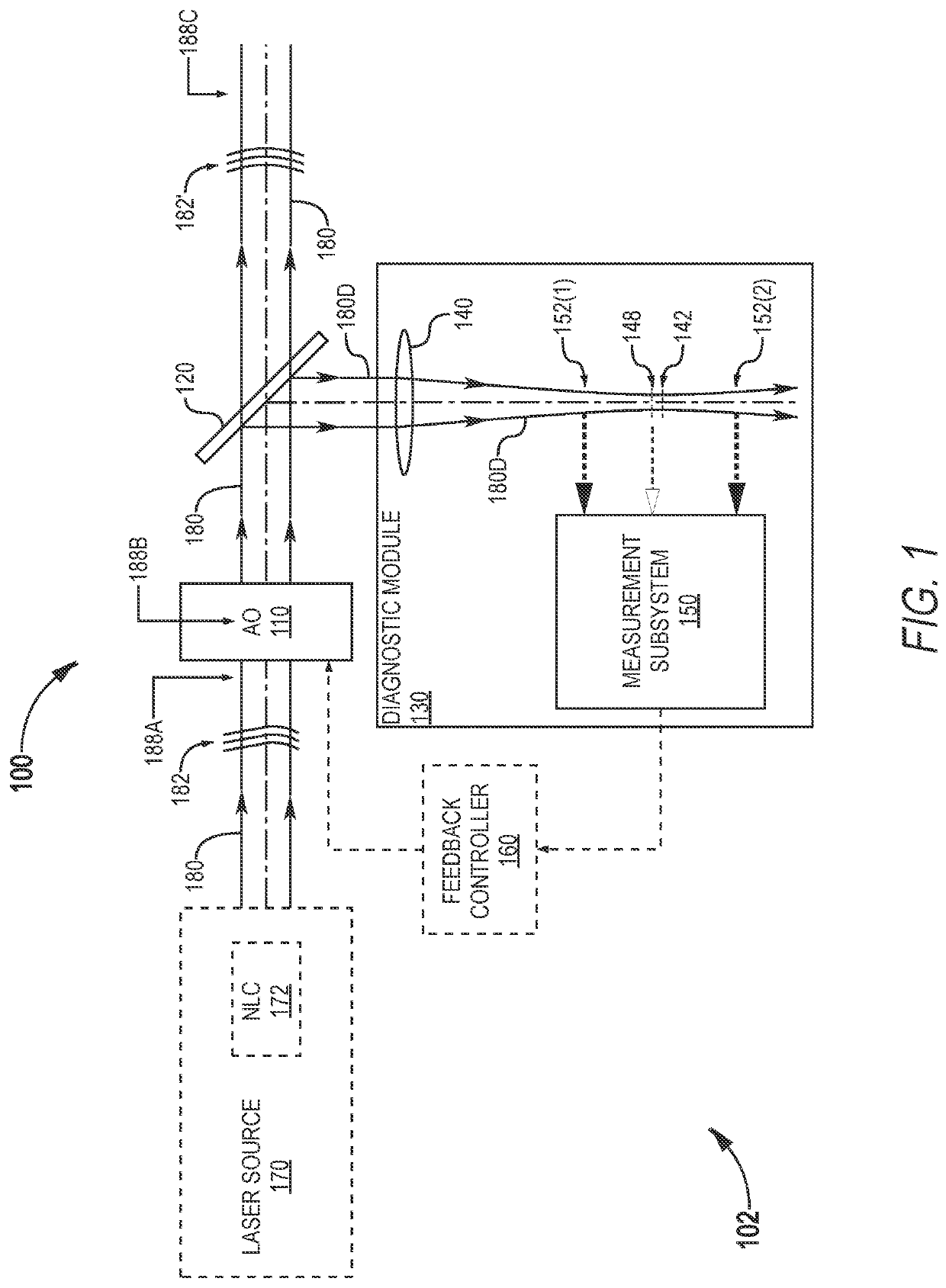

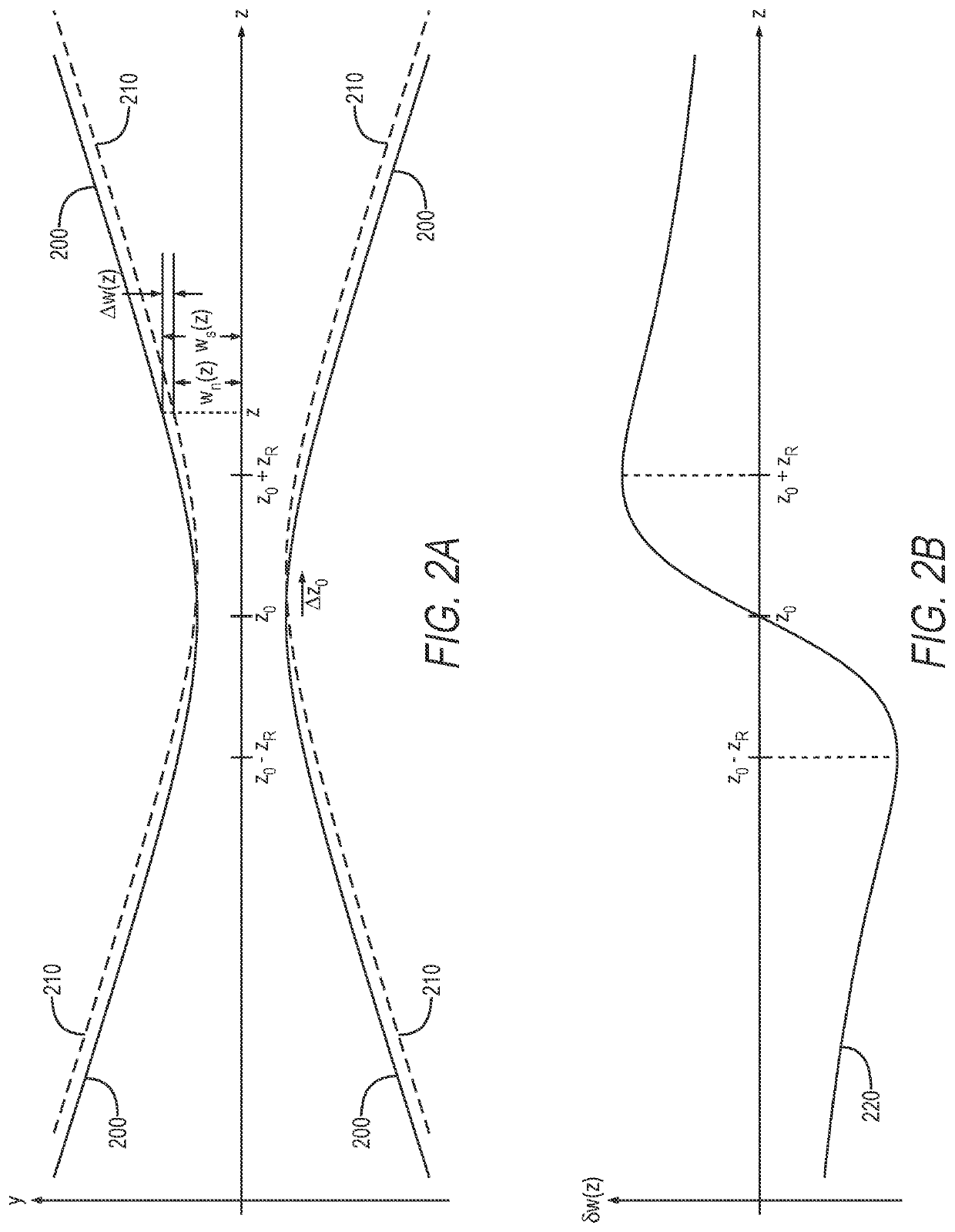

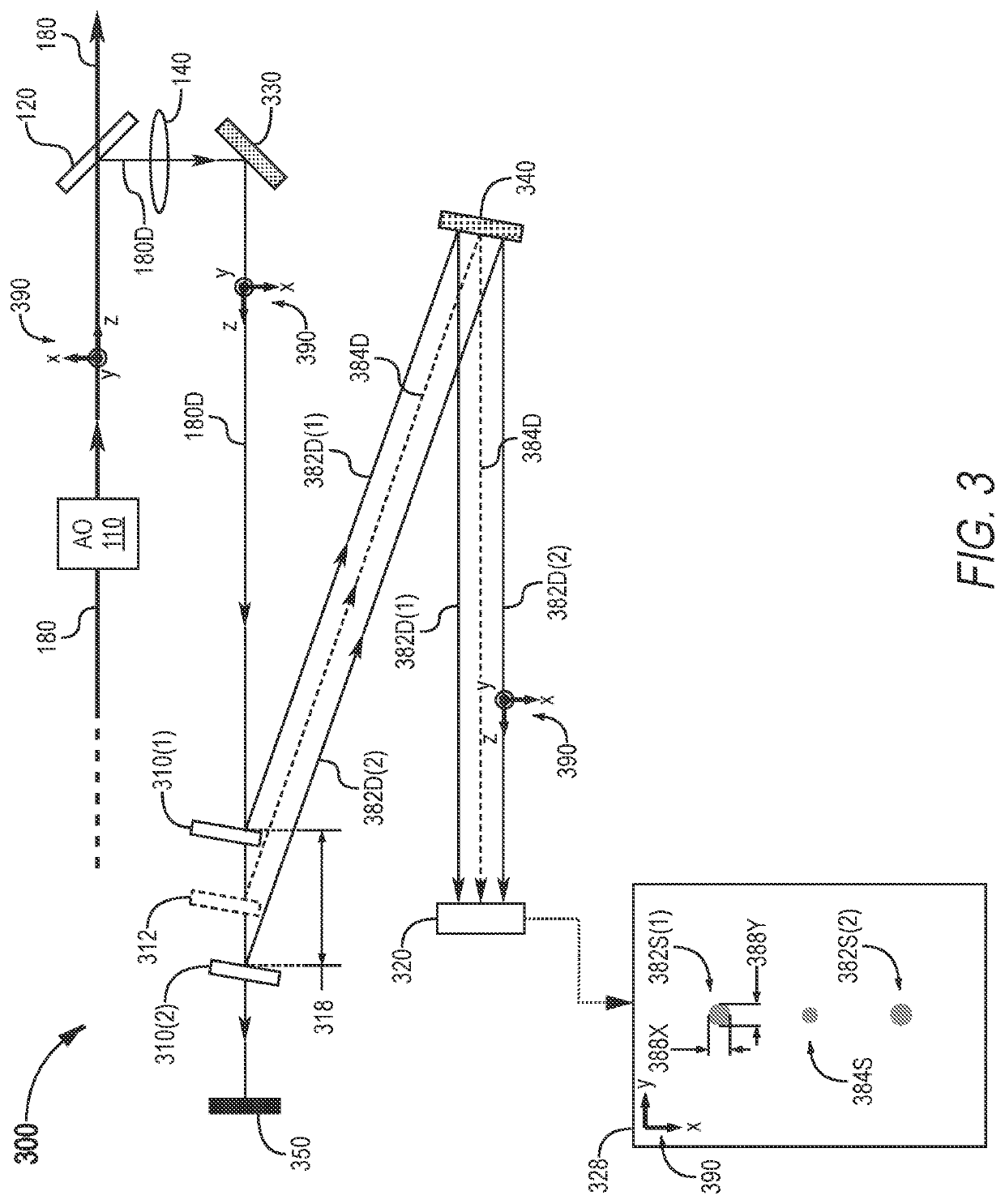

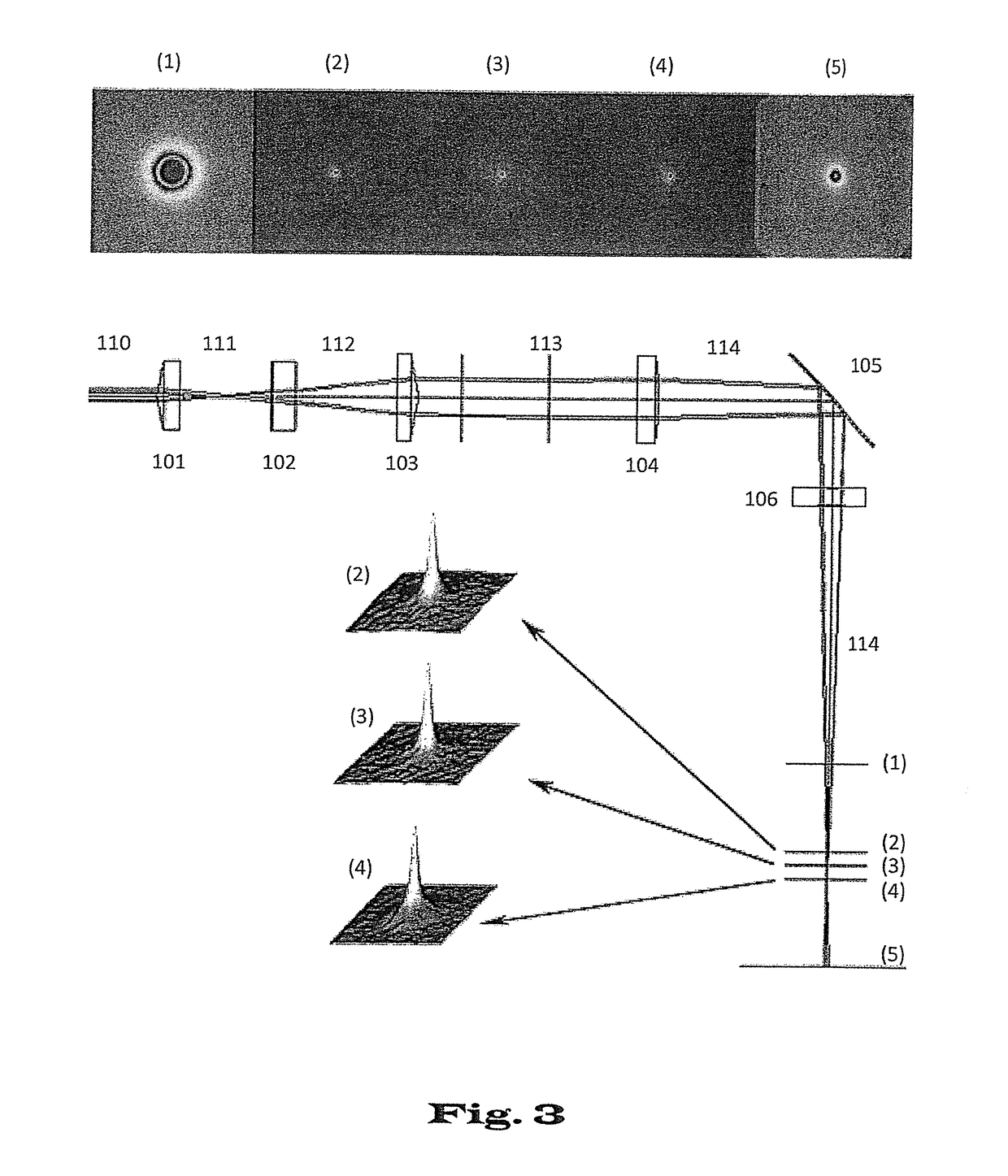

Laser beam wavefront correction with adaptive optics and mid-field monitoring

PendingUS20220163787A1Reduce complexityLow costPhotometryOptical resonator shape and constructionWavefrontLight beam

A system for correcting the wavefront of a laser beam includes a beamsplitter for splitting off a fraction of the laser beam to be used as a diagnostic beam, a focusing element for bringing the diagnostic beam to a focus, a measurement subsystem for measuring sizes of the diagnostic beam at upstream and / or downstream locations with respect to a nominal location of the focus, and at least one adaptive optic, located upstream from the beamsplitter, for correcting the wavefront of the laser beam at least partly based on the measured sizes of the diagnostic beam at the upstream and / or downstream locations. The upstream and downstream locations correspond to mid-field locations in the laser beam as imaged by the focusing element. The system takes advantage of the sensitivity of the laser beam size to a waist location shift being greatest at one Rayleigh length from the nominal waist location.

Owner:COHERENT LASERSYST

Mode-locked solid-state laser apparatus

A mode-locking solid-state laser apparatus is a soliton-type mode-locking solid-state laser apparatus, having a solid-state laser medium, a saturable absorption mirror and a negative group velocity dispersion element in a resonator, wherein the solid-state laser medium and he absorption mirror are disposed at a distance not greater than twice a Rayleigh length. Then, the absorption modulation depth Delta R of the saturable absorption mirror is set to a value not less than 0.4%, and the absolute value lDl of a total intracavity dispersion amount when light having a predetermined wavelength makes one round trip in the resonator, which is represented by the following mathematic expression (1), is set within a pulse bandwidth in which operation modes other than a fundamental period soliton pulse can be suppressed by the saturable absorption mirror.

Owner:FUJIFILM CORP

Mode-locked solid-state laser apparatus

InactiveCN101399426BStable soliton mode oscillationOptical resonator shape and constructionOptical axisLight beam

The invention relates to a mode-locked solid-state laser apparatus having a resonator which includes a solid-state laser medium, a saturable absorption mirror, and a negative group dispersion element therein, in which the solid-state laser medium and the saturable absorption mirror are disposed at a distance not greater than twice a Rayleigh length which is determined by the beam radius of oscillation light formed at the saturable absorption mirror. The apparatus further includes a dichroic mirror in the resonator that reflects excitation light inputted from a direction crossing the optical axis of the resonator toward the solid-state laser medium and transmits oscillation light.

Owner:FUJIFILM CORP

Thick plate myriawatt-level fiber laser perforation method

PendingCN114871600ARaise the Rayleigh lengthLong focal lengthLaser beam welding apparatusOptical ModuleThick plate

The invention relates to a thick plate myriawatt-level fiber laser perforation method, which comprises a conventional cutting machine mounted on a cutting platform, and comprises the following steps: S1, an optical control module is added on the conventional cutting, and the optical control module comprises a perforation focus lens module and a cutting focus lens module; s2, a workpiece to be cut is placed on a cutting platform, and a punching focus lens module is selected; s3, setting hole parameters of the punching focus lens module, such as laser power, pulse form and light emitting time; s4, a punching focus lens module is opened, and punching is carried out; and S5, a control system of a conventional cutting machine is used, a punching focus lens module is switched, and cutting is carried out. The device has the advantages that the optical module is added, the focusing diameter and the Rayleigh length of a laser beam are controlled, and the high-power laser drilling quality and efficiency are improved.

Owner:西北工业大学太仓长三角研究院

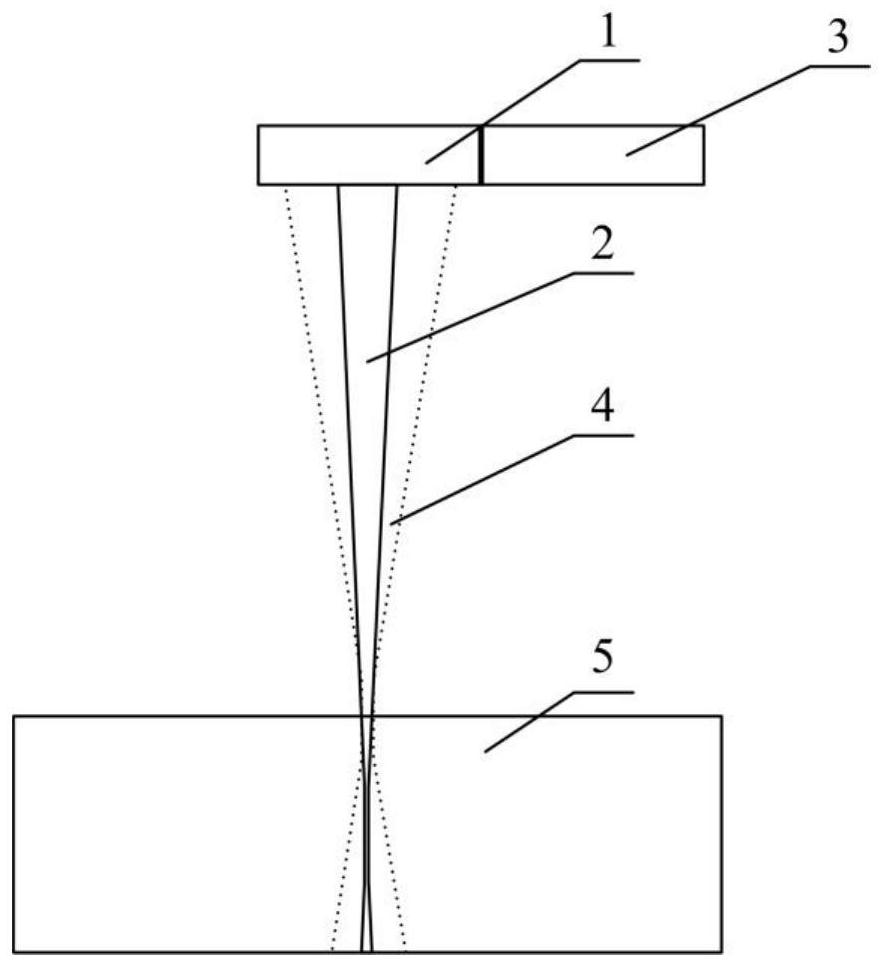

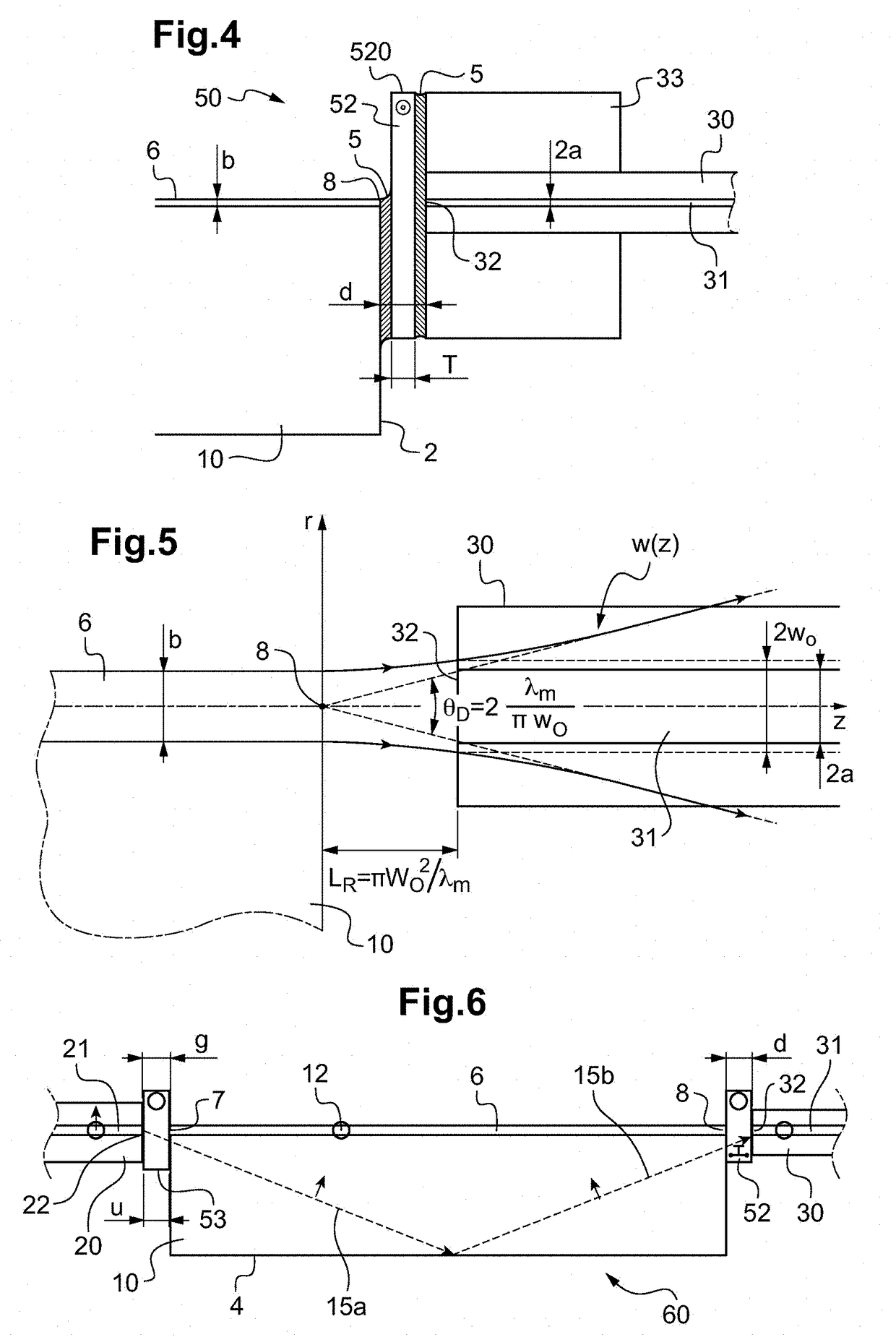

Waveguide polarizing optical device

ActiveUS20170212305A1Raise the ratioSuppression of insertion lossOptical fibre with polarisationPolarising elementsRefractive indexPolarizer

Disclosed is a waveguide polarizing optical device, including a first waveguide polarizer (6), a section of a second optical waveguide (31) and a second thin-plate polarizer (52) having a physical thickness T and a refractive index n, the second thin-plate polarizer (52) being disposed on the optical path between a waveguide end (8) of the first polarizer (6) and one end (32) of the second optical waveguide (31), the physical distance d between the waveguide end (8) of the first polarizer (6) and the end (32) of the second optical waveguide (31) being less than or equal to twice the Rayleigh length and the physical thickness T of the second polarizer (52) being less than or equal to the physical distance d.

Owner:EXAIL

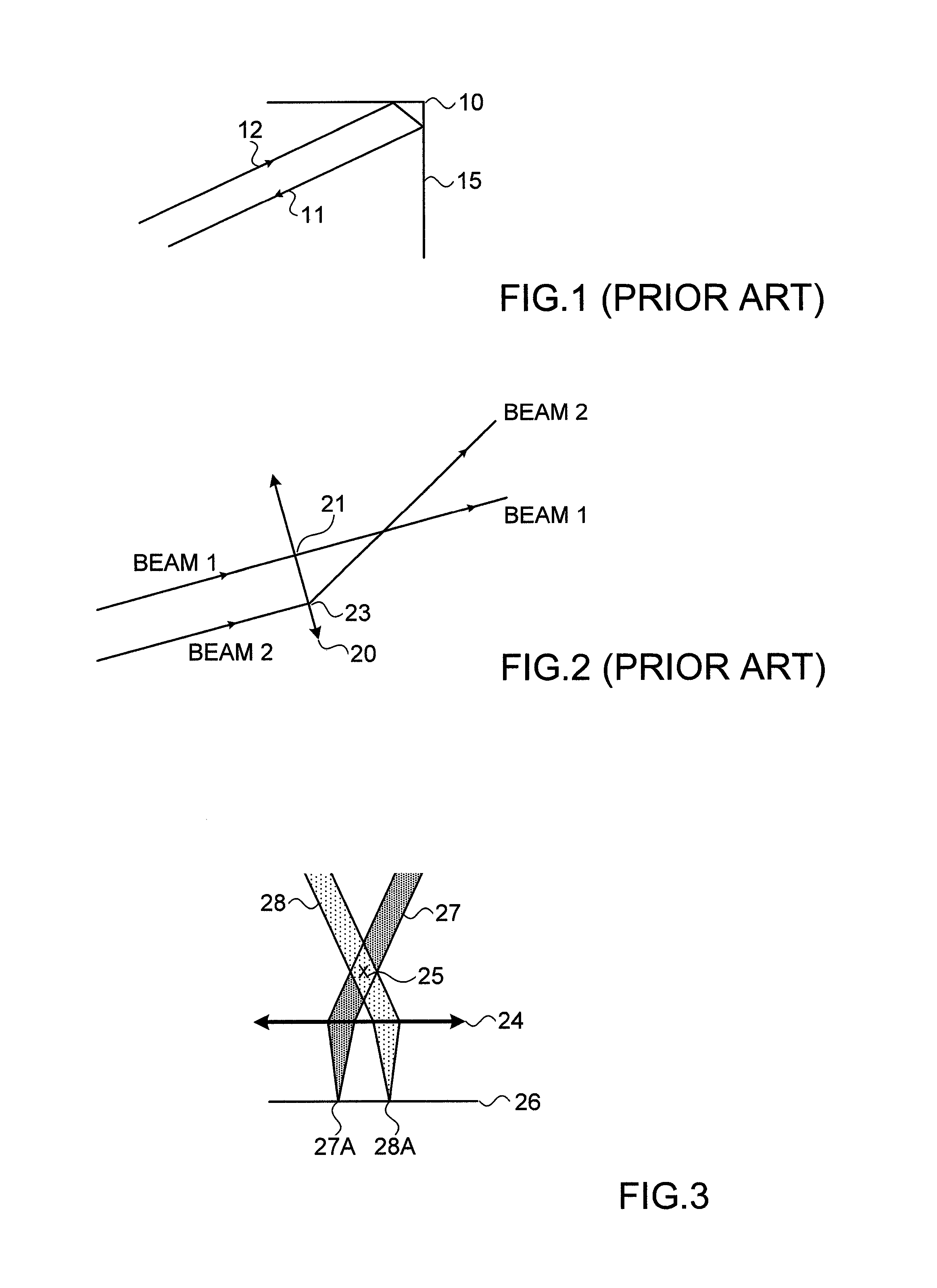

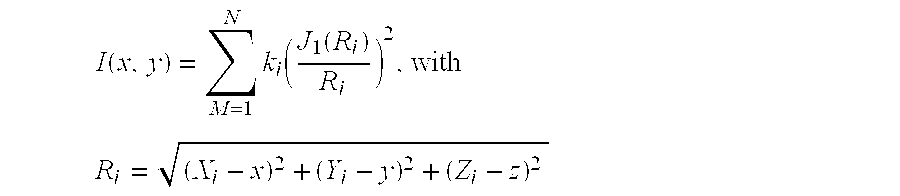

Superresolution off axis telescope using the maximum in the laplacian orthogonal to isophote ridge tops

InactiveUS20050273283A1Digital variable/waveform displaySpecial data processing applicationsAlgorithmRayleigh length

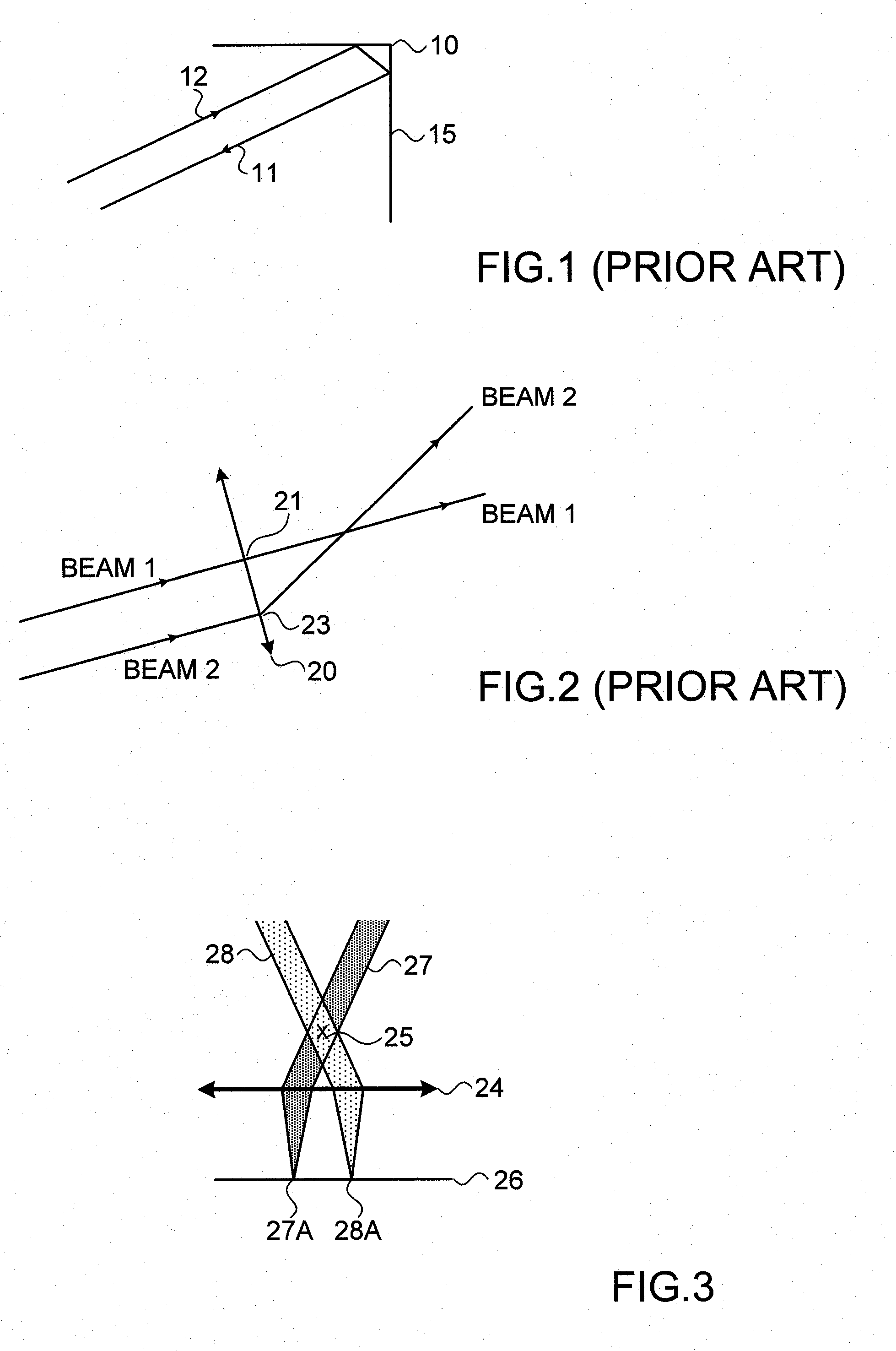

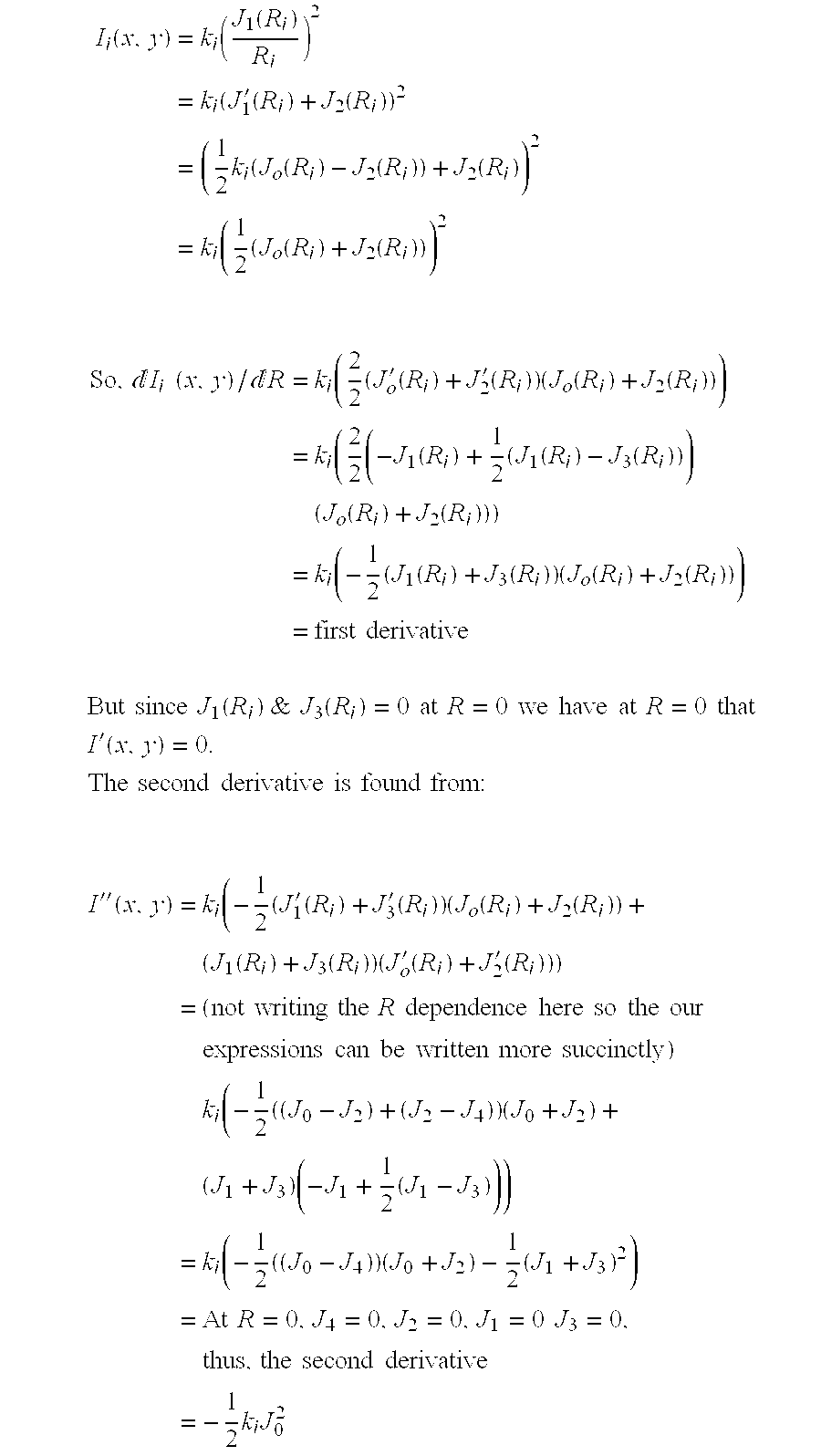

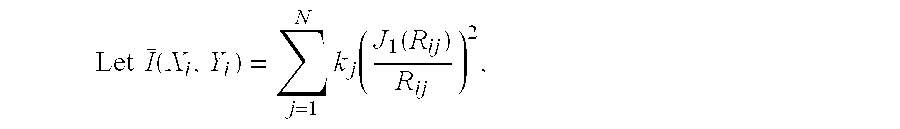

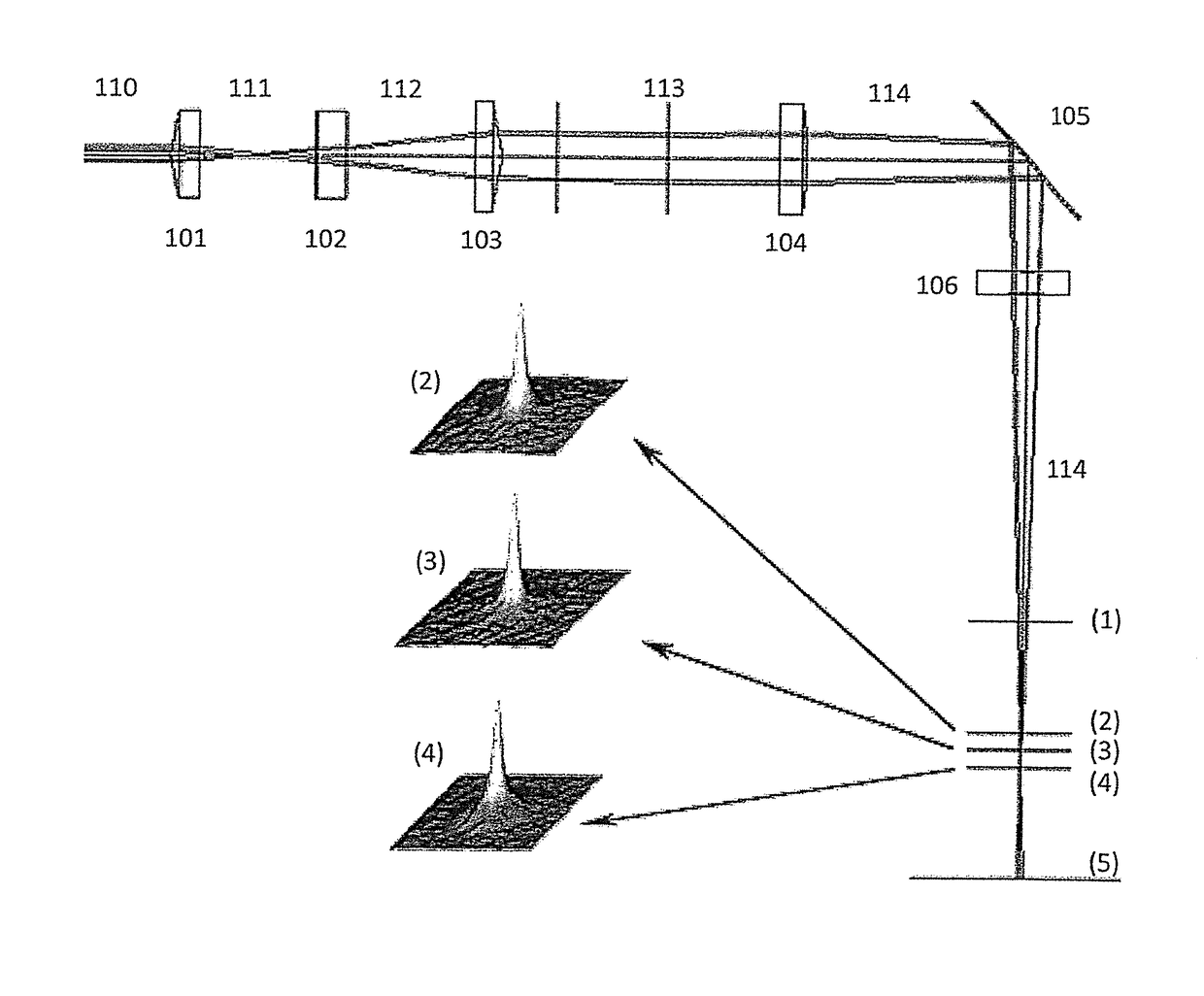

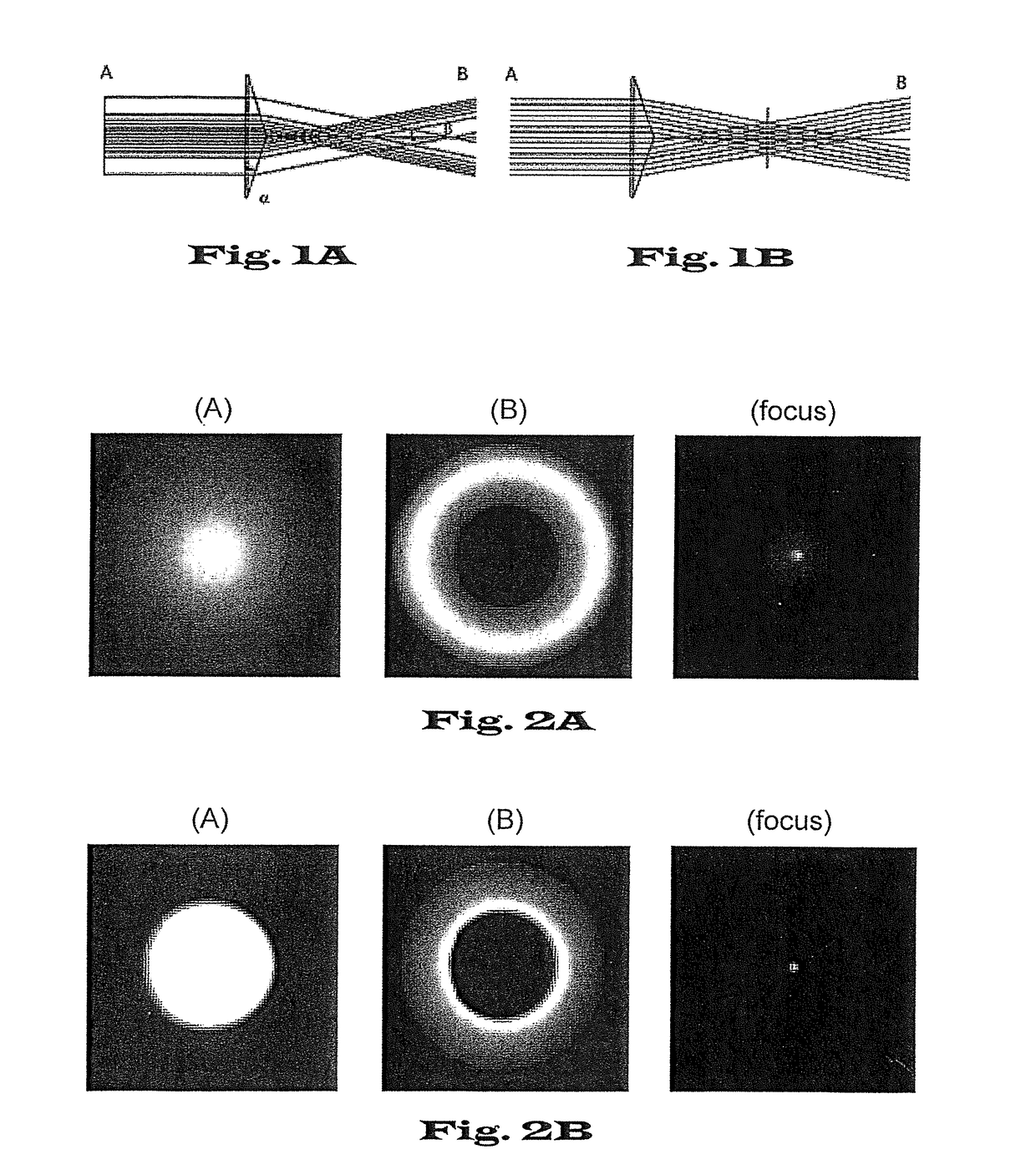

There are many de-convolution algorithms (using Fourier transforms for example) that allow calculation of ki and Ri given the image values of I (xi, yi). The problem arises when the PSF's are closer together than a Rayleigh length: the number of artifact images (false images) available from a typical de-convolution algorithm may then be very large. Thus the overall probability of a false de-convolved image also is very large. This is the ambiguous image problem first identified by Toraldo di Francia (Reference 1). We solve this problem by finding the maximum in the Laplacian (i.e., take largest second derivative) along the isophote ridges on which the first derivative=0 (on a circle around the maximum). To correctly use this algorithm we must apply it to an off axis telescope.

Owner:MAKER DAVID JOEL

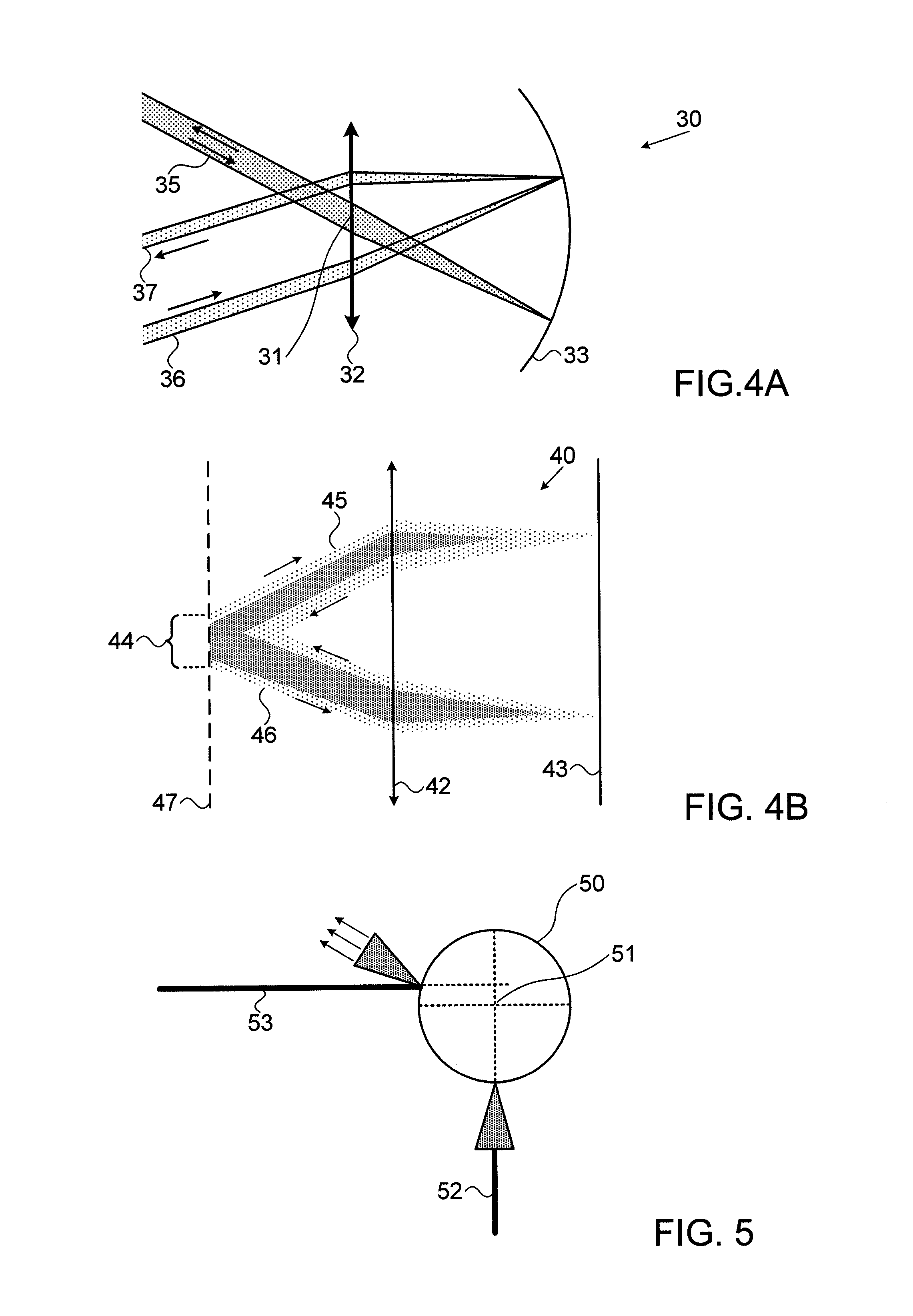

Light sheet microscopy using meso-optical elements

ActiveUS10088657B2Avoid it happening againHigh lengthMicroscopesFluorescence/phosphorescenceLight beamRayleigh length

Owner:DODT HANS ULRICH +1

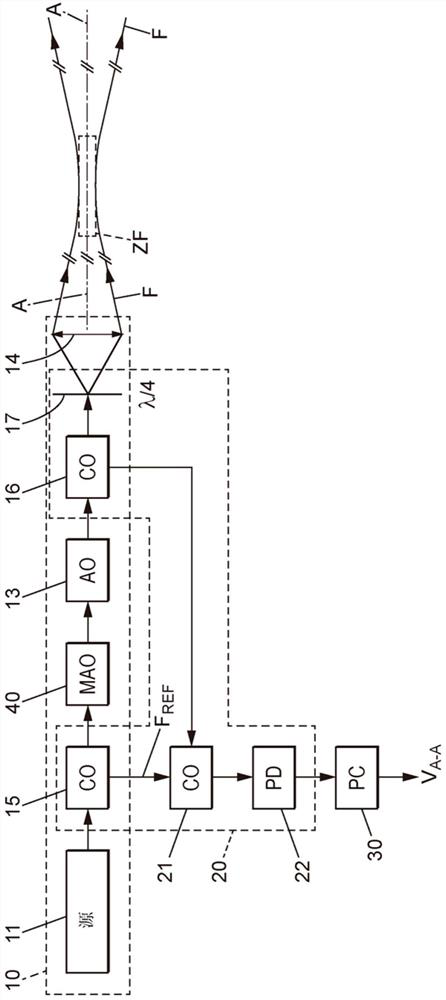

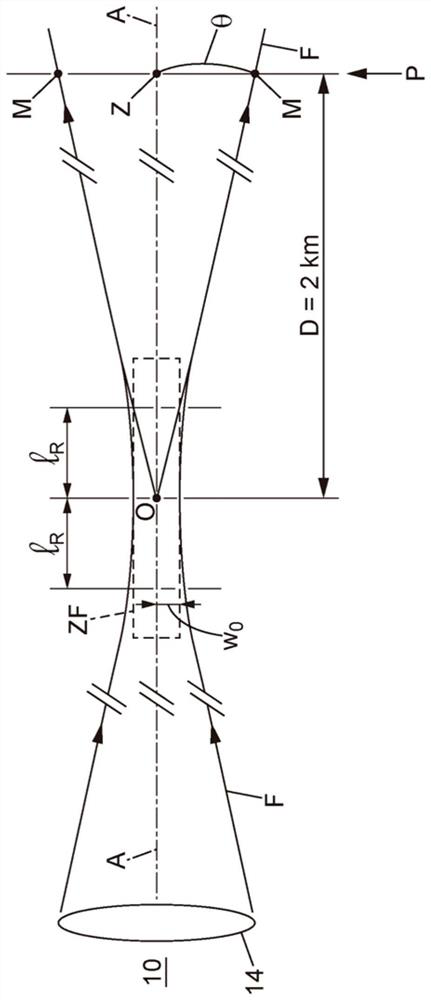

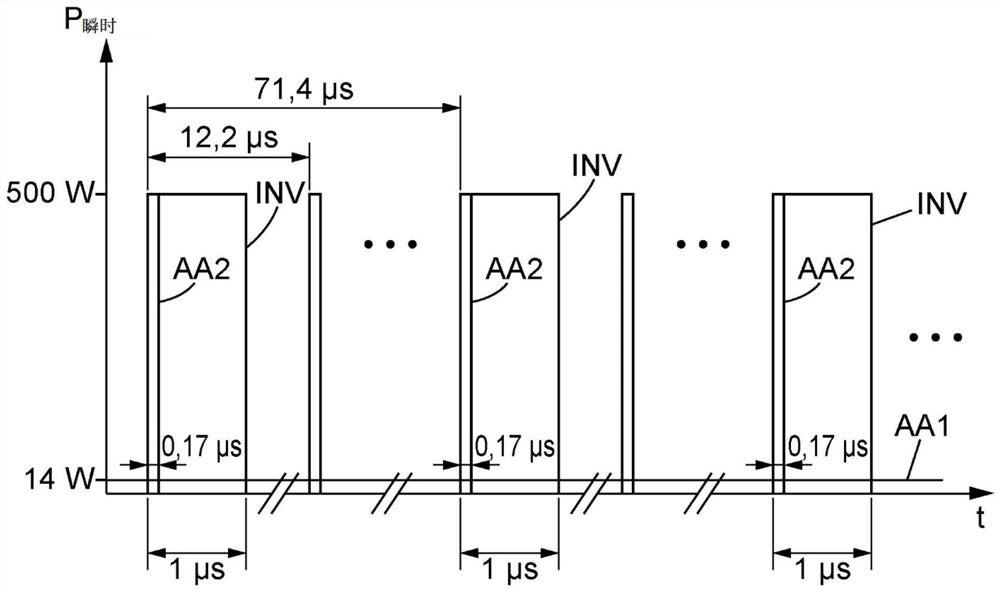

Lidar system for wind measurement

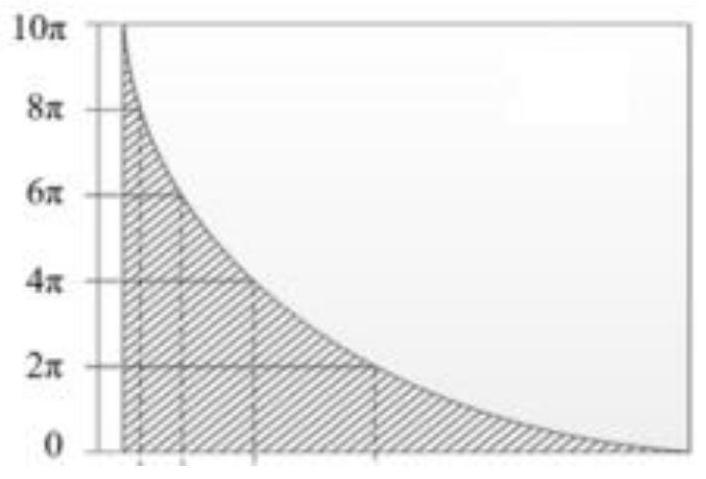

A lidar system adapted to perform a wind measurement related to a focal zone (ZF) of a laser beam (F) emitted by the system. The system comprises time control means (40) for the laser beam adapted to place this laser beam in the form of successive laser pulses such that each laser pulse has a single length greater than or equal to twice the Rayleigh length (lR) divided by the propagation velocity of the laser pulse in the atmosphere and less than 20 [mu] s. Advantageously, the individual length of each laser pulse is between 0.2 and 5 times the coherence time of the effective atmosphere in the focal region. The lidar system provides a better spectral CNR ratio at an equivalent spatial resolution than the spectral CNR ratio of a system at a current technology development level.

Owner:国家航空航天研究所

Mode-locked solid-state laser apparatus

InactiveUS7864821B2Small and stable CW mode-locked laserReduce the numberOptical resonator shape and constructionSolid-state laser deviceGroup velocity dispersion

Owner:FUJIFILM CORP

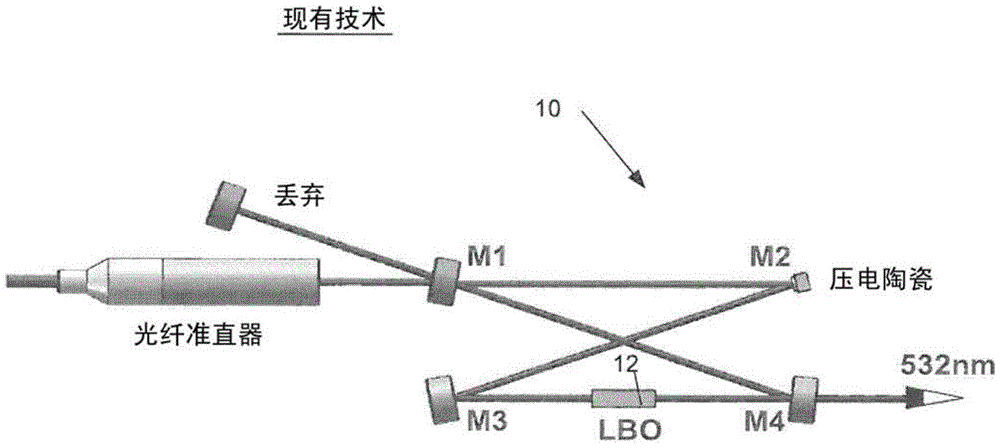

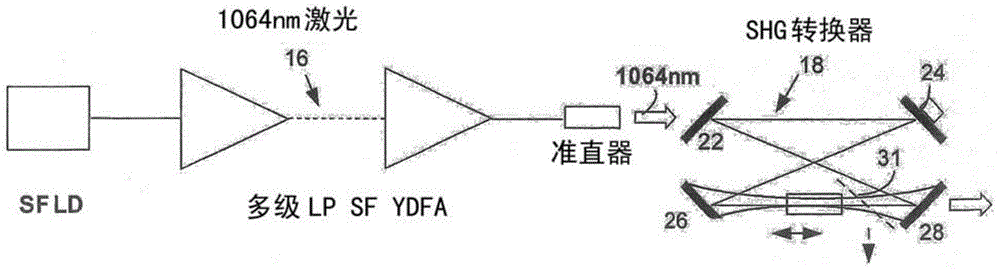

Resonant Enhanced Frequency Converter

A frequency converter for converting a single-mode input beam at a fundamental frequency to an output beam at a converted frequency is configured with a plurality of phase-separated optical components defining a resonant cavity. The optical assembly shapes the input beam to have at least one beam waist within the cavity. The frequency converter also includes a nonlinear crystal located within the resonator in a diverging beam having a Rayleigh length less than the round-trip length of the resonator such that the center of the crystal is aligned with the beam waist along the beam path. separate, or the nonlinear crystal is located in a collimated beam whose Rayleigh length is greater than the resonator round-trip length.

Owner:IPG PHOTONICS CORP

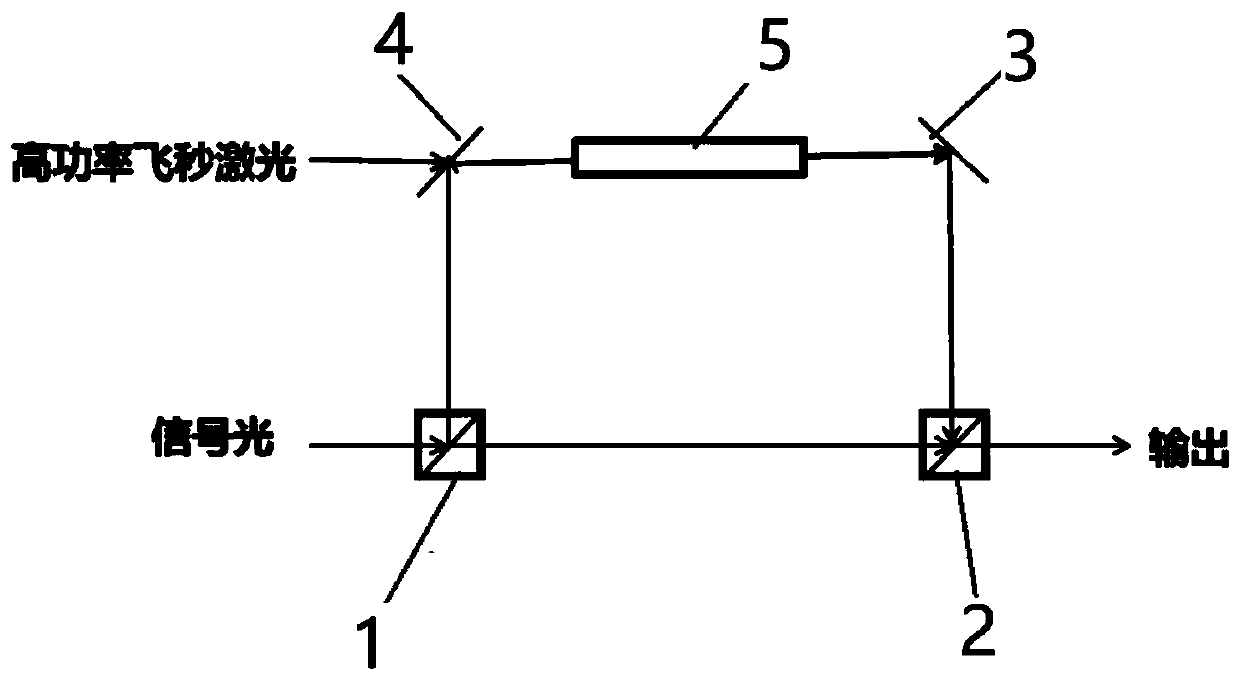

Method for realizing high-speed optical switch response and ultra-high-speed optical modulation optical switch device

ActiveCN111142192AHigh speed modulationCoupling light guidesNon-linear opticsDiffraction effectUltra high speed

The invention provides a method for realizing high-speed optical switch response and an ultra-high-speed optical modulation optical switch device. High-power pulse laser is adopted, the defect that the propagation distance of a diffraction effect exceeds several times of Rayleigh length can be eliminated on the basis of the self-focusing effect and plasma defocusing effect of the laser in a transmission process; and therefore, an optical filament can be obtained. A large number of physical effects are involved in a laser filamentation process; an optical filament generation area is accompaniedby refractive index modulation, the response speed of the refractive index modulation is related to the pulse width and power of ultrafast laser; and when the peak power of the ultrafast laser reaches a certain threshold value, the frequency of the response of a liquid generated optical filament to refractive index modulation can reach gigahertz. The ultra-high-speed refractive index modulation is applied to an optical modulation optical switch to realize ultra-high-speed optical switch response.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

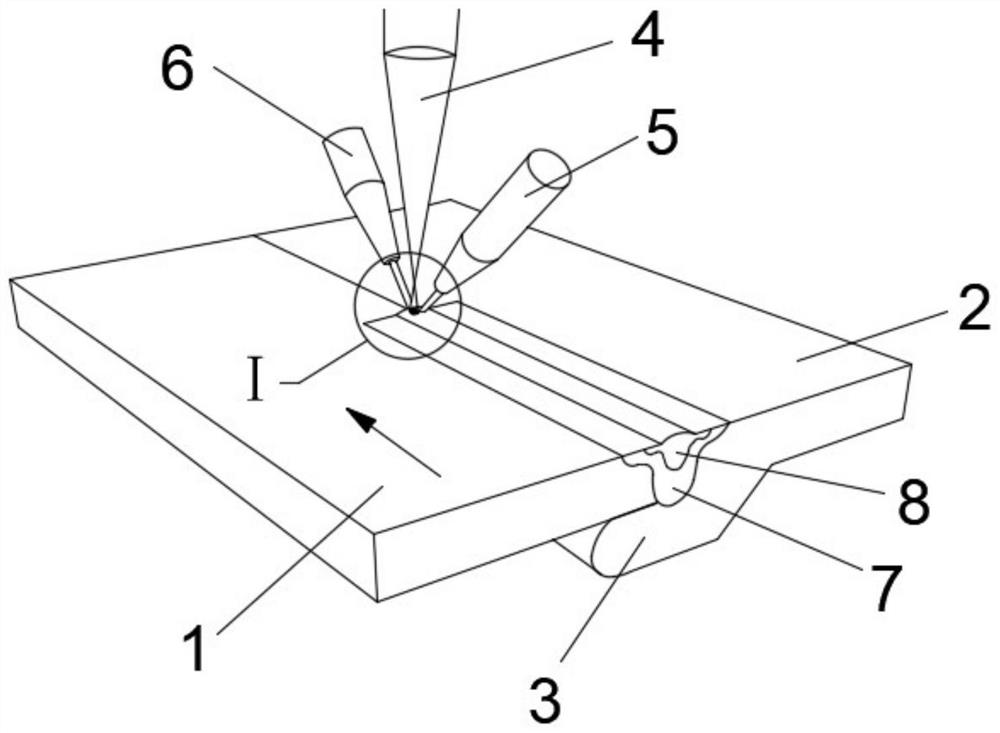

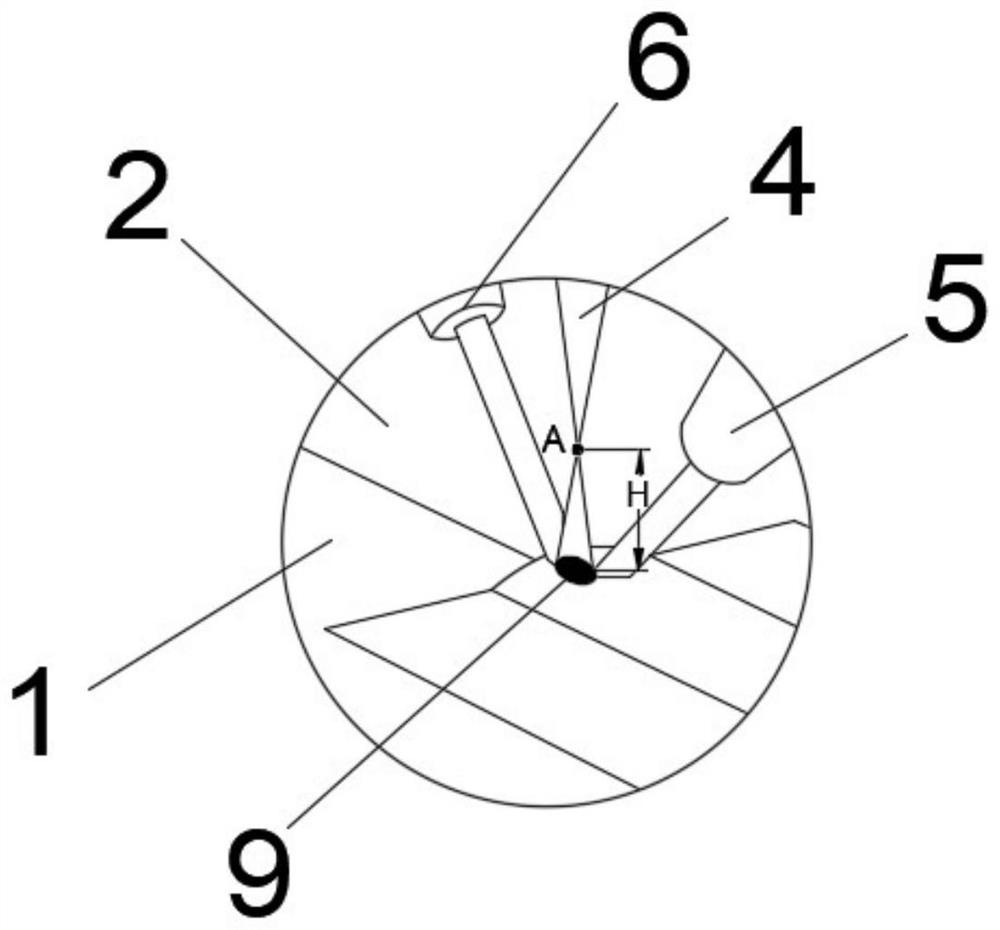

Hybrid welding continuous welding method and device, welded product, car body

ActiveCN110000475BIncreased defocusReduce power densityLaser beam welding apparatusRayleigh lengthWeld seam

The invention relates to the technical field of laser arc welding, in particular to a hybrid welding continuous welding method and device, a welded product, and a car body. The method of the present invention includes: performing composite welding on the groove of the weldment by coupling laser and polarity-changing arc; wherein, the defocusing amount of the laser is not less than the Rayleigh length of the laser. The method of the present invention effectively reduces the power density of the laser on the surface of the weldment, reduces the depth-to-width ratio of the weld, increases the diameter of the welded hole, effectively reduces the hole caused by the collapse of the welded hole, and further solves the problem of the prior art Welding porosity defects are difficult to escape, reduce the generation of hydrogen pores, effectively improve welding stability and reliability, and improve the mechanical properties of welds.

Owner:CRRC QINGDAO SIFANG CO LTD +1

A UV nanosecond laser direct writing microfluidic chip preparation system and method

ActiveCN110744206BReduce oxidationReduce chippingLaboratory glasswaresLaser beam welding apparatusConvertersUltraviolet

The invention relates to a preparation system and method for an ultraviolet nanosecond laser direct writing microfluidic chip. The microfluidic chip preparation system includes: an ultraviolet nanosecond laser, an electronically controlled aperture, a laser beam expander, a beam converter, and a beam Rotator, lens, dichroic mirror, laser cutting head, three-dimensional mobile platform and control device. The invention adopts a beam converter composed of a binary phase plate and an axicon lens, which can effectively generate smooth and high-quality first-class zero-order and long-Rayleigh The length of the Bessel laser can effectively erase the first-order aperture outside the zero-order light in the center of the zero-order Bessel beam, thereby effectively improving the processing quality of the Bessel beam. The invention can realize laser direct writing microfluidic chip processing with high aspect ratio, improve laser processing efficiency, and has simple system structure and easy operation, and can be used for high-efficiency and high-quality processing of microfluidic chips in various schemes.

Owner:广州市凯佳光学科技有限公司

Piercing method and laser processing apparatus

ActiveCN107000121AEffective through processingLaser beam welding apparatusLaser processingThick plate

Provided are a piercing method and a laser processing apparatus (1) that can perform a piercing process on a thick plate within a short period of time. In a processing method for performing a piercing process on a metallic material (W) by using laser light with a wavelength in the 1 micrometer band, when the focal beam diameter of the laser light is defined as d and the Rayleigh length is defined as Zr, the piercing process is performed while 8 <= Zr / d <= 12 is maintained. The focal position of the laser light is set to the surface of a workpiece (W) or the outside of the workpiece (W). With regard to the beam profile of the laser light, single-mode laser light is transformed into a bowler-hat shape by a beam-quality tunable device (13).

Owner:AMADA HLDG CO LTD

Piercing processing method and laser processing machine

Owner:AMADA HLDG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com