Pin-like light beam generation device and deep hole laser machining device and method

A generation device and laser processing technology, applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of low precision of deep hole laser processing, unfavorable deep hole etching processing, short beam Rayleigh length, etc. The effect of avoiding the increase of the processing aperture, which is conducive to the deep etching and reducing the difficulty of the etching process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Preferred embodiments of the present invention will be specifically described below in conjunction with the accompanying drawings, wherein the accompanying drawings constitute a part of the application and together with the embodiments of the present invention are used to explain the principle of the present invention, but not to limit the scope of the present invention.

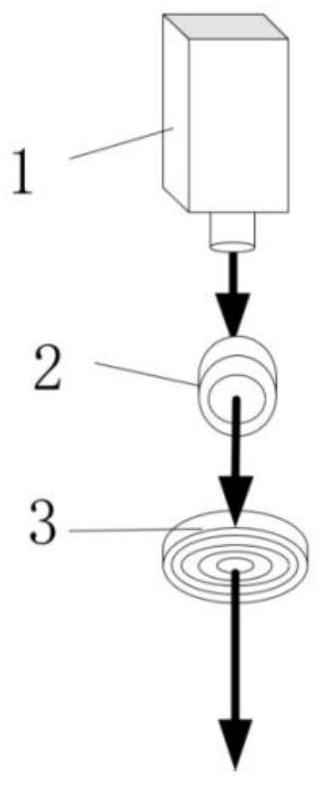

[0052] A specific embodiment of the present invention discloses a device for generating sharp beams. Such as figure 1 As shown, the device includes a laser 1 , a collimation component 2 , and a phase mask 3 . in,

[0053] Laser 1, used to generate a Gaussian beam.

[0054] The collimating component 2 is used for collimating the Gaussian beam generated by the laser 1 . Optionally, a collimating mirror may be used, or one or more mirrors may be used instead of the collimating component 2 to collimate the Gaussian beam.

[0055] The phase mask 3 is used to control the cubic phase wavefront of the col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com